Wear Resistance of Gear Teeth of Gearbox Gears of Tractors

Operating in Dusty Conditions

Najmiddin Mirzaev

1a

, Amirkul Irgashev

1b

and Nargiza Igamberdieva

2c

1

Tashkent State Technical University, Department of Service Technic 100095, Tashkent, Uzbekistan

2

Joint Belarusian-Uzbek Interindustry Institute of Applied Technical Qualifications in Tashkent,

100000, Tashkent, Uzbekistan

Keywords: Gearbox Wear, Abrasive Particles, Dusty Conditions.

Abstract: The article deals with the issues of wear resistance of gear teeth of wheel tractor gearboxes operating in dusty

conditions. Methods are developed: modelling of gears being in coupling with samples having a cylindrical

shape; experimental studies of wear occurring on the contact areas of the tooth profile surface, taking into

account the degree of oil contamination by abrasive particles and wear products, load and the process of

slippage between the teeth of gears.

1 INTRODUCTION

Carrying out of researches directed on determination

of term of replacement of oil in a gearbox, in real

friction pairs, demands much time and big expenses

of material means as during carrying out of tests in

field conditions oil samples are taken from a gearbox

with intervals of 125 hours of work and volume of

200-250 ml, with the subsequent filling of fresh oil in

a crankcase of the unit. The final oil sampling is

carried out after 1000 hours of operation, as the

specified time corresponds to the frequency of oil

change in the unit, according to the technical

instructions for the tractor operation for the gearbox

(Ishmuratov et al., 2023).

2 MATERIALS AND METHODS

During tractor operation, considerable amounts of

mechanical impurities accumulate in the gearbox.

The main component is abrasive particles of soil

origin, mainly consisting of oxides of silicon,

aluminium and wear products in the form of iron. The

composition of mechanical impurities in the oil was

determined by spectral analysis on the photometric

a

https://orcid.org/0009-0007-0829-5877

b

https://orcid.org/0000-0002-7826-1687

c

https://orcid.org/0000-0050-5009-0541

unit MFS-3, and the concentration of mechanical

impurities according to the results of analysis of oil

samples relating to each pair of gears of the gearbox

gears that are in the meshing.

The results of the analysis of the composition of

mechanical impurities show the presence in the oil of

the unit wear products in the form of iron, as well as

abrasive particles in the form of silicon oxides and

aluminium. The tests were carried out in the gearbox

oil during one replacement period corresponding to

1000 hours of tractor operation (Irgashev, 2005).

In order to reduce the duration, increase the

degree of accuracy of experimental studies carried out

to determine the wear resistance of gear teeth, it is

advisable to conduct tests on the friction machine,

using roller samples, whose dimensions correspond

to the geometric and kinematic parameters of the gear

gearing, which determine the radius of curvature of

the contact surfaces and the degree of slippage

occurring between the teeth of gears.

Determination of the acceleration coefficient of

wear test of gear teeth with abrasive particles is based

on a linear relationship between the concentration of

abrasive particles in the tub of the friction machine

and the amount of wear occurring in the samples of

gears with abrasive particles.

216

Mirzaev, N., Irgashev, A. and Igamberdieva, N.

Wear Resistance of Gear Teeth of Gearbox Gears of Tractors Operating in Dusty Conditions.

DOI: 10.5220/0014244500004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 216-221

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

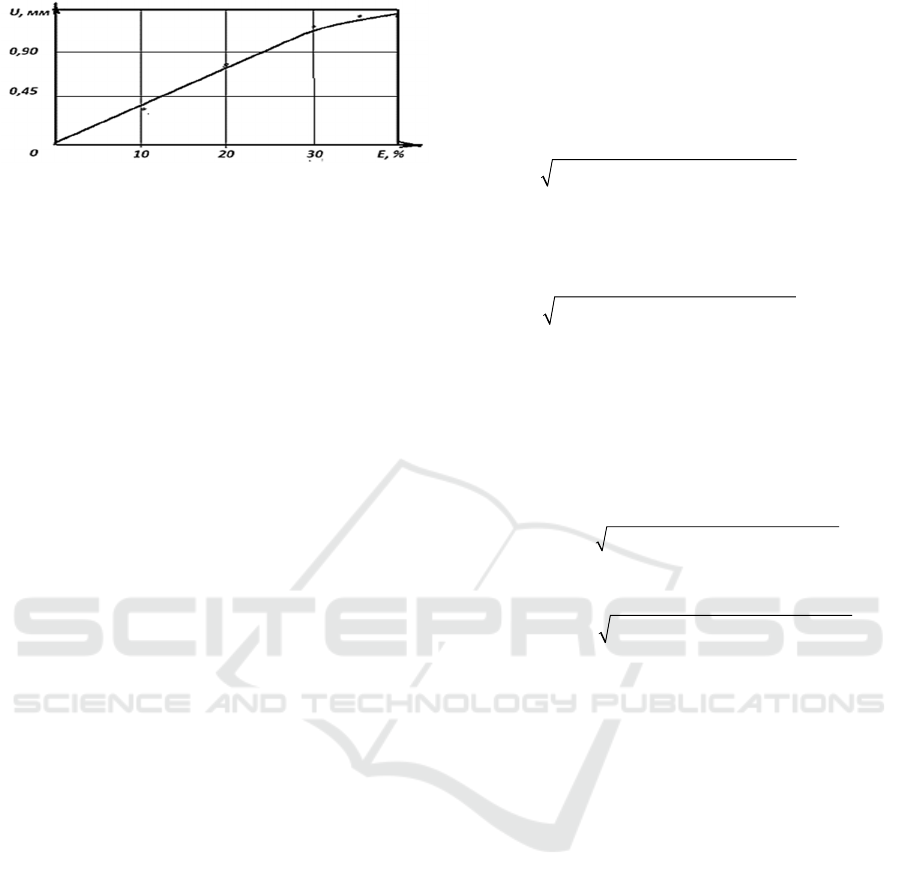

Figure 1: Variation of the wear value of the roller specimen

depending on the concentration of abrasive particles in the

oil Variation of the wear value of the roller specimen

depending on the concentration of abrasive particles in the

oil.

Carrying out of wear test on the friction machine

allows to reduce duration of works as: firstly, angular

speeds of samples established on a shaft of the

friction machine are higher, than speeds of gears in a

gearbox; secondly, concentration of abrasive

particles in oil change in operational conditions, at

dustiness of environment 0,82 g/m3, habituates 0,35

%. According to the figure 1, the dependence of

change of wear value on the concentration of

abrasive particles is linear, so the increase in the

concentration of abrasive particles is maintained up

to 31,5 %.

Increase of acceleration coefficient of wear test

(see table 1) in 158,4 times gave the possibility to

reduce the duration of wear test of gear wheel from

300 hours to 113,6 min, the test was carried out on

roller samples modelled by expressions (Ishmuratov

& Irgashev, 2020; Ishmuradov & Hamroev, 2024).

Each meshing point of the gear has its own radius

of curvature and degree of relative slip between them

according to the profile of the involute to be meshed.

In order to obtain a wear curve, the involute tooth

surface was divided into 8 parts, for each of which

the characteristic values of the degree of slippage

were determined.

Test specimens are made of gear material, the

surfaces of which are hardened in accordance with

the modes provided by the technological process of

hardening gear teeth (Myshkin & Petrokovets, 2007).

If in the gear meshing occurs between the head of

the tooth of the leading (driven) and the foot of the

tooth of the (leading) gear, then the radius of the

sample modelling the head (foot) of the tooth of the

leading (driven) gear is equal to:

1,2

0, 5

шг

m

ρψ

=⋅⋅

where

1,2

ψ

- the degree of relative slippage

occurring between the head (foot) of the tooth of the

leading (driven) and the foot (head) of the tooth of the

tooth of the slave tooth of the (driving) gear.

The calculated values of the degree of relative

slip occurring between the teeth of the meshing gears

were determined by the following expressions:

- provided that the meshing occurs between the

tooth head of the driving gear and the tooth stem of

the driven gear:

22 2

1

sin 4 sin 4

шш

z к z к

ψα α

= ⋅ +⋅⋅ ⋅ ±⋅

(1)

- provided that the engagement is between the

tooth head of the idler gear and the tooth foot of the

drive gear:

22 2

2

sin 4 sin 4

кк

z к z к

ψα α

=⋅ +⋅⋅⋅ ⋅

(2)

Then, the radius of curvature of the samples

modelling the operation of gears meshing occurs

between the head (foot) of the tooth of the driving

(driven) gear and the foot (head) of the tooth of the

driven (master) gear:

- the head (foot) of the tooth of the drive (driven)

pinion:

22 2

0,5 sin 4 sin 4

шш ш

mz к z к

ραα

=⋅⋅ ⋅ +⋅⋅⋅ ±⋅

(3)

- of the tooth of the idler gear tooth (head):

22 2

0, 5 sin 4 sin 4

кк к

mz к z к

ραα

=⋅⋅ ⋅ +⋅⋅⋅ ⋅

(4)

The sizes of abrasive particles participating in the

process of wear are chosen according to GOST 9206-

80 26/22, 10/8,5 microns and the sizes of the same

abrasive particles according to GOST 3647-80 are

designated by M28, M10. Average sizes of abrasive

particles added to oils in a tub of the friction machine

at wear test made 14,9 microns.

Duration of testing samples of gears for wear

resistance on the friction machine depend on the

material of gear teeth, modes of heat treatment,

geometric and kinematic parameters, coefficient of

acceleration of wear test. Calculated indicators

affecting the coefficient of acceleration of wear test,

wear resistance and duration of wear test of samples

made of gear materials on the rolling friction

machine are given in Table 1.

Wear Resistance of Gear Teeth of Gearbox Gears of Tractors Operating in Dusty Conditions

217

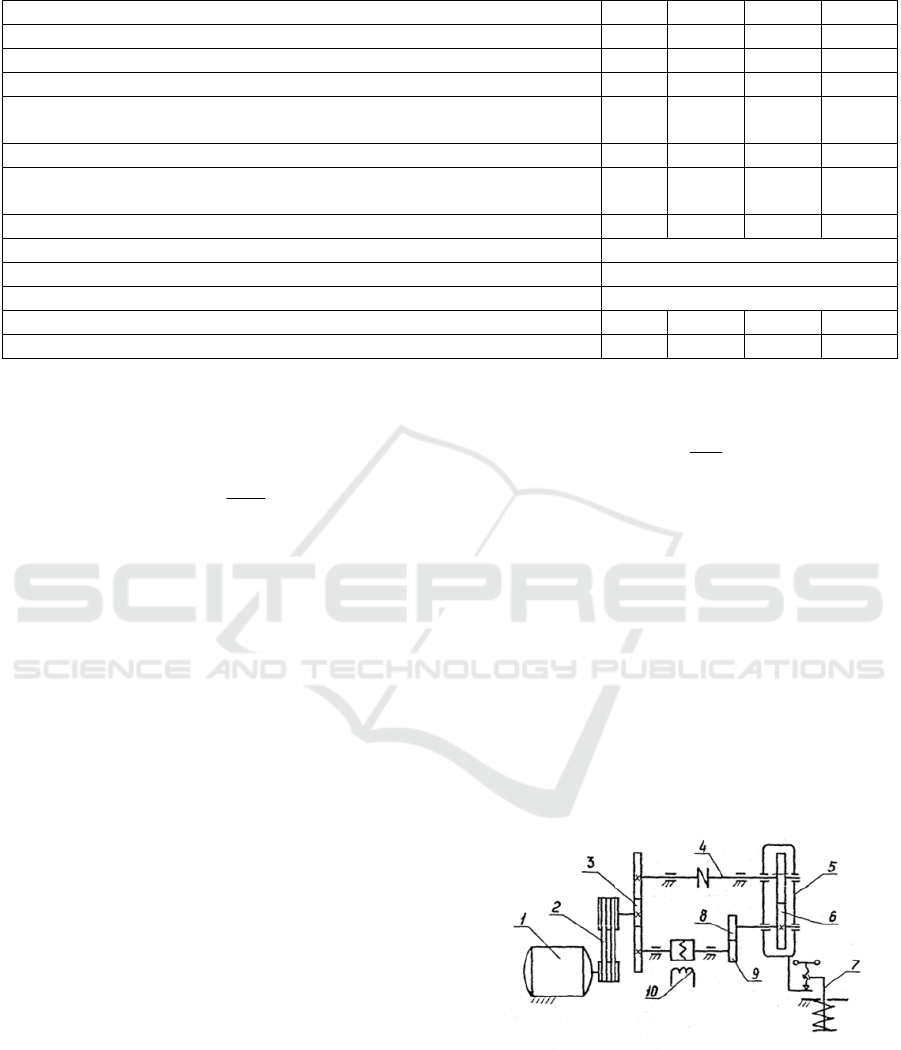

Table 1: Gear indicators affecting the test acceleration factor and the duration of the wear test of the specimens.

Indicatorsnwear test II III IY Total

P

ercenta

g

e of oil chan

g

e time, % 15 30 25 70

P

roportion of oil chan

g

e time, hours 150 300 250 700

A

vera

g

e speed of driven shaft, min

-1

476 567 667 -

N

umber of revolutions of the output shaft during the oil change period

(ten thousand revolutions)

428,4 1020,6 1000,5 2449,5

R

otational speed of the lower sample, min

-1

1000 1000 1000 -

N

umber of revolutions of the lower friction sample (ten thousand

r

evolutions)

900 1800 1500 4200

A

cceleration coefficient of test specimens and

g

earbox drive shaft tes

t

2,10 1,76 1,50 1,71

Concentration of abrasive accumulations durin

g

the oil chan

g

e period, % 0,35

Concentration of abrasive particles in friction machine oil, % 31,5

Test acceleration factor at 31.5% abrasive particle concentration in oil 90

Total test acceleration facto

r

189,0 158,4 135,0 153,9

D

uration of the wear test on the friction machine 47,6 113,6 111,1 272,3

The speed of rotation of the drive shaft of the

gearbox during one minute is determined by the speed

of rotation of the engine crankshaft, according to the

ratio below:

д

i

ду i

n

n

ii

=

⋅

where

д

n

- the frequency of rotation of the

crankshaft of the engine during one minute,

д

n =

2200 min

-1

;

ду

i

- the gear ratio of the gear

transmission, transferring torque to the intermediate

shaft of the transmission box, with the value

ду

i

=1,29,

which will provide the average speed of rotation of

the intermediate shaft 1700 min

-1

. The number of

revolutions of the driving shaft of the gearbox perfect

for one term of oil change is calculated by the

following expression:

ма i мх

N

nt=⋅

where

м

х

t

- gearbox oil change period, min

The wear test was carried out on the friction

machine on samples made on the radius of curvature

of gear teeth, heat treatment of friction surfaces of

which was carried out taking into account the load to

the real conditions of operation of gear wheels, taking

into account their location in the intermediate and

driven shafts of the transmission box. Thus tested

lower samples had contact with oil in a bath of the

friction machine having a composition of abrasive

particles. The wear test of the specimens was carried

out at the rotational speed of the bottom specimen of

the friction machine 1000 min

-1

.

The general coefficient of acceleration of wear

test includes two components, one of them takes into

account the rotational speed of the bottom specimen

mounted on the friction machine and is determined by

the expression:

им

ас

у

к

N

к

N

=

where

им

N

- number of revolutions of the lower

sample tested for wear resistance on the friction

machine;

ук

N

- number of revolutions of the driven

shaft for the period of oil change in the gearbox.

The second component was determined by the

ratio of the maximum concentration of abrasive

particles in the oil of the friction machine tub, which

has a linear dependence on the maximum wear of the

samples (1.25 mm), presented in Figure 1.

At carrying out of experimental researches the

used abrasive particles on maximum and minimum

sizes and on strength have special values which

should correspond to requirements of GOST 9206

and GOST 3647-80.

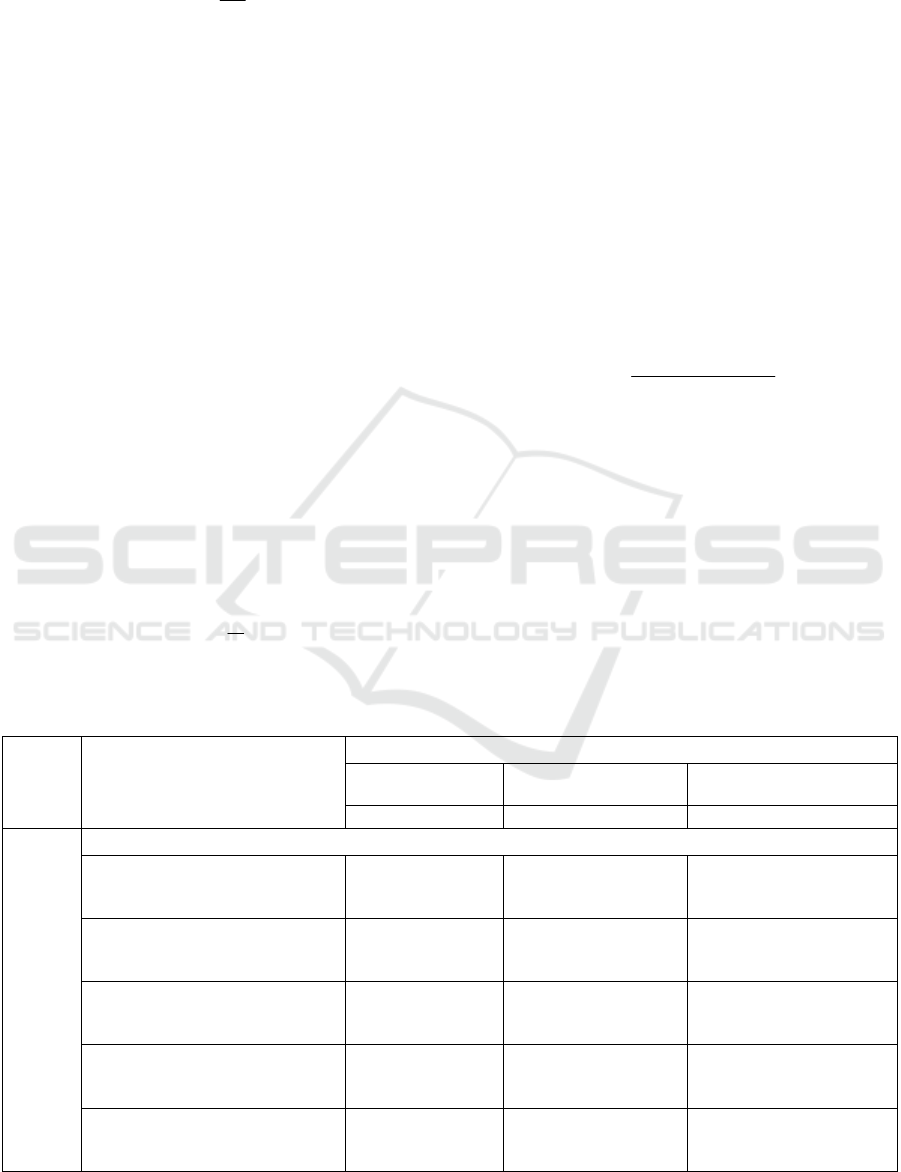

Figure 2: Kinematic scheme of the rolling friction machine

1 - electric motor; 2 - V-belt transmission; 3 - gear transfer

box; 4 - shaft; 5 - carriage; 6 - gear drive upper sample; 7 -

spring loading mechanism; 8 - upper sample; 9 - lower

sample; 10 - inductive sensor for measuring the friction

torque.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

218

The acceleration factor of a wear test involving

abrasive particles in oil is equal to:

им

а

у

к

к

ε

ε

=

where

им

ε

- concentration of abrasive particles in

the tub of the friction machine before the test, %;

ук

ε

- concentration of abrasive particles in the gearbox oil

corresponding to the period of their replacement, %.

The calculated values of the acceleration coefficient

of the wear test were

а

к =

90.

The total coefficient of acceleration of wear test is

determined as a product of coefficients of

acceleration of wear test of samples, being in oil bath

of the friction machine (Fig. 2) and with participation

of abrasive particles in oil, that is:

ас а

кк к=⋅

where

ас

к

- acceleration coefficient of wear test of

specimens being in the oil bath of the friction

machine.

Time wear test on the friction machine friction

samples made of gearbox gear materials, determined

for the period of oil change for each gear, taking into

account their share in each gear and the coefficient of

acceleration of wear resistance test, is determined by

the following ratio:

х

им

t

t

к

=

where t

x

- the fraction of oil change time in the

gearbox under consideration, min.

3 RESULTS AND DISCUSSION

Determination of the average wear rate of gear teeth

arising during the oil change period of the tractor

gearbox operating in an abrasive environment, makes

it possible to determine the service life of gears in

operating conditions. Modelling the work of gear

teeth involved in meshing samples - roller analogues

on the basis of geometric and kinematic parameters

allows you to reduce the duration of wear test and has

an impact on improving the accuracy of measurement

of wear of the friction surfaces under study.

For definition of average wear rate of samples the

following expression is offered:

0,033

м

м

ем

М

в t

γ

πγ ρ

=

⋅⋅ ⋅⋅⋅

where - value of wear of the sample by mass, g; -

density of wear products, g/mm3; - radius of the

tested sample for wear by mass, mm; - contact width

of the tested sample for wear, mm; - duration of wear

test of the sample, min.

The value of wear of the samples tested for wear

resistance was determined by weighing on analytical

scales by the difference in mass of samples before and

after wear test, the measurement was carried out with

an accuracy of 0.1 mg. The results of the study are

given in Table 2.

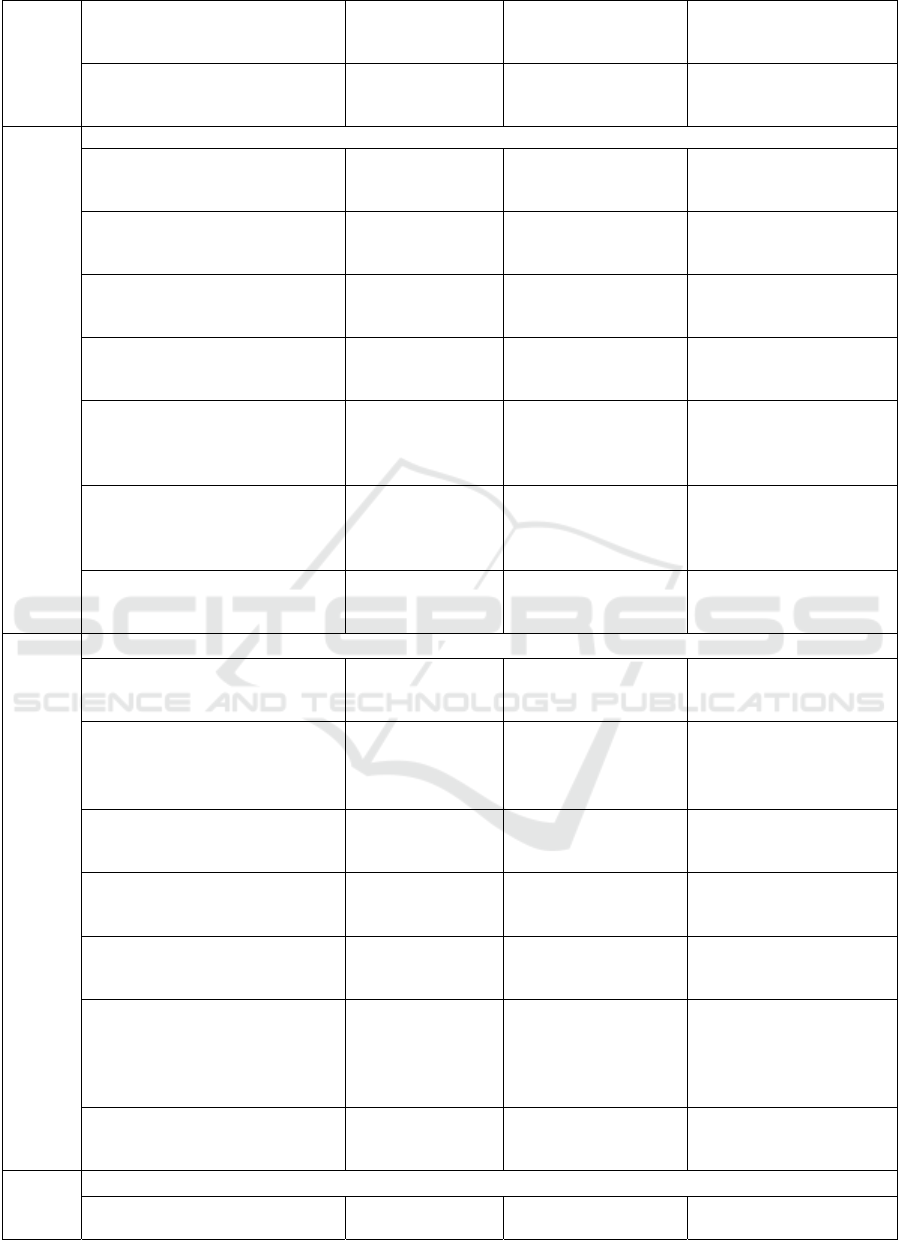

Table 2: Results of wear test of specimens made of gear materials on the radius of curvature curvature of gear teeth, carried

out on a rolling friction machine.

№

Indicators

Gear tooth height factor, k

On the head of the

tooth

At the engagement pole On the stem of the tooth

1,0 0 1,0

1

Radius of curvature of tested samples of gear teeth, mm

On a permanent hitch:

on the drive shaft;

intermediate shaft

28,94

35,78

23,94

30,78

28,06

35,07

In first gear:

intermediate shaft;

idler shaft

49,46

15,26

44,46

10,26

48,95

13,53

In second gear:

intermediate shaft;

idler shaft

47,75

16,97

42,75

11,98

47,22

15,43

In third gear:

the intermediate shaft;

idler shaft

46,03

18,68

41,04

13,68

45,49

17,29

In fourth gear:

intermediate shaft;

idler shaft

44,33

20,39

39,33

15,39

43,76

19,12

Wear Resistance of Gear Teeth of Gearbox Gears of Tractors Operating in Dusty Conditions

219

In fifth gear:

intermediate shaft;

idler shaft

38,34

26,38

33,34

21,38

37,69

25,41

In sixth gear:

intermediate shaft;

idler shaft

32,36

32,36

27,36

27,36

31,58

31,58

2

Wear value of the gear test specimen by mass, g

r

On a permanent hitch:

on the drive shaft;

intermediate shaft

0,071

0,088

0,007

0,009

0,069

0,086

In first gear: intermediate shaft;

idler shaft

0,121

0,037

0,012

0,004

0,120

0,033

In second gear:

intermediate shaft;

idler shaft

0,117

0,042

0,012

0,004

0,116

0,038

In third gear:

intermediate shaft;

idler shaft

0,113

0,046

0,011

0,005

0,111

0,042

In fourth gear:

intermediate shaft;

idler shaft

0,109

0,056

0,011

0,006

0,107

0,047

In fifth gear:

intermediate shaft;

idler shaft

0,094

0,065

0,009

0,007

0,092

0,062

In sixth gear:

intermediate shaft;

idler shaft

0,079

0,080

0,008

0,008

0,077

0,077

3

Value of linear wear of the gear test specimen, mm

On a permanent hitch:

on the drive shaft;

intermediate shaft

0,644

0,499

0,061

0,047

0,614

0,476

In first gear:

Intermediate shaft

idler shaft

0,065

0,015

0,006

0,002

0,062

0,014

In second gear:

intermediate shaft;

idler shaft

0,134

0,038

0,013

0,004

0,128

0,036

In third gear:

intermediate shaft;

idler shaft

0,257

0,086

0,024

0,008

0,245

0,082

In fourth gear:

intermediate shaft;

idler shaft

0,205

0.080

0,020

0,008

0,196

0,076

In fifth gear:

gear on the intermediate shaft;

pinion on the idler shaft

0,104

0,067

0,010

0,006

0,099

0,065

In sixth gear:

intermediate shaft;

idler shaft

0,046

0,046

0,005

0,005

0,044

0,044

4

Wear rate of the gear sample, mm/hour

On a permanent hitch:

on the drive shaft;

0,00064

0,00006

0,00061

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

220

intermediate shaft 0,00050 0,00005 0,00048

In first gear:

intermediate shaft;

idler shaft

0,00093

0,00021

0,00009

0,00002

0,00089

0,00020

In second gear:

intermediate shaft;

idler shaft

0,00089

0,00025

0,00008

0,00002

0,00085

0,00024

In third gear:

intermediate shaft;

idler shaft

0,00086

0,00029

0,00008

0,00003

0,00082

0,00028

In fourth gear:

intermediate shaft;

idler shaft

0,00082

0,00032

0,00008

0,00003

0,00078

0,00031

In fifth gear:

intermediate shaft;

idler shaft

0,00069

0,00045

0,00007

0,00004

0,00066

0,00043

In sixth gear:

intermediate shaft;

idler shaft

0,00058

0,00058

0,00005

0,00005

0,00055

0,00055

4 CONCLUSIONS

1. Analytical dependencies are offered, allowing

to calculate the degrees of relative slippage

occurring between the teeth of the meshed

gears and radius of curvature of the contact line

radius of the teeth of the driving and driven

gears taking into account, geometric and

kinematic parameters of the gear meshing.

2. Developed a method of accelerated wear test of

the gear gearing modelling the work of gear

teeth roller samples made by their radius of

curvature, while providing high accuracy of the

results obtained on the wear profile of gear

teeth determined by wear test roller analogues.

3. Analytical dependence is obtained, allowing to

determine the wear rates of the teeth of the

driving and driven gears, taking into account

the values of wear on the mass of samples,

radius of curvature, contact width and duration

of wear test.

REFERENCES

Irgashev, A., 2005. Methodological bases of increase of

wear resistance of gears of heavy-loaded gears of

machine units. Dissertation of Doctor of Technical

Sciences, Tashkent, p. 244.

Ishmuradov, Sh. & Hamroev, R., 2024. Disc rotary plough

for agriculture mechanization. E3S Web of Conferences,

548, 08017.

https://doi.org/10.1051/e3sconf/202454808017.

Ishmuratov, H.K., Irgashev B.A., 2020. Assessment of the

wear resistance of gearwheel teeth in an open toothed

gear under the conditions of a high level of dust.

Journal of Friction and Wear, 41(1), 85-90.

https://doi.org/10.3103/S1068366620010092.

Ishmuratov, H.K., Mirzaev, N.N., Abdullaeva, B.,

Mamasalieva, M.I., 2023. Energy analysis of wear

sliding friction units. E3S Web of Conferences, 383,

04019. https://doi.org/10.1051/e3sconf/202338304019.

Myshkin, N.K. & Petrokovets, M.I., 2007. Friction,

lubrication, wear. Physical Bases and Technical

Applications of Tribology. Moscow: Fizmatlit, p. 368.

Wear Resistance of Gear Teeth of Gearbox Gears of Tractors Operating in Dusty Conditions

221