To Question Use Caddy for Transportation Vegetables

Gulchehra Juraeva

a

, Nargiza Maxmudova

b

, Muqaddas Djabborova

c

and Gulnoz Abdikayimova

d

Tashkent State Technical University, 100095, University str. 2, Tashkent, Uzbekistan

Keywords: Soft Containers, Transportation, Polypropylene.

Abstract: The paper discusses the use of soft containers (MC) for transportation of vegetables, especially root crops.

Until recently, MK, simply put bags, used in agriculture for cargo weighing up to 100 kg. As the increase in

the proportion of mechanization in the urgent becomes the use of MK larger size, because their advantage is

obvious. The article discusses the pressure on the walls of production of small and large size MC and

compared with the strength of polypropylene fabric. The calculation of pressure on the walls of the MC shown

the possibility of using different density PP fabric.

1 INTRODUCTION

In the following years, comprehensive measures were

implemented in the Republic to support international

carriers, to introduce modern information

technologies in the provision of logistics services and

to create an effective transport infrastructure.

Despite the large-scale practical work carried out

today in the field of transport and logistics, there are

still systemic shortcomings in this field, requiring

improvement of certain norms and harmonization

based on world experience, reducing the sector's

share in the hidden economy.

2 MATERIALS AND METHODS

The widespread use of soft containers in the world

today makes them an advantage over other types of

containers (metal, wood, plastic, small wooden crates,

iron barrels vaxacoza), which are associated with a

number of advantages.

− small capacity coefficient of transport comb

(0.01....0,02);

− small price (5-10$ 1 T per load);

a

https://orcid.org/0009-0009-8710-3769

b

https://orcid.org/0000-0001-6552-2510

c

https://orcid.org/0000-0003-0835-1879

d

https://orcid.org/0000-0003-3739-8430

− complex mechanization in loading, laying,

unloading, storage, inability when using a

simple bag;

− achieve a high utilization rate when applying

soft containers to the storage area, especially

when laying up.

In recent years, there has been a sharp increase in the

transportation of soft containers and the storage of

cargo (Melikhova and Tekuteva, 2012), (Umarov and

Salimov, year?).

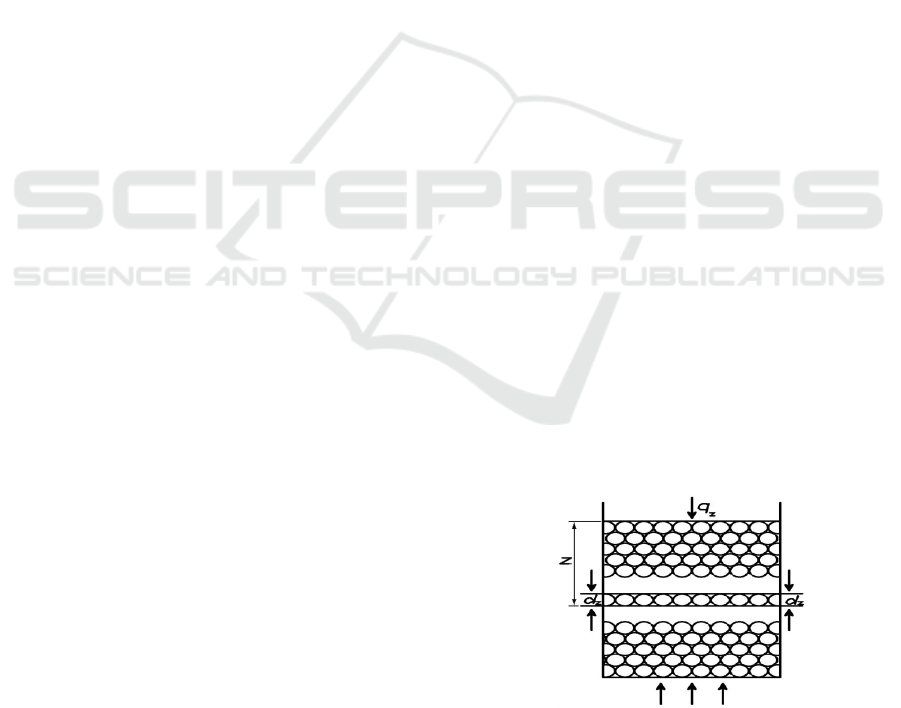

Figure 1: First made and modern soft containers. The

Taykon softok contaner s on the left. In the mddle

95x95x130 four stanzas, sngle layer, bottom drop knot.

212

Juraeva, G., Maxmudova, N., Djabborova, M. and Abdikayimova, G.

To Question Use Caddy for Transportation Vegetables.

DOI: 10.5220/0014244000004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 212-215

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

Experimental-industrial soft containers designed

to transport liquid foods such as sunflower oil are

being produced. Then soft containers, hermetically

sewn from dense material, are provided with fasteners

that are placed on the platform (1000x1200 mm) and

installed at the corners (Levachev, 1984).

The filling of the soft container is carried out

through a special valve using a pump. The platforms

can be increased to closed railway cars, large-ton

cutters. Such a wide and effective application of soft

containers today is a significant competition for

traditional containers.

Soft containers were first manufactured in 1919 by

the Japanese firm" Taiyo Kogro Co". The farm is

designed to carry a scattered load on the railway, with

a small lift at the head of a soft container named

"Taykon". It was then that the United States and

Western European countries began to apply the cargo.

For the first namanu, natural fibers were used – cotton

palatnos, brizent and hakozo.

They did not have a high level of resistance , and

they quickly rotted and did not have a long service life,

so the external support system, on which supports

were installed inside or outside, was made of standing

upright angular carcass.

In the middle of the 20th century, the development

of the chemical industry of the 1950s and 1970s,

synthetic polyamide and paliefir fibers were applied

when working the edges of the load canter. Polyamide

fibers (nylon, Capron, perlon and hakazo) are very

resistant to chemicals, able to withstand water and

forces. Its disadvantage is wear and tear under the

influence of light, and the coefficient of stretching is

relatively high.

Polyfoil fabrics (teripen, tetran, diopen) are crispy,

resistant to sunlight and atmospheric influences, but

have the property of static electricity collection.

Fabrics from artificial fiber (viscase, artificial silk)

have also been used in cargo container Assembly,

which are robust and transmit initial 60% resistance

due to moisture exposure in their durability and

subsequent hydrolysis.

The shipping container (Big-beglar)is made of

quality, foliar before the shipping elements and now

the hook.

In the CIS countries, cargo containers with the

following description are used:

− SPK-1.5 m mainly designed for polystyrene

Transportation, two-layer, 4-hook hole

pogruzchik, loading and unloading;

− KS-superphosphate, designed for granular

polyethylene, made of poddon, rubber-added

fabric, similar in size to the current Belting

material 1.3 m3, length 910 mm, width 700 mm,

height 180 mm, climbing capacity 1.5 t;

− MK P, j-L. For different load, from rubber-

mixed fabrics visnoxa, Capron, kouchik (brands

Skms, nk, Ski and SKD), lifting holes with a

tape on MKR, J-ada ironwork.

In the above types, the weight went up to 95 kg

due to the addition of rubber as a fabric, and

sometimes it was not planked.

Currently, patents for more than 2000 inventions

have been obtained on soft containers. Despite the

large number of patents, their main elements remained

the same; loading and unloading nodes, load elements,

hanging pendants, pocket for documents.

The soft container is processed from different

fabrics according to the load mass and purpose for the

upper layer material, making 1-2 layers after the load

is filled some soft containers have a cylinder,

sometimes a parallelepiped form. Big beglar (soft

containers, Big beg–big bag) is a widely used

universal.

The most commonly used sizes of soft containers:

• two stanzas, one stanza, two stanzas, two

stanzas;

• 75x75x125 double stanza, single layer;

• 75x75x125 double stanza, double layer;

• 75x75x150 double stanza, single layer;

• 95x95x130 four stanzas, single layer;

• 95x95x150 four stanzas, single layer;

• 95x95x180 four stanzas, one layered.

3 RESULTS AND DISCUSSION

The issues of establishing the production of big-begs

in the conditions of Uzbekistan, conducting research,

calculating pressure on bags, finding fabrics that can

raise this pressure and sewing soft containers should

be considered.

We consider the structure of the container to

determine the size of the pressure on the wall of soft

containers (Figure 2).

Figure 2: Drawing to calculate the magnitude of the product

impact forces on the walls of soft containers in the q

x

layer

at a depth of Z.

To Question Use Caddy for Transportation Vegetables

213

From the upper surface we separate the

elementary layer of d

z

at the depth of Z, and if the

product has

γ

mass, the force directed from the top

in the layer is q

z

and from the bottom is q

z

+dq

z

force,

and the forces of friction by the wall are affected. The

force falling from the top to the load is negative.

The equation of forces is expressed as:

γ

z

Sd

z

+Sq

z

– Sq

z

–Sd

z

–fEq

z

S=0

Thus, if we consider the horizontal layer for the

product (potatoes, apples, pears, carrots, etc.) that is

being put to maintain the equilibrium conditions and

calculate the forces of action, it is possible to find a

pressure of q

z

at a depth of Z. As an example, the

pressure acting on the container wall is q

z

, and the

pressure on the product is calculated relative to the

potato and the carrot product. On an industrial scale,

soft containers of 500-1000 kg are used. The density

of potatoes is 650 kg/m

3

, the density of carrots is 550

kg/m

3

. We bring a calculation methodology for a

simple bag. At a depth of container radius r = 0.25 m

Z, the friction angle of the product is 25

0

.

S=

Rπ

2

counting

S=0,196m

2

U=2

Rπ

U=1,57

m assuming that

The coefficient of internal friction of the product

is equal to the tangent of internal friction:

f=tg

25tg=α

0

=0,4663

Side pressure coefficient E=

α+

α−

sin1

sin1

, sin

25sin=α

0

= 0,4226

While Е=0,4 (2) and (3) from formulas q

z

and q

x

we find the q

x

Table 1: Table for calculating the pressure of potatoes on

the bottom and wall of the container.

Characteristic

Z, m q

z, Pа

q

x, Pа

Size field

positioning

depth, m

0,1 4600 1840

0,2 8490 3390

0,3 12020 4810

0,4 15560 6220

0,5 18740 7500

0,6 20160 8060

0,7 22280 8890

0,8 24050 9620

0,9 25460 10180

1,0 26880 10750

We take the size of the container as 95x95x1300

CM, and in the next table we will calculate the effect

of potatoes on the wall.

Table 2: Calculation of the effect of potatoes on the wall.

Characteristic

Score

Z, m depth

1,3

Container eni a, m

0,95

Container length b, m

0,95

q

x МPа

0,85

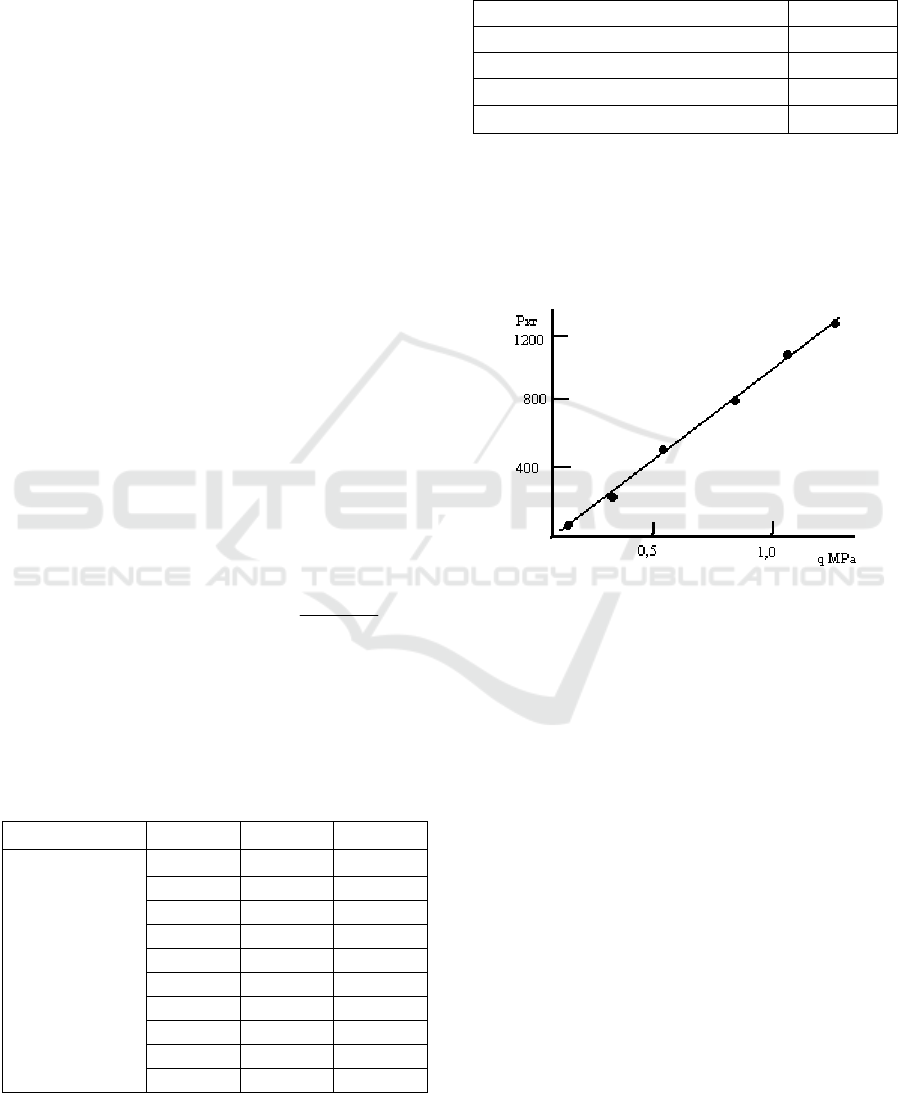

The result of the research and their discussion.

The following outline graph illustrates the

dependence of pressure on the walls and bottom of a

soft container with a small volume and a large volume

and the weight of the product inside the container

(Figure 3).

Figure 3: Pressure on the walls of the soft container and the

weighted attachment of the product.

4 CONCLUSIONS

As can be seen from the graph, the Wall pressure on a

large container did not exceed 1.5 MP. Soft containers

have been produced from PP in recent years. Ppni has

the property to withstand pressure up to 40 MPa

(Proizvodstvo, 2024). Such highly resistant PP fabrics

are used to produce very large containers with a load

of 3-4 tons (Proizvodstvo, 2024). So, it is possible to

produce small soft containers for agricultural

products from thin PP fabric and thicker fabric for

large bags, and fulfil orders according to the technical

indicators of PP fabric.

REFERENCES

http://agrobiznes.ru/agro/agroprod_0004010

http://agrosetka.ya.ru/ - this page is not found !!!

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

214

http://www.center-pack.ru/articles/polipropilen-i-oblast-

ego-primeneniq - not found !!!!

Levachev N.A., 1984. Mechanization of loading and

unloading, transport and storage operations in the food

industry. – M.: Light and Food Industry.

Melikhova L.V., Tekuteva L.A., 2012. Raspredelenie

davleniya v myagkix container dlya xraneniya

plodoovotshnoy produktsii. Khranenie I pererabotka

selkhozsirya, № 10: 54-55.

Proizvodstvo P ?????????????????

Umarov V.F., Salimov G.I., 2013. TASHSTU The use of

optimal containers for transportation and storage of

agricultural products. St. Petersburg, International

Conference. Institute of Cold, 352-353.

To Question Use Caddy for Transportation Vegetables

215