Designing of the Cavities Device Circuit for Installation in Canal of

Fan Sprayer

Khusniddin Irisov

1a

, Ma'oruf Djiyanov

1b

, I Bekmurodov

2c

and Navruz Abdiyev

1d

1

Tashkent State Agrarian University, 100140, University Str. 2, Tashkent, Uzbekistan

2

University of Public Safety, Tashkent Region, 100109, Uzbekistan

Keywords: Cavitation Device, Spray Optimization, Droplet Dispersion.

Abstract: In article is described the structure, operation and advantages of the spreader (caviator) used in the fight

against pests and diseases in agricultural crops, viticulture and horticulture, as well as its advantages over

other spreaders. Also, installing the caviator device on the nozzle of fan sprayers (passing the symmetry of

the axis equal to "k-k" passing through the center of the spray nozzle and selecting point "a" from it, passing

horizontal lines from point "a" to create points " c " and " b ", A scheme was designed to find the point d that

defines the triple part of the conical expander by passing a line 45

0

below the point " b ", and to determine the

point "e" where the axis symmetry of the capillary channel passed at a distance of l

0

from the point "d". The

optimal design parameters of the caviator (diameter of the base of the conical expander that expands the liquid

droplet flow, internal diameter of the injection chamber) are defined in the article. In order to deliver liquid

droplets to a long distance, the method of installing the cavity nozzle at an optimal distance from the fan

nozzle, the distribution of the free air flow from the spray fan in the atmospheric environment and the methods

of selecting the operating modes of the spraying process (the speed of the air flow containing liquid droplets),

the performance of the fan sprayer were determined.

1 INTRODUCTION

The yield and weight of the product in agricultural

crops depend on the type of seed planted, the strength

of the land, the period of planting and vegetation, as

well as the contamination of the fields with disease-

spreading microorganisms, the extent of

contamination with diseased plant residues, the types

and levels of disease spreaders and pathogens.

Disease infections and disease-spreading pests in

most cases can multiply in the roots of weeds in the

initial phase of development and then spread to

cultivated plants (Matchanov, 2016; Akhmetov &

Mirzaev, 2018; Farmonov, 2020; Matmurodov, 2020;

Eshpulatov et al., 2021; Matchanov et al., 2021;

Djiyanov, 2022; Djiyanov et al., 2024).

To fulfill these tasks, it is important for farms

today to increase productivity using intensive

a

https://orcid.org/0000-0001-9555-8813

b

https://orcid.org/0000-0002-7346-539X

c

https://orcid.org/0000-0001-9555-8813

d

https://orcid.org/0009-0002-4089-9201

technologies in the field of agriculture, to protect the

crop from pests, diseases and weeds.

Increasing their volume and quality due to the

reduction of losses caused by most pests, diseases and

weeds to agricultural products, reducing the negative

impact of existing spraying technologies on the

environment and people, solving the problems of its

prevention is reflected in the integrated protection of

plants.

The size of the spray droplets determines the

effective effect of the chemical or biopreparation and

the economic efficiency of the treatment. As the

droplet size decreases, i.e. as the level of spray quality

increases, the working fluid consumption decreases.

According to experts, the technical efficiency of

using boom sprayers for pre-harvest defoliation or

desiccation of cotton in the small-volume spraying

method is high because the spraying process is carried

out close to the cotton stalks. In this case, the

148

Irisov, K., Djiyanov, M., Bekmurodov, I. and Abdiyev, N.

Designing of the Cavities Device Circuit for Installation in Canal of Fan Sprayer.

DOI: 10.5220/0014224000004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 148-152

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

preparation is carried out due to the kinetic energy of

the treated liquid under the influence of gravitational

force and partial air flow (Derksen, 1994; Podgornyj,

2021; Usenov, 2021; Khaliknazarov et al., 2021;

Khaliknazarov & Ibrokhimov, 2024).

Many authors have proven in their studies that the

use of fan sprayers in a small amount mode is

effective in the treatment of cotton fibers (Jobnson &

Swetnam, 2000).

Different types of sprinklers are being produced

in the world (Sudit, 1973) and complex scientific and

practical research works are being conducted to create

their new projects(Sudit, 1973; Jobnson & Swetnam,

2000; Alimova et al., 2022; Irisov & Bekmurodov,

2023; Khudayorov et al., 2023a; Khudayorov et al.,

2023b; Irisov & Khamidov, 2023).

It is possible to chemically treat the underside of

the plant leaves with the help of the air stream created

on the side of the spray fan. The advantages of

oscillating fan sprayers in the horizontal plane are the

ability to quickly maneuver on turning lanes, the large

coverage width, the ability to process plants from

both sides along with their entire height.

Based on the results of the analysis, a working

hypothesis was adopted that the formation of highly

dispersed droplets can be achieved by the influence

of the kinetic energy of the local and main air currents

generated by the spray fan on the thin liquid film that

is ejected from the nozzle slit (Irisov & Bekmurodov,

2023; Irisov & Khamidov, 2023).

2 MATERIALS AND METHODS

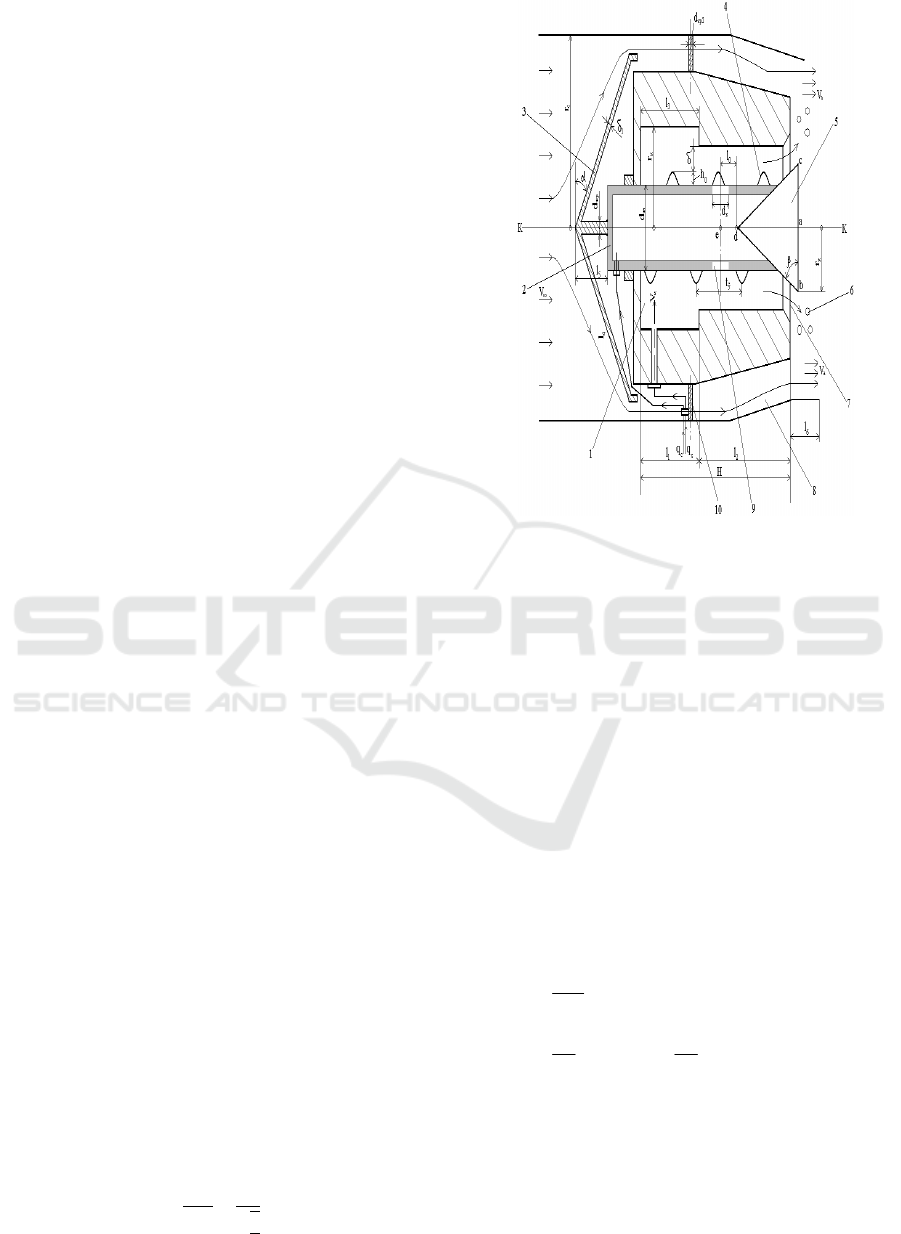

We use the M2:1 scale to design a schematic for

installing a cavitation device (Irisov & Bekmurodov,

2023; Irisov and Khamidov, 2023; Saidova et al.,

2024) on a fan spray nozzle, which creates a thin film

of liquid that is ejected from the nozzle's annular slit

to produce highly dispersed droplets (Figure 1).

The design stage consists of:

We transfer the symmetry of the axis equal to "k-

k" passing through the center of the spray nozzle and

select the point "a" from it.

We create points "c" and "b" by passing horizontal

lines from point "a". Let's define the distance between

these points. From the constructive side, "ac" and

"ab" are equal to rk. Therefore, we can find the

diameter of the base of the conical expander that

expands the liquid droplet flow from the following

expression (𝑎 =10 𝑚𝑚;𝛽 = 45

):

𝑑

=2𝑟

=2

𝑎

𝑡𝑔𝛼

=

10

2

2

= 15 𝑚𝑚

Figure 1: Designing the scheme of placement of the

Caviator device on the fan spray nozzle: 1 – feeding

chamber; 2 – central tube; 3.5 – current expanders; 4 –

spiral deflector-turbulizer; 6 – small drops; 7.8 – nozzle; 9

– capillary channel; 10 – bracket.

We pass the beam 45

0

below the point "b" and find

the point d, which defines the third part of the conical

expander.

We determine the point "e", which is 6 mm from

the point "d", where the axial symmetry of the

capillary channel passes, in which from the structural

side

We accept equal to

мммммkpммkмму

ммммoммk

dddt

hd

14;4;40;2...5,1

;0,2...5,1;2;4...3

2

====

===

δ

We determine the inner diameter of the feeding

chamber in the following proportions:

or

.112,104

2

14

)6...3(

2

14

,

2

ммк

м

к

d

d

d

≈=+=+=

Δ+=

As the fluid consumption decreases, it is

recommended to take the value of

Δ as low as

possible. Otherwise, the process of crushing the drops

coming out of the caviar nozzle will be much more

difficult.

Designing of the Cavities Device Circuit for Installation in Canal of Fan Sprayer

149

The number of spiral windings in the deflector-

turbulizer should not be less than 2..3 on the upper

and lower sides of the capillary channel 9. Too few or

too many packages can adversely affect the stability

of the worker being transferred.

A conical flow expander 3 is poured on the

windward side of the cavity. It allows the flow of air

transmitted by the fan to surround the caviar without

great resistance, and the small liquid drops ejected

from the caviar nozzle 7 can mix deeper with the air

flowing around the spray nozzle and deliver them to

a longer distance, thus increasing the technical

efficiency of the working fluid used.

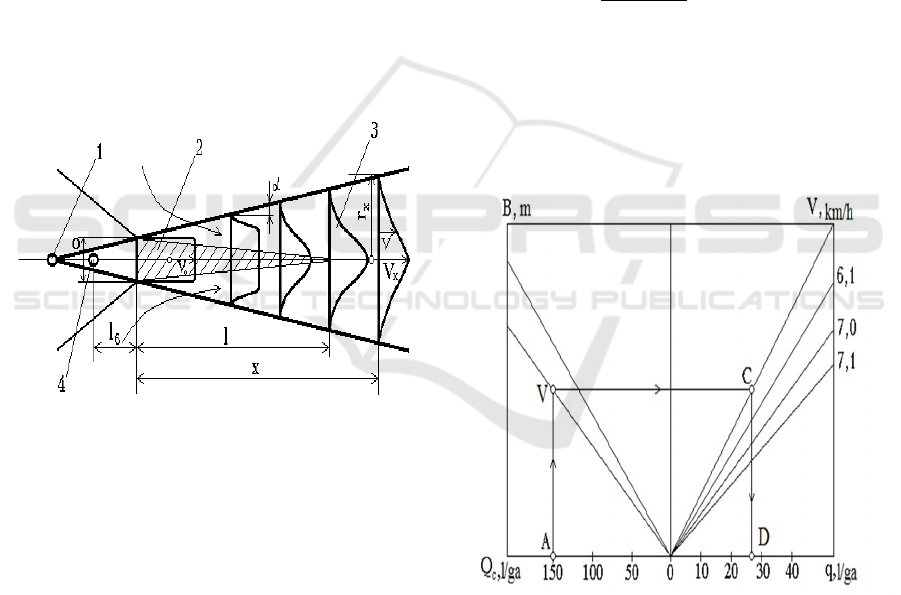

The second way to deliver liquid droplets to a long

distance is to install the cavity nozzle 7 at an optimal

distance of 16 from the fan nozzle 8. Because the

initial velocity vo of the air to the triangular core of

the turbulent air flow from the nozzle 8 (dashed in

Fig. 2) is constant and the length of the distance is

equal to е=0,335d/

η

- (where d is the diameter of the

core of the fan nozzle; d - turbulence coefficient

(fountains for ƞ=0.07...14).

Figure 2: Distribution scheme of the free air flow coming

out of the spray fan in the atmosphere: 1 – flow pole; 2 –

current core; 3 – transition section; 4 – the point where the

caviar nozzle is installed; d - nozzle diameter; v

о

– the initial

speed of the air leaving the nozzle; a – expansion angle; r

х

– the radius of the cross-section of the fountain at the

distance x from the nozzle; ƞ - turbulence coefficient.

3 RESULTS AND DISCUSSION

Velocity of air flow with liquid droplets in the axis of

symmetry of the section at distance "x" from the

nozzle:

),145,0//(48,0 += daxvv

ox

m/s (1)

Fan sprayer performance:

Q=sv

ўр

т

, m

3

/s; (2)

v

ўр

т

= (0,75...1,0) v

о

, m/s, (3)

where, s – is the cross-sectional area of the fan

nozzle, m

2

;

v

aver

– the average speed of the air coming out of

the nozzle, m/s.

Moving away from the axis, the speed v

о

decreases and becomes zero at its extreme point. The

air velocity vx at any cross-section of the main part

located in the core of the flow is zero at the flow limit

(distance R

x

), decreasing as it moves away from the

fan nozzle.

Fluid flow rate that should flow out of the сaviator

device every minute:

600

* nBvQ

q

c

c

=

, l/min

(4)

where В – is the coverage width of the aggregate

during processing, m; v – unit speed, km/h; n – the

number of cavities installed in the nozzle, pcs.

Working fluid consumption qc can also be

determined using a nomogram (Figure 3).

Figure 3: Nomogram for determining the required amount

of working fluid.

For it, the fluid consumption Q

c

given from the

nomogram is selected and the quantity q located on

the abscissa axis along the arrow A→V→S→D is

found. If q<50 l/ha, the eye of the side capillary

channels in the central tube is adjusted closer to the

nozzle 7 and the liquid consumption is reduced, if

q>50 l/ha, on the contrary, the eye of the side

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

150

capillary channels is pushed into the cavity of the

condensing chamber 1 and the liquid consumption is

increased. It is also possible to use the central tube,

which corresponds to the cavity of the side capillary

channel.

Both high-dispersed and polydispersed drops are

formed from the recommended carrier systems and

have universal properties. And traditional zasitkikh

systems do not have such an opportunity.

At the end of the design, the main contour lines of

the cavity device and the fan nozzle are drawn in dark

color

.

4 CONCLUSIONS

The use of the correction system of Caviator devices

allows obtaining both highly dispersed and

polydispersed droplets in a given spray unit itself.

The treatment system of the Caviator devices can

also be used as boom sprayers.

The above-mentioned expressions and design

allow to choose the most optimal constructions of

caviators, to justify their main parameters and

operating modes

.

REFERENCES

Akhmetov, A.A., Mirzaev, B.S., 2018. Technical means for

chemical plant protection (Tashkent).

Alimova, F.A., Primkulov, B.Sh., Saidova, M.T., &

Boboniyozov, E.A., 2022. Combined aggregate for

strip tillage and simultaneous sowing of re-crops. IOP

Conference Series: Earth and Environmental Science,

1112, 012021. https://doi.org/10.1088/1755-

1315/1112/1/012021

Derksen, R.C., 1994. Hydraulic nozzles for boom sprayers.

NRAES, p. 6.

Djiyanov, M., Tadjibekova, I., Temirkulova, N., 2022.

Development of models for functioning of a universal

service center in agriculture of Uzbekistan. IOP

Conference Series: Earth and Environmental Science,

1068, 012004. DOI: 10.1088/1755-

1315/1068/1/012004.

Djiyanov, M., Xalilov, R., Isakova, F., 2024. Justification

of commercialization of export-oriented harvesting

apparatus for intensive processing of cotton boxes. BIO

Web of Conferences, 85, 01034.

https://doi.org/10.1051/bioconf/20248501034.

Eshpulatov, N., Khalmuradov, T., Khalilov, R., Nurmanov,

S., Omonov, D., 2021. Theoretical substantiation of the

influence of electric pulse processing on the process of

obtaining juice from grapes and fruits. E3S Web of

Conferences, 264, 04086.

https://doi.org/10.1051/e3sconf/202126404086.

Farmonov, E., Lakaev, Sh., Khalilov, R., & Gorlova, I.,

2020. Aeromechanical purification of freshly harvested

seed heaps of desert fodder plants. IOP Conference

Series: Materials Science and Engineering, 883,

012097. DOI: 10.1088/1757-899X/883/1/012097.

Irisov, Kh.D., Bekmurodov, I. R., 2023. Theoretical aspects

of substantiating the parameters of the working body of

an environmentally comfortable spraying unit. IOP

Conference Series: Earth and Environmental Science,

1284, 012041. DOI: 10.1088/1755-

1315/1284/1/012041.

Irisov, Kh., Khamidov, G., 2023. Formation of highly

dispersed droplets with harmless effect on the

environment and the results of their mathematical and

statistical processing. E3S Web of Conferences, 386,

03003. https://doi.org/10.1051/e3sconf/202338603003.

Jobnson, M.P., Swetnam, L.D., 2000. Sprayer nozzles:

selection and calibration. University of Kentucky. – Pat

3. – p. 6.

Khaliknazarov, U., Akbarov, D., Tursunov, A., Gafforov,

S., & Abdunabiev, D., 2021. Existing problems of

drying cocoon and making chrysalis feeble, and their

solutions. IOP Conference Series: Earth and

Environmental Science, 939, 012020. DOI:

10.1088/1755-1315/939/1/012020.

Khaliknazarov, U., Ibrokhimov, U., 2024. Design of a

water pump-solar source system for drinking water

supply. BIO Web of Conferences, 85, 01004.

https://doi.org/10.1051/bioconf/20248501004.

Khudayorov, Z., Khalilov, R., Gorlova, I., Mirzakhodjaev,

S., & Mambetsheripova, A., 2023a. Mathematical

model of water drop trajectory in artificial rainfall. E3S

Web of Conferences, 365, 04011.

https://doi.org/10.1051/e3sconf/202336504011.

Khudayorov, Z., et al., 2023b. Deflector nozzles of rain

irrigation machines. E3S Web of Conferences, 390,

01033. https://doi.org/10.1051/e3sconf/202339001033.

Matchanov, R., Rizayev, A., Astanakulov, K., Tolibaev, A.,

Karimov, N., 2021. Combined cotton picker with

interchangeable devices. IOP Conf. Series: Earth and

Environmental Science IOP Conference Series: Earth

and Environmental Science, 677, 1–6. DOI:

10.1088/1755-1315/677/5/052021.

Matchanov, R.D., 2016. Plant protection in the system

culture-pest-drug-machine (Tashkent)

Matmurodov, F., Dustkulov, A., & Abdiyev, N., 2020.

Mathematical simulation of transfer mechanisms of

crocheting potato harvesting machine. IOP Conference

Series: Materials Science and Engineering, 883,

012176. DOI: 10.1088/1757-899X/883/1/012176.

Podgornyj, Yu.I., Skeeba, V.Yu., Kirillov, A.V.,

Maksimchuk, O.V., Lobanov, D.V., & Martyushev,

N.V., 2021. Algorithm for the cams synthesis for the

slay mechanism drive. Journal of Physics: Conference

Series, 2061, 012039. DOI: 10.1088/1742-

6596/2061/1/012039

Saidova, M., Tursunbaev, S., Boltaeva, M., & Isakulova,

N., 2024. Comparison of pneumatic sowing machines

by the number of seeds in the slots of the discs and the

distance between the slots. BIO Web of Conferences,

Designing of the Cavities Device Circuit for Installation in Canal of Fan Sprayer

151

105, 01004.

https://doi.org/10.1051/bioconf/202410501004.

Sudit, J.M., 1973. Research and development of a

methodology for designing the spraying bodies of field

sprayers. Dissertation (Moscow: Agropromizdat).

Usenov, A.B., et al., 2021. Study of cellulose extraction and

cavitation from plant raw materials. IOP Conference

Series: Earth and Environmental Science, 868, 012047.

DOI: 10.1088/1755-1315/1112/1/012148.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

152