Substantiation of Basic Parameters of Gear Teeth of Open Gears on

Wear Resistance

Ishmuratov Hikmat

a

and Mamasalieva Mukaddas

b

Tashkent State Technical University, 100095, University str. 2, Tashkent, Uzbekistan

Keywords: Gear Teeth, Wear Resistance, Open Gear Transmission.

Abstract: In the article the method of calculation of speed of wear of open gear transmission by protrusions of roughness

which are on surfaces of friction of teeth having rounded forms, in the presence of slipping between teeth of

gears and pure rolling occurring in a zone of contact of initial circles of meshing gears without participation

of abrasive particles, taking into account bending stress arising at transmission of circumferential force is

resulted. As a result of the formation on the friction surfaces of the teeth of the teeth of the open gear

transmission of the equilibrium roughness is accompanied by an increase in the actual contact area of the teeth.

Therefore, the friction surfaces of gear teeth can operate without seizure at higher loads. Roughness of gear

teeth surfaces, formed as a result of mechanical processing, under friction under the influence of

circumferential force in meshing accompanied by rolling and slipping are subjected to plastic deformation.

1 INTRODUCTION

For open gears the most characteristic type of loading

leading to tooth breakage is the bending stress arising

from the circumferential force in the meshing. The

radial component of the circumferential force

deforming the roughness of the friction surfaces of

gear teeth leads to the formation of equilibrium

(operational) roughness, differing from the original

(technological) form (Myshkin et al., 2007; Dubovik,

2015; Ishmuratov, 2019; Mamasalieva, 2024).

Profilograms obtained from the friction surfaces of

gear teeth after the formation of equilibrium

roughness show that their protrusions and hollows of

irregularities have relatively close dimensions in

height and has a sufficiently large radius of

volumetric curvature than at the technological

roughness (Mamasalieva, 2024). As a result of the

formation of equilibrium roughness on the friction

surfaces of the teeth of the open gear transmission, the

actual contact area of the teeth is increased.

Therefore, the friction surfaces of gear teeth can

operate without seizure at higher loads. According to

the theory of fatigue wear, wear products from the

friction surfaces of gear teeth are separated after a

small number of repeated deformation protrusions of

a

https://orcid.org/0009-0008-2266-0372

b

https://orcid.org/0000-0002-9175-905X

roughness having a rounded shape. As a result, the

process of wear of gear teeth occurs in the presence

between the teeth of rolling with slippage, occurring

on the head and foot of the teeth, and wear of teeth in

the pure rolling occurring in the contact zone of the

initial circles. For these types of contact of gear teeth

the rate of wear is determined.

2 MATERIALS AND METHODS

Taking into account the research results given in

(Gorlenko et al., 2014; Ishmuratov, 2019) and in

order to simplify the calculation of wear rate, the

protrusions of roughnesses of tooth friction surfaces,

participating in the process of wear are modeled in the

form of spheres (Fig. 1) with the volume radius equal

to (r).

At contact, in the process of wear of gear teeth,

roughness protrusions are embedded to the rubbing

surfaces, and under the influence of the radial

component of the circumferential force transmitted

by the gear mesh, these roughnesses can be partially

deformed. When slippage occurs between the gear

teeth, the embedded roughness protrusions plow a

Hikmat, I. and Mukaddas, M.

Substantiation of Basic Parameters of Gear Teeth of Open Gears on Wear Resistance.

DOI: 10.5220/0014242500004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 191-196

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

191

deepened path on the friction surfaces of the teeth

(Myshkin et al., 2007).

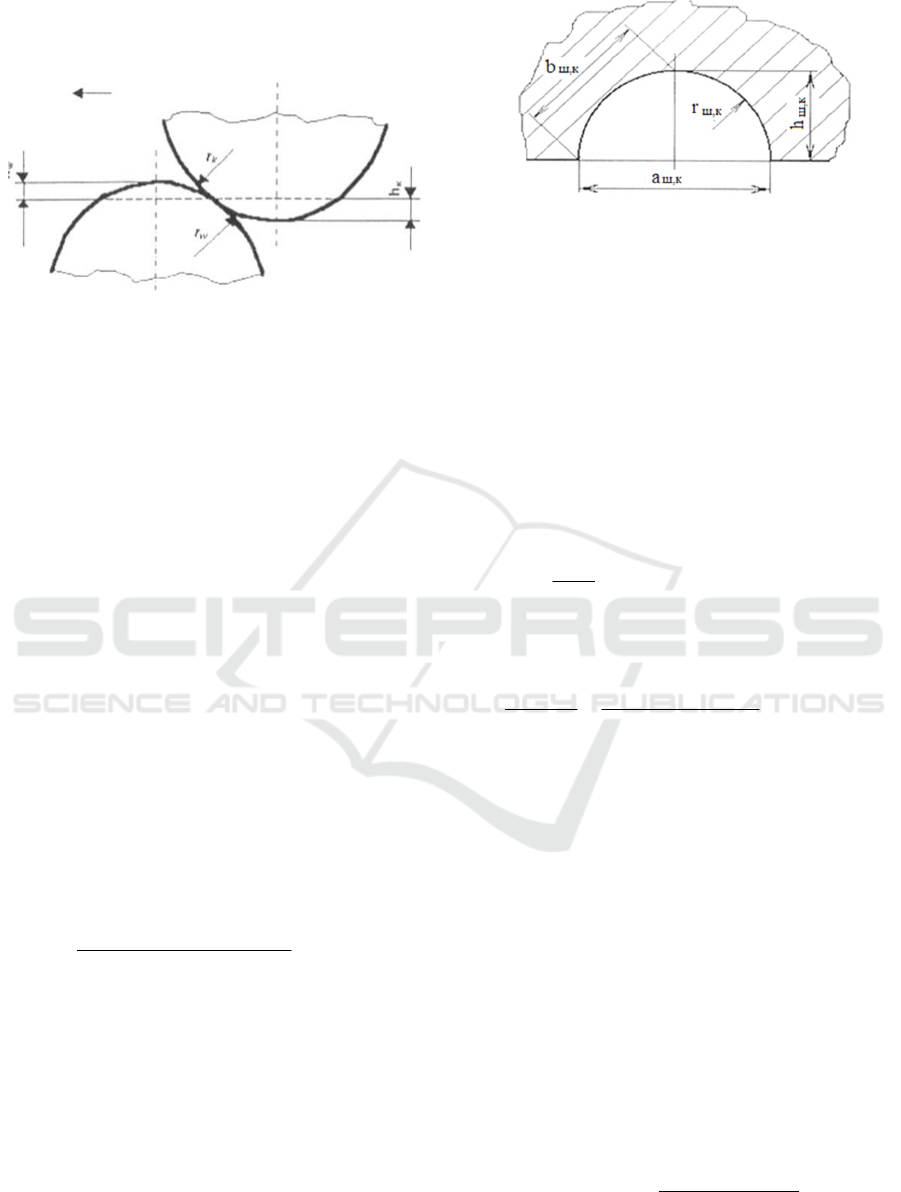

Figure 1: Schematic of contact of roughness protrusions

during friction.

In the process of force interaction of meshing gear

teeth, the volume of deformed material depends on

the depth of embedding, the radius of volume

curvature of roughness protrusions, the path of

relative slippage of teeth, the number of roughness

protrusions located along the length of the width of

the contact area and which participate in the process

of deformation of friction surfaces (Myshkin et al.,

2007).

3 RESULTS AND DISCUSSION

Wear resistance, in the presence of slippage between

gear teeth. According to the results of the study

obtained in the works (Myshkin et al., 2007),

(Ishmuratov, 2019), (Gorlenko et al., 2014),

(Ishmuratov et al., 2023), (Irgashev, 2005), between

the diameter of the contact spot introduced to the

friction surfaces of the teeth roughness protrusions

and the circumferential force (P) acting on these

protrusions, at the contact of friction surfaces of gear

teeth there is a relationship:

4

,

2

, кшобкш

HМca

P

⋅⋅⋅⋅

=

π

, Н (1)

where aш,к - diameter of the contact spot of the

introduced roughness protrusion to the friction

surfaces of teeth, m; c - coefficient depending on the

shape of protrusions and on the hardening of the

material (Ishmuratov 2019); Mоб - the total number

of roughness protrusions located on the working area

of contact of teeth; - hardness of the material of the

driving (driven) gear, MPa.

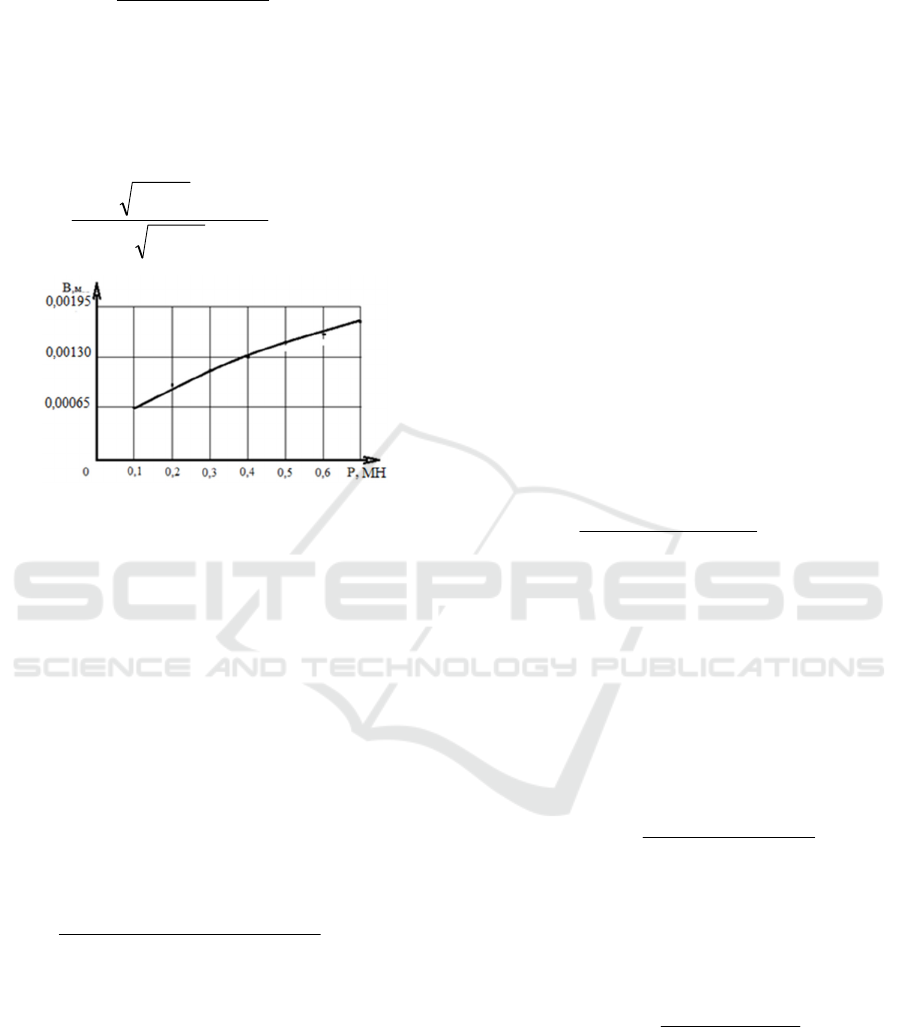

Figure 2: Scheme for determination of geometrical

parameters of roughness protrusion introduction into the

friction surface of gear teeth.

To calculate the tooth wear rate, it was

conventionally assumed that the dimensions of the

roughness protrusions in terms of height and

volumetric radius of curvature are the same. Which

are located sequentially along the length and height

of the tooth. During friction, the roughness

protrusions are partially embedded in the friction

surfaces of the contacted tooth surfaces. According to

the accepted conditions of arrangement of protrusions

of roughness of friction surfaces, their number of

located along the length of gear teeth L, is equal to:

кш

a

L

М

,

=

.

Then the load carried by a single roughness

protrusion:

4

,

2

,, кшкшкш

Hca

L

aP ⋅⋅⋅

=

⋅

π

,

We assume that the circumferential force

transmitted by the open gear working in dry friction

are perceived by the protrusions of irregularities

located on the contact surface of the teeth, their

strength depends on the bending stress arising at the

foot of the teeth, then the circumferential force

perceived by all protrusions of irregularities located

on the contact area of the teeth is equal:

кш

кш

из

аМmkР

,

,

2 ⋅⋅⋅⋅⋅=

σ

(2)

where is the maximum bending stress occurring

on the plane of the circle of the troughs located on the

tooth leg of the driving (driven) gear, MPa; is the

coefficient of tooth height relative to the dividing

circle of the gears; m is the meshing module, m.

For approximate calculations, equating

expressions (1) and (2) and solving them with respect

to the hardness of the material is obtained:

ca

mk

H

кш

кизш

кш

⋅⋅

⋅⋅⋅

=

,

,

,

8

π

σ

.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

192

From the obtained expression it is possible to

obtain the ratio of material hardness and bending

stress in the gear mesh, the optimal value of which is

approximated as Hш,к = 1.88.σ из ш,к..

Due to the fact that the contact patches of the

embedded roughness protrusion has an approximate

circular shape then the contact patches of the friction

surface of the teeth of the driving (driven) gears, is

calculated by the expression (Irgashev, 2005),

кш

кизш

кш

кш

Hc

km

HcL

P

a

,

,

,

,

54,2

27,1

⋅

⋅⋅⋅

=

⋅⋅

⋅

=

σ

, м. (3)

According to the scheme presented in Fig. 2 the

depth of introduction of roughness protrusions to the

friction surfaces at the contact of gear teeth is

determined and the dependence is obtained,

кшкш

шк

кш

Hc

a

h

,,

,

0019,0

θ

⋅

⋅

=

, м (4)

There is a relationship between the volume radius

of curvature rш,к and the depth of introduction of the

roughness protrusion of the gear teeth hш,к

(Ishmuratov and Irgashev, 2020):

кшкш

кш

Hc

h

r

,,

,

3

θ

⋅⋅

=

, м (5)

The length of the chord of the segment (bш,к ),

formed as a result of embedding a rounded roughness

protrusion, is determined according to the scheme

shown in Fig. 2, in which the calculated values of the

contact spot diameter aш,к , embedding depth hш,к

and volume radius of curvature (rш,к ) of roughness

protrusions are taken into account,

5,0

,,

,

,,,

)(

816,0

2

кшкш

кш

кшкшkw

Нс

h

rhb

θ

⋅⋅

⋅

=⋅⋅=

, м. (6)

We calculate the cross-sectional area of the

deformed metal volume as a result of the introduction

of a single roughness protrusion located on the

friction surface of the teeth of the driving (driven)

gear (Ishmuradov et al., 2024):

(

)

кш

изкшкшкшшк

кш

Hс

mhkbah

F

,

,,,

,

448,2

15

86

⋅

⋅⋅⋅⋅

=

+⋅

=

σ

, m

2

. (7)

The number of roughnesses located on the tooth

length of the driving (driven) gear (Irgashev, 2005)

taking into account the expression (3), we obtain:

из

кш

mk

HcL

М

σ

⋅⋅

⋅⋅⋅

=

,

39,0

(8)

Considering the value of the cross-sectional area

of the deformed volume of metal la as a result of

introduction of one roughness protrusion from (7),

paths of relative slip of roughness protrusions located

on the surface of contacted teeth (Ishmuradov et al.,

2024) and the number of roughnesses located on the

tooth length of gears M calculated by the expression

(8) after some simplification we obtain the expression

for calculation of the volume of deformation of the

material of the driving (driven) gear, by all

protrusions of roughnesses located on the contact

surface, in the presence of slip between the teeth of

gears is equal to:

ψ

⋅+⋅⋅⋅⋅== )1(

3

,

,

,,,,

imLh

z

МsFv

кш

кш

кшкшкшкш

, m

3

(9)

Here, the slip coefficient of the contacted gear

teeth is denoted by , which is defined through the

reduced number of teeth,

ααψ

sin44sin

222

пршпр

zkkz −±+=

,

where is the reduced number of gear teeth, ; here

zш , zк are the numbers of teeth of the driving and

driven gears, respectively.

In the expression, the plus sign in front of is

placed when the tooth head slip is calculated, the

minus sign is used to calculate the tooth foot slip.

In the process of friction roughness protrusions of

teeth of one gear for each cycle of loading contact

with different protrusions of roughness of another

gear. And the roughness of the teeth of these gears

differ from each other in density of arrangement on

the tooth surface and in size. In addition, during

contact, the roughness protrusions themselves may

partially deform and change their original shape. The

same roughness protrusion and deformed counter

body surface can meet each other after a certain

number of loading cycles of gears, which is taken as

the probability of re-deformation, to calculate the

value, its obtained dependence (Ishmuradov et al.,

2024):

кшкш

из

кшкш

из

кш

kw

НcLz

mk

НcLz

mk

Мz

,,,,,

,

56,2

39,0

1

⋅⋅⋅

⋅⋅⋅

=

⋅⋅⋅⋅

⋅⋅

=

⋅

=

σ

σ

η

(10)

Failure of deformed surfaces of gear teeth occurs

according to the fatigue theory of wear, after a certain

number of repeated loadings.

The number of loading cycles leading to the

destruction of the deformed tooth surface of the

driving (driven) gear is equal to:

()

t

кшкшp

n

,,

ψ

=

(11)

where is the coefficient of relative elongation of

the leading (driven) gear material; t is the coefficient

of frictional fatigue of the gear material, for gears

made of steel, t=1.3.

Then, in general, the wear rate of gear teeth of

open gears, in the presence of slippage between gear

teeth is determined by:

Substantiation of Basic Parameters of Gear Teeth of Open Gears on Wear Resistance

193

()

()

кшp

кшкшкш

кшд

nF

nv

,

,,,

,

⋅

⋅⋅

=

η

γ

, m/h (12)

where nш,к is the speed of rotation of the driving

(driven) gear; F is the area of contact of meshing pairs

of gear teeth F=BL.

Widths of contact of gear teeth of the zone of

initial circles is calculated by the expression

(Ishmuradov et al., 2024):

пр

пр

EL

P

B

⋅

−⋅⋅⋅

=

)1(04,3

2

μρ

, м, (13)

Figure 3: Variation of tooth contact width from

circumferential force in a gear mesh.

where μ is the Poisson's ratio; is the reduced

radius of curvature of the rolling zone gear teeth.

The graph of change in the contact width of the

teeth, depending on the circumferential force

presented in Fig. 3 is obtained by expression (12) with

the following initial data: =9,78; =0,03; Eпр =

215000 MPa shows that increasing the contact width

of the gear teeth leads to an increase in the

circumferential force transmitted by the gear.

Substituting the values from expression (9) , η

,wk from (10) and (11) into (12) taking into account,

and after some simplification, we obtain an

expression for calculating the wear rate of the driving

(driven) gear, in the presence of slippage between the

teeth,

()

кшкршкшпрпр

изкшкш

kwд

НnсzLЕ

Рknimh

,,

2

,

25,0

5,0

,,

,

)1(

)1(8,910

⋅⋅⋅⋅−⋅⋅⋅

⋅⋅⋅⋅⋅+⋅⋅⋅

=

μρ

σψ

γ

,m/h (14)

In Table 1 as an example of the results of

calculation of the amount of wear of the teeth of the

pinion gears of the driving gear depending on the

meshing module in the presence of slippage between

the teeth of the gears ψ = 1.035, the coefficient of

tooth height from the initial circumference of the

driving gear k = 1; the speed of rotation of the driving

gear nш = 2.92 r / s; maximum bending stress at the

foot of the teeth σиз = 153.7 MPa; reduced modulus

of elasticity Eпр =215000MPa; gear ratio i=0,125

(gear accelerating); number of teeth of the driving

pinion zш =88; deformation factor c = 3; hardness of

the material of the driving pinion Hш =282 MPa; the

number of deformation cycles leading to the

destruction of the deformed surface of the driving

pinion at =6% is nрш = 10,273. The results of

calculating the resource of the driving pinion are

shown in the table. For calculation it is accepted that

according to the recommendations proposed in the

"Encyclopedia of Mechanical Engineering XXL"

limit wear of gear teeth is 20% of the tooth thickness.

Wear resistance of gear teeth, when rolling. In the

rolling zone of gear teeth, the process of wear as noted

above occurs as a result of deformation of localized

volumes of metal friction surfaces. When between the

friction surfaces of gear teeth are absent slippage

from the introduction of protrusions of roughness in

their contact zone formed crater-shaped wells, with

wear products are formed after a certain number of

repeated deformation of the friction surface of gear

teeth protrusions of roughness rounded shape. In this

case, the rate of wear of gear teeth in the contact zone

of the initial circles, when rolling in general form is

determined by the expression:

),(

,),(1

),(

kwpnk

kwоkwн

kwд

nF

nMv

⋅

⋅⋅⋅

=

η

γ

δ

,m/hour (15)

where Mоб is the total number of roughness

protrusions located on the contact area of gear teeth.

To calculate the deformed volume of metal of

contact surfaces of gear teeth with one roughness

protrusion of spherical shape, taking into account the

diameter of the contact spot aw,к and hardness of the

gear material H ,w,к when the roughness protrusion

of the tooth surface has a rounded shape, when rolling

the zone of the initial circles of the contacted gear

teeth, the dependence [7] is obtained:

шк

изгкш

wkH

Hс

mk

v

⋅⋅

⋅⋅⋅

⋅=

9

75,5

3332

,

)(1

σθ

, m

3

(16)

In the contact zone of the initial circles of the

meshing gears - the value of the gear tooth height

coefficient in the zone of the initial circle k can be

represented by the ratio of the tooth contact width to

the meshing modulus,

шк

изгкш

wkH

Hс

В

v

⋅

⋅⋅

⋅=

332

,

)(1

639,0

σθ

,

then expression (16) has the form,

The contact areas of the friction surfaces of the

rolling zone of the gear teeth are equal:

BLF

n к

⋅=

, m

2

(17)

The amount of deformation of friction surfaces

depends on the number of roughness protrusions . To

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

194

calculate the number of roughness protrusions located

along the contact width of gear teeth, the dependence

is obtained:

из

кшшк

b

ВE

Hc

М

σ

μρ

⋅⋅

⋅⋅−⋅⋅

=

,

2

)1(69,1

(18)

The number of consecutive roughnesses located

on the tooth length of the driving (driven) gear is

determined by expression (8).

Table 1: Basic parameters of calculation on wear resistance of teeth of the driving pinion of open gear

transmission.

Hitching modulus

m, m

Shes-tern tooth length

L, m

The width of the con-

tine tact B, m

Tooth contact area F

к

, m

2

Hitching modulus

m, m

Tooth base area F

о

, m

2

Bending stress, at the tooth

foot

σ

,

MPa

Hitching modulus

m, m

Depth of penetration of the

roughness protrusion

h

Radius of curvature of the

p

inion contact point

Drive gear tooth wear rate

ш

γ

m/hour

Permissible wear of gear tooth,

m

Resource

leading

gears,

hour

1 2 3 4 5 6 7 8 9 10 11 12 13

0,001 0,025 0,0001

2

0,0000069

6

0,014 0,0000910

6

153,

7

0,001 0,0001

4

0,0016

7

0,000000066

2

0,00031

4

4743

0,002 0.029 0,0002

4

0,0000139

2

0,028 0,0001821

2

153,

7

0,002 0,0002

8

0,0033

4

0,000000162

2

0,00062

8

3872

0,004 0,037 0,0004

8

0,0000278

4

0,056 0,0003642

4

153,

7

0,004 0,0005

6

0,0066

8

0,000000359

6

0,00125

6

3492

0,006 0,045 0,0007

2

0,0000417

6

0,084 0,0005463

6

153,

7

0,006 0,0008

4

0,0100

2

0,000000543

2

0,00188

4

3468

0,008 0,053 0,0009

6

0,0000556

8

0,112 0,0007284

8

153,

7

0,008 0,0011

2

0,0133

6

0,000000710

0

0,00251

2

3538

0,010 0,061 0,0012

0

0,0000696

0

0,140 0,0009106

0

153,

7

0,010 0,0014

0

0,0167

0

0,000000862

1

0,00314

0

3642

According to [8], in the contact zone of the initial

circles of the meshing gears, only rolling occurs,

without slippage of the teeth. For this case:

radius of curvature of the tooth profile of the drive

gear,

αρ

sin5,0 ⋅⋅⋅=

шш

zm

, м;

radius of curvature of the tooth profile of the

driven gear,

αρ

sin5,0 ⋅⋅⋅⋅= izm

шk

, м.

The total number of roughness protrusions located

on the tooth contact area, taking into account

expressions (8) and (18) is equal:

3

3

,

22

)(

)1(34,0

из

кшшк

bоб

BE

HcL

MММ

σ

θμρ

⋅⋅

⋅⋅⋅⋅−⋅⋅

=⋅=

(19)

The calculated value of the probability of repeated

deformation , by the roughness protrusion of the

same deformed surface is determined by the

dependence (10) [9]:

Substituting the values of η from (10), from (11),

v1н(w,k) from (12), Fnк from (16), Mоб(ш,к) , from

(19), into (14) finally obtains:

PLi

nB

t

кш

кшизкш

kwд

м/ч. ,

5950

2/1

,

2/1

,

2/52/52

,

),(

⋅⋅⋅

⋅⋅⋅⋅

=

ψ

σθ

γ

(20)

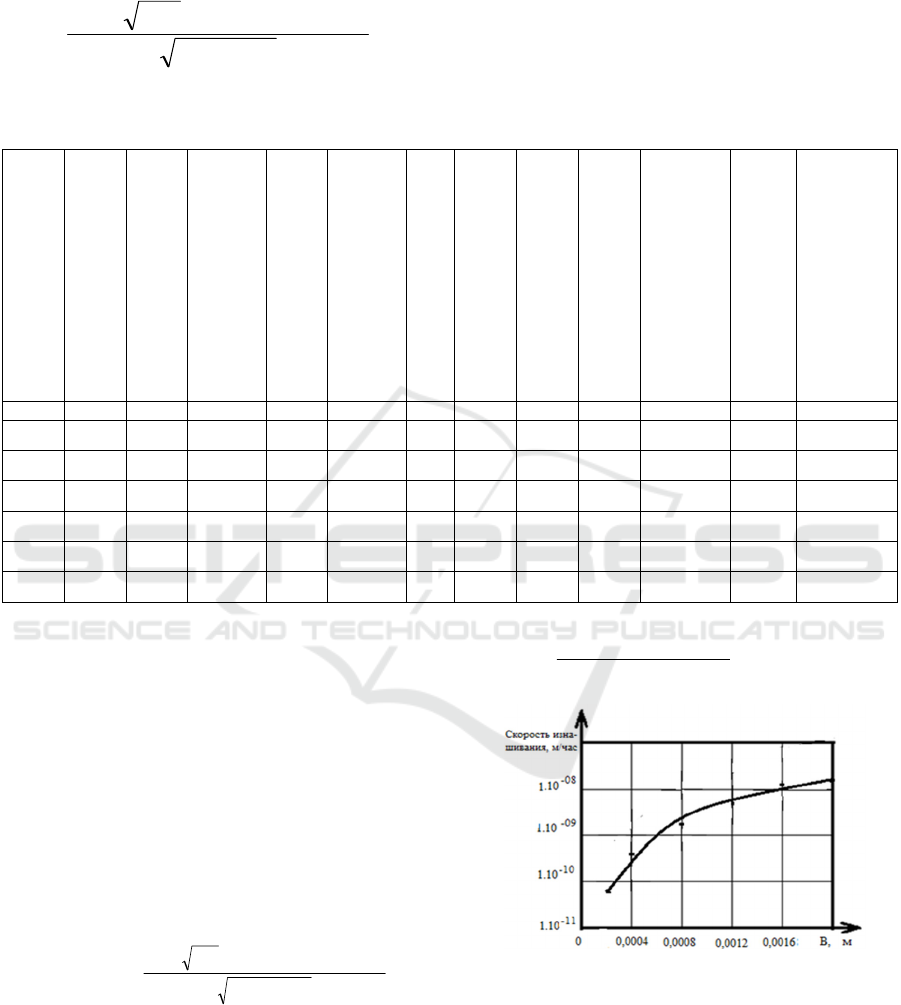

Figure 4: Variation of the wear rate of the driving gear tooth

depending on the contact width of the gear teeth.

The resulting expression show that the rate of

wear of gear teeth in the contact zone of the initial

circles of the initial circles of the meshing gears,

rolling zone depends on the tooth length, gear ratio

and frictional fatigue of the material, the width of

Substantiation of Basic Parameters of Gear Teeth of Open Gears on Wear Resistance

195

contact of gear teeth, bending stress arising at the

foot.

Dependence of the change in wear rate of the

rolling zone of the teeth of the driving gear presented

in Fig. 4 is obtained from expression 20 at the

following initial data: θ = 4,23*10-6 1/MPa; nш =

2,92 rpm/s; p = 0,14 MN; i = 0,125; L = m0,058; σиз

= 153,7 MPa; ψш = 6 %; i = 2.

4 CONCLUSIONS

The rate of wear of gear teeth in the presence of

slippage between the teeth of the gears increases with

increasing modulus of meshing, speed of rotation of

the driving (driven) pinion, decreases with increasing

number of teeth of the driving (driven) pinion and

friction fatigue of the material of the driving (driven)

pinion.

In the contact zone of the initial circles of the

leading and driven gears to increase the rate of wear

leads to an increase in the contact width of the teeth,

bending stress and the speed of rotation of the leading

(driven) gear, the speed of rotation of the leading

(driven) gear, to decrease, increase the gear ratio,

tooth length of the gears, friction fatigue and

circumferential force transmitted by the gear mesh.

With an increase in the width of contact up to

0.0008 m wear rate of teeth in the rolling zone of the

initial circles of the gears involved in the meshing

grows more intensively, further increase in the width

of contact of teeth up to 0.0020 m leads to an increase

in the rate of wear of teeth less intensively.

Established the relationship between the bending

stress arising at the foot of the tooth and the hardness

of the material gears, to increase the wear resistance

of gear teeth is most effective when the ratio of

hardness to bending stress arising at the foot of the

tooth is 1.88 times.

REFERENCES

Dubovik E. A. Features of wear of gear transmissions of

transmissions // Friction and lubrication in machines

and mechanisms. - 2015, № 3, 31-35 с. Mamasalieva

M. The influence of the tread pattern on the

performance of a tractor engine // E3S Web of

Conferences, 2024, 471, 01007

Myshkin N.K., Petrokovets M.I. Friction, lubrication, wear.

Physical bases and technical applications of tribology.

Moscow: Fizmatlit, 2007. 368 с.

Ishmuratov H. K. Theoretical substantiation of the resource

of gears of cotton harvesting machines by the criterion

of wear. - D. in technical sciences (PhD). - Tashkent,

2019, 156 p.

Gorlenko O. A. A., Makarov G. N., Shnyrikov I. O.

Increase of contact endurance of teeth of spur spur gears

// Friction and lubrication in machines and mechanisms.

- 2014, № 6, 25-27 с.

Ishmuratov H.K., Mirzaev N.N., Abdullaeva, B.,

Mamasalieva, M.I. // Energy analysis of wear sliding

friction units. E3S Web of Conferences, 2023, 383,

04019.

Ishmuradov Sh., Hamroev R. // Disc rotary plough for

agriculture mechanization. E3S Web of Conferences,

2024, 548, 08017

Irgashev A. Methodological bases of increase of wear

resistance of gears of heavy-loaded gears of machine

units. - Dissertation of Doctor of Technical Sciences. -

Tashkent, 2005, 244 p.

Ishmuratov H.K., Irgashev B.A. Assessment of wear

resistance of gear teeth of open gear transmission in

conditions of increased dust level. Journal of friction

and wear. Vol. 41, Issue 1, 2020, 85-90 p

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

196