Features of the Use of Ozone for Long-Term Storage of Agricultural

Products

Iroda Tadjibekova

a

and Dilnoza Pirmatova

b

Tashkent State Agrarian University, 100140, University str. 2, Tashkent, Uzbekistan

Keywords: Ozone Storage, Agricultural Product Preservation, Disinfection.

Abstract: Improving the efficiency of storage of agricultural products is one of the most important tasks of modern

science. There are many methods widely used today, but one of the most effective is the use of ozone. Ozone

is known to have strong oxidizing properties and is a strong oxidizing agent. Ozone is very toxic even in low

concentrations. It finds limited use in industrial synthesis (for example, in the production of succinic acid

from products and waste from rubber production) and in therapy (so-called ozone therapy). Several methods

are used to obtain ozone, each of which has its own advantages. But, before using ozone as an effective means

of storage, it is necessary to correctly determine the dose, timing and technology of ozone treatment

.

1 INTRODUCTION

To ensure sustainable development of agriculture, it

is necessary to intensively introduce modern

innovative methods and techniques for long-term

storage of agricultural products. The use of

innovative methods guarantees a significant

reduction in agricultural losses. The basis of

innovative activity in the agricultural sector is the

development and effective use of modern methods of

storing agricultural products. To apply modern

methods of storing agricultural products, it is

necessary to determine the causes of losses of fruits

and vegetables during storage.

Losses of agricultural products are a complex

phenomenon. Only with long-term storage of

agricultural products, losses of grown products reach

35-40%. The basis of innovative activity in the

agricultural sector is the development and effective

use of modern methods of storing agricultural

products. Agricultural products go through many

stages before reaching the consumer. At each stage,

losses appear that need to be reduced (Gabler et al.,

2010), (Servili et al., 2017), (Kangliang et al., 2018),

(Khaliknazarov et al., 2024), (Crupi et al., 2013).

a

https://orcid.org/0009-0005-8093-1968

b

https://orcid.org/0009-0005-5060-3031

2 MATERIALS AND METHODS

When storing products, the main causes of losses are

weight loss during the process of respiration,

evaporation and germination, with losses of water and

dry matter from 10 to 35% of the total weight loss.

Moreover, the loss of water is a value that is different

for each type of raw material. For example: for

apples, grapes, spinach, lettuce, broccoli, carrots in

bunches with leaves it is 3-4%, for pears, cherries,

peaches, strawberries, raspberries, currants, beets,

peas, cucumbers, beans 5-6%, for carrots, beets,

white cabbage, potatoes - 7-8%, etc.

If these indicators are exceeded, then the product

becomes unsuitable for sale.

No less losses occur due to diseases, which can

very quickly spread to a large mass of products. In the

case of diseases, there is also the factor that losses in

this case are very difficult to predict. We must not

forget about mechanical losses, since during long-

term storage the physical and mechanical

characteristics of the product change, that is, turgor is

lost and the density and hardness of the fruit changes.

Quite a large number of products become losses

from mechanical damage, especially at the final stage

of storage, when, as a result of ripening, the pulp of

fruits and vegetables softens and their strength

Tadjibekova, I. and Pirmatova, D.

Features of the Use of Ozone for Long-Term Storage of Agricultural Products.

DOI: 10.5220/0014224500004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 169-171

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

169

decreases. The deterioration of quality indicators is

due to both natural causes and the influence of

external factors. Therefore, for longer preservation of

agricultural products, it is necessary to create optimal

storage conditions (Turdiboyev et al., 2022),

(Djiyanov et al., 2024), (Djiyanov et al., 2024),

(Djiyanov et al., 2022), (Isakova et al., 2024).

3 RESULTS AND DISCUSSION

Currently, a fairly large number of methods are used.

One of them is the use of ozone (O3). It has long been

known that ozone has bactericidal properties. It is

known that in order for the shelf life of products to

increase by 1.5 - 2 times, the ozone concentration

value is sufficient to be 10 mg/m3 with a treatment

duration of 4 hours. But it should be noted that

different types of agricultural products have different

physical, mechanical and chemical properties. The

ozone treatment regimes for potatoes and grapes will

differ significantly from each other.

In Uzbekistan, for long-term storage, late-

ripening grape varieties are most often used:

Nimrang, Taifi pink, Oktyabrsky, Uzbek Muscat,

Taifi white. For long-term storage, grapes are treated

with sulfur dioxide or potassium metabilsulfite in

chambers cooled to -2°, the storage period in which is

4.5-7 months. The same grape varieties, not treated

with antiseptics at a temperature of about 0°, are

stored for 2.5-3 months.

Grapes are generally treated with sulfur dioxide

(SO2) to effectively control the development of

Botrytis cinerea and act as an antioxidant. But sulfur

dioxide can lead to poisoning and allergies to the

consumer, so additional treatment with ozone (O3) is

recommended. At the same time, the ozonation

process reduces the amount of fungicidal residues on

the surface of grape berries, which also affects the

safety of consumption. After treatment with

fungicides, the grapes were placed in long-term

storage and treated with 3 mg/m3 of ozone for 3 hours

3 times a week, which showed intensive destruction

of the amount of fungicides by 52%.

This fact suggests that the use of an ozonizer not

only prevents product spoilage but also ensures the

safety of product consumption. Compared to the

treatment with various chemicals, ozone is considered

less dangerous, since it does not accumulate or settle

on the surface of vegetables and fruits. The ozone

molecule is unstable and has the property of self-

disintegration. It is due to this property that ozone is

a strong oxidizing agent and an exceptionally

effective disinfectant. The instability of ozone

necessitates its production directly at the point of

consumption.

Experience shows that the shelf life of fruits and

vegetables can be doubled on average while

preserving the delicate aroma of the fruit. So, when

berries (strawberries, raspberries, grapes) are treated

with ozone at a dose of 3 - 8 mgOz/m3, their shelf life

increases by 2 times. After treating apples with ozone

at a dose of 4 - 6 mgOz/m3, their shelf life at a

temperature of +5°C increases to 5 months.

It must be remembered that unpurified and

undisinfected air in storage is a factor leading to

product spoilage. A very large number of different

microorganisms are constantly suspended in the air of

the storage facility: bacteria, fungal spores and mold.

These microorganisms, after processing the

container, storage and surface of the product, still

penetrate into the storage and affect the safety of the

product.

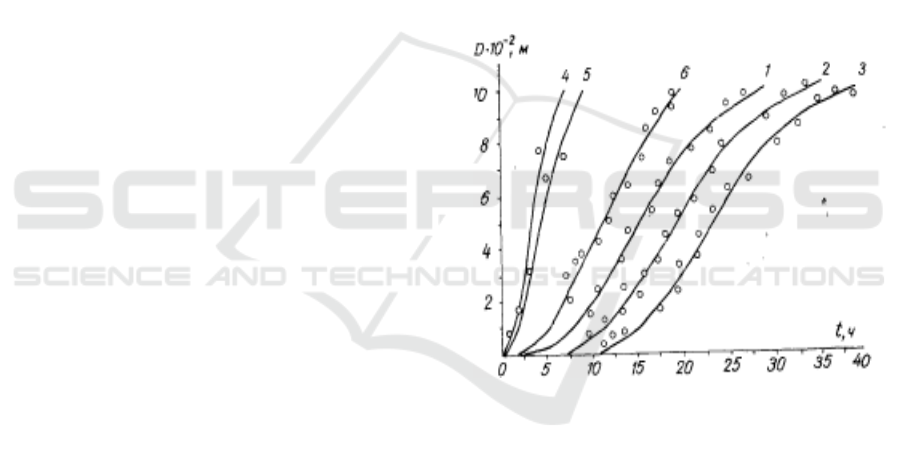

Figure 1: The dependence of the growth rate of the fungus

Fusarium solani on the duration of ozonation.

Figure 1 shows the dependence of the growth rate

of the fungus Fusarium solani on the duration of

ozonation. Therefore, the correctly selected

ozonation regime is important.

Since the object of the study was late-ripening

grape varieties: Nimrang, Taifi pink, Oktyabrsky,

Muscat Uzbekistan, Taifi white. For long-term

storage, grapes are treated with sulfur dioxide or

potassium metabilsulfite. But treatment with

chemicals can have a negative effect on the

consumer’s body. Ozone, in its properties of

destroying bacteria and viruses, is 2.5-6 times more

effective than ultraviolet rays and 300-6000 times

more effective than chlorine. Moreover, unlike

chlorine, ozone even destroys worm cysts. Suggested

ozone treatment regimes are presented in Table 1.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

170

Table 1: Suggested ozone treatment regimes.

Grape

variety

Ozone

concent

ration

mg/m3

Ozonation

duration

time

N

umber of

treatments

per week.

N

imrang

3-4 3 3

Octobe

r

3-6 3 4

Taifi

pink

3-6 3 4

Uzbek

Muscat

3-8 4 4

Tayfi

white

3-8 3 3

Husaini

5 3 2

The Table 1 presents the data obtained during

ozone treatment of products stored for long-term

storage in the refrigerator.

It should be noted that there is information in

the literature that the use of ozone in combination

with other technologies such as irradiation with

ultraviolet rays (UV) stimulates an increase in the

amount of antioxidants. Ozone fumigation and M.

albus biofumigation reduced gray mold incidence to

9.7 and 4.4%, respectively.

Ozone is a fairly strong oxidizing agent; its

oxidation potential is approximately 20% higher than

that of chlorine. Ozone effectively destroys aromatic

hydrocarbons in the air of vegetable stores and

refrigerators. Thus, the use of ozone provides an

additional effect of room deodorization. Ozone by its

nature is an unstable form of oxygen. O3 gas

disintegrates quite quickly and turns into safe oxygen.

In this way, ozone compares favorably with

traditionally used toxic substances used for

processing fruits and vegetables and vegetable stores.

4 CONCLUSIONS

To summarize, we can draw the following

conclusions about the feasibility of using ozone for

processing fruits and vegetables. Ozone has a strong

disinfectant effect. Ozone effectively decomposes

toxins formed on the surface of fruits and vegetables.

Ozone effectively destroys unpleasant specific odors

of rot. After treating stored fruits and vegetables with

ozone, no deterioration in their quality and consumer

properties was detected.

Periodic treatment of vegetable stores with small

doses of ozone repels various rodents and affects

insects. The technology of using ozone for processing

fruits and vegetables, refrigerators and vegetable

stores is quite simple but effective. And it should be

noted that the cost of processing fruit and vegetable

products using ozone is lower than the use of

chemical disinfectants, and the cost of electricity for

processing fruit and vegetable products stored in a

refrigeration chamber with a volume of 1000 m3 is 3

- 7 kWh per week.

REFERENCES

Gabler, F.M., Mercier, J., Jiménez, J.I., 2010. Smilanick,

J.L. Integration of continuous biofumigation with

Muscodor albus with pre-cooling fumigation with

ozone or sulfur dioxide to control postharvest gray

mold of table grapes. Postharvest Biology and

Technology, 55, pp. 78-84.

Servili, A., Feliziani, E., Romanazzi, G., 2017. Exposure to

volatiles of essential oils alone or under hypobaric

treatment to control postharvest gray mold of table

grapes. Postharvest Biology and Technology, 133, pp.

36-40

Kangliang Sheng, Huanhuan Zheng, ShanShan Shui,

LingYan, Changhong Liu, Lei Zheng., 2018.

Comparison of postharvest UV-B and UV-C treatments

on table grape: Changes in phenolic compounds and

their transcription of biosynthetic genes during storage.

Рostharvest Biology and Technology, 138, pp. 74-81

Khaliknazarov, U., Ibrokhimov, U. 2024, BIO Web of

Conferences, 85, 01004

https://doi.org/10.1051/bioconf/20248501004

Crupi, P., Pichierri, A., Basile, T., Antonacci, D., 2013.

Postharvest stilbenes and flavonoids enrichment of

table grape cv Redglobe (Vitis vinifera L.) as affected

by interactive UV-C exposure and storage conditions.

Food Chemistry, 141, pp. 802-808

Turdiboyev, A., Khaliknazarov, U., Akbarov, D.,

...Abdullaeva, S., Butaev, T. 2022, AIP Conference

Proceedings, 2686, 020019

Djiyanov, M., Xalilov, R., Isakova, F. 2024, BIO Web of

Conferences, 85, 01034

https://doi.org/10.1051/bioconf/20248501034

Djiyanov, M., Tadjibekova, I., Temirkulova, N.,

Kholmuradov, O. 2024, Lecture Notes in Networks and

Systems, 733, 565–571

Djiyanov, M., Tadjibekova, I., Temirkulova, N. 2022, IOP

Conference Series: Earth and Environmental Science,

1068(1), 012004 doi:10.1088/1755-

1315/1068/1/012004

Isakova, F., Tadjibekova, I., Kurbonov, F. 2024, BIO Web

of Conferences, 85, 01037

https://doi.org/10.1051/bioconf/20248501037

Features of the Use of Ozone for Long-Term Storage of Agricultural Products

171