The Influence of Suspension Plough Support Wheel Diameter and

Width on Its Performance Indicators

Abdusalim Tukhtakuziev

1a

, Abdurakhmon Rasuljonov

1b

, Sherzod Barlibaev

2c

,

Dilfuza Karimova

3d

and Madina Turdiyeva

3e

1

Scientific-Research Institute of Agricultural Mechanization, Samarkand str. 41, Yangiyul dis., Tashkent reg., Uzbekistan

2

Tashkent Institute of Irrigation and Agricultural Mechanization Engineers, National Research University,

K. Niyazi str. 39, Tashkent, Uzbekistan

3

Andijan Institute of Agriculture and Agrotechnology Oliygoh str. 1, Kuyganyor, Andijan, Uzbekistan

Keywords: Support Wheel, Plough Performance, Depth Stability.

Abstract: The article presents the results of theoretical and experimental studies conducted on the study of the influence

of the diameter and width of the support wheel of the suspension plough on the driving depth and its stability,

and on the basis of this, to determine their optimal values. In theoretical studies, it was noted that the stability

of the driving depth at the level of requirements is mainly ensured by the correct choice of the diameter of the

plough support wheel and the width of it, and for a three-body suspension plug, their value is not less than 35

and 16 cm, respectively. In order to verify these obtained results, we prepared a three-body suspension plough

and conducted experimental studies using it. For conducting experimental studies, the base wheels with the

diameter and the width of the beam at 5 cm intervals from 30 cm to 50 cm and from 10 cm to 30 cm,

respectively, were prepared. In experimental studies, the influence of the diameter of the plough support wheel

and the width of its furrow, the driving depth, its mean square deviation, the vertical pressure force exerted

by the support wheel on the soil, and the plow's traction resistance were studied. In order to reduce the

influence of various variable factors on the obtained results, the experiments were carried out on specially

prepared agro-funds, that is, they were first plowed, then leveled and fully irrigated. Based on the results of

experimental studies, the following can be noted: in order for the plough to work stably at the specified depth,

the diameter of the support wheel should be at least 40 cm, and the width of the rim should be at least 20 cm.

These results fully correspond to the results of theoretical studies.

1 INTRODUCTION

It is known that the depth of cultivation and its

stability are the main performance indicators of all

soil tillage machines. If the tillage depth is at the

required level and its stability is ensured, i.e. it is

uniform development and ripening of crops and a

high yield will be achieved, otherwise, crops will

develop and ripen unevenly, productivity will

decrease. This situation has been proven in many

studies conducted in Uzbekistan and foreign

countries. For this reason, there are strict

a

https://orcid.org/0009-0003-4950-4840

b

https://orcid.org/0000-0003-4669-9526

c

https://orcid.org/0009-0004-5991-7425

d

https://orcid.org/0009-0007-5214-000X

e

https://orcid.org/0000-0008-1033-1247

requirements and restrictions on the depth of

cultivation and its deviation from the specified for

each tillage machine (Tukhtakuziev & Rasuljonov,

2020a; Tukhtakuziev & Rasuljonov, 2020b;

Turdaliev et al., 2022; Djurayev et al., 2022).

The depth of tillage and its stability and impact on

the development and productivity of cotton and grain

crops have been studied. It was noted by them that the

change of the tillage depth from the set acceptable

value to one side or the other will lead to a 12-15

percent decrease in crop yield (Norchayev et al.,

116

Tukhtakuziev, A., Rasuljonov, A., Barlibaev, S., Karimova, D. and Turdiyeva, M.

The Influence of Suspension Plough Support Wheel Diameter and Width on Its Performance Indicators.

DOI: 10.5220/0014072700004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 116-122

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

2021; Mukhamedov et al., 2020; Umurzakov et al.,

2022; Tukhtakuziev et al., 2023).

The above indicates that it is an important issue to

ensure that the tillage depth of soil tillage machines is

uniform at the required level.

This article presents the results of theoretical and

experimental studies on the influence of the diameter

and width of the suspension plough support wheel on

the stability of the plowing depth, and based on this,

their optimal values that ensure the evenness of the

plowing depth are at the required level.

2 MATERIALS AND METHODS

It is known from the literature (Sineokov & Panov,

1977; Mamatov, 2007; Norchayev et al., 2021;

Norchayev et al., 2022; Saidova et al., 2024) that the

following condition must be met for the suspension

plough to sink to a specified depth and to run stably

(uniformly) at this depth:

Q

Z

=Q

M

(1)

Where Q

Z

- vertical pressure force applied to the

soil by the support wheel of the plough, kN;

Q

M

- the optimal value of the vertical pressure

force applied to the soil by the support wheel of the

plough, which ensures the stability of the working

(plowing) depth, kN.

when the condition (1) Q

Z

<Q

M

is met, the base

wheel of the plough is constantly pressed against the

field surface, as a result, the plough sinks to the

specified depth and works without changing the

plowing depth.

Q

Z

>Q

M

otherwise, the support wheel

of the plough cannot adequately adjust to the

unevenness of the field surface, and too much energy

is spent pulling the plough

When the condition (1) is fulfilled, the change of

plough plowing depth during the working process is

mainly due to the change of the depth of immersion

of the support wheel into the soil. Based on this, we

will study the depth of immersion of the plough

support wheel into the soil during the work process.

In this case, we consider that the supporting wheel of

the plough is rigidly knotted, that is, it does not

deform.

Let the support wheel of the plough move along

the field and create a track at the depth h0 (Fig. 1).

We separate the elementary surface dS=Bтdl (where

Вт is the width of the plough base wheel, m; dl - the

elemental cross-section separated from the plough

base wheel, m) from the part of the base wheel axle

in interaction with the soil. The elementary reaction

force of the soil acting on this surface is equal to:

m

dN pB dl=

, (2)

where p - relative pressure of the soil on the axis

of the plough support wheel, Pa;

As is known from the literature (Sharov, 1964;

Sablikov, 1968; Klenin & Sakun, 1994), the relative

pressure of the soil on the base wheel width, taking

into account the speed of the unit:

()

2

0

1

cos cos

п

m

qh kV

p

p

αα

′

+

==

(3)

Figure 1: The scheme for determining the depth of

immersion of the plough support wheel into the soil.

where p

m

- relative resistance of the soil to vertical

crushing, Pa;

q

0

- static volume compression coefficient of the

soil, N/m

3

;

h ‘- vertical deformation of the soil at the

considered point, m;

k

n

- proportionality coefficient, s

2

/m

2

;

α- the central angle determining the location of the

elemental surface separated from the part of the base

wheel bearing in contact with the ground relative to

the vertical diameter of the base wheel.

Taking into account expression (3), expression (2)

is written as follows:

()

2

0

1

cos

m п

qhB kV dl

dN

α

′

+

=

(4)

Based on the scheme in figure 1:

(5)

()

0

cos cos

2

D

h

αα

′

=−

The Influence of Suspension Plough Support Wheel Diameter and Width on Its Performance Indicators

117

(6)

where α

0

- the angle of the base wheel sinking

into the ground, °;

dα - elementary angle, °.

Taking expressions (5) and (6) into account,

expression (4) becomes:

()

()

22

00

1coscos

4cos

m п

qBD kV

dN d

αα

α

α

+−

=

(7)

divide into vertical and horizontal

components. The sum of the vertical

components is equal to the vertical

compressive force exerted by the supporting

wheel on the soil, i.e.:

()

()

0

22

00

0

1coscos

cos

4

m п

Z

qBD kV

QdN d

α

αα

α

α

+−

==

(8)

Integrating the right side of the expression (8),

we get the following result

()

()

22

0000

1sincos

4

m п

Z

qBD kV

Q

αα α

+−

=

(9)

From the schematic in Fig.1

(10)

(11)

(12)

Taking these expressions into account, expression

(9) becomes:

()

()

2

2

0

00

2

00 0

1

2

2 2 arcsin .

4

m п

Z

qB D kV

D

hh

QDhhDh

D

+

−

=−−−

(13)

Q

Z

=Q

M

= 3,5 kN (for a three-mouldboard

suspension plough) (Klenin & Sakun, 1994), q

0

=

1.75·107 N/m

3

(Mamatov, 2007), k

n

= 0.08 (Shiryaev,

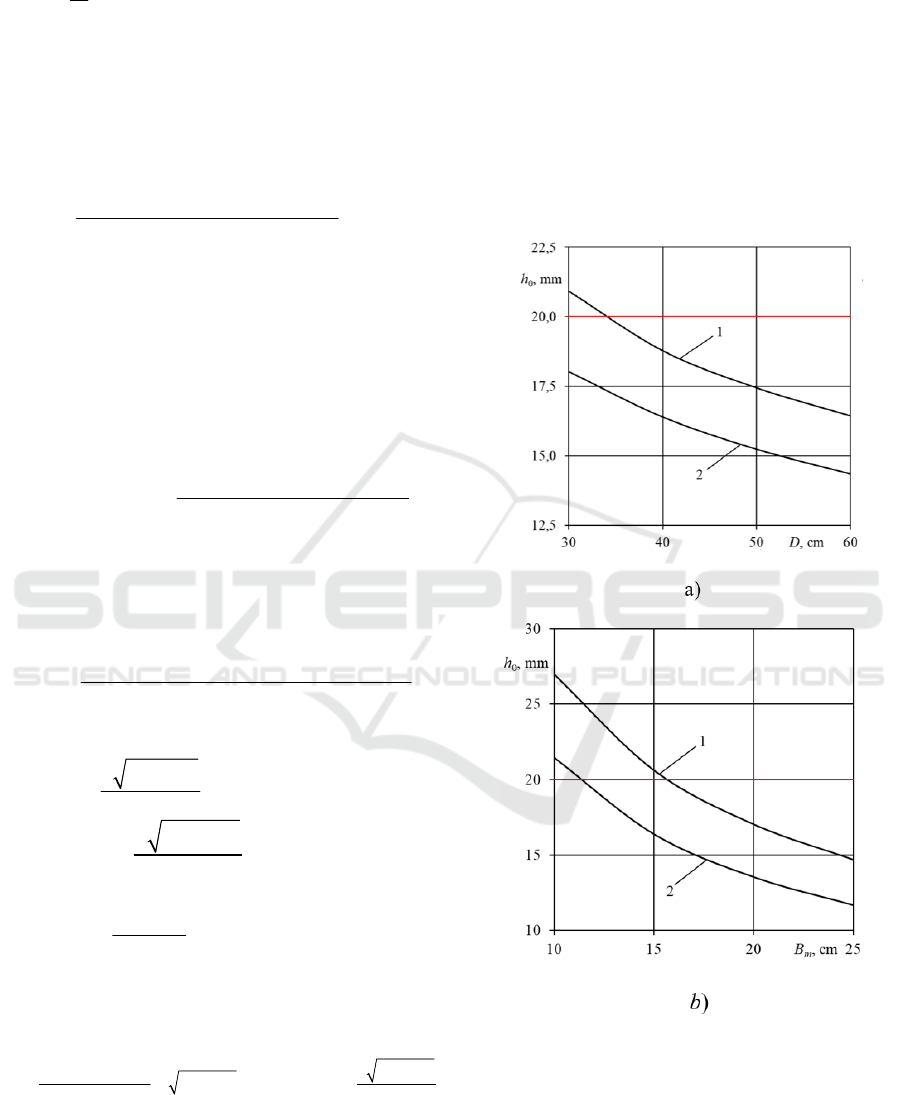

1988) assuming V= for speeds of 6 and 9 km/h using

the numerical solution method according to the

expression (13), graphs of the change in the depth of

the plough support wheel into the soil h

0

were

constructed depending on D and B

m

(Fig. 2). It can be

seen from the obtained data that as the width and

diameter of the wheel width increased, the depth of

its immersion in the soil decreased, and therefore, the

actual working depth was closer to the specified

working depth.

Figure 2: 1, 2 - the speed of movement is 6 and 9 km/h,

respectively Graphs of the change of the depth of the plough

support wheel into the soil depending on its diameter (a)

and the width of the bridge (b).

2

D

dl d

α

=

dN

Z

dN

X

dN

Z

dN

Z

Q

2

00

0

2

sin

D

hh

D

α

−

=

2

00

0

2

arcsin

Dh h

D

α

−

=

0

0

2

cos

D

h

D

α

−

=

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

118

3 RESULTS AND DISCUSSION

The increase in speed from 6 km/h to 9 km/h also

reduced the ground contact depth of the main wheel.

According to existing agrotechnical requirements, the

deviation of plowing depth from the specified should

not exceed 2 cm. For this, the graphs presented in Fig.

2 show that the diameter of the plough support wheel

should not be less than 35 cm and the width of its

width should not be less than 16 cm.

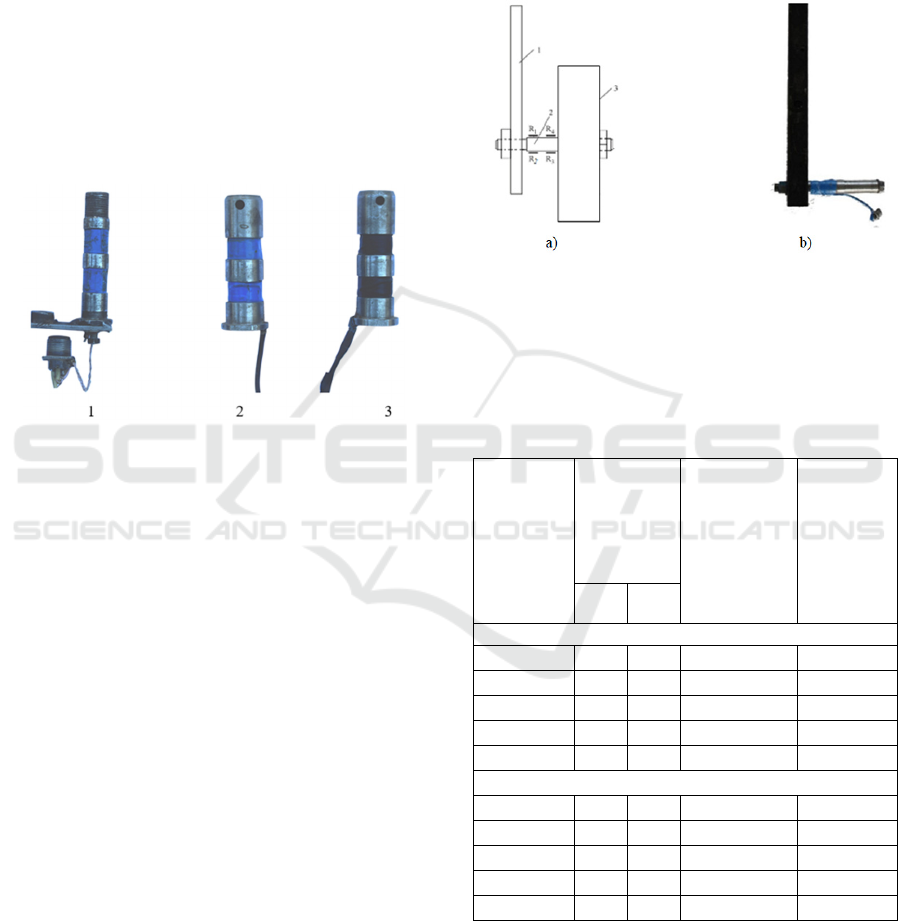

Experimental studies were conducted in order to

verify the results obtained in the conducted

theoretical studies and to determine the influence of

the width and diameter of the plough support wheel

on its performance. In order to conduct experimental

studies, a three- mouldboard suspension plough was

developed in the "Soil Cultivation Machines"

laboratory of SRIAM to be aggregated with wheeled

tractors of class 3-4 (Fig. 3).

Figure 3: Overview of suspension plug. Frame 1; 2

nd

suspension device; 3

rd

corps; 4

th

base wheel

Experimental studies were carried out in agro

fund specially prepared to create the same working

conditions throughout the field, i.e. first plowed, then

leveled and thoroughly irrigated. The soil of the field

where the experiments were conducted is gray soil of

medium-heavy, slightly mechanical composition, and

underground water is located at a depth of 10-12 m.

Before conducting the experiments, the moisture,

density and hardness of the soil in layers of 0-10, 10-

20, 20-30 and 30-40 cm was defined according to

GOST 20915-11 “Testing of agricultural machinery.

Methods for determining test conditions” (GOST

20915-11, 2013). According to the obtained results,

in the 0-10-20, 20-30 and 30-40 cm layers, they are

15.7, 17.3, 18.1 and 18.9 percent, respectively, and

their hardness is 1.57, 3.19, 3.45 and 4.21 MPa and

the density was 1.33, 1.42, 1.57 and 1.61 g/cm

3

.

For conducting experimental studies, base wheels

with a diameter and a width of 5 cm at an interval of

30 cm to 50 cm and 10 cm to 30 cm were prepared

(Figures 4 and 5).

Figure 4: Support wheels with a diameter of 30 (a), 35 (b),

40 (v), 45 (g) and 50 (e) cm.

In the experiments, the plowing depth is 35 cm,

the vertical distance from the base plane of the

suspension plough to the lower suspension points and

the vertical distance between its upper and lower

suspension points are 80 cm and 90 cm, respectively,

the longitudinal distance from the edge of its first

mouldboard share to the axis of the supporting wheel

is 80 cm, and the aggregate speed of movement was

set at 6 and 9 km/h. The driving depth and its mean

square deviation, as well as the traction resistance of

the suspension plough and the vertical pressure force

exerted by the support wheel on the soil were taken

as the main indicators.

Figure 5: Support wheels with a diameter of 10 (a), 15 (b),

20 (v), 25 (g) and 30 (e) cm.

The Influence of Suspension Plough Support Wheel Diameter and Width on Its Performance Indicators

119

Plowing depth UzDSt 3355:2018 "Testing of

agricultural machinery. Machines and weapons for

deep tillage. Test program and methods" (GOST

20915-11, 2013). In this case, the plowing depth was

determined after each pass of the plough along the

edge formed by the final casing using an edge gauge.

For each option, 50 measurements were made in four

repetitions (twice in this direction, twice in this

direction). The measurement error was 0.5 cm.

Plough tensile strength UzDSt 3193:2017

"Testing of agricultural machinery. It was determined

using tensometric fingers (Fig. 6) according to the

method of energy assessment of machines"

(Dospekhov, 1979; O‘zDSt 3193, 2017; O‘zDSt

3355, 2018; Alimova et al., 2023).

Figure 6: General view of the fingers.1

st

upper index finger;

2, 3 lower right and left tensofingers.

The vertical compressive force applied to the soil

by the support wheel was also determined using the

tensometry method. In this case, the axle with the

strain gauges glued was used (Fig. 7). During

tensometry, IP-238M measuring equipment was used

to record signals from strain gauges. Before and after

the experiments, the tension fingers and the bullet to

which the strain gauges were glued were calibrated.

The data obtained in the experimental studies were

processed by the methods of mathematical statistics

(O‘zDSt 3193, 2017) and the arithmetic mean values

and mean square deviations of the indicators were

determined. In experimental studies, the plough was

aggregated with a New Holland T 7060 tractor. The

results obtained in experimental studies are presented

in Tables 1 and 2.

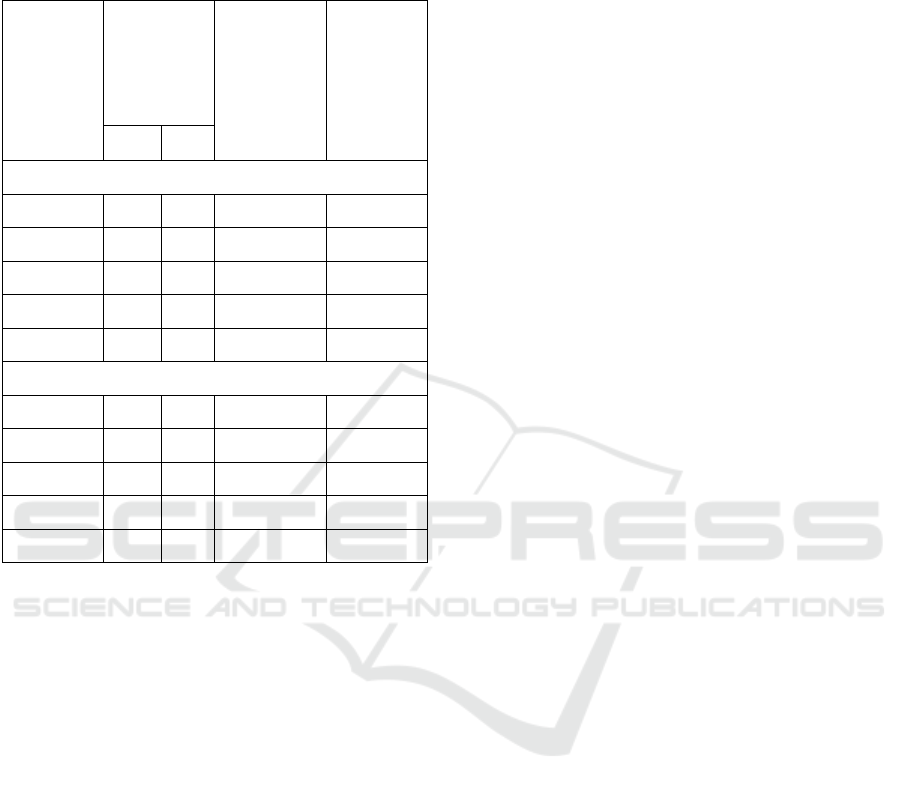

From the results presented in Table 1, it can be

seen that the plowing depth and its mean square

deviation decreased with the increase in the diameter

of the plough support wheel. When the diameter of

the base wheel increased from 30 cm to 50 cm, the

plowing depth decreased from 35.8 cm to 35.1 cm and

from 35.7 cm to 34.9 cm at speeds of 6 and 8 km/h,

respectively, its root mean square deviation ±

Decreased from 1.24 cm to ± 1.06 cm and from ± 1.29

cm to ± 1.07 cm. The reason for this is that an increase

in the diameter of the support wheel leads to an

increase in the surface of its interaction with the soil,

and as a result, the depth of immersion of the support

wheel into the soil decreases. This causes the plowing

depth and its root mean square deviation to decrease

and match the target.

Figure 7: Tensometric axis installation scheme (a) and

general view (b) 1st column; 2

nd

strain gauge glued axis; 3

rd

base wheel.

Table 1: The plowing depth of the diameter of the

suspension plough support wheel and its root mean square

deviation, the vertical pressure force exerted by the support

wheel on the soil and its traction effect on resistance.

Diameter

of

suspension

plough

support

wheel, cm

Powing

depth and

its mean

square

deviation,

cm

Vertical

compressive

force exerted

by the

support

wheel on the

soil, kN

Pulling

resistance

of

suspension

plough,

kN

М

ўр

±σ

V=6km/h

30 35,8 1,24

3,73

28,7

35 35,5 1,13

3,62

28,1

40 35,3 1,10

3,54

27,7

45 35,2 1,07

3,49

27,2

50 35,1 1,06

3,41

26,9

V=8 km/h

30 35,7 1,29

3,67

29,4

35 35,4 1,21

3,54

28,7

40 35,2 1,14

3,48

28,1

45 35,1 1,09

3,39

27,8

50 34,9 1,07

3,31

27,5

According to the results of the experimental

research, it should be noted that when the diameter of

the base wheel increased from 30 cm to 40 cm, the

mean square deviation of the plowing depth at both

speeds decreased rapidly, and when it increased from

40 cm to 50 cm, its rate of decrease decreased.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

120

Table 2: The plowing depth and root mean square deviation

of the width of the suspension plough support wheel, the

vertical compressive force exerted by the support wheel on

the soil and its effect on traction resistance.

The width

of the axle

of the

suspension

plough

support

wheel, cm

Plowing

depth and

its mean

square

deviation,

cm

The vertical

compressive

force of the

support

wheel is

applied to

the soil, kN

Pulling

resistance

of

suspension

plough,

kN

М

ўр

±σ

V=6 km/h

10 37,1 1,51 3,85 31,1

15 35,9 1,33 3,69 28,9

20 35,4 1,15 3,52 27,9

25 34,9 1,05 3,42 27,1

30 34,5 1,02 3,29 26,5

V=9 km/h

10 36,8 1,58 3,73 31,9

15 35,9 1,39 3,59 29,5

20 35,1 1,17 3,43 28,7

25 34,7 1,10 3,32 28,3

30 34,3 1,06 3,18 27,8

For example, when the diameter of the base wheel

increased from 30 cm to 40 cm, the mean square

deviation of the plowing depth decreased by ± 0.11-

0.17 cm, and when it increased from 40 cm to 50 cm,

it decreased by ± 0.03-0.05 cm. This indicates that the

diameter of the support wheel should be at least 40

cm in order for the plough to work stably at the

specified depth.

An increase in the diameter of the suspension

plough support wheel from 30 cm to 50 cm reduces

its traction resistance from 28.7 kN to 26.9 kN at a

speed of 6 km/h and from 29.4 kN to 27.5 kN at a

speed of 8 km/h came This is due to the fact that the

plowing depth decreases with the increase in

diameter.

An increase in the diameter of the suspension

plough support wheel from 30 cm to 50 cm led to a

decrease in the vertical pressure force exerted by it on

the soil, that is, this force decreased from 3.73 kN at

a speed of 6 km/h to 3.41 kN at a speed of 8 km/h.

Reduced from 3.67 kN to 3.31 kN. This is due to the

reduction of the vertical distance between the base

wheel axis and the instantaneous center of rotation of

the plough.

At the diameter values of 35-45 cm, the pressure

force applied to the soil by the support wheel was at

the required level (3.5 kN).

From the results presented in Table 2, it can be

seen that the plough depth and its mean square

deviation decreased with the increase in the width of

the support wheel hub. When the wheelbase width

increased from 10 cm to 30 cm, the plowing depth

decreased from 37.1 cm to 34.5 cm and from 36.8 cm

to 34.3 cm at speeds of 6 and 9 km/h, respectively.

Decreased from ± 1.51 cm to ± 1.02 cm and from ±

1.58 cm to ± 1.06 cm. However, the rates of reduction

of plowing depth and root mean square deviation

decreased with increasing wheelbase width. For

example, at a speed of 6 km/h, when the width of the

support wheel hub increases from 10 cm to 20 cm, the

plowing depth decreases by 1.7 cm and its root mean

square deviation decreases by ± 0.36 cm, when it

increases from 20 cm to 30 cm, these indicators are

suitable were 0.9 cm and ± 0.13 cm, respectively. At

a speed of 9 km/h, these changes were 1.7 cm and ±

0.41 cm and 0.8 cm and ± 0.11 cm, respectively.

When the width of the wheel hub is less than 15

cm, the suspension plough is sunk deeper than

specified, that is, the plowing depth is greater than the

specified 35 cm, and when it is greater than 20 cm,

the plug is sunk to the specified depth.

An increase in the width of the wheelbase from 10

cm to 30 cm led to a decrease in the traction resistance

of the suspension plough, that is, the traction

resistance of the plough decreased from 31.1 kN to

26.5 kN at a speed of 6 km/h, to 31.9 at a speed of 9

km/h. reduced from kN to 27.8 kN. This is explained

by the fact that an increase in the width of the wheel

hub causes a decrease in the depth of its immersion in

the ground.

An increase in the width of the suspension plough

support wheel from 10 cm to 30 cm has led to a

decrease in the vertical pressure force exerted by it on

the soil, that is, this force is from 3.85 kN at a speed

of 6 km/h to 3.29 kN at a speed of 9 km/h and

decreased from 3.73 kN to 3.18 kN. This can be

explained by the fact that an increase in the width of

the support wheelbase has led to a decrease in the

plowing depth. In the range of 15-25 cm values

of the base wheel axle, the pressure force exerted by

it on the soil was at the required level (3.5 kN).

Therefore, in order for the suspension plough to

work stably at the specified depth and for the vertical

pressure force applied to the soil by the support wheel

to be at the required level, its width should be at least

20 cm. The results obtained in experimental studies

showed that the results obtained in theoretical studies

are correct.

The Influence of Suspension Plough Support Wheel Diameter and Width on Its Performance Indicators

121

4 CONCLUSIONS

On the basis of the above, it is possible to draw the

following conclusion: in order for the suspension

plow to work stably at the specified depth, the

diameter of the supporting wheel and the width of the

beam should be at least 40 cm and 20 cm,

respectively.

REFERENCES

Alimova, F.A., Saidova, M.T., & Primkulov, B.Sh., 2023.

Pneumatic feed mechanism for accurate sowing of bare

cotton seeds. IOP Conference Series: Earth and

Environmental Science, 1231(1), 012012.

https://doi.org/10.1088/1755-1315/1231/1/012012.

Djurayev, A.D., Alimukhamedov, Sh.P., Turdaliev, V.M.,

Sheraliev, I.I., & Sherboev, M., 2022. Vibrational

motion of soil-compaction tools in agriculture. Russian

Engineering Research, 42, 969–971.

https://doi.org/10.3103/S1068798X22100094.

Dospekhov, B.A., 1979. Methodology of field experience.

Moscow: Kolos, p. 416.

GOST 20915-11, 2013. Testing of agricultural machinery.

Methods for determining test conditions. Moscow:

Standartinform, p. 23.

Klenin, N.I. & Sakun, V.A., 1994. Agricultural and

reclamation machines. Moscow: Kolos, p. 751.

Mamatov, F.M. 2007. Wood roasting machine. Tashkent:

Fan, p. 338.

Mukhamedov, Z., Turdaliev, V.M. & Kosimov, A.A., 2020.

Kinematic nonuniformity of the rotation of a toothed

belt transmission with a composite pulley. Russian

Engineering Research, 40, 705–709.

https://doi.org/10.3103/S1068798X20090130.

Norchayev, D.R., Xaliqulov, M.A., Shermuxamedov, X.P.,

& Ibragimova, G.N., 2021. Test results of the new Root

Crop Harvester. IOP Conference Series: Earth and

Environmental Science, 868(1), 012059.

https://doi.org/10.1088/1755-1315/868/1/012059.

Norchayev, D.R., Xaliqulov, M.A., Turkmenov, X.I.,

Shermuxamedov, X.P., & Ibragimova, G.N., 2022.

Acceptable solutions for harvesting root crops in the

soil climate of the Republic of Uzbekistan. IOP

Conference Series: Earth and Environmental Science,

1076(1), 012029. https://doi.org/10.1088/1755-

1315/1076/1/012029 .

O‘zDSt 3193: 2017. The countryside is covered with

machinery. He is a source of energy.” Tashkent, p. 21.

O‘zDSt 3355: 2018. The countryside is covered with

machinery. A machine for deep drawing of pipes and

pipelines. Synovlarning guidelines and methodology.

Tashkent, p. 70.

Sablikov, M.V., 1968. Agricultural machines. Part 2.

Fundamentals of theory and technological calculation.

Moscow: Kolos, p. 296.

Saidova, M., Tursunbaev, S., Boltaeva, M., & Isakulova, N.,

2024. Comparison of pneumatic sowing machines by

the number of seeds in the slots of the discs and the

distance between the slots. BIO Web of Conferences,

105, 01004.

https://doi.org/10.1051/bioconf/202410501004.

Sharov, N.M., 1964. On the uniformity of the stroke depth

of a mounted plow with an increase in the speed of

movement of the unit. Proceedings of the MIISP, 25-

37.

Shiryaev, A.M., 1988. Near-sowing soil compaction.

Mechanization of agriculture. Moscow, 3, p. 33-35.

Sineokov, G.N. & Panov, I.M., 1977. Theory and

calculation of tillage machines. Moscow:

Mashinostroenie, p. 328.

Tukhtakuziev, A., & Rasuljonov, A.R., 2020a. Ensuring the

stability of the processing depth of suspended soil

mounted machines. IOP Conference Series: Earth and

Environmental Science, 614(1), 012156.

https://doi.org/10.1088/1755-1315/614/1/012156 .

Tukhtakuziev, A., & Rasuljonov, A., 2020b. Results of

laboratory and field experiments on an experimental

mounted chisel cultivator. Effectiveness of Innovative

Technological and Technical and Social and Water

Management, 112-115.

Tukhtakuziev, A., Rasuljonov, A.R., Turkmenov, H.I.,

Irgashev, A.A., & Barlibaev, S., 2023. Ensuring the

stability of the suspended chisel-cultivator processing

depth. E3S Web of Conferences, 390, 01038.

https://doi.org/10.1051/e3sconf/202339001038.

Turdaliev, V.M., Alimukhamedov, S.P., Mukhamedov, Z.,

Komilov, S.R., 2022. Measuring the variable center

distance in a chain transmission. Russian Engineering

Research, 42 (Suppl 1), 57–59.

https://doi.org/10.3103/S1068798X23020259.

Umurzakov, A.K., Turdaliev, V.M. & Khakimov, U.A.,

2022. Low-power hydraulic motor for mobile

micropower stations and pumps. Russian Engineering

Research, 42(8), 791–793.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

122