Regarding the Creation of a Vertical Spindle Cotton Picking Machine

for Harvesting Cotton in a Single Pass

Masharif Khojiyev

a

, Dilfuza Kambarova

b

and Mubarakhan Atadjanova

c

Tashkent State Technical University, 100095, University str. 2, Tashkent, Uzbekistan

Keywords: Planting Machine, Automation, Seedlings.

Abstract: In Uzbekistan, the climatic conditions do not allow cotton to open up more than 80-90%, so cotton is harvested

when it is 50-60% open, even when the field yield is 25-30 c/ha. This is done using horizontal spindle

machines (HSM). As a result, harvesting costs increase significantly and the quality of the harvested cotton

fiber deteriorates. To address this issue, it is proposed to install a six-drum (triple-processing) harvesting

apparatus on the MKh-1.8 model machine at TSTU. This setup allows for harvesting cotton when the bolls

are 85-90% open and ensures that 93-94% of the cotton yield can be collected. In this process, the cotton left

on the ground does not exceed 3%, and the contamination of the cotton in the hopper does not exceed 8%.

1 INTRODUCTION

It is well known that cotton raw material production

is a labor-intensive process. For raw material

production, in the autumn, the fields are plowed to a

depth of 35-40 cm with a two-layer plow, and the

upper layer is leveled. Considering that 70% of the

arable land in our republic is saline, in the autumn or

early spring, a special device (chelp) is prepared to

wash away the salinity of the land, and these areas are

irrigated 2-4 times to flush out the salt.

2 MATERIALS AND METHODS

After the salinity has been washed out, the fields are

leveled 4-6 days later, and then they are loosened to a

depth of 20-25 cm using ChKU-4A chisel-cultivators.

If necessary, based on agronomic requirements, the

fields are fertilized in strips to a depth of 15-20 cm

with fertilizers such as nitrogen, phosphorus,

potassium, and organic or other microelement

fertilizers.

Depending on the climatic conditions and the

specific characteristics of each zone, cotton seeds are

sown into the soil using tractor-seeder units. After the

a

https://orcid.org/0009-0003-3236-8977

b

https://orcid.org/0000-0003-0389-5930

c

https://orcid.org/0000-0002-9753-816X

cotton seedlings, which emerge from the sown seeds,

develop two to three leaves, the furrows are prepared,

and the first irrigation is applied to the cotton rows.

Subsequently, the cotton rows undergo several

mechanized treatments, including soil loosening,

fertilization, furrow preparation, irrigation, and

weeding, as well as pest control and other necessary

operations.

After 2-3 of the cotton bolls have opened,

defoliation of the cotton fields is carried out.

Currently, after the cotton has ripened and 50-50% of

the bolls have opened, manual harvesting of the

cotton starts in approximately 70% of the fields.

Before mechanical cotton harvesters collect the raw

cotton, the cotton plants undergo defoliation,

meaning that the green leaves are chemically treated

to be removed at a rate of 50-70%. The leaf drop

occurs within 3 days.

Until the year 2000, according to cotton

cultivation technology (GOST 22587-91) (Sablikov,

1985; Shpolyanskiy, 1985; Matchanov, 2010; Rizaev,

2017), the first machine harvest was carried out after

75-80% of the cotton leaves had fallen due to

defoliation, and when 55-60% or more of the bolls

had opened.

The second machine harvest was conducted 10-15

days after the first one, when an additional 20-25% of

112

Khojiyev, M., Kambarova, D. and Atadjanova, M.

Regarding the Creation of a Vertical Spindle Cotton Picking Machine for Harvesting Cotton in a Single Pass.

DOI: 10.5220/0014071600004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 112-115

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

the bolls had ripened and opened. In some regions, a

third machine harvest was also performed. After this,

the leftover cotton on the ground and on the cotton

stalks was collected by harvesters. Due to the fact that

this two-stage technology led to longer harvesting

periods and increased harvesting costs, it is no longer

commonly used by modern farming operations.

Currently, in farming operations, machine

harvesting is conducted when 80-90% of the cotton

bolls are open. An analysis of the technological

process and agronomic indicators of the MХ-1.8

vertical spindle cotton harvesting machines (VSH

PТМ) reveals that the harvesting efficiency does not

exceed 80-85%. Additionally, cotton loss on the

ground is about 4-5%, and contamination of the

cotton in the bunker reaches 10-11%. These

agronomic indicators result in a cotton price that does

not meet the satisfaction of farmers and reduces the

effectiveness of the MХ-1.8 vertical spindle

machines. Consequently, farmers use the MХ-1.8

machines only in certain situations or when no better

alternatives are available (GOST 22587-91),

(Sablikov, 1985; Shpolyanskiy, 1985; Matchanov,

2010; Rizaev, 2017; Matchanov, 2018; Matchanov,

2023; Matchanov, 2024).

Due to the increasing cultivation of fast-ripening

and high-yielding cotton varieties in Uzbekistan,

horizontal spindle cotton harvesting machines (from

the USA and China) with high efficiency and

productivity have been widely used in the country's

farming operations and cotton clusters. These

machines are employed in fields where cotton bolls

are 80-90% or more open. When harvesting cotton

with these machines, the harvesting efficiency

indicators can reach up to 90-95% (Matchanov, 2010;

Matchanov, 2018; Matchanov, 2023; Matchanov,

2024).

Because of climatic conditions and weather

variations in Uzbekistan, cotton bolls often do not

open 80-90% of the time every year. Consequently,

even when cotton bolls are 50-60% open and the yield

in the field is 25-30 centners per hectare, harvesting

with horizontal spindle machines (HSM) has proven

to be ineffective based on current practical

experience. This is because, in such cases, harvesting

costs increase sharply and the quality of the harvested

cotton deteriorates. Specifically, HSMs collect cotton

with bolls that are not fully open and ripe.

Additionally, the cost of cotton harvested by HSMs is

significantly higher compared to vertical spindle

machines (VSM), making farmers uninterested in

using these machines.

3 RESULTS AND DISCUSSION

In the 1960s and 1970s, the high-efficiency vertical

spindle cotton harvesting machines (VSH) were

developed through scientific research and

experimental design work carried out by the staff of

the Institute of Mechanics and Seismic Stability of

Structures of the Academy of Sciences of Uzbekistan

in collaboration with the "Toshselmash" factory

engineers. The ANTX-1.2 and ANTX-1.8 models of

VSH machines created during this period continue to

fully meet the demands of modern farming

operations, as evidenced by practical experience.

Therefore, recognizing the scientific significance of

these developments is considered an important task

(Matchanov, 2010; Rizaev, 2017).

Between 1975 and 1983, based on the ANTX-1.2

and ANTX-1.8 models of vertical spindle cotton

harvesting machines (VSH), a new model, the 3XVN-

1.8 "Dostlik," was developed in collaboration with

the staff of the "Toshselmash" factory and the

Tashkent Institute of Irrigation and Melioration

(TIQHM). State tests confirmed that this machine

could achieve up to 93-94% harvesting efficiency for

cotton bolls that were 85-90% open in a single pass.

The machine featured a cotton harvesting

apparatus with a three-row spindle drum (6 spindles

in a single row) and an automatic adjustment

mechanism for the working gap. It was produced on

an industrial scale at the "Toshselmash" factory and

passed state testing. After addressing some

constructive flaws identified during the state trials,

the machine was recommended for implementation in

agricultural practice. However, the main drawback

noted in the test report was that the contamination

level of the cotton in the machine's bunker was 2-3%

higher compared to serially produced VSH models

(Matchanov, 2010; Rizaev, 2017; Matchanov, 2018;

Karimov et al., 2019; Matchanov, 2023; Matchanov,

2024).

At TSTU scientific researchs was conducted to

address the shortcomings of the previously mentioned

cotton harvesting apparatus and to improve its design.

The following recommendations were developed

based on the results of this research (Karimov et al.,

2019; Khajiev et al., 2024):

1. To achieve a picking efficiency of 93-94%, it is

necessary to install drums with a diameter of 216 mm

(along the spindle rotation axis) on the new picking

apparatus, along with 10 spindles (with a spindle

spacing of 67.8 mm on the drum), and to place pairs

of drums that provide triple processing of the cotton

(6 drums in a single row of the picking apparatus).

Regarding the Creation of a Vertical Spindle Cotton Picking Machine for Harvesting Cotton in a Single Pass

113

2. To increase the energy efficiency of the

machine, reduce the coefficient of spindle drum

slippage to between 1.3 and 1.35.

3. Install a simplified mechanism on the VSH

PTM picking apparatus that automatically adjusts the

working tension based on the field's

agroenvironment.

4. To ensure even loading of each pair of drums

and reduce contamination of the cotton in the hopper,

install the drums on the picking apparatus with

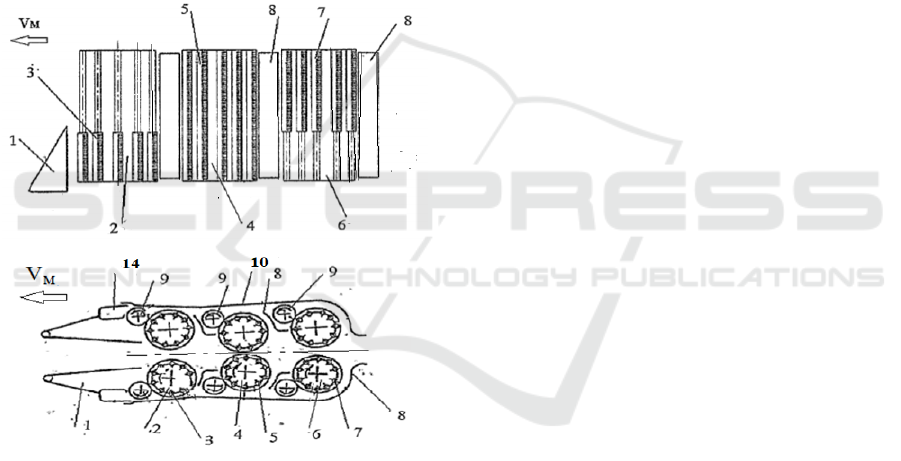

adjustable height (see Figure 1, positions 2, 4, and 6

as shown).

5. Install spiral-shaped cotton separators, as

proposed by Academician Sadriddinov A.S., on the

picking apparatus.

These recommendations aim to enhance the

performance, efficiency, and quality of the cotton

harvesting process.

Figure 1: Diagram of the cotton picking apparatus designed

to harvest 93-94% of cotton with 85-90% of the bolls

opened in a single pass:1 - Elevation frame; 2 - First pair of

drums (working height from the ground: 220 mm); 3 -

Spindles (working height from the ground: 220 mm); 4 -

Second pair of drums (working height: 615 mm); 5 -

Spindles (working height: 615 mm); 6 - Third pair of drums

(working height from the top: 400 mm); 7 - Spindles

(working height from the top: 400 mm); 8 - Shield; 9 -

Spiral-shaped cotton separator; 10 - Shield; 11 - Collection

chamber.

4 CONCLUSIONS

1. At Tashkent state technikal university, a vertical

spindle cotton harvesting machine (VSH) with

three pairs of drums (6 drums in a single row)

was designed, which can achieve up to 93-94%

harvesting efficiency when 85-90% of the cotton

bolls are open. The main parameters and design

of this harvesting apparatus were developed

based on these capabilities.

2. For use in Uzbekistan's farming operations, it is

recommended to install a vertical spindle

harvesting apparatus with three pairs of drums (6

drums in a single row) on the MХ-1.8 machine.

This apparatus provides triple processing of open

cotton bolls.

3. Currently, the complex and expensive horizontal

spindle cotton harvesting machines produced

abroad (in the USA and China), which

significantly increase the cost of cotton

harvesting and severely degrade the quality of the

harvested cotton in our natural climate and

weather conditions, should be replaced. It is

recommended to switch to the MХ-1.8 VSH with

the triple-processing drum apparatus (6 drums in

a single row).

4. Implementing the recommended MХ-1.8 VSH

with a three-pair drum harvesting apparatus in

farming practices will improve the economic

efficiency of the farms and enhance the

effectiveness of the VSH machines.

REFERENCES

GOST 22587-91. Cotton Harvesting Machines. General

Technical Conditions.

Karimov, V.U., Karimov, A.Y., 2019. State and Prospects

of Cotton Growing Mechanization. Namangan, 159.

Khajiev, M.Kh., Karimov, V.U., 2024. Cotton Harvesting

Apparatus. Patent Description for Useful Model

UZFAP 02366, XPK8 A 01D 46/14 (2006.01).

December 29, 2023. Bulletin No. 12: 4.

Matchanov, R.D., 2010. Cotton Harvesting Machines.

Tashkent, 273.

Matchanov, R.D., 2018. Pages of Life. Tashkent: Fan

Publishing House of the Academy of Sciences of the

Republic of Uzbekistan, 280.

Matchanov, R.D., 2023. Development of a Cotton

Harvesting Machine for Selective Cotton Picking.

Tashkent: Fan Publishing House of the Academy of

Sciences of the Republic of Uzbekistan, 191.

Matchanov, R.D., 2024. Chronicle of Domestic

Agricultural Machinery. Tashkent: Zamin Nashr, 303.

Rizaev, A.A., 2017. Study and Creation of High-Efficiency

Working Organs for Cotton Harvesting Apparatus.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

114

Tashkent: Fan Publishing House of the Academy of

Sciences of the Republic of Uzbekistan, 169.

Sablikov, M.V., 1985. Cotton Harvesting Machines.

Moscow: Mashinostroenie, 152.

Shpolyanskiy, D.M., 1985. Technological Foundations of

Working Organs Parameters and Schemes of Cotton

Harvesting Machines. Tashkent: Mehnat, 255.

Regarding the Creation of a Vertical Spindle Cotton Picking Machine for Harvesting Cotton in a Single Pass

115