Review and Analysis of Batteries for Electric Vehicles in the Central

Asian Climate

Jakhongir Mirzaabdullaev

a

, Rustam Tillahodjaev

b

, Oybek Daminov

c

and Rustamjon Mirzajonov

d

Tashkent State Technical University, Energy Engineering and Professional Education Department,

100095, Tashkent, Uzbekistan

Keywords: Electric Vehicles, Battery Analysis, Central Asian Climate.

Abstract: This article discusses a review and analysis of batteries for electric vehicles in the dry and hot climate of

Central Asia. Suitable battery types were selected for electric vehicles operating under these conditions.

1 INTRODUCTION

Recently, more and more cars are switching from

hydrocarbon fuel (gasoline, diesel fuel, methane,

propane-butane, alternative fuels of plant origin, etc.)

to electric traction. Of course, the latter is still far

from the classic internal combustion engines in terms

of its characteristics, but progress does not stand still,

and if gasoline and diesel engines still hold the palm,

then very soon there will be a mass transition to more

environmentally friendly and silent electric engines,

that is, electric vehicles (Daminov et al., 2022;

Daminov et al., 2022; Daminov et al., 2022; Daminov

et al., 2022).

At the moment, the weak point of an electric car

is the battery. Lithium-ion batteries are mainly used

now. Such batteries, with their advantages associated

with relatively small sizes, suffer more from the

process of deterioration of characteristics over time.

Most of these batteries cannot serve for more than

five years. The number of charge-discharge cycles

(short charge and discharge cycle time, the battery

can withstand up to 2000 cycles) does not affect the

resource as much as age. To achieve maximum

battery life, it is necessary to use currents equal to half

the capacity when charging. And it is undesirable to

exceed the limit of one capacity, as this leads to a

sharp reduction in service life (Uddin et al., 2016; De

Dudley et al., 2017; Sutter et al., 2018; Lai et al.,

a

https://orcid.org/0000-0002-1002-2946

b

https://orcid.org/0000-0003-4137-1273

c

https://orcid.org/0000-0001-7876-1289

d

https://orcid.org/0000-0008-5289-0001

2018; El Ghossein, et al., 2019; Fan et al., 2019; Fang

et al., 2019; Han et al., 2019; Harting et al., 2019).

2 MATERIALS AND METHODS

A battery is already a set of many elements. Several

cells are connected into a battery when the

characteristics of one cell are not enough. If

connected in series, the voltage increases according

to the battery connection formula. If connected in

parallel, the battery capacity increases. It can include

not only battery elements, but also auxiliary control

electronics.

Capacity is a battery characteristic measured in

ampere-hours (A·h). For example, a capacity of 2 A·h

means that the battery can deliver a current of 1 A for

two hours and 2 A for one hour. Ampere-hour (A·h)

is a non-systemic unit of measurement of electric

charge, used mainly to characterize the capacity of

electric batteries.

Figure 1: Voltage dependence on capacitance.

240

Mirzaabdullaev, J., Tillahodjaev, R., Daminov, O. and Mirzajonov, R.

Review and Analysis of Batteries for Electr ic Vehicles in the Central Asian Climate.

DOI: 10.5220/0014247500004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 240-247

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

A charged battery with a declared capacity of 1

A·h is theoretically capable of providing a current of

1 ampere for one hour (or, for example, 10 for 0.1

hour, or 0.1 A for 10 hours). In practice, too high a

battery discharges current leads to less efficient

power output, which non-linearly reduces its

operating time with such a current and can lead to

overheating.

The derived unit milliampere-hour (mA·h) is also

often used, which is usually used to indicate the

capacity of small batteries (Barcellona & Piegari,

2017; Abdullaev, 2022; Ismatov et al., 2023).

The value in ampere-hours can be converted to the

system unit of charge measurement - coulomb. Since

1 C/s is equal to 1 A, then, converting hours to

seconds, we get that one ampere-hour will be equal to

3600 C.

The battery capacity also depends on the

discharge current. Usually, the higher it is, the smaller

the capacity. Battery manufacturers usually indicate

the capacity obtained during discharge with some

measly current of 100 mA.

The graphic diagram shows the characteristics

of a Li-ion battery, which is discharged at different

current strengths. The higher the current, the lower

the discharge curve (Tillaxodjayev & Juraboev, 2021;

Tillyahodjaev & Mirzaev, 2022; Umerov et al., 2022;

Umerov et al., 2024).

C is a letter of the Latin alphabet that measures

the ratio of current strength to battery capacity, that

is, how many times the current exceeds the capacity.

If the battery has a capacity of 2 A·h and is discharged

at a current of 4 A, then we can say that it is

discharged at a current of 2 C. The thing is that the

greater the capacity of the battery, the easier it is to

give current to it, and therefore it is more convenient

to use such a characteristic than just amperes.

Energy is a characteristic that allows you to

compare batteries with different voltages. It is

measured in watt-hours and is roughly calculated by

multiplying the battery voltage by its capacity

(Musabekov et al., 2023; Musabekov et al., 2023;

Musabekov et al., 2023; Matmurodov et al., 2024).

Often, battery manufacturers indicate only the stored

charge in mAh (mA·h) in their technical

specifications, while others indicate only the stored

energy in W·h (W·h). Both characteristics can be

called "capacity" (not to be confused with electrical

capacity as a measure of a conductor's ability to

accumulate charge, measured in farads). Calculating

the stored energy from the stored charge is generally

not easy: it requires integrating the instantaneous

power supplied by the battery over the entire period

of its discharge. If high accuracy is not required, then

instead of integrating, you can use the average values

of voltage and current consumption, using the

formula that follows from the fact that

1 W = 1 V · 1 A:

1 W · h = 1 В · 1 А·h.

That is, the stored energy (in watt-hours) is

approximately equal to the product of the stored

charge (in ampere-hours) and the average voltage (in

volts):

E = q · U.

Example

The technical specification of the device states

that the “capacity” (stored charge) of the battery is 2.2

A·h, the operating voltage is 3.7 V. Then the

“capacity” (stored energy) is 2.2 A·h · 3.7 V = 8.14

W·h = 8.14 W · 3600 s = 29.304 kJ.

When identical batteries are connected in series,

the "capacity" remains the same, when connected in

parallel, it is added up. For example, for two batteries,

each with a voltage of 3.7 V and a stored charge of

2200 mAh, a series connection will create a source

with a voltage of 7.4 V and a stored charge of 2200

mAh, a parallel connection will create a source with

a voltage of 3.7 V and a stored charge of 4400 mAh.

Internal resistance of batteries - Li-ion battery

with a capacity of 2.2 A·h and a nominal voltage of

3.7 V. When fully charged, the battery has a voltage

of approximately U = 4 V. What current I will flow

through the battery if a resistor with a resistance of R

= 1 Ohm is connected to it? Based on the formula I =

U / R not 4 amperes, but slightly less - about 3.75 A.

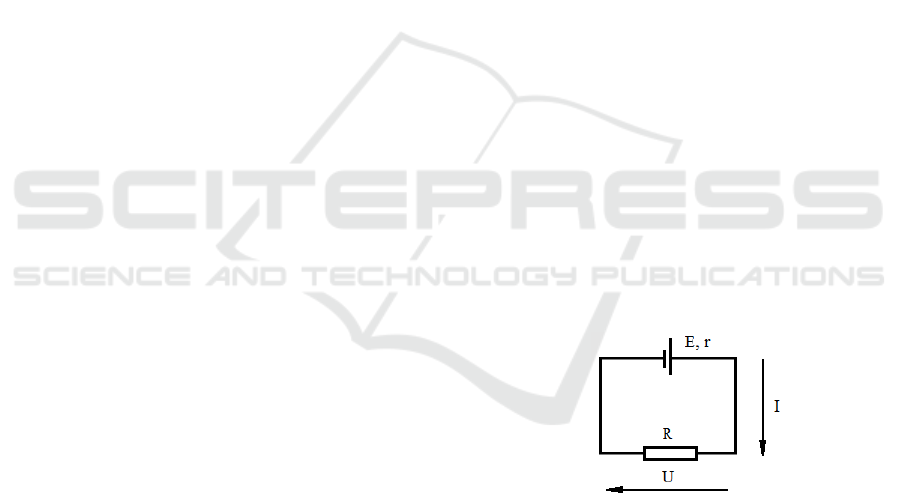

Figure 2: Battery resistance determination diagram.

Internal resistance of the battery if we measure the

voltage on the battery to which the resistor is

connected, we will see that it is approximately equal

to 3.75 V - the voltage on the battery has dropped due

to the fact that the diffusion rate of ions in the

electrolyte is not infinitely high.

The battery is represented as a two-terminal

network with EMF (electromotive force - voltage

without load) E and internal resistance r. It is assumed

that part of the battery EMF drops on the load, and the

other part - on the internal resistance of the battery. In

other words, it is assumed that the formula is correct:

Review and Analysis of Batteries for Electric Vehicles in the Central Asian Climate

241

E = (R + r) · I

We can roughly determine the internal resistance

of a 3.7V, 2.2Ah DC battery.

r = (E ‒ U) / I = (4В – 3,75V) / 2,2А = 0,11 Om.

Battery types

The electrical and operational characteristics of

the battery depend on the material of the electrodes

and the composition of the electrolyte. The following

batteries are currently the most common:

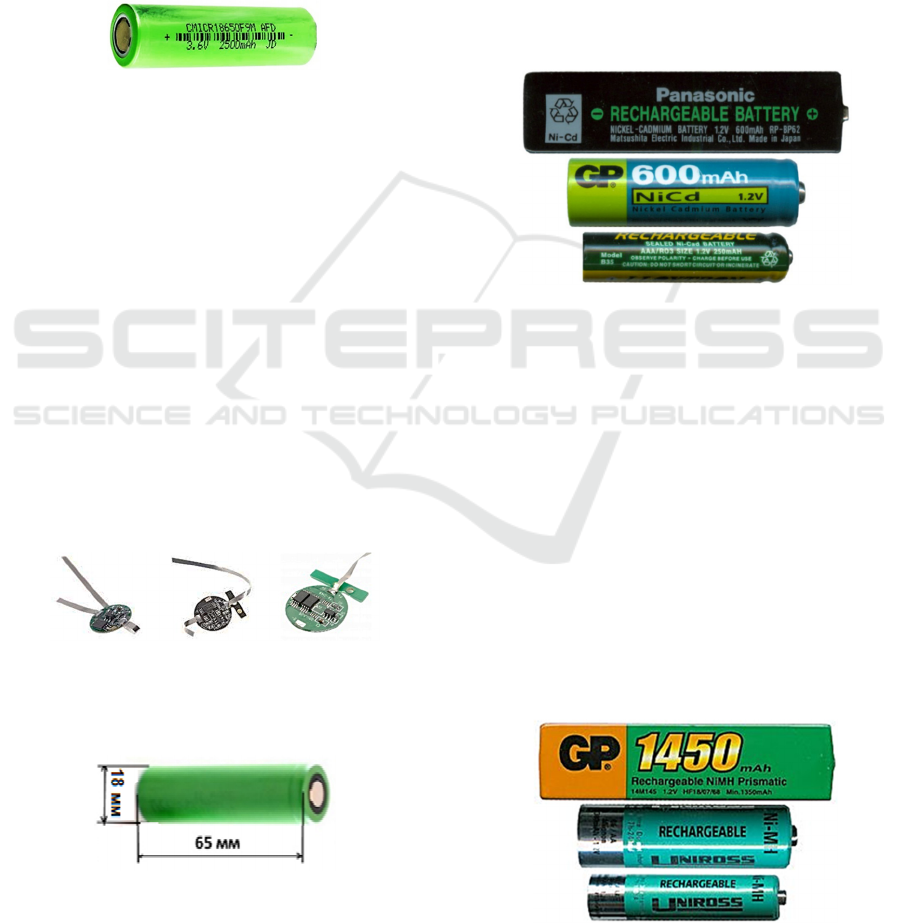

Li-ion ‒ lithium-ion. They have the highest

energy capacity. They discharge quickly when used

in the cold season.

Figure 3.

They deteriorate when discharged below 2.5 V.

They are explosive when overcharged above 4.2 V.

That is why many Li-ion batteries have a special

board under the case that switches off the current

when the voltage is below 2.5 V or above 4.2 V. Such

batteries have the word "protected" in the name.

Unprotected batteries without a special board cannot

be used in the battery. For more information on

protection - Li-ion batteries and their balancing, see

below. They lose capacity over time, even from

simply lying on a shelf. They lose capacity especially

quickly at high temperatures (Barcellona & Piegari,

2017; Venugopal et al., 2019). The easiest way to

avoid this problem is to use protected batteries. These

are the ones bought for all kinds of LED flashlights.

Protected batteries have a small board like this inside

the case:

Figure 4.

A popular size for lithium-ion batteries is 18650

(18mm wide and 65mm long).

Figure 5.

These are the ones used in laptop batteries. They

are located behind the plastic battery case. The same

ones are used in the Tesla Roadster electric sports car.

A nickel-cadmium battery (NiCd) is a

secondary chemical power source in which the

cathode is nickel oxide hydrate Ni(OH)2 with

graphite powder (about 5–8%), the electrolyte is

potassium hydroxide KOH with a density of 1.19–

1.21 with the addition of lithium hydroxide LiOH (to

form lithium nickelates and increase capacity by 21–

25%), and the anode is cadmium oxide hydrate

Cd(OH)2 or metallic cadmium Cd (in powder form).

The EMF of a nickel-cadmium battery is about 1.37

V, and the specific energy is about 45–65 Wh/kg

(Burzy et al., 2019).

Figure 6.

Depending on the design, operating mode (long or

short discharges) and purity of the materials used, the

service life is from 100 to 900 charge-discharge

cycles. Modern (lamellar) industrial nickel-cadmium

batteries can serve up to 20-25 years.

Nickel-cadmium batteries (NiCd), along with

Nickel-Saline batteries, can be stored discharged,

unlike nickel-metal hydride (NiMH) and lithium-ion

batteries (Li-ion), which must be stored charged. A

nickel-metal hydride battery (Ni-MH or NiMH) is a

secondary chemical power source in which the anode

is a hydrogen metal hydride electrode (usually nickel-

lanthanum or nickel-lithium hydride), the electrolyte

is potassium hydroxide, and the cathode is nickel

oxide (Canals et al., 2018; Chin et al., 2018; Dambone

et al., 2018; Chen et al., 2024).

Figure 7.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

242

Research into NiMH battery technology began in

the 1970s as an attempt to overcome the shortcomings

of nickel-cadmium batteries. However, the metal

hydride compounds used at that time were unstable

and the required characteristics were not achieved. As

a result, the development of NiMH batteries stalled.

New metal hydride compounds stable enough for use

in batteries were developed in 1980.

Since the late 1980s, NiMH batteries have been

steadily improving, primarily in terms of energy

density. Their developers have noted that NiMH

technology has the potential to achieve even higher

energy densities.

A lithium-polymer battery (lithium-ion

polymer battery; abbreviations: Li-pol, Li-

polymer, LIP, Li-poly, etc.) is an improved design

of a lithium-ion battery. A polymer material is used

as an electrolyte (Worwood et al., 2018), (Wu et al.,

2019), (Xia et al., 2021), (Yehorov et al., 2024),

(Zhang and Lyu, 2018). It is used in mobile phones,

digital equipment, radio-controlled models, etc.

Figure 8.

Fully compatible with Li-ion. Unlike Li-ion, they

can deliver strong currents - 10-40 C. They can be of

any thickness and shape. They are suitable for

powering very miniature devices, such as compact

micro-equipment. They are usually sold in an already

assembled battery, with protective boards and cables

for balancing. They work even worse in the cold.

Lithium iron phosphate battery (LiFePO4,

LFP) is a type of electric battery, which is a type of

lithium-ion battery that uses LiFePO4 as a cathode.

Further evolution of lithium batteries. Batteries of

the future. Unlike Li-ion, they: are not afraid of frost;

are not fire hazardous; deliver currents up to 50 C; can

be charged with a strong current in 15 minutes; have

a huge number of charge-discharge cycles (2000-

8000 up to a loss of 20% of capacity); are practically

not subject to capacity loss during storage (Tom,

2012; Noh et al., 2019; Osara & Bryant, 2019).

Figure 9.

Disadvantages compared to Li-ion: more

expensive and have lower capacity; have lower

energy capacity; are not compatible with

conventional Li-ion cells due to a different voltage

range of 2-3.65 V. And, just like Li-ion, require

compliance with their voltage range of 2-3.65 V.

Lanthanum fluoride battery (La-Ft) is a very

powerful chemical current source with a solid

electrolyte. The anode is metallic lanthanum or

cerium, the electrolyte is lanthanum fluoride with the

addition of barium fluoride (about 6%) or, in the case

of a cerium anode, cerium (III) fluoride with the

addition of strontium fluoride, the cathode is bismuth

or lead fluoride with the addition of potassium

fluoride (~ 6%).

Figure 10.

Additions of potassium and alkaline earth metal

fluorides promote disordering in the anion sublattice

of lanthanum/cerium fluorides, which ultimately

leads to a 6-8-fold increase in the specific

conductivity of the solid electrolyte.

Lithium titanate battery (Li4Ti5O12) is a

variant of lithium-ion batteries that uses lithium

titanate (Li4Ti5O12) as an anode. To increase the

area, the anode has a nanocrystalline structure.

Figure 11.

This solution allows for an anode surface area of

up to 100 m2/g, compared to 3 m2/g for carbon,

which allows for a significant increase in the recharge

rate and high current density (De et al., 2018; Jinlei et

al., 2019; Wei et al., 2024).

A silver-cadmium battery (Ag-Cd) is a chemical

current source in which the anode is cadmium, the

Review and Analysis of Batteries for Electric Vehicles in the Central Asian Climate

243

electrolyte is potassium hydroxide, and the cathode is

silver oxide.

Figure 12.

Compared to a silver-zinc battery, it has lower

specific characteristics (EMF 1.6 V, 45-90 Wh/kg),

but at the same time a significant service life (over

3000 charge-discharge cycles, which is explained by

the fact that during charging, due to the lower

solubility of cadmium in alkali, cadmium dendrites

do not form).

NMC - one of the most successful options for the

implementation of a lithium-ion electrochemical

system is a combination of nickel, manganese and

cobalt.

Figure 13.

NMC battery in the 18650 cell size for moderate

load has a capacity of 2800 mAh and can provide a

current of 4-5 A. The capacity can be increased to

4000 mAh. But the maximum current is 20 A. Over

2000 charge-discharge cycles (Hildebrand et al.,

2018), (Kovtun et al., 2024), (Kuo et al., 2019),

(Wang et al., 2004).

LiCoO2 is a lithium-cobalt battery in the 18650

cell size with a capacity of 2400 mAh can be charged

and discharged with a current not exceeding 2400

mAh.

Figure 14.

Charge-discharge cycles 500-1000. Performance

at low and high temperatures.

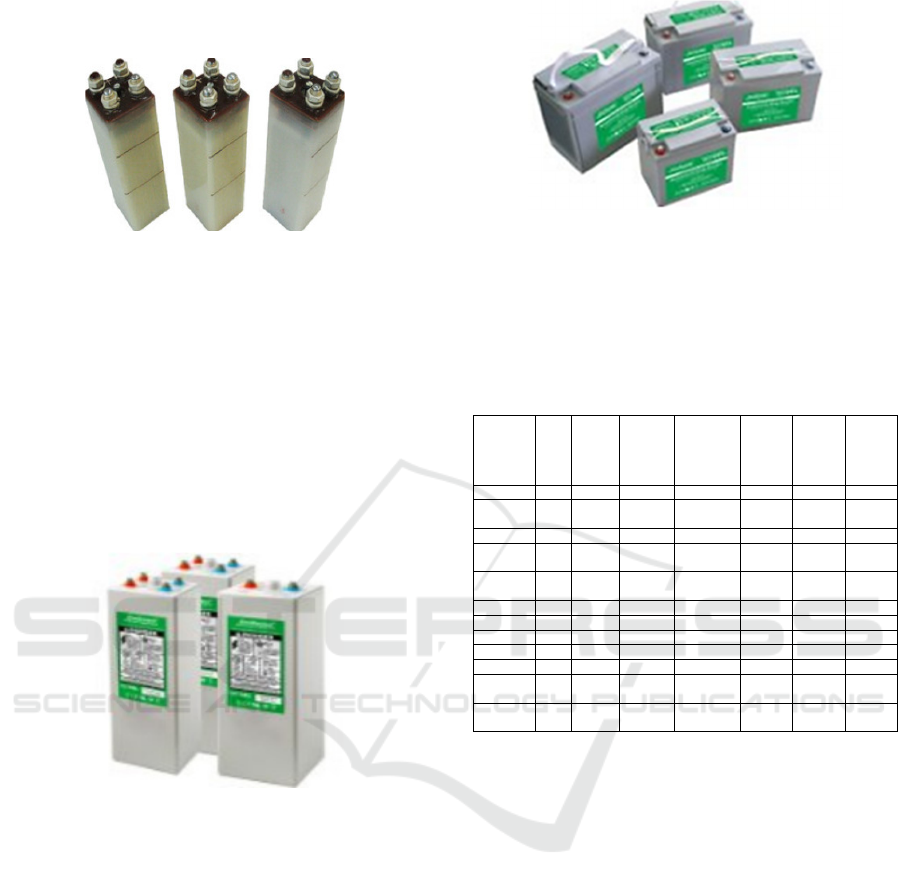

Below are the parameters of batteries that can be

used in electric vehicles.

Table 1: Average values obtained in the experiment.

Designatio

n

EMF

(V)

Energy

capacity

(Wh/kg)

Energy

density

(Wh/dm3)

Operating

temperature

(°С)

Number

of

charge/

discharge

cycles

Self-

discharge

per year

(%)

Fast

charge

time

(minutes)

NiC

d

1,37 237 50-150 -50…+40 100-900 10 1,5

Ni-MH or

NiMH

1,25 300 150 -60…+50 300-500 100 1,5

Li-

p

ol 3,7 161 120 -20…+60 1000 60 1,5

LiFePO4 3,3 90-250 220-350 -30…+50 2000-

8000

50 -

La-Ft 2.3-

2.7

290-350 1330 +400…+50

0

- - -

Li4Ti5О12 3,7 30-110 177 -30...+60 15000 5 7

Ag-C

d

1,6 45-90 120 -30…+50 3000 - -

Li-ion 3,7 110-250 - -20…+60 1000 - 60

Lea

d

-Acid 2,1 135 1250 -40…+40 200-300 36-120 480-720

Ni-Zn 1,65 60 255 -30…+40 250-370 - 120

NMC 3,6-

3,7

150-220 - +210 1000-

2000

- 180

LiCoО2 3,0-

4,2

150-240 - +150 500-1000 - 180

3 RESULTS AND DISCUSSION

But whatever the layout, batteries are at the top of this

list. Electric vehicles use batteries assembled into a

single block with a series, parallel and mixed

connection. Since when choosing the optimal

connection scheme, you can achieve a positive effect

by reducing the number of batteries and, accordingly,

the weight of the battery block (Daminov et al.,

2022a; Daminov et al., 2022b; Yehorov et al., 2024).

The battery of the TESLA electric car has been of

interest to specialists in this field for some time, who

have sought to learn the secret of the connection. In

principle, this is not a secret, but a competent choice

of batteries with high energy capacity (Wh/kg),

energy density (Wh/dm3) and the number of

charge/discharge cycles.

These justifications can be summarized in the

following simple arithmetic solutions.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

244

A lithium-ion battery has the following

parameters. 3.7 V and 2.2 Ah.

Power of one battery;

3,7 · 2,2 = 8,14 WA/h

If you connect 100 cells in parallel or in series, or

even combine them, the result is obtained according

to the formula;

1003,72,2 = 814 WA/h

Tesla model S has 7104 batteries with a capacity

of 85,000 W (A/h). According to the data, these

batteries are manufactured by Panasonic.

The parameters of the battery are NCR 18650B,

voltage 3.6 V and current 3.4 Ah. It consists of 16

modules of 5300 W (A/h). One module has 444

elements. There are 6 groups of 74 batteries. These

batteries are connected in parallel, and the power of

the groups is calculated using the formula;

3,6 3,4 7104=86952 WA/h

We have considered different ways of connecting

batteries. In turn, we can draw the following

conclusions. Regardless of how you connect the

batteries, the maximum value of w·h (running time in

hours) will remain unchanged. In particular, among

different manufacturers of electric vehicles, the same

w·h (power hour) remains unchanged when analyzing

the Tesla Model C, which has a battery capacity of 85

kWh. When calculating losses of approximately ≈85

kW (A/h), these calculations show that the range of a

Tesla electric car has nothing to do with the

connection of the battery.

4 CONCLUSIONS

We conducted our research, considering from the

small list which is provided above it is difficult to

choose what met the requirements of the electric

vehicle manufacturers. The parameters are not

unambiguous and go to the optimal solution.

Therefore, based on the climate of the Central Asian

region for electric vehicles, it is necessary to select

the appropriate battery suitable for operation in a hot

and dry environment. The most suitable elements

from the above list are lithium-titanate batteries

(Li

4

Ti

5

O

12

). The battery is more optimal in

parameters and meets the minimum requirements

presented for the battery for electric vehicles such as

a long service life based on charge-discharge cycles

and the shortest charging time (Tillaxodjayev et al.,

2021; Daminov et al., 2022).

Currently, the most pressing problem for many

electric vehicle manufacturers, including Tesla

electric vehicles, is to increase the mileage. The

power reserve depends on some characteristics of the

electric vehicle, in particular, on the power of the

main source of electricity in it - batteries, which can

be provided by choosing more advanced batteries.

And the aspect associated with the problem of

environmental safety associated with the disposal of

used batteries can be compensated for by batteries

with a long service life and rational use of battery

capacity.

ACKNOWLEDGMENT

The management of the Tashkent State Technical

University named after Islam Karimov and the staff

of the department of “Energy Engineering and

Vocational Education” express deep gratitude to the

World Bank for the allocated grant and the Academic

Innovation Fund under the Ministry of Higher

Education, Science and Innovation of the Republic of

Uzbekistan as well as the Islamic Development Bank

for the assistance provided in the implementation of

this project.

REFERENCES

Abdullaev I.Y. The importance of electric vehicles around

global areas. Scientific and Technical journal of

Namangan Institute of Engineering and Technology.

Tom 7 Volume 4, 2022 year. ISSN 2181-8622 pp 204-

210.

Barcellona, S.; Piegari, L. Lithium ion battery models and

parameter identification techniques. Energies 2017, 10,

2007.

Bazarov, B., Axmatjanov, R., Tojiyev, J., Azimov, A. The

concept of improving the performance indicators of

gas-cylinder vehicles. E3S Web of Conferences, 2023,

434, 02008

Burzy´nski, D.; Pietracho, R.; Kasprzyk, L.; Tomczewski,

A. Analysis and modeling of the wear-out process of a

lithium-nickel manganese-cobalt cell during cycling

operation under constant load conditions. Energies

2019, 12, 3899.

Canals Casals, L.; Igualada, L.; Corchero, C. The effect of

building energy management systems on Battery

Aging. E3S Web Conf. 2018, 61, 00014.

Chen, W., Cheng, Z., Wen, Q., ... Volkova, O., Liu, J. Ya

High-Strength Nonoriented Electrical Steel with

Excellent Magnetic Properties Accomplished by Cu–Ni

Multialloying. Steel Research International, 2024

Chin, C.; Gao, Z.; Chiew, J.; Zhang, C. Nonlinear

temperature-dependent state model of cylindrical

LiFePO4 battery for open circuit voltage, terminal

Review and Analysis of Batteries for Electric Vehicles in the Central Asian Climate

245

voltage and state-of-charge estimation with extended

Kalman filter. Energies 2018, 11, 2467.

Dambone Sessa, S.; Tortella, A.; Andriollo, M.; Benato, R.

Li-ion battery-flywheel hybrid storage system:

Countering Battery Aging during a grid frequency

regulation service. Appl. Sci. 2018, 8, 2330.

Daminov O., Mirzajonov R., Turdiev J., Usmonov J.

Improving energy efficiency of electric vehicles.

International Conference on Electrical Facilities and

informational technologies 2022 (ICEF 2022). "New

Intelligence Technology: Past, Present and Future".

Turin polytechnic university in Tashkent, Uzbekistan.

August 10-13, 2022. pp. 61-64.

Daminov O.O., Juraboev A.Z., Daminov L.O., Kurbanov

A.M. Analysis of energy sources for electric vehicles.

International Conference on Electrical Facilities and

informational technologies 2022 (ICEF 2022). "New

Intelligence Technology: Past, Present and Future".

Turin polytechnic university in Tashkent, Uzbekistan.

August 10-13, 2022. pp. 37-41.

Daminov O.O., Mirzajonov R.I. Indicators of electric car

batteries. Actual problems of materials science,

innovative technologies of materials acquisition and

welding production - 2022. Republican scientific and

technical conference. A set of materials. November 19,

2022. - T.: 2022. - pp. 270-271.

Daminov O.O., Juraboev A.Z., Kersten S. Working process

of cells and batteries. Journal: Technical science and

innovation. 2022, №2. - P. 134-140

https://unilibrary.uz/articles/303207

De Hoog, J.; Jaguemont, J.; Abdel-Monem, M.; Van Den

Bossche, P.; Van Mierlo, J.; Omar, N. Combining an

electrothermal and impedance aging model to

investigate thermal degradation caused by fast

charging. Energies 2018, 11, 804.

De Sutter, L.; Berckmans, G.; Marinaro, M.; Smekens, J.;

Firouz, Y.; Wohlfahrt-Mehrens, M.; Van Mierlo, J.;

Omar, N. Comprehen sive aging analysis of volumetric

constrained lithium-ion pouch cells with high

concentration silicon-alloy anodes. Energies 2018, 11,

2948.

Dudley, G.; Blake, R.; Lucas, L. Mars Express Lithium Ion

batteries performance analysis. E3S Web Conf. 2017,

16, 06002.

El Ghossein, N.; Sari, A.; Venet, P. Lifetime prediction of

lithium-ion capacitors based on accelerated aging tests.

Batteries 2019, 5, 28.

Fan, J.; Zou, Y.; Zhang, X.; Guo, H. A novel state of health

estimation method for lithium-ion battery in electric

vehicles. J. Phys. Conf. Ser. 2019, 1187, 022014.

Fang, Q.; Wei, X.; Lu, T.; Dai, H.; Zhu, J. A state of health

estimation method for lithium-ion batteries based on

voltage relaxation model. Energies 2019, 12, 1349.

Han, X.; Feng, X.; Ouyang, M.; Lu, L.; Li, J.; Zheng, Y.;

Li, Z. A comparative study of charging voltage curve

analysis and state of health estimation of lithium-ion

batteries in Electric Vehicle. Automot. Innov. 2019, 2,

263–275.

Harting, N.; Wolff, N.; Röder, F.; Krewer, U. State-of-

health diagnosis of lithium-ion batteries using nonlinear

frequency response analysis. J. Electrochem. Soc. 2019,

166, A277.

Hildebrand, S.; Rheinfeld, A.; Friesen, A.; Haetge, J.;

Schappacher, F.M.; Jossen, A.; Winter, M. Thermal

analysis of lini0.4co0.2mn0.4o2/mesocarbon

microbeads cells and electrodes: State-of-charge and

state-of-health influences on reaction kinetics. J.

Electrochem. Soc. 2018, 165, A104.

Ismatov, J., Aripdjanov, M., Mirzaabdullaev, J., ... Mirzaev,

A., Viarshyna, H. Operating indicators in diesels with

reduced heat and energy losses. IOP Conference Series:

Earth and Environmental Science, 2023, 1142(1),

012021

Jinlei, S.; Lei, P.; Ruihang, L.; Qian, M.; Chuanyu, T.;

Tianru, W. Economic Operation Optimization for 2nd

use batteries in Battery Energy Storage Systems. IEEE

Access 2019, 7, 41852–41859.

Jutt V.E., Stroganov V.I. Electric vehicles and vehicles with

a combined power plant. Calculation of speed

characteristics: textbook. Allowance / V.E. Jutt and V.I.

Stroganov. - Moscow: MADI, 2016 - 108 p. (11-35 p.)

Kovtun, O., Levchenko, M., Höntsch, S., ... Gräbner, M.,

Volkova, O. Recycling of iron-rich basic oxygen

furnace dust using hydrogen-based direct reduction.

Resources, Conservation and Recycling Advances,

2024, 23, 200225

Kuo, T.J.; Lee, K.Y.; Chiang, M.H. Development of a

neural network model for SOH of LiFePO4 batteries

under different aging conditions. IOP Conf. Ser. Mater.

Sci. Eng. 2019, 486, 012083.

Lai, X.; Qiao, D.; Zheng, Y.; Yi, W. A novel screening

method based on a partially discharging curve using a

genetic algorithm and back-propagation model for the

Cascade Utilization of retired lithium-ion batteries.

Electronics 2018, 7, 399.

Matmurodov, F.M., Daminov, O.O., Sobirov, .Sh.,

Abdurakxmanova, M.M., Atakhanov, F.U.M. Dynamic

simulation of force loading of drives of mobile power

facilities with variable external resistance. E3S Web of

Conferences, 2024, 486, 03001

Musabekov, Z., Daminov, O., Ismatov, A. Structural

solutions of the supercharged engine in the output and

input system. E3S Web of Conferences, 2023, 419,

01015

Musabekov, Z., Ergashev, B., Daminov, O., Khushnaev,

O., Kurbanov, A., Kukharonok, G. Efficiency and

environmental indicators of diesel engine operation

when using water injection. IOP Conference Series:

Earth and Environmental Science, 2023, 1142(1),

012024

https://iopscience.iop.org/article/10.1088/1755–1315

Musabekov, Z., Tillahodjaev, R., Mirzayev, A.,

Yangibayev, A., Uralova, H. Increasing energy

efficiency as a result of the influence on the operation

of a Sano automobile engine with the adding of

hydrogen as an additive to primary fuel. IOP

Conference Series: Earth and Environmental Science,

2023, 1284(1), 012038

Noh, T.-W.; Ahn, J.-H.; Lee, B.K. Cranking capability

estimation algorithm based on modeling and online

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

246

update of model parameters for Li-ion SLI Batteries.

Energies 2019, 12, 3365.

Osara, J.; Bryant, M. A thermodynamic model for lithium-

ion battery degradation: Application of the degradation-

entropy generation theorem. Inventions 2019, 4, 23.

Optimization of the resource of defining operating modes

of traction batteries of electric vehicles: Dissertation for

the degree of Candidate of Technical Sciences / B.K.

Ospanbekov. - Moscow: MADI, 2017 - 170 p. (10-46

p.)

Tom Denton. Automobile Electrical and Electronic

Systems. Fourth Edition. – New York: Routledge,

2012. 703 p.

Tillaxodjayev R.R., Juraboev A.A. Analysis of batteries for

electric vehicles and their calculations. International

scientific and technical journal “Innovation technical

and technology”, 2021, vol. 2, no. 1, pp. 99-103.

Tillyahodjaev R.R., Mirzaev A.A. Efficiency of using solar

collectors in energy saving and saving energy

resources. Technical science and innovation №4/2022

year.

Uddin, K.; Perera, S.; Widanage, W.; Somerville, L.;

Marco, J. Characterising lithium-ion battery

degradation through the identification and tracking of

electrochemical battery model parameters. Batteries

2016, 2, 13.

Umerov F.Sh., Inoyatkhodjaev J.Sh., Asanov S.E.

The prospects for the development of electric vehicles

in Uzbekistan. Журнал Acta of Turin Polytechnic

University in Tashkent ВЕСТНИК, 2022, 30, – С. 65-

68. Published Online June 2022 in Acta TTPU

(http://www.acta.polito.uz/)

Umerov, F., Daminov, O., Khakimov, J., Yangibaev, A.,

Asanov, S. Validation of performance indicators and

theoretical aspects of the use of compressed natural gas

(CNG) equipment as a main energy supply source on

turbocharged internal combustion engines vehicles.

AIP Conference Proceedings, 2024, 3152(1), 030017

Venugopal, P.; Vigneswaran, T. State-of-health estimation

of Li-ion batteries in electric vehicle using INDRNN

under variable load condition. Energies 2019, 12, 4338.

Wang X. et al. // J. Crystal Growth. 2004. – vol. 267. –

p.184.

Wei, X., Zhao, W., Ilatovskaia, M., ... Ma, G., Volkova, O.

Effect of Calcium Addition on the Aluminum Alloy

A201 Foam. Advanced Engineering Materials, 2024,

26(10), 2302093

Worwood, D.; Algoo, R.; McGlen, R.J.; Marco, J.;

Greenwood, D. A study into different cell-level cooling

strategies for cylindrical lithium-ion cells in automotive

applications. Int. J. Powertrains 2018, 7, 199.

Wu, Y.; Li, W.; Wang, Y.; Zhang, K. Remaining useful life

prediction of lithium-ion batteries using neural network

and bat-based particle filter. IEEE Access 2019, 7,

54843–54854.

Xia, B.; Chen, G.; Zhou, J.; Yang, Y.; Huang, R.; Wang,

W.; Lai, Y.; Wang, M.; Wang, H. Online parameter

identification and joint estimation of the State of charge

and the state of health of lithium-ion batteries

considering the degree of polarization. Energies 2019,

12, 2939. Energies 2021, 14, 8072 32 of 33

Yehorov, A., Wei, X., Mazepa, S., Sherstneva, A.,

Volkova, O. Oxidation Behavior of MgO-C

Refractories Containing Metallic Aluminum, Calcium

Magnesium Aluminate Aggregates, and Carbores P.

Steel Research International, 2024

Zhang, L.; Lyu, C. Decomposition study of degradation

reasons for licoo2-based 14500 lithium-ion batteries

using a nondestructive method. IEEE Access 2018, 6,

44417–44432.

Review and Analysis of Batteries for Electric Vehicles in the Central Asian Climate

247