Parametric Modeling in CAD Programs for Plow Design

Feruza Alimova

1a

, Bekzod Primqulov

2b

and Ergash Boboniyozov

1c

1

Tashkent State Technical University, Foundry Technologies Department, 100095 Tashkent, Uzbekistan

2

The Association of Building Materials Industry of Uzbekistan, R&D Center, 100059 Tashkent, Uzbekistan

Keywords: Parametric Modelling, Plow Design, CAD Programs.

Abstract: This article provides a brief analysis of research and development in agricultural engineering, including

parametric modeling. The main advantages of parametric modeling are indicated, promising methods for

designing plows in the conditions of Uzbekistan are analyzed. Parametric modeling of plows is considered

with the aim of optimizing their design to create more efficient, adaptable and productive plows. An analysis

of the role of automated design systems in the fast and high-quality production of a new product is given. The

factors influencing the increase in design efficiency and acceleration of product manufacturing time are

analyzed. The problem of designing plow bodies, which are the main working parts of the plow and have a

complex working surface, is considered. The main dependencies are presented that describe the radius and

the height of the center of the circle, the radius of the guide curve, as well as intermediate values of the angles

of the generatrixes with the wall of the furrow. Parameters such as the working width of the plow body, the

working depth, the angles of inclination of the forming furrows to the furrow wall, and the angle of installation

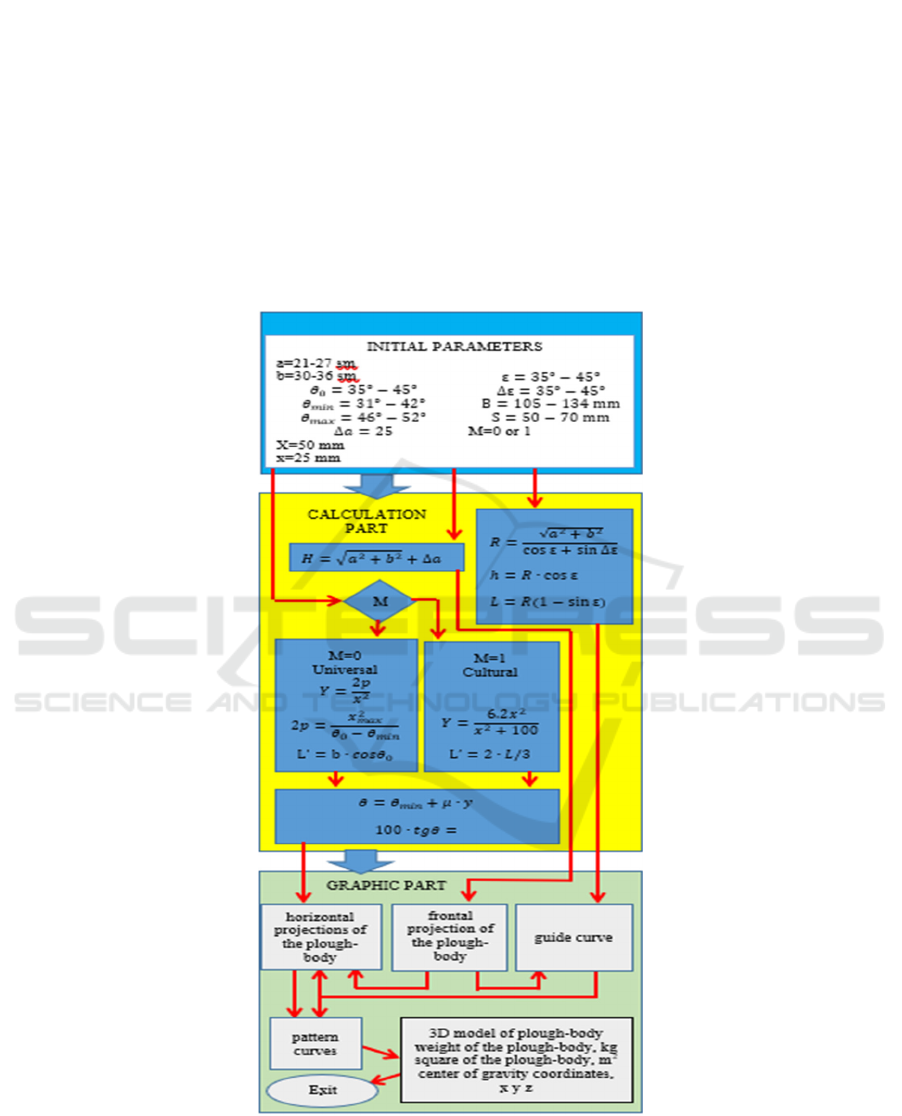

of the plowshare blade to the bottom of the furrow were analyzed. Using CAD software, a flowchart was

drawn up for the parametric modeling of the plow body. By changing the input parameters, it is possible to

construct a furrow profile, a frontal contour and a horizontal projection of the plowshare and blade, and a

graph of changes in the angles of the generatrixes with the wall of the furrow. A graphic image was obtained

- a 3D model of plow bodies of various designs, such as universal and cultural. It is possible to obtain

preliminary data on the mass of the plow body, the area of the working surface, and the coordinates of the

plow body center of gravity. It is shown that this method of construction and mathematical calculations are

easily amenable to automatic calculation and drawing in educational and research processes. In addition, the

presented modular system will significantly improve the production and adaptability of plows, providing the

ability to readjust them for specific working conditions.

1 INTRODUCTION

The most important solution to the problems of

creating and improving soil cultivation tools is to

substantiate the rational forms of their working

surfaces. In this direction, conducting targeted

research on creating forms of working surfaces of

tillage implements that carry out high-quality

implementation of the technological process in

accordance with agrotechnical requirements with

minimal energy costs is an urgent task and requires a

practical solution. According to the existing practice

of designing soil-cultivating implements, there is

usually no justification for the geometric parameters

a

https://orcid.org/0000-0003-1463-6969

b

https://orcid.org/0009-0002-0115-5816

c

https://orcid.org/0000-0003-4321-1783

of the surfaces of their working bodies. The working

surface is taken from the number of ready-made

analogue surfaces. Graphic-analytical methods for

designing surfaces require a lot of computational and

graphic work and do not make it possible to justify

surface parameters, both from the point of view of

meeting agrotechnical requirements and energy costs.

It is possible to improve the agrotechnical and energy

performance of the created working bodies through

the use of computer modeling methods and tools.

Modeling the surface of the working body of a tillage

implement will allow you to: describe the geometry

of the surface and its changes when varying

parameters; identify connections between the

Alimova, F., Primqulov, B. and Boboniyozov, E.

Parametric Modeling in CAD Programs for Plow Design.

DOI: 10.5220/0014241500004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 181-186

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

181

geometric parameters of the surface and the

agrotechnical and energy characteristics of the

working body; evaluate options for working surface

geometry at the design stage.

Let's consider parametric modeling, i.e. modeling

using the parameters of model elements and the

relationships between these parameters. This allows

you to examine various design schemes in a short

time by changing parameters or geometric

relationships and avoid fundamental errors (Maslov,

2019; Azimov et al., 2020). Parametric modeling

differs significantly from conventional 2D drawing or

3D modeling. In the case of parametric design, the

designer creates a mathematical model of objects with

parameters, when changing which changes the

configuration of the part, mutual movements of parts

in the assembly, etc.

There are 2D parametric modeling and 3D

parametric modeling. Parameterization of 2D

drawings is usually available in medium and heavy-

duty CAD systems. However, these systems rely on

three-dimensional design technology, and the

possibility of parameterizing two-dimensional

drawings is practically not used. 3D parametric

modeling is a much more effective (but also more

complex) tool than 2D parametric modeling. The

existence of a parametric description of an object is

the basis for the entire design process1 (Jagtap et al.,

2021).

Parametric modeling plays a very important role

in creating and automatically updating high-quality

models in product design. Using this method, the

production process can be analyzed and optimized.

Parametric modeling can be briefly explained in the

following areas:

1. Process modeling. Parametric modeling allows

you to accurately describe production processes.

Using parameters, you can model different stages of

the process and connect them with each other. For

example, you can analyze the process by parameters

such as hardness, temperature, time, pressure.

2. Optimization. With parametric modeling,

parameters can be changed to improve process

efficiency. This helps achieve goals such as

increasing production speed, reducing costs or

improving quality.

3. Simulation. Simulation can be used to simulate

how a process operates under different conditions.

This helps to identify problems that may arise in the

production process in advance and create a plan to

solve them.

4. Decision Making: Parametric modeling can be

used to predict the impact of decisions made during a

manufacturing process. This allows you to analyze

the results of decisions and choose the best option.

5. Process monitoring and analysis. Process

changes can be monitored and analyzed using

parametric modeling. This is useful for quickly

responding to changes and ensuring process stability.

Through parametric modeling, manufacturing

processes become more efficient and easier to

manage, which improves overall production quality

and efficiency. Parametric models provide ease of

automated changes, instant updates, and optimized

design. The main goal of this method is to simplify

the geometric shape of the product, conduct

comparative control of properties and optimize the

system (Blednykh and Khudyakov, 1989; Makarova,

2000).

Modern engineering production is characterized

by the complexity of product design and rapid change

of products, as well as short production times. In such

conditions, it is necessary to speed up production and

increase its efficiency, as well as ensure the

competitiveness of products (Hedau et al., 2023). The

design stage is a complex, labor-intensive stage in the

production of a new product. The main time and

material costs when introducing a new product into

production are spent on the design process. Therefore,

the role of automated design systems in the fast and

high-quality production of a new product when

automating the design process is invaluable (Juraev et

al., 2019).

2 MATERIALS AND METHODS

Parametric modeling in CAD programs is important

in the development of various new equipment designs

in agricultural engineering. The complex surface of

the working bodies when cultivating the soil

determines the quality of the work process (Alimova,

2023). For example, the process of designing the

working surface of a plow body is a complex and

time-consuming process.

For parametric modeling when designing the

plow body, the method of graphically constructing

working surfaces using one guide curve and a given

law of changing the angle of the generatrices with the

field side was used. This method was developed for

the design of cylindrical working surfaces of plough-

bodies (GOST 65-62). Graphic techniques are based

on the theory of working surfaces of plow bodies and

basic relationships established experimentally.

Analytical design of a working surface according to

given agrotechnical indicators is associated with great

difficulties, since they require studying the

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

182

relationship between the geometric parameters of the

surface and the quantitative characteristics of the

resulting treatment.

The general procedure for designing all

mouldboards is the same, only some values taken at

the beginning of the calculation differ. First, construct

a frontal projection of the plough-body contour and

projections of the generatrices on it, then horizontal

projections of the generatrices and plough-body

contour, projections of vertical sections of the

plough-body surface perpendicular to the direction of

movement when plowing, and vertical sections

perpendicular to the ploughshare blade. The initial

data for constructing the working surface of any type

of mouldboard are the plowing depth and the width of

the layer (Primkulov et al., 2022; Alimova et al.,

2024).

In addition, based on existing data developed by

practice, parameters characterizing the installation of

the ploughshare are specified, i.e. angle θ

0

of

installation of the ploughshare to the wall of the

furrow, angle ɣ of installation of the ploughshare to

the bottom of the furrow, as well as angles θ

min

and

θ

max

. We consider the given agrotechnical parameters

of the plow body design to be variable.

Figure 1: Block diagram of algorithm for parametric modeling of the plough-body.

Parametric Modeling in CAD Programs for Plow Design

183

3 RESULTS AND DISCUSSION

To create an automatic design program for the

plough-body, we can use the KOMPAS 3D program,

which is part of the CAD software.

Sequence of creating an automatic design

program

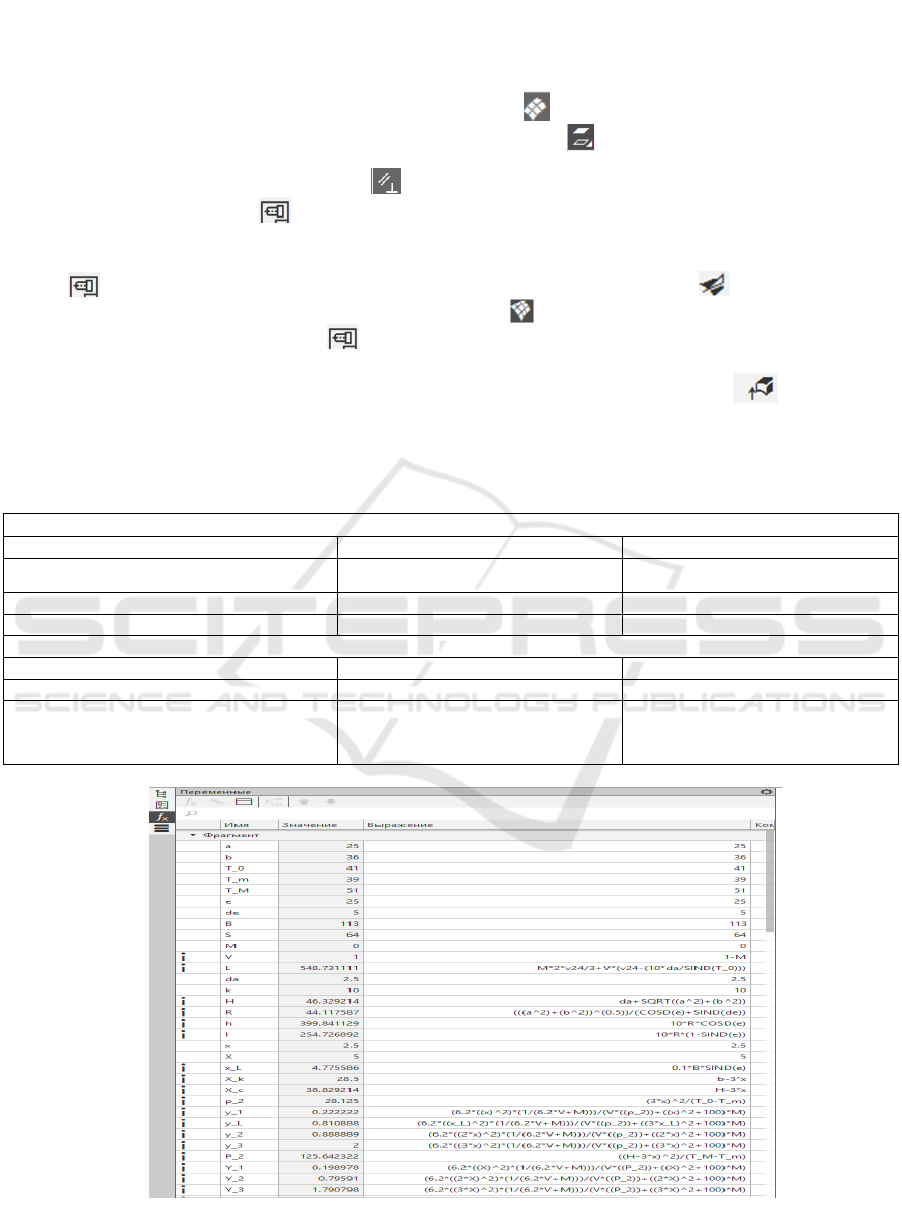

1. The parametric mode command is

launched in the drawing section of the KOMPAS

3D program;

2. Using the change command in the drawings

section of the KOMPAS 3D program, enter the

specified parameters and formulas used in the design

(Fig. 1). In the drawings section of the

KOMPAS;

3D program, the dimensions of each line used in

the design of the plough-body are entered into

functional connections using specified parameters or

directly specified parameters;

4. We create new working documentation through

the “Create” department for the design of the plough-

body in the KOMPAS 3D program;

5. To create the plough-body, use the commands

in the Frame and surfaces section;

6. This command creates parallel planes by

entering the distance between the planes;

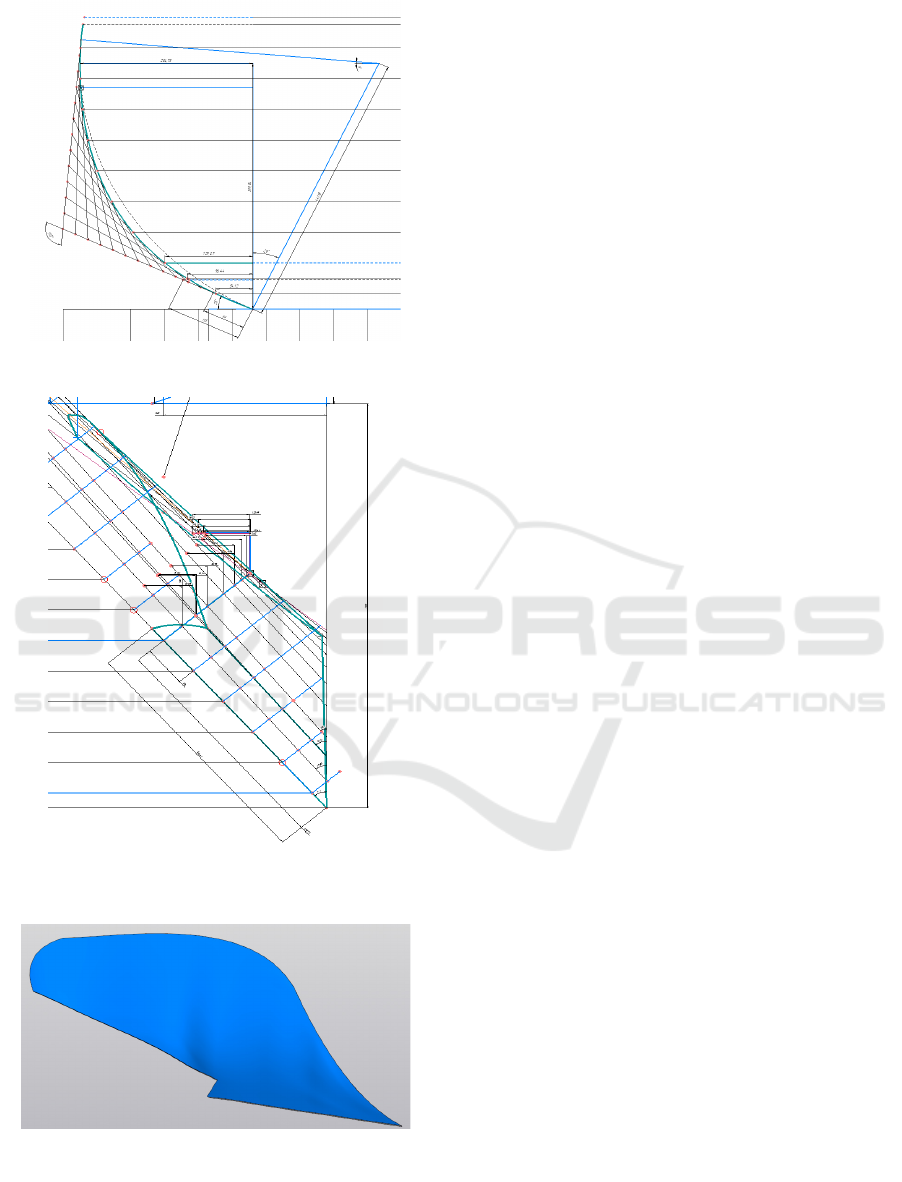

7. In the process of designing a plough-body

based on design rules, we use pattern curves, where

each pattern curves is placed on parallel planes;

8. At the next stage, we connect the curves of the

model using the commands “Surface truncation”

and “Surface along a network of curves” and

create the working surface of the plow body.

9. The thickness of the surface is added to the

resulting working surface using the Fiberboard

Add Thickness command and a 3D model of the plow

body is created.

Table 1: Table of entered and received results.

Initial parameters

Mouldboard t

yp

e Cultural Universal

Working width 0.36 metr 0.32 metr

Plowin

g

de

p

th 0.25 met

r

0.22 met

r

ϴ

0

37º 41º

Obtained parameters

Weight 10.067 kg 13.098 kg

S

q

uare 0.375 m

2

0.495 m2

Center of gravity coordinates x=127.564 mm

y=484.109 mm

z=99.684 mm

x=167.564 mm

y=514.109 mm

z=130.684 mm

Figure 2: Entering parameters using the variables command.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

184

Figure 3: Construct of guide curve.

Figure 4: Construct of horizontal projection of mould board

when M=0.

Figure 5: Model of the plough-body obtained as a result of

using a computer-aided design program.

4 CONCLUSIONS

By learning deeply about computer-aided design

systems, other types of functionally related design

processes can be easily automated.

Through an in-depth study of parametric modeling in

CAD programs, it is possible to automate complex

design processes with other types of functional

connections, determine metal consumption in

advance and select the appropriate type of production

for the project.

As parametric modeling becomes more important in

the latest CAD programs, this method remains an

important part of the design editor with advanced

features for design acceleration, automatic updates

and feature monitoring.References

REFERENCES

Alimova, F., Saidova, M., Boboniyozov, E., & Mirzayev,

B., 2024. Analysis of the state of mechanized sowing of

rice in seedlings. BIO Web of Conferences, I-CRAFT-

2023 85 https://doi.org/10.1051/bioconf/20248501032

Alimova, F.A., 2023. Mathematical modeling of small soil

channel laboratory stand drive and evaluation of its

energy state - ETESD-II-2023 IOP Conf. Series: Earth

and Environmental Science 1284, 012031 IOP DOI:

10.1088/1755-1315/1284/1/012031.

Azimov, B.M., Sulyukova, L.F., Akhmedov, Sh. A.,

Azimov, M.B., 2020. Article name. International

Journal of Mechanical and Production Engineering

Research and Development (IJMPERD), 10(3): 4953–

4962.

Blednykh V.V., Khudyakov S.A., 1989. Mathematical

model of the working surface of the plow body.

Technology in Agriculture, 2: pages?.

Hedau, J., Dixit, S., Dhurde, T., Gharatkar, N., Shende, R.,

2023. Design and Fabrication of Multipurpose

Agricultural Machine: View Certificate.

https://doi.org/10.22214/ijraset.2023.50922

Jagtap, G., Bhade, T., Gade, P., Gonsalves, W., Bharati,

G.K., 2021. Design and fabrication of rice

transplantation machine. International Journal of

Creative Research Thoughts (IJCRT), 9(5): d358-360.

Juraev, T.K., Murodov, N.M. & Naimov, S. T., 2019.

Application the Geometric Modeling Methods and

Systems in Design Engineering and Manufacturing on

Example of Agriculture Engineering. Design and

Manufacturing, DOI: 10.5772/intechopen.89974

Makarova, E.I., 2000. Modeling the surface of the working

body of a soil-cultivating and sowing implement. Topic

of the dissertation and abstract on the Higher

Attestation Commission of the Russian Federation

05.20.01, Candidate of Technical Sciences

Maslov, G.G., 2019. Optimization of parameters of a multi-

functional unit based on a spring harrow. International

Parametric Modeling in CAD Programs for Plow Design

185

Journal of Engineering and Advanced Technology,

9(1): 1915-1918

Primkulov B.Sh., Boboniyozov E.A., 2022. Guidelines for

practical exercises in “automated design”. -Tashkent:

ToshDTU, 32.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

186