Analysis of the Technology for Reducing the Amount of Gas Pores

and Non-Metallic Inclusions in Liquid Steel Alloys

Nozimjon Kholmirzaev

1a

, Nosir Saidmakhamadov

2b

, Jamshidbek Khasanov

3c

,

Shokhista Saidkhodjaeva

3d

, Abdujalol Bektemirov

1e

, Bekzod Yusupov

4f

,

Ibrokhim Nosirkhujaev

4g

and Nargiza Sadikova

1h

1

Tashkent State Technical University, Foundry Technologies Department, 100095 Tashkent, Uzbekistan

2

The Association of Building Materials Industry of Uzbekistan, R&D center, 100059 Tashkent, Uzbekistan

3

Andijan Machine Building Institute, Technology of Machine Building, 170100 Andijan, Uzbekistan

4

Аlmalyk Branch of Tashkent State Technical University, Technologic Machines and Equipment Department,

110100 Аlmalyk, Uzbekistan

Keywords: Gas Pores, Non-Metallic Inclusions, Liquid Steel.

Abstract: In this article, research was conducted on low-alloy steel alloy 35XGCL (analog is JIS G 5111). Research is

aimed at reducing the amount of gas pores and non-metallic inclusions in the liquid alloy. This process was

carried outside of furnace. SEM/EDS analyzes were conducted on each experimental sample obtained during

the research. In the research, the analysis of the effect of Al and Zr elements on reducing the amount of oxygen

and nitrogen in the liquid alloy is presented. For experiments, the alloys were melted in an electric arc furnace.

Experiments were conducted with different amounts of Al and Zr. As a result, ZrO

2

and Al

2

O

3

were formed.

Processing in an argon flow after exposure to the elements increased the possibility of cleaning from large-

sized (>7 µm) inclusions. At the end of the research, the cleaning of the alloy from gas pores and non-metallic

inclusions led to a significant improvement in mechanical properties.

1 INTRODUCTION

The quality of iron and its alloys, particularly steel

products, is generally determined by the minimal

presence of harmful elements P and S. However, in

accordance with modern materials science and

construction requirements, the amount of non-

metallic additives and gas cavities in the composition

of alloys is becoming increasingly significant.

Therefore, engineering teams are also focusing on

these aspects when producing cast products. Usually,

the components added during the alloy melting

process are very important. Especially through

a

https://orcid.org/0009-0008-9662-4796

b

https://orcid.org/0000-0002-7460-5972

c

https://orcid.org/0009-0009-0741-1375

d

https://orcid.org/0009-0008-8663-5061

e

https://orcid.org/0009-0002-2583-0900

f

https://orcid.org/0000-0002-2066-1872

g

https://orcid.org/0009-0007-8527-1826

h

https://orcid.org/0009-0006-7197-8059

modification, improving the hardness and wear

resistance of steel alloys by post-processing, while

also eliminating certain defects, gas cavities, and the

presence of non-metals found in castings, is one of

the main achievements of casting technologies. This

primarily refers to modification and refining in the

ladle.

Despite the limited amount of non-metallic

additives in steels, they significantly affect the

properties of the steel. It is impossible to completely

remove certain types of non-metals from the alloy

composition; we can only reduce their quantity and

dispersion in such a way as to minimize the damage

248

Kholmirzaev, N., Saidmakhamadov, N., Khasanov, J., Saidkhodjaeva, S., Bektemirov, A., Yusupov, B., Nosirkhujaev, I. and Sadikova, N.

Analysis of the Technology for Reducing the Amount of Gas Pores and Non-Metallic Inclusions in Liquid Steel Alloys.

DOI: 10.5220/0014260800004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 248-252

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

to the quality of the alloy. Non-metallic additives of

this type mainly occur in the form of compounds as

a result of chemical reactions during the melting of

the alloy. Oxides (FeO, Al

2

O

3

, SiO

2

), carbides (Fe

3

C,

WC), nitrides (TiN, AlN), and sulfides (FeS, MnS)

are among them. Other types of non-metals arise

from various separations. For example, the

separations of furnace, ladle, and mold materials

(Garcia-Casas et al., 2022; Beeley, 2001; Kendra,

2001; Tursunbaev et al., 2001; Tursunbaev et al.,

2001). Gas voids are similar; they occur in the alloy

due to the influence of oxygen during melting, and

they can be completely eliminated in one stage. If

partially lost under normal production conditions,

they can be completely eliminated under special

conditions, such as in vacuum production.

It is also very important to be able to eliminate

such defects with metallurgical solutions under

normal production conditions. This, in turn, opens

the door for research in this area. In particular,

scientists A.G. Svjazin, J. Siwka, Z. Skuza, and A.

Hutnylar have provided useful recommendations on

the formation and prevention of gas voids in their

scientific research titled "The Gas Blow-Holes

Forming in Nitrogen Iron Alloys and Steels during

their Crystallization” (Svjażin et al., 2022).

According to them, non-metals can also be partially

purified during the reduction of gas voids from the

alloy composition. In this case, the effectiveness of

the deoxidizer's influence in the chemical reaction

plays an important role.

2 MATERIALS AND METHODS

The research work was carried out on high carbon

steel 65Г and low-alloyed 35XГСЛ alloys. Such

alloys are typically used to manufacture parts of

automobile bodies, sheets, strips, and various

geometrically shaped components, particularly

various wheels, springs, gears, sliding devices,

friction discs in braking systems, and bearing

housings, which require wear resistance and hardness

(Sheraliev et al., 2001). To reduce gases in the usual

composition of the alloy, aluminum was introduced

in solid form at a concentration of 0.5% through out-

of-furnace refining (Callister & Rethwisch, 2007;

Turaxodjayev, 2016). Metallurgical and construction

methods were used to reduce non-metals in the

composition. In the metallurgical method, flux was

added, while in the construction method,

modifications were made to the casting mold feeders

(Turaxodjayev, 2016; Tursunbayev et al., 2023;

Kholmirzaev et al., 2023; Kholmirzaev et al., 2024a).

In these gas-voids, to purify the liquid metal,

aluminum (Al) was added at a concentration of 0.5%

based on the total weight of the alloy in an out-of-

furnace condition. Aluminum (Al) was introduced

into the liquid alloy composition using three different

methods. In the first case, when the liquid metal in the

furnace reached a ready state, that is, when it reached

the pouring temperature into the ladle, 0.2%

aluminum was added to the heated ladle, and the

liquid alloy in the furnace was poured over it. In the

second method, after pouring the liquid alloy into the

ladle, 0.2% aluminum was added, and in the next

stage, the liquid alloy in the ladle was introduced after

being cleaned of slag. That is, 0.1% aluminum was

added to the liquid alloy at the pouring temperature

into the prepared mold, while the ladle was kept in the

sand-clay mold during the pouring of the liquid alloy.

In total, 0.5% aluminum was introduced. The process

occurring in the ladle was as follows (Kholmirzaev et

al., 2023; Ermatov et al., 2022; Mardonov et al.,

2023a; Mardonov et al., 2023b; Mardonov et al.,

2023).

Figure 1: Samples taken after refining.

In these gas-voids, to purify the liquid metal,

aluminum (Al) was added at a concentration of 0.5%

based on the total weight of the alloy in an out-of-

furnace condition. Aluminum (Al) was introduced

into the liquid alloy composition using three different

methods. In the first case, when the liquid metal in the

furnace reached a ready state, that is, when it reached

the pouring temperature into the ladle, 0.2%

aluminum was added to the heated ladle, and the

liquid alloy in the furnace was poured over it. In the

second method, after pouring the liquid alloy into the

ladle, 0.2% aluminum was added, and in the next

stage, the liquid alloy in the ladle was introduced after

being cleaned of slag. That is, 0.1% aluminum was

added to the liquid alloy at the pouring temperature

into the prepared mold, while the ladle was kept in the

Analysis of the Technology for Reducing the Amount of Gas Pores and Non-Metallic Inclusions in Liquid Steel Alloys

249

sand-clay mold during the pouring of the liquid alloy.

In total, 0.5% aluminum was introduced. The process

occurring in the ladle was as follows (Kholmirzaev et

al., 2023, Kholmirzaev et al., 2024b, Ermatov et al.,

2022, Mardonov et al., 2023a, Mardonov et al.,

2023b).

[3FeO] + [2Al] → [3Fe] + (Al

2

O

3

) + Q

Here, aluminum serves to remove oxygen in the

form of aluminum oxide. By applying this method, it

was possible to eliminate non-metallic additives and

gas porosity from the liquid alloy.

Samples taken from the refined alloy were

checked for hardness and microstructures. The

HBRV-187.5 Digital Hardness Tester device was

effectively used to determine the hardness.

Figure 2: HBRV-187.5 Digital Hardness Tester.

3 RESULTS AND DISCUSSION

To test the state of gas porosity, pre- and post-

research samples were processed using a mini

analytical balance with very high accuracy.

Additionally, the level of porosity was observed by

monitoring the identical cross-sectional surfaces of

the cast part obtained from the alloy (Fig. 3 a, b, c).

The samples obtained in casting form were first

polished for testing in the relevant trials. Then,

modern equipment was used to compare its

mechanical properties and structural changes.

Figure 3: Appearance of gas porosity in cast products.

The mechanical properties of the samples,

particularly hardness, were determined using two

methods: Brinell and Rockwell. The hardness test

results are presented in Table 1.

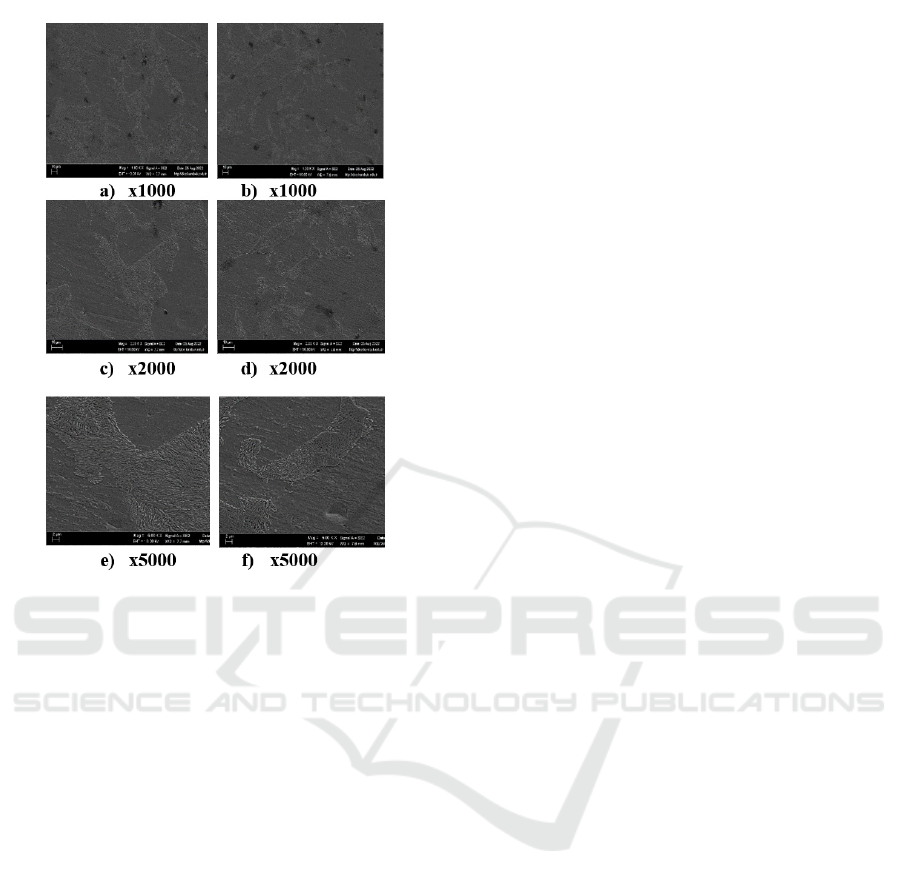

After the hardness test, the samples were

processed using a Grinding and polishing machine.

Once the research samples were prepared, images of

the alloy's microstructure were obtained using the

"Zeiss Ultra Plus Field Emission SEM" scanning

electron microscope (Fig. 4).

Table 1: The results of the test on hardness.

S/n Hardness HBW

1. Cast samples

203 247 262 264

2.

Cast samples

with heat

treatment

245 307 323 328

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

250

Figure 4: Microstructure images obtained from low-alloy

steel alloy of 35XГСЛ brand using Zeiss Ultra Plus Field

Emission SEM scanning electron microscope at

magnifications from x1000 to x5000.

4 CONCLUSIONS

By analyzing the results of the research, it can be

concluded that the technology for optimal melting of

low-alloyed 35 XGCL steel in an electric arc furnace

has achieved energy and resource efficiency in

obtaining cast products. An aluminum element was

introduced into the liquid alloy outside the furnace,

resulting in high-quality cast products free from

gases. The implementation of the developed

technology has reduced the amount of gas porosity in

the cast products obtained from the steel alloy. By

improving the binding clays in the sand-clay mold

mixture, it was possible to produce sulfur-free cast

products. As a result of the implementation, the gas

permeability of the sand-clay molds increased by 13-

15%. By improving the design of the placement of the

valve components inside the mold, resource-efficient

and economically viable cast products were achieved.

Consequently, the raw material consumption for

obtaining cast products decreased by 23-26%. To

enhance the physical-mechanical and technological

properties of the valve components cast in sand-clay

molds, TiC nanocoatings were applied and subjected

to thermal treatment, which resulted in improved

wear resistance and hardness of the alloys.

REFERENCES

Beeley, P., 2001. Foundry Technology. Second edition,

India.

Callister, W.D., Rethwisch, D.G., 2007. Fundamentals of

materials science and engineering: an integrated

approach. 3rd ed. United States.

Ermatov, Z., Dunyashin, N., Yusupov, B., Saidakhmatov,

A., & Abdurakhmonov, M., 2022. Modelling the

chemical composition process concerning formation of

metals from manual arc surface on the basis of the

electrode coating charge components classification.

International Journal of Mechatronics and Applied

Mechanics, 12.

https://doi.org/10.17683/ijomam/issue12.25.

Foundry Technology – II. C. B. S. E., Shiksha Kendra, 2,

Community Centre, Preet Vihar, Delhi–110301

Garcia-Casas, A., Jiménez-Morales, A., 2022.

Encyclopedia of Materials: Metals and Alloys.

Kholmirzaev, N., Khasanov, J., Abdullayev, B.,

Saidkhodjaeva, S., Bektemirov, A., Sadikova, N., ... &

Nurdinov, Z., 2024a. Improving the technology of

obtaining highquality castings from steel in sand-clay

molds. E3S Web of Conferences, 525, 03012. EDP

Sciences.

Kholmirzaev, N., Turakhodjaev, N., Saidmakhamadov, N.,

Khasanov, J., Saidkhodjaeva, S., & Sadikova, N.,

2023. Development of Technology of Making Shafts

from Steel Alloy 35XGCL. Lecture Notes in Networks

and Systems, 762. https://doi.org/10.1007/978-3-031-

40628-7_18.

Kholmirzaev, N., Turakhodjaev, N., Saidmakhamadov, N.,

Khasanov, J., Bektemirov, A., & Sadikova, N., 2024b.

Effects of titanium (Ti) contents on the wear resistance

of low-alloy steel alloys. E3S Web of Conferences, 525,

03003. EDP Sciences.

Mardonov, U., Khasanov, O., Ismatov, A., &

Baydullayev, A., 2023. Studies concerning water-based

coolants under magnetic field during a metal-cutting

process (turning). Lecture Notes in Networks and

Systems, 762. https://doi.org/10.1007/978-3-031-

40628-7_26.

Mardonov, U., Tuyboyov, O., Abdirakhmonov, K., &

Tursunbaev, S., 2023. Mathematical approach to the

flank wear of high-speed steel turning tool in diverse

external cutting environments. International Journal,

(14), 19. Doi:

https://dx.doi.org/10.17683/ijomam/issue14.3.

Svjażin, A.G., Siwka, J., Skuza, Z., Hutny, A., 2022. The

Gas Blow-Holes Forming in Nitrogen Iron Alloys and

Steels during their Crystallization. Materials Science

Forum, 318-320.

https://doi.org/10.4028/www.scientific.net/MSF.318-

320.377.

Analysis of the Technology for Reducing the Amount of Gas Pores and Non-Metallic Inclusions in Liquid Steel Alloys

251

Tursunbaev, S., Ashirbaev, A., Valiev, A., Xalimov, M., &

Tashimov, N., 2023. The effect of the amount of lithium

in aluminum lithium alloys on the property of fluidity.

E3S Web of Conferences, 414.

https://doi.org/10.1051/e3sconf/202341704010.

Tursunbaev, S., Turakhodjaev, N., Odilov, F.,

Mardanokulov, S., & Zokirov, R., 2023. Change in

wear resistance of alloy when alloying aluminium alloy

with germanium oxide. E3S Web of Conferences, 401.

https://doi.org/10.1051/e3sconf/202340105001.

Tursunbayev, S., Turakhodjayev, N., Mardanokulov, S.,

Zokirov, R., & Odilov, F., 2023. The effect of lithium

on the mechanical properties of alloys in the Al-Li

system. E3S Web of Conferences, 390.

https://doi.org/10.1051/e3sconf/202339005046 .

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

252