Assessment of the Degree of Activity of Abrasive Particules in the of

Machine Components Involved in the Wear Process

Khikmat Ishmuratov

1a

, Madrakhim Allanazarov

2b

and Tolib Khalmuradov

2c

1

Tashkent State Technical University named after Islam Karimov, Tashkent, Uzbekistan

2

Tashkent State Agrarian University, Tashkent, 100140, Uzbekistan

Keywords: Abrasive Particles, Wear Process, Oil Replacement.

Abstract: This article considers the regularities of abrasive particles activity changing in the oil of machine units, which

take part in the process of gear-wheel wear at constant and increasing concentration varying with the number

of loading cycles of gear teeth, considering the share of crushed abrasive particles in one loading cycle of the

gearing which is used to determine the oil replacement time in the machine unit.

1 INTRODUCTION

One of the factors that most significantly affect the

results of calculation and experimental determination

of the wear resistance of gear materials is the degree

of activity of abrasive particles in the oil of machinery

transmission units.

In the process of friction for each cycle of loading

of gear teeth, the concentration of active abrasive

particles in the oil of the machine constantly changes.

It occurs because of crushing of abrasive particles,

being in oil of the aggregate and entering of a fresh

portion from environment (Ishmuratov, 2019;

Mirzaev et al., 2019; Mamatov et al., 2021;

Mirzakhodjaev et al., 2021; Khudayorov et al., 2023;

Khudayorov, et al., 2023; Khudayorov,et al., 2023;

Mirzakhodjaev et al., 2024; Mirzakhodjaev et al.,

2024). Therefore, when assessing the wear resistance

of gear teeth and the oil change period in the units it

is necessary to consider the regularities of abrasive

particles activity change in the process of oil

circulation. Analysis of the state of the matter in

question showed that in the literature this issue is not

sufficiently covered, mainly limited to the study of

the process of crushing abrasive particles located in

the contact zone of gear teeth (Ishmuratov et al.,

2020; Djiyanov et al., 2022; Astanakulov et al., 2023;

a

https://orcid.org/0009-0008-2266-0372

b

https://orcid.org/0009-0009-3602-4841

c

https://orcid.org/0000-0002-3704-8361

Djiyanov et al., 2024; Djiyanov et al., 2024; Isakova

et al., 2024; Irisov et al., 2024).

The purpose of this work is to obtain

computational dependences for estimating the

activity of abrasive particles, at their constant and

increasing concentrations.

2 MATERIALS AND METHODS

In heavily loaded gears, the load falling on the

abrasive particles in the wedge-shaped gap of gear

teeth, in most cases exceeds their compressive

strength, as a result of which these particles are

subjected to crushing (Zhigaev, 1971; Melnikov,

1999). Because according to (Mirzakhodjaev et al.,

2024) the coefficient of re-crushing of abrasive

particles equal to 7, after crushing process, the size of

crushed abrasive particles should not exceed:

da<Rz+h

0

, m, (1)

where R

z

is the roughness height of the friction

surfaces of the gear teeth, m; h0 is the thickness of the

oil film between the friction surfaces of the gear teeth,

m.

In the process of gear teeth wear, abrasive

particles of the size corresponding to expression (1)

128

Ishmuratov, K., Allanazarov, M. and Khalmuradov, T.

Assessment of the Degree of Activity of Abrasive Particules in the of Machine Components Involved in the Wear Process.

DOI: 10.5220/0014223100004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 128-131

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

do not come into force interaction with friction

surfaces, and wear from their influence does not

occur.

The total concentration of abrasive particles in the

oil of the unit can be constant and increasing in time,

because of their penetration from the environment.

Let us see how the abrasive particles activity changes

for these cases.

3 RESULTS AND DISCUSSION

The total concentration of abrasive particles in the oil

is constant, its value in time remains constant, i.e., no

new portions of abrasive particles enter the oil from

the outside. This variant is characteristic for testing of

roller samples of cogwheels for wear resistance on the

friction machine MI-1M. The size of abrasive

particles used for wear testing should be greater than

the sum of the roughness height and oil film thickness

(exceeding 4 microns). In this case, the initial

concentration of abrasive particles in the unit oil was

taken equal to their total concentration (ε

max

).

At crushing of active abrasive particles,

depending on number of loading cycles, their

concentration decreases (fig.1, graphs 1, 2). Let us

consider changes of abrasive particles activity in the

process of wear resistance test, after each loading

cycle. Loading cycle is one complete revolution of a

spherical toothed wheel specimen, which is dipped

into oil containing abrasive particles of spherical

shape (Irgashev et al., 2021; Ishmuratov et al., 2023).

After the first load cycle:

The concentration of crushed abrasive particles,

1max1d

A

εε

=

, (2)

where A

1

is a coefficient taking into account the

share of crushed abrasive particles for one cycle of

loading, at constant total concentration of abrasive

particles in oil. For calculation of A1 value the

dependence is offered (Djiyanov et al., 2024b),

1

.

2

cp m

mt

Rld

A

G

π

γ

=

, (3)

here R - radius of curvature of sample,

surrounding in oil, m; dcp - average size of abrasive

particles, participating in wear process, m; 1 - contact

length of samples, m; γ

m

- oil density, kg/m

3

; Gm.t -

amount of oil, poured into friction machine tank at

test on wear resistance of samples, made of cogwheel

material, kg,

concentration of active abrasive particles in the

friction machine oil after the first loading cycle,

1max 1

(1 )

A

εε

=−

.

After the second loading cycle:

The concentration of crushed abrasive particles,

211max 1

(1 )

d

A

A

εε ε

== −

;

concentration of active abrasive particles,

2

212 max1 1 max 1

(1 ) (1 )

d

A

AA

εεε ε ε

=− = − = −

Similarly, after k loading cycles:

The concentration of crushed abrasive particles,

1

11 max 1 1

(1 )

k

kd k

AAA

εε ε

−

−

== −

, (4)

concentration of active abrasive particles,

max 1

(1 ) .

k

k

A

εε

=−

(5)

The obtained analytical dependencies show that at

constant total concentration of abrasive particles,

which are in oil, increase of abrasive particles size,

radius of curvature and width of contact of samples,

made of toothed wheels material, dipped in oils in the

friction machine tub, leads to growth of their crushing

intensity. This is explained by the fact that increasing

the radius of curvature leads to a narrowing of the

wedge-shaped gap between the samples of the friction

process, leading to an increase in the contact area

between the surfaces of samples and abrasive

particles, due to which, increases the number of

adhered and crushed abrasive particles on the contact

surfaces of friction (Akhmetov et al., 2021;

Zhanikulov et al., 2022; Akhmetov et al., 2023).

The received analytical dependences show that at

constant total concentration of the abrasive particles

being in oil, the increase in size of abrasive particles,

radius of curvature and width of contact of the

samples made of gear wheel material dipped in oils in

the bath of friction machine leads to increase in

intensity of their crushing. This is explained by the

fact that increasing the radius of curvature leads to a

narrowing of the wedge-shaped gap between the

samples occurring in the friction process, leading to

an increase in the contact area between the surfaces

Assessment of the Degree of Activity of Abrasive Particules in the of Machine Components Involved in the Wear Process

129

of samples and abrasive particles, thereby increasing

the number of adhered and crushed abrasive particles

on the contact surfaces of friction.

2. The initial concentration of abrasive particles in

the oil of the unit is zero; it increases with increasing

number of loading cycles of the driven gear (fig. 1,

graphs 3, 4). This case corresponds to the real

operating conditions of the gear transmission in the

unit.

Let us assume that tightness of crankcase and

dustiness of environment during exploitation of

machines remain constant. As a result, penetrated

abrasive particles from the environment are subjected

to crushing and the concentration of active abrasive

particles in the machine oil changes constantly during

each load cycle (Akhmetov et al., 2023).

After the first loading cycle of the gear wheel:

concentration of crushed abrasive particles,

1

0

d

ε

=

,

concentration of active abrasive particles,

1 z

εδ

=

,

where is the number of active abrasive particles

entering the unit oil during one cycle of the driven

gear loading, % rev.

After the second cycle of gear wheel loading:

concentration of crushed abrasive particles is,

2dz

B

εδ

=

where B - the coefficient taking into account the

share of crushed abrasive particles at their arrival

from the environment, corresponding to the operating

conditions of machine units,

1

2

cp m p

m

nmd L k

B

G

γ

=

(6)

here n

1

- the number of gear pairs in the unit,

dipping in oil; m - meshing module, m; L - gear tooth

length, m; G

m

- quantity of oil in the unit, kg; k

p

-

coefficient taking into account the heterogeneity of

abrasive particles size that penetrate into the unit,

depending on the dusty environment and abrasive

particle size value in the oil k

p

= 0,40 - 0,65,

2

2(2)

zz z

BB

εδδδ

=−= −

Similarly, after k1 cycles of gear wheel loading:

concentration of crushed abrasive particles,

1

1

(1)

kd z

Bk

εδ

=−

(7)

concentration of active abrasive particles

1

111

((1))

kzkdz

kkBk

εδεδ

=−= − −

(8)

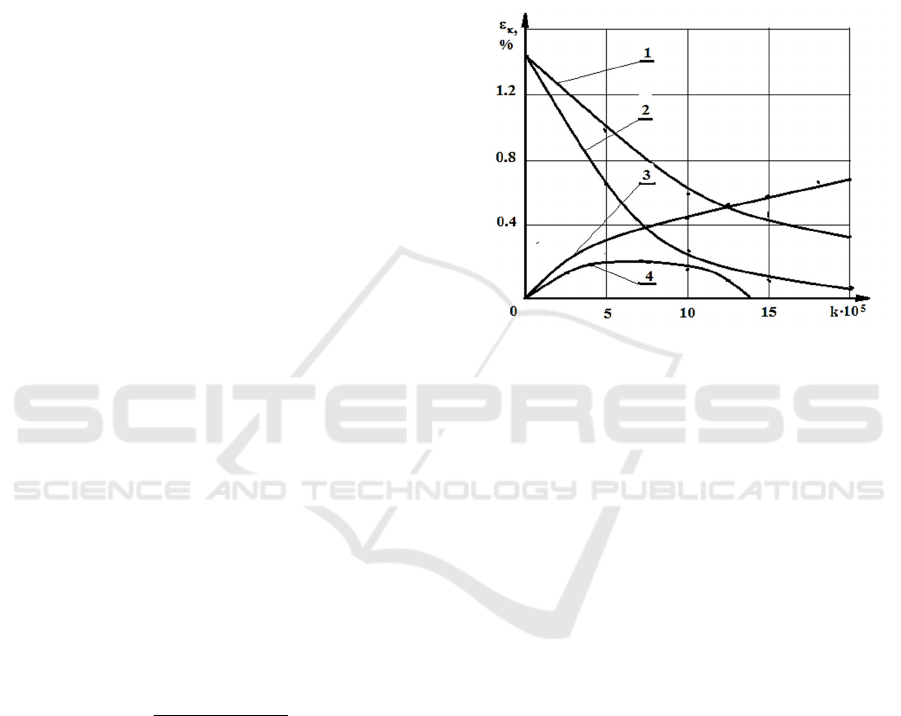

Figure 1: Change of concentration of active abrasive

particles in aggregate oil from the meshing module and

number of cycles of loading: 1, 2 - total concentration of

abrasive particles in oil is constant; 3, 4 - the initial

concentration of abrasive particles in aggregate oil is equal

to zero and changing for each cycle of loading, 1, 3 – m =

0,010 m; 2, 4 – m = 0,015 m

Graphical dependencies presented in Fig. 1,

obtained from expression (6 and 8) graphs 3, 4,

constructed at: n

1

=2; d

cp

=0,000012 m; L=0,058 m; γ

m

= 910 kg/m

3

; k

p

=0,5; G

m

=20 kg; δ

z

=0,65 10

-6

%/rev

show, that if initial concentration of abrasive particles

in oil is zero, with increase of loading cycles

concentration of crushed abrasive particles gradually

increases, after its value reaches some critical value,

it slightly decreases. This can be explained by the

excessive amount of crushed abrasive particles in the

oil of the unit compared to the abrasive particles

coming into the unit from the environment.

4 CONCLUSIONS

Thus, the obtained expressions for determining the

activity of abrasive particles (9) make it possible to

calculate:

1. durations of wear testing of gear wheel material

on samples at a constant total concentration of

abrasive particles in the oil;

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

130

2. the period of oil replacement of units of

machines with toothed gears, working in the presence

of abrasive particles in the working environment

REFERENCES

Akhmetov, A.A., Akhmedov, Sh.А., Allanazarov, M.A.,

Asamov, R.H. 2023, IOP Conference Series: Earth and

Environmental Science, 1138(1), 012047

doi:10.1088/1755-1315/1138/1/012047

Akhmetov, A.A., Allanazarov, M.A., Muratov, L.B.,

Kambarova, D.U. 2021, IOP Conference Series: Earth

and Environmental Science, 868(1), 012075.

Astanakulov, K., Kurbonov, F., Isakova, F. 2023, E3S Web

of Conferences, 381, 01001

https://doi.org/10.1051/e3sconf/202338101001

Djiyanov, M., Tadjibekova, I., Temirkulova, N. 2022, IOP

Conference Series: Earth and Environmental Science,

1068(1), 012004 doi:10.1088/1755-

1315/1068/1/012004

Djiyanov, M., Tadjibekova, I., Temirkulova, N.,

Kholmuradov, O. 2024, Lecture Notes in Networks and

Systems, 733, 565–571

Djiyanov, M., Xalilov, R., Isakova, F. 2024, BIO Web of

Conferences, 85, 01034

https://doi.org/10.1051/bioconf/20248501034

Irgashev, Kh K Ishmuratov, M A Allanazarov, K Kh

Ishmuratova. Assessment of ambient dust limit of open

gear of cotton harvester. IOP Conf. Series: Earth and

Environmental Science 868 (2021) 012068 рр.1-12.

doi:10.1088/1755-1315/868/1/0120686.

Irisov, K., Gorlova, I., Khudaev, I. 2024, BIO Web of

Conferences, 105, 01016

https://doi.org/10.1051/bioconf/202410501016

Isakova, F., Tadjibekova, I., Kurbonov, F. 2024, BIO Web

of Conferences, 85, 01037

https://doi.org/10.1051/bioconf/20248501037

Ishmuratov H K, Irgashev B A. Assessment of the Wear

Resistance for Gearwheel Teeth in an Open Toothed

Gear under the Conditions of a High Level of Dust.

Journal of Friction and Wear. Volume 41, Issue 1,

January 1, 2020, Pages 85-90.

Ishmuratov Kh K 2019 Dissertation of the degree of Doctor

of Philosophy in Technical Sciences (PhD) 156.

Kh. K. Ishmuratov, Mirzaev N.N., Abdullaeva B.,

Mamasalieva M.I. Energy analysis of wear sliding

friction units. E3S Web of Conferences 383, 04019

(2023)

https://doi.org/10.1051/e3sconf/202338304019.

Khudayorov, Z., Khalilov, R., Gorlova, I., Mirzakhodjaev,

S., Mambetsheripova, A. 2023, E3S Web of

Conferences, 365, 04011

https://doi.org/10.1051/e3sconf/202336504011

Khudayorov, Z., Khalilov, R., Mirzakhodjaev, S.,

Nurmikhamedov, B., Mamasov, S. 2023, E3S Web of

Conferences, 376, 02013

https://doi.org/10.1051/e3sconf/202337602013

Khudayorov, Z., Mirzakhodjaev, S., Khalilov, R.,

Nurmikhamedov, B., Mamasov, S. 2023, E3S Web of

Conferences., 390, 01033

https://doi.org/10.1051/e3sconf/202339001033

Mamatov, F., Mirzaev, B., Mirzahodzhaev, S., Uzakov, Z.,

Choriyeva, D. 2021, IOP Conference Series: Materials

Science and Engineering, 1030(1), 012164 DOI:

10.1088/1757-899x/1030/1/012164

Melnikov V Z. Increased bearing capacity and wear

resistance of gears. Tractors and agricultural machines.

1999. №2

Mirzaev, B., Mamatov, F., Ergashev, I., Kodirov, U.,

Ergashev, G. 2019, E3S Web of Conferences, 135,

01065 https://doi.org/10.1051/e3sconf/201913501065

Mirzakhodjaev, S., Djiyanov, M., Nurmikhamedov, B.,

Mamasov, S. 2024, BIO Web of Conferences, 85,

01035 https://doi.org/10.1051/bioconf/20248501035

Mirzakhodjaev, S., Shodiev, K., Uralov, G., Badalov, S.,

Choriyeva, D. 2021, E3S Web of Conferences, 264,

04047 https://doi.org/10.1051/e3sconf/202126404047

Mirzakhodjaev, S., Utaganov, K., Musurmonov, A. 2024,

BIO Web of Conferences, 85, 01036

https://doi.org/10.1051/bioconf/20248501036

Zhanikulov, S., Khalmuradov, T., Allanazarov, M. 2022,

IOP Conference Series: Earth and Environmental

Science, 1112(1), 012015 DOI 10.1088/1755-

1315/1112/1/012015

Zhigaev V D. Durability of quartz sand grains. 1971. №1.

С. 101-105.

Assessment of the Degree of Activity of Abrasive Particules in the of Machine Components Involved in the Wear Process

131