Results of Sorting Rice Seeds in an Energy-Saving Electric Sorting

Device

Bakhodir Tagaev

a

and Nematjon Akramov

b

Scientific-Research Institute of Agricultural Mechanization, Samarkand str. 41, Yangiyul dis., Tashkent reg., Uzbekistan

Keywords: Electric Sorting, Rice Seeds, Seed Quality.

Abstract: This article discusses the design of an energy and resource-saving electric sorting device, its circuit diagram,

operating principle, definition of operating modes, designed for sorting rice seeds and obtaining seeds with

high quality, similar biological properties, high fertility and potential yield in laboratory and field conditions,

in addition informations on experimental studies on the selection of rice seeds, the study of the physical and

mechanical properties of selected rice seeds, as well as the results of determining their fertility in laboratory

and field conditions. The energy and resource-saving electric sorter can be used in rice seed preparation

technological systems, rice clusters and farms.

1 INTRODUCTION

It is known that the quality indicators of seeds

prepared for planting, along with other agrotechnical

measures, play a very important role in obtaining a

bountiful harvest of agricultural crops. After all, the

uniform and smooth germination of seedlings,

subsequent growth, ripening of the crop and, finally,

rice yield directly depend on the quality indicators of

seeds prepared for planting. Therefore, improving the

quality indicators of rice seeds prepared for planting

is one of the urgent tasks today.

The quality of rice seeds can be improved by

various methods, including selective breeding. It is

known from scientific sources that in order to obtain

high-quality seeds of agricultural crops that are close

to each other in biological properties, with high

fertility and potential yield in laboratory and field

conditions, it is necessary to sort them according to

all important physical and mechanical properties

(Rosaboev, 2015; Tagaev & Akramov, 2024). Sorting

crop seeds in an electric field fully meets this

requirement. Because the electric field affects the

seeds with directed electric field strengths of varying

magnitudes, taking into account all their important

physical and mechanical properties. As a result, in an

electric field, crop seeds are sorted according to all

a

https://orcid.org/0009-0005-3639-4771

b

https://orcid.org/0000-0003-3128-2124

important physical and mechanical properties,

namely: weight, geometric dimensions, density,

electrical resistance, dielectric absorption and other

similar important properties.

2 MATERIALS AND METHODS

Considering the above, as a result of research and

design work carried out within the framework of the

State Scientific and Technical Program in recent years

at the Research Institute of Agricultural

Mechanization, an energy and resource-saving

electric sorting device was created that improves the

quality indicators of agricultural crops, including

seeds rice (Patent, 2022a). The essence of an energy-

and resource-saving electric sorting device that

improves the quality indicators of rice seeds is that

the electric field on the surface of the working

elements is created in two different conditions, that is,

as a result of friction, two dielectric materials appear

between the support electrodes, rotating against each

other, and opposing coils wound into grooves directed

in a two-way spiral toward the dielectric drum. As a

result, the seeds are exposed to the total electric field

strength, which increases the accuracy of their sorting

into seed and technical fractions.

222

Tagaev, B. and Akramov, N.

Results of Sorting Rice Seeds in an Energy-Saving Electric Sorting Device.

DOI: 10.5220/0014245000004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 222-228

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

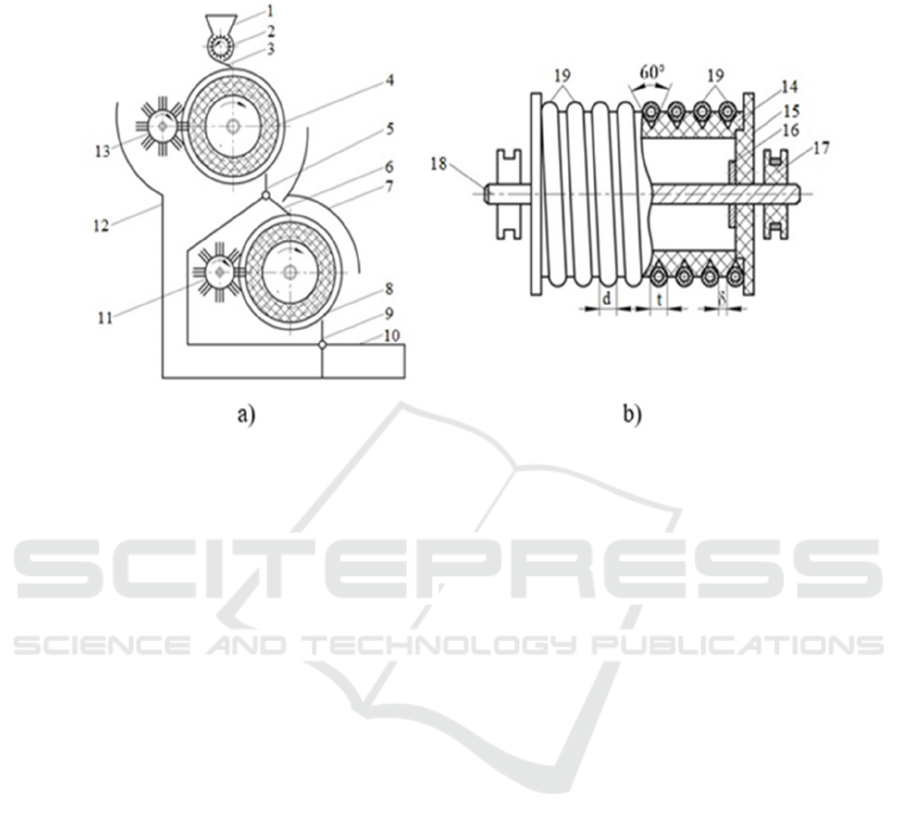

The figure shows a schematic diagram and

working element of an energy- and resource-saving

electric sorting device that improves the quality

indicators of rice seeds.

Figure 1: Schematic diagram (a) and working body (b) of an energy and resource-saving electric sorting device that improves

the quality indicators of rice seeds:1-loading hopper; 2-provider; 3, 6-pull-out board; 4, 8-working body; 5, 9-dividing plane;

7, 12 - protective walls; 10-reception hopper; 11, 13 - separating brushes; 14- polyethylene pipe; 15-sided discs; 6-flanges;

17 current transmitters; 18-shaft; 19-opposite electrodes.

The working bodies of the energy- and resource-

saving electric sorting device, which improves the

quality indicators of rice seeds, are made of

polyethylene pipe 14, and two-lane helical grooves

with a depth angle “γ”, width “t1” and distance equal

to “δ1”, directed towards the surface of the working

body located above and surrounded by electrodes of

the opposite direction with a diameter d 1 close to the

thickness of a rice seed. On the surface of the

working body located below, two-lane helical

grooves are made with a depth angle “γ”, width “t2 ”

and the distance between them, directed towards “δ2

” and electrodes with the opposite direction c wind

diameter d 2 around them, then is close to the width

of a rice seed . A polyethylene pipe 14 with double-

sided helical grooves is fixed to the shaft 18 using side

disks 15 and flanges 16 made of dielectric material.

Electrodes of opposite sign 19 are connected to a high

voltage source through a current sensor 17.

The operating principle of an energy and

resource-saving electric sorting device that improves

the quality indicators of rice seeds is as follows. When

it is connected to the network using an electric motor

and gearbox, feeder 2, working bodies 4 and 8,

separating brushes 11 and 13 are rotated. At this time,

rice seeds to be sorted are delivered from loading

hopper 1 to the surface of working body 4 at the same

speed through the feeder 2 and the sliding board 3.

The seeds, falling on the surface of the rotating

working body 4, are placed between the electrodes 19

in the opposite direction in terms of their thickness.

In addition to the force of the electric field, seeds are

also affected by centrifugal force, gravity, inertia,

reaction forces and friction. Depending on the mutual

relationship of the acting forces, depending on their

physical and mechanical properties, rice seeds are cut

from the surface of the working body 4 at different

angles, high-quality seeds fall on the surface of the

lower working body 8, and low-quality seeds are cut

off when turning at large angles or are separated using

brushes 11. Technical fraction 10 enters the receiving

hopper.

Rice seeds, cut from the surface of the upper

working body 4 and falling onto the surface of the

lower working body 8, are placed between electrodes

19 with opposite directions and the sorting process is

repeated. Rice seeds, sorted by thickness, width and

other important properties, are cut from the surface of

the lower working body 8, separated into the seed

fraction of the receiving hopper 10, placed in bags

and sent for sowing. Seeds adhering to the surface of

the working body 8 are cut at large angles or separated

with a brush and fall into the technical fraction of the

receiving hopper 10. In this sequence, the

technological process of sorting rice seeds continues

in an energy and resource-saving electric sorting

Results of Sorting Rice Seeds in an Energy-Saving Electric Sorting Device

223

device (Tukhtakuziev & Rasuljonov, 2020; Patent,

2022b; Abdullaev et al., 2023; Tukhtakuziev et al.,

2023; Alimova et al., 2024a; Alimova et al., 2024b).

The force of the electric field with great force

attracts rice seeds to the surface of the working

bodies, which allows, firstly, to increase the accuracy

of their separation into seed and technical fractions,

and secondly, to increase the efficiency of the device.

3 RESULTS AND DISCUSSION

Good results have been obtained in experimental

studies on the selection of rice seeds.

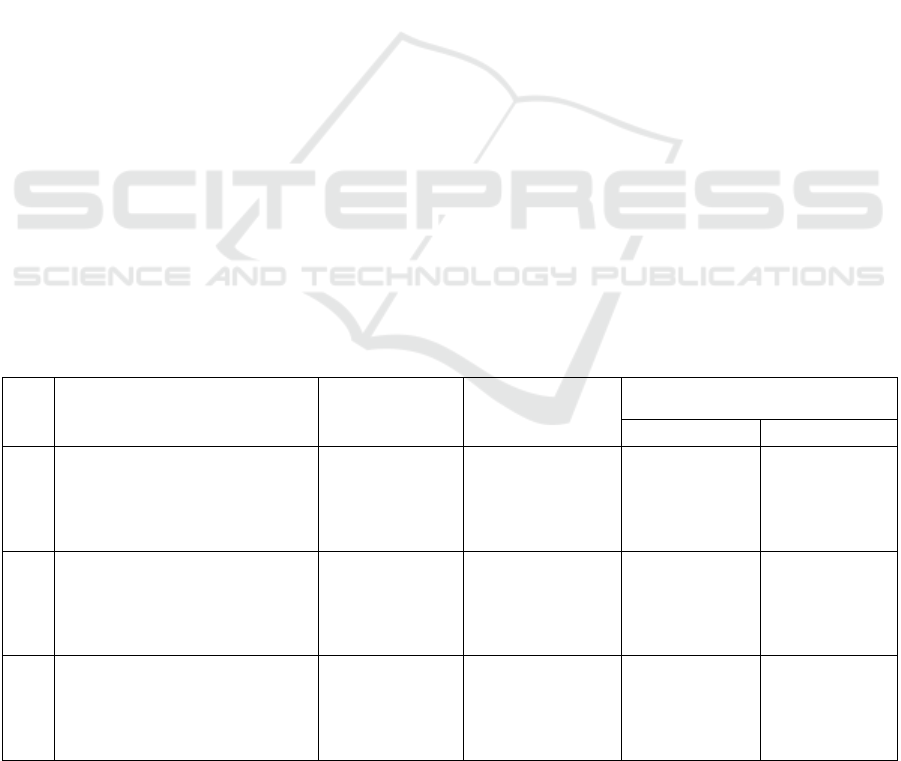

In Table 1, the diameter of the working body of an

energy-resource-saving electric sorting device that

improves the quality indicators of rice seeds is D =

350 mm, the voltage applied to the electrodes with

opposite signs is U = 1500 V, and the number of

revolutions of the working body is n = 40; The results

of the selection of rice seeds at 50 and 60 min -1 are

presented.

As can be seen from the results presented in Table

1, the diameter of the working bodies and the voltage

applied to the electrodes in the opposite direction do

not change, and with a change in the number of

revolutions, the sorted rice seeds are divided into

fractions and the mass of 1000 seeds changes.

In particular, if the number of revolutions of the

working body is n=40 min -1, the mass of 1000 grains

of rice containing 74.6% rice seeds, divided into the

seed fraction, will be 31.24 grams, which is 3.07

grams more than control, then the number of

revolutions of the working body n = 60 min -1, the

mass of 1000 grains of rice with 93.6% seeds divided

into the seed fraction was 29.26 grams, which

increased by 1.09 grams compared to the control.

That is, with an increase in the number of revolutions

of the working parts of the energy and resource-

saving electric sorting device, which increases the

quality indicators of rice seeds, the separation of

sorted rice seeds into a seed fraction was observed.

increases, and the mass of 1000 seeds decreases.

A different picture was observed in the technical

faction. With an increase in the number of revolutions

of the working bodies, the number of rice seeds

separated into the technical fraction and the mass of

1000 seeds in it decreased. In particular, at the number

of revolutions of the working bodies n=40 min -1, the

mass of 1000 grains of 25.4% barley seeds, divided

into a technical fraction, is 19.15 grams, which is

reduced by 9.59 grams compared to the control, the

number of revolutions of the worker organ n= 60 min

-1, the weight of 1000 grains of 6.4% rice seeds,

divided into the technical fraction, was 12.23 grams,

which decreased by 15.94 grams compared to the

control. With an increase in the number of revolutions

of the working bodies, the number of seeds separated

into the technical fraction, and a decrease in the mass

of 1000 seeds in it, low-quality and light rice seeds

are mixed into the seed fraction.

Table 1: Results of sorting rice seeds at different speeds of the working body.

№

The number of revolutions of the

working body and the name of the

fractions

Share-large

separation, %

Weight of 1000

seeds, g

Control the difference is in the

b

aton

G %

1 P = 40 min

-1

Control

After sorting:

- seed fraction

-technical faction

100.0

74.6

25.4

28.17

31.24

19.15

-

+3.07

-9.59

-

+10.80

-33.9

2 P = 50 min

-1

Control

After sorting:

- seed fraction

-technical faction

100.0

84.5

14.5

28.17

30.92

14.09

-

+2.75

-14.08

-

+9.76

-49.98

3 P = 60 min

-1

Control

After sorting:

- seed fraction

-faction of technicians

100.0

93.6

6.4

28.17

29.26

12.23

-

+1.09

-15.94

-

+3.87

-56.59

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

224

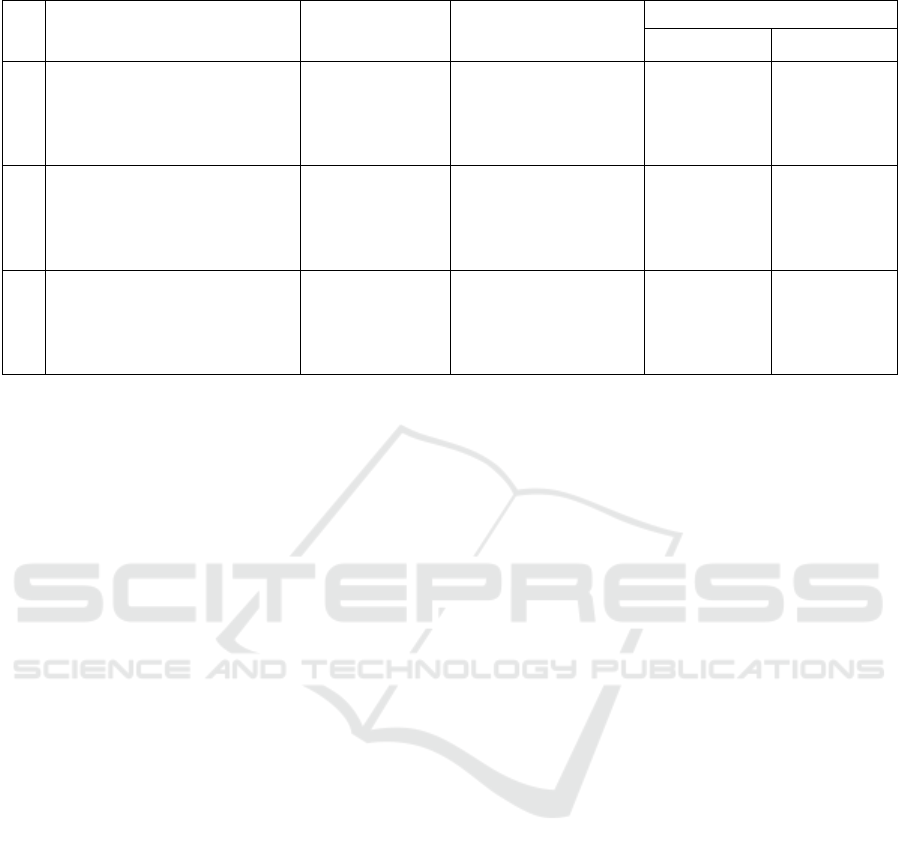

Table 2: The result of sorting rice seeds in a pilot copy of an energy and resource-saving electric sorting device.

№ Voltage value and faction name Fractionation, % Weight of 1000 seeds, g

Difference compared to control

G %

1 U =1000 V

Control

After sorting:

- seed fraction

-technical faction

100.0

90.79

9.21

27.78

29.18

13.95

-

+ 1.4

- 13.83

-

+5.04

- 49.78

2 U = 1 50 0 V

Control

After sorting:

- seed fraction

-technical faction

100.0

80.92

19.08

27.78

30.43

17.06

-

+2.65

- 10.72

-

+ 9.54

- 38.59

3 U = 2000 V

Control

After sorting:

- seed fraction

-technical fraction

100.0

68.37

31.63

27.78

31.90

19.42

-

+4.12

-8.36

-

+14.83

-30.09

Based on the analysis of the results obtained, we

can come to the following conclusion: from the point

of view of manufacturability, the diameter of the

working bodies D= 350 mm, the magnitude of the

voltage applied to the electrodes in the opposite

direction is the most optimal operating mode for the

precise separation of rice seeds into seed and

technical fractions in energy and a resource-saving

electric sorting device. Achieved at U = 1500 V and

an equal number of revolutions of the working body.

up to n = 50 min -1. In this mode, the weight of 1000

grains of 84.5% of rice seeds, divided into the seed

fraction, was 30.92 grams, which increased by 2.75

grams compared to the control.

Table 2 presents the results of sorting rice seeds in

a pilot version of an energy- and resource-saving

electric sorter. Experimental studies: diameter of the

working parts of the electrosorting device D = 350

mm, speed n = 50 min, electric field strength E =

6∙105 V/m and voltage applied to the electrodes with

the opposite direction U = 1000, carried out at 1500

and 2000 V.

From the results presented in Table 2, it is clear

that with a change in the voltage applied to the

opposite electrodes, there is a division of rice seeds

into fractions and a change in the mass of 1000 seeds.

Specifically, if the magnitude of the voltage applied

to the electrodes in the opposite direction is U = 1000

V, the weight of 1000 grains of 90.79% rice seeds

divided into the seed fraction will be 29.18 grams,

which is increased by 1.4 grams. Compared to the

control, at U = 2000 At equal V, the weight of 1000

grains of rice with 68.37% seeds divided into the seed

fraction was 31.90 grams, which increased by 4.12

grams compared to the control.

In the technical fraction, with an increase in the

voltage applied to the electrodes in the opposite

direction, an increase in the delamination of rice seeds

into it and an increase in the mass of 1000 seeds were

observed. In particular, with a voltage applied to the

electrodes equal to U = 1000 V, the mass of 1000

grains of 9.21 percent rice seeds, divided into a

technical fraction, is 13.95 grams, which is reduced

by 13.83 grams compared to the control., at U =2000

V. The weight of 1000 grains of 31.63% rice seeds,

divided into the technical fraction, was 19.42 grams,

which decreased by 8.36 grams compared to the

control.

U = 1500 V to electrodes in the opposite direction.

in an experimental copy of an energy- and resource-

saving electric sorting device. With this strain size,

the weight of 1000 rice seeds, divided into a seed

fraction of 80.92%, was 30.43 grams, which

increased by 2.65 grams compared to the control.

Experimental study on rice seed sorting found that

since the original seeds contain various impurities, as

well as broken and very small seeds, we propose to

sort these seeds after pneumatic or mechanical sorting

using energy and resource-saving electrical

equipment. sorter.

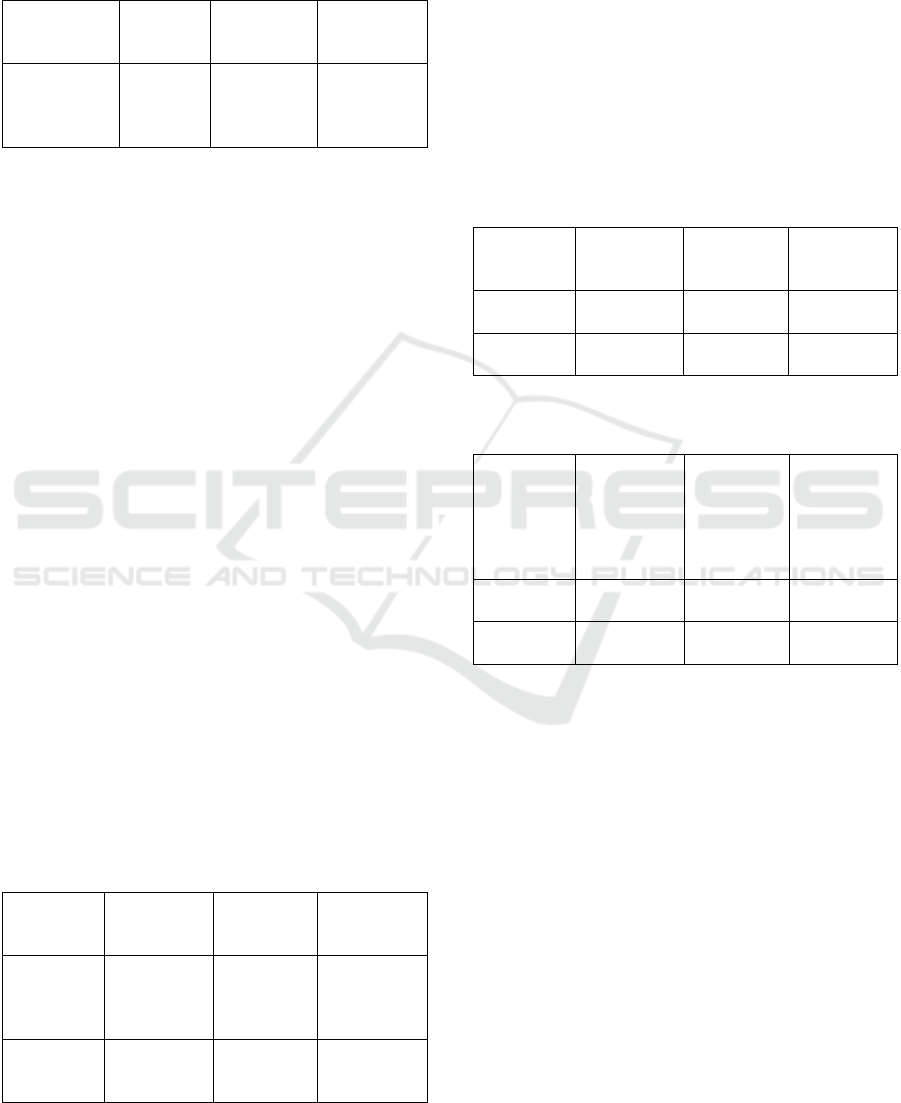

In table Figure 3 presents the results of a study

of the mass of 1000 rice seeds sorted in the original

and prototype of an energy- and resource-saving

electric sorting device.

From the results presented in Table 3, it is clear

that the mass of 1000 seeds of the first initial rice with

mass, standard deviation σ = 0,81 grams and

coefficient of variation V = 2.92 %, m = 27.78 grams,

after sorting in In a prototype of an electric sorting

device, the seed mass of 1000 fractionated rice seeds

Results of Sorting Rice Seeds in an Energy-Saving Electric Sorting Device

225

at σ = 0.36 grams and V = 1.18 % was m = 30.43

grams, compared to the control Δ m = 2.65 grams

increased.

Table 3: Results of the study of the mass of 1000 rice seeds.

Seeds and

faction name

Weight

of 1000

seeds,

g

Standard

deviation σ

,

g

Coefficient

of variation

- enti V , %

Rice seeds:

- control

- seed

fraction

27.78

30.43

0.81

0.36

2.92

1.18

Analysis of the results presented in Table 3 shows

that in a prototype of an energy- and resource-saving

electric sorting device, when sorting rice seeds, with

an increase in weight by 1000 seeds, seeds of similar

weight are obtained. This is clearly visible from the

coefficients of variation in the mass of 1000 rice seeds

in the control and seed fractions. The value of the

coefficient of variation decreased by 2.5 times

compared to the control in the variant with division

into the seed fraction.

Thus, as the weight of rice grains increases when

sorted in an energy and resource-saving electric

sorter, they become closer to each other.

In table 4 presents the results of a study of the

geometric dimensions of rice seeds sorted in the

original and prototype of an energy- and resource-

saving electric sorting device.

From the results presented in Table 4, it is clear

that there were some changes in the geometric

dimensions of rice seeds when they were sorted in an

energy- and resource-saving electric separator.

The geometric dimensions of rice seeds - length,

width and thickness - in the control variant and after

sorting in an energy- and resource-saving electric

separator are equal to a = 8.59 mm, b = 3.68 mm and

c = 2.09 mm . device, in the version with the

separation of seeds into fractions a = 8.76 mm, b =

3.69 mm and c = 2.24 mm.

Table 4: Results of a study of the geometric dimensions of

rice seeds.

Seeds and

faction

name

Geometric

dimensions

a, b, c, m

m

Medium

square σ,

m

m

Variation

coefficients

V, %

Rice seed:

- Control

8.59

3.68

2.09

0.61

0.25

0.31

7.09

6.92

14.64

- seed

faction

8.76

3.69

2.24

0.58

0.22

0.11

6.59

5.88

4.72

Analysis of the results presented in Table 4 shows

that when sorting rice seeds in an energy- and

resource-saving electric sorting device, the geometric

dimension’s increase, and the geometric dimensions

of the seeds come closer to each other. Thus, it was

noticed that the coefficients of variation in the

geometric dimensions of seeds divided into the seed

fraction were reduced compared to the control.

Table 5 presents the results of a study of the

sphericity coefficient of rice seeds sorted in a primary

and energy- and resource-saving electric sorting

device.

Table 5: Results of the study of the coefficient of sphericity

of rice seeds.

Seeds and

faction

name

Sphericity

coefficient

Standard

deviation

σ, m

m

Coefficient

of variation

V, %

Rice seed:

- Control

0.43

0.03

7.13

- seed

faction

0.43 0.03 7.04

Table 6: The result of determining the germination of rice

seeds in laboratory conditions.

Seeds and

faction

name

Fertilizer

application

in

laboratory

conditions,

%

Standard

deviation

σ, mm

Coefficient

of variation

V, %

Rice seed:

- Control

0.43

0.03

7.13

- seed

faction

0.43 0.03 7.04

From the results presented in Table 5, it can be

seen that the sphericity coefficients did not change

when sorting rice seeds in an energy and resource-

saving electric sorter. We can come to the following

conclusion: rice seeds are sorted according to all their

sizes, length, width and thickness in an energy and

resource saving electric sorting device. Consequently,

the sphericity coefficient of seeds divided into the

seed fraction after sorting does not change compared

to the control.

In table 6 presents the results of determining the

germination of rice seeds sorted in laboratory

conditions using an initial and energy and resource-

saving electric sorting device.

From the results presented in Table 6, it is clear

that after sorting rice seeds in an energy and resource-

saving electric sorter, in the version with separation

into the seed fraction, the accuracy in laboratory

conditions was higher than in control. The purity of

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

226

rice seeds in laboratory conditions was 91.25% for the

control variant, and 94.0% for the seed fraction,

which is 3.75% higher than the control.

Analysis of the results presented in Table 6 shows

that when sorting rice seeds in an energy- and

resource-saving electric separator, not only the

quality in the laboratory increases, but also the quality

of the seeds separated into seed fractions in the

laboratory. conditions are close to each other. This is

also evidenced by the coefficients of variation in the

quality of rice seeds, divided into control and seed

fractions, in laboratory conditions.

Thus, sorting rice seeds in an energy- and

resource-saving electric sorter not only produces

seeds with high fertility in vitro, but also seeds with

similar fertility in vitro. Table 7 presents the results of

determining the germination of rice seeds sorted

under field conditions in the original and energy- and

resource-saving electric sorting device.

Table 7: The result of determining the germination of rice

seeds in laboratory conditions.

Seeds and

faction

name

Fertilizer

application

in

laboratory

conditions,

%

Standard

deviation

σ, mm

Coefficient

of variation

V, %

Rice seed:

- Control

61.50

1.00

1.63

- seed

faction

72.50 3.11 4.29

Table 7, it is clear that sorting rice seeds in an

energy and resource-saving electric sorter allows not

only to obtain seeds with high fertility in laboratory

conditions, but also in field conditions. Fertilization

of rice seeds under field conditions was 61.5% in the

control, 72.5% in the seed fraction after sorting,

which was 11.0% higher than the control.

From the results presented in Table 7, it is also

clear that sorting rice seeds in an energy- and

resource-saving electric sorting device not only

increases their field fertility, but also makes it

possible to obtain seeds with similar field fertility.

This is evidenced by the coefficients of variation in

the germination of rice seeds in the control variant

and those allocated to the seed fraction under field

conditions.

Thus, sorting rice seeds in an energy- and

resource-saving electric sorting device produces

seeds with high and similar field fertility.

Analysis of the results presented in Tables 6 and 7

shows that sorting rice seeds in an energy- and

resource-saving electric sorter makes it possible to

obtain seeds with high and close germination in

laboratory and field conditions.

A study of the physical and mechanical properties

of rice seeds sorted in an energy- and resource-saving

electric separator showed that not only in weight, but

also in density, geometric dimensions and biological

properties, they are close to each other, have high

fertility and potential yield. in laboratory and field

conditions. It can be concluded that sorting rice seeds

in an energy and resource-saving electric sorter

creates the basis for growing a rich harvest from

them.

Further research and development should be

aimed at developing a prototype energy- and

resource-saving electric sorter, as well as

experimental studies on seed sorting of other crops.

4 CONCLUSIONS

1. The use of devices used in practice based on the

pneumomechanical method of sorting rice

seeds does not allow obtaining seeds of the

required level, since they are sorted according

to one important characteristic.

2. Creation of an electric field between electrodes

of the opposite direction on the surface of the

upper and lower working bodies of an energy-

and resource-saving electric sorting device due

to the attraction of rice seeds to it by a large

electric field force, high-quality rice seeds with

similar biological properties, laboratory and

providing good seeds with high fertility and

potential yield in field conditions.

3. It is necessary to carry out further research

work to improve a prototype of an energy- and

resource-saving electric sorting device, as well

as to conduct experimental studies on sorting

seeds of other agricultural crops.

REFERENCES

Abdullaev, M., Akramov, N., Mirzaeva, G., & Tursunov,

M., 2023. Effectiveness of using electrochemically

activated water with an acidic medium in breeding grain

moth (cytotroga cerealella oliv) in biolaboratories. E3S

Web of Conferences, 452, 01046.

https://doi.org/10.1051/e3sconf/202345201046.

Alimova, F., Saidova, M., Boboniyozov, E., & Mirzayev,

B., 2024b. Analysis of the state of mechanized sowing

of rice in seedlings. BIO Web of Conferences, 85,

01032. https://doi.org/10.1051/bioconf/20248501032.

Alimova, F., Saidova, M., Primqulov, B., & Erdem, T.,

2024a. Optimization of the parameters of the pneumatic

Results of Sorting Rice Seeds in an Energy-Saving Electric Sorting Device

227

feed mechanism for precise clustered sowing. BIO Web

of Conferences, 85, 01026.

https://doi.org/10.1051/bioconf/20248501026

Patent, 2022a. Patent of the Republic of Uzbekistan No.

IAP 6674. Device for sorting seeds of agricultural

crops. A.T. Rosaboev et al., Bulletin. – No. 1.

Patent, 2022b. Patent of the Republic of Uzbekistan No.

IAP 06833. Universal dielectric device for sorting seeds

of agricultural crops. A.T. Rosaboev et al., Bulletin. –

No. 4.

Rosaboev, A.T., 2015. Elektr saralagich kurilmasini

takomilashtirish natizhasi. Energy va Resourcestezhash

Muammolari, 3, 205-209.

Tagaev, B.K. & Akramov N.N., 2024. Theoretical study of

the process of sorting rice seeds under the influence of

an electric field. International Journal of Advanced

Research in Science, Engineering and Technology,

11(4), 21639-21644.

Tukhtakuziev, A., & Rasuljonov, A.R., 2020. Ensuring the

stability of the processing depth of suspended soil

mounted machines. IOP Conference Series: Earth and

Environmental Science, 614(1), 012156. DOI:

10.1088/1755-1315/614/1/012156.

Tukhtakuziev, A., Rasuljonov, A. R., Turkmenov, H. I.,

Irgashev, A. A., & Barlibaev, S., 2023. Ensuring the

stability of the suspended chisel-cultivator processing

depth. E3S Web of Conferences, 390, 01038.

https://doi.org/10.1051/e3sconf/202339001038.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

228