Optimization of Bush-Guiding Efficiency in Vertical-Spindle Cotton

Pickers Through Elliptical Drum Design: A Simulation-Based Study

Shavkat Ravutov

1a

, Khushnud Yakubov

2b

, Umidjon Rajapbaev

1,3 c

and Shahzod Komilov

1d

1

Tashkent State Technical University, 100095, Tashkent, Uzbekistan

2

Urgench State University, Kh. Alimdjan Street, Urgench, 220100, Uzbekistan

3

Tashkent Institute of Irrigation and Agriculture Mechanization Engineers', National Research University,

Tashkent, Uzbekistan

Keywords: Elliptical Drum, Cotton Harvester, Spindle Efficiency.

Abstract. This work is dedicated to studying the influence of the design features of the elliptical drum of a vertical-

spindle cotton picker machine on the efficiency of the spindles. The interaction of individual pressing sectors

of the new drum with cotton bushes in the working gap of the cotton picker is investigated. The "GeoGebra"

dynamic mathematics software, which is open-source, was used to simulate the movement of the spindles and

the pressing sectors of the elliptical drum. The software allows virtual manipulation of the geometric

dimensions of the drum's structural elements. By simulating the movement of the spindles and the pressing

sectors of the elliptical drum, a comparison was made of the impact characteristics on the cotton bushes by

the spindles and the pressing sectors of both the elliptical and standard drums. A computer graphical method

was developed to assess the effectiveness of the pressing sector's impact on the cotton bushes as they are

introduced into the working chamber. It was found that by controlling the geometric parameters of the pressing

sector and other dimensions of the elliptical drum, the bush-guiding capability of the vertical-spindle cotton

picker machine can be significantly improved.

1 INTRODUCTION

In Central Asia, the cotton harvesting period is

extended by at least 15-20 days, making the

organization of a one-time harvest of this valuable

raw material more challenging. This extended period

complicates the effective use of high-performance

horizontal-spindle cotton harvesting machines (HS

CHM), which, due to the high activity of their

working parts, collect cotton from both mature and

immature bolls, thereby reducing the quality of the

harvested raw material (Yakubov et al., 2024a).

Conversely, vertical-spindle cotton harvesting

machines (VS CHM) selectively collect cotton only

from mature bolls, providing an advantage in terms of

quality. However, the VS CHM, which are currently

produced in small batches in the Republic of

Uzbekistan, struggle to compete with HS CHM in

a

https://orcd.org/0009-0006-3486-1548

b

https://orcd.org/0009-0009-8171-9917

c

https://orcd.org/0009-0002-4088-1562

d

https://orcd.org/0009-0009-7854-9216

terms of collection completeness and productivity,

particularly in high-yield scenarios (more than 35-45

centners per hectare) (Yakubov et al., 2024b).

Extensive theoretical and experimental studies have

identified that the primary reason for the low

collection completeness of VS CHM is the limited

contact area of the spindles with the cotton plants and

the insufficient number of spindles simultaneously

engaging with the cotton bolls during harvesting

(Rzaev, 2017; Ravutov, 2019).

Another issue affecting the efficiency of VS CHM

is the steep angle at which cotton plants enter the

working chamber, which causes an accumulation of

plant mass in front of the working slot. This

accumulation complicates the even distribution and

proper orientation of the cotton bolls on the spindles

within the impact zone (Ravutov, 2019; Turanov et

al., 2021a). According to the current technological

94

Ravutov, S., Yakubov, K., Rajapbaev, U. and Komilov, S.

Optimization of Bush-Guiding Efficiency in Vertical-Spindle Cotton Pickers Through Elliptical Drum Design: A Simulation-Based Study.

DOI: 10.5220/0014067600004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 94-98

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

scheme of the VS CHM, as the machine moves along

the cotton rows, the spindle drums—installed in pairs

on the machine—are supposed to pull the plants into

the working slot in a vertical position. However, this

does not occur as expected because the spindles in the

working zone rotate in the opposite direction relative

to the drum, preventing the plants from entering the

working chamber vertically. Consequently, the plants

are forcibly introduced into the working chamber,

leading to crop losses and damage to the plant

elements before they fully enter the chamber. Many

studies focusing on the interaction between the

spindles and the cotton plants at the entry point into

the working chamber, as well as the issue of plant

mass accumulation in front of the machine's working

chamber, have attributed these problems to the design

features of VS CHM (Abdazimov et al., 2011;

Shoumarova et al., 2022; Shoumarova et al., 2023).

These studies suggest that addressing these issues

within the current serial designs of VS CHM is

challenging. To facilitate the entry of plants into the

working chamber in a vertical position, previous

research recommended altering the direction of

spindle rotation around their axes in this zone.

Specifically, friction drives of the spindles were

modified: a reverse rotation block replaced the direct

rotation belt in the collection zone, and a direct

rotation belt was installed in another section. Field

tests of this modified spindle drive yielded positive

results regarding plant entry into the working

chamber. However, due to a decrease in the angular

speed of the spindles by approximately 20% and

reduced spindle activity in this zone, no significant

improvement in collection completeness was

observed (Rzaev, 2017; Rizaev, 2022).

Further studies (Turanov et al., 2021b) proposed

incorporating a special plant guiding mechanism into

the drum design. This mechanism not only prevents

the plants from tilting forward during harvesting but

also ensures proper orientation of the cotton bolls on

the spindles in the working zone. While the modified

machine with the plant guiding mechanism showed

some improvement in agronomic performance, field

tests revealed frequent breakdowns of the

mechanism's elements.The aforementioned studies

indicate that the drawbacks of VS CHM can be

mitigated by using elliptical drums. Our previous

theoretical research on the kinematics and dynamics

of the elliptical drum has shown that employing

elliptical drums significantly enhances the machine's

agronomic performance and spindle efficiency, while

retaining all the benefits of the vertical-spindle cotton

harvesting principle (Ravutov et al., 2023a). Prior

research in this area primarily focused on the

structure and kinematics of the elliptical drum

mechanism, with some attention given to its

dynamics (Ravutov et al., 2023b; Bahadirov et al.,

2021). A comparative analysis of spindle activity

between the serial drum and the elliptical drum

revealed significant advantages in favor of the

elliptical drum (Ravutov et al., 2022; Ravutov et al.,

2023b).

2 MATERIALS AND METHODS

On the elliptical drum, each spindle is mounted on a

separate cassette and has a separate pressing sector,

which are also very important structural elements of

the drum. By changing the geometric parameters of

the links of the elliptical drum mechanism, the

kinematic mode of the spindle and the pressing sector

can be controlled (Bahadirov et al., 2021).

Another distinctive feature of the elliptical drum

is the variability of the spindle speed modes in the

working zones. Thus, when the spindle enters the

collection zone, it has one speed, and when it exits the

zone, it has another. Moreover, unlike the serial drum,

the relative speed of the spindle has an increasing

characteristic (Bahadirov et al., 2021). These and

other kinematic and structural features of the elliptical

drum complicate the analysis of the impact pattern of

the working parts on the cotton plants to some extent,

and it is convenient to obtain initial information

through direct observation of the working parts'

movements (Bahadirov et al., 2021; Ravutov et al.,

2023b). Traditionally, such observations were

conducted using high-speed filming of the process

(Sablikov, 1985). This method provides a real picture

of observations; however, it requires careful

preparation of experimental resources and significant

time and labor for processing the obtained results.

This study is dedicated to examining and

comparatively analyzing the interaction features of

the spindles and pressing sector of elliptical and serial

drums with elements of the cotton plant.

Recently, simulating the movement of mechanical

system parts using various computer programs has

become popular among designers of new machines.

The use of simulation programs often eliminates the

need for labor-intensive and costly experimental

studies (Amanov et al., 2019).

In the existing technology, the elements of cotton

plants first encounter the spindles and pressing

sectors of the drum, and they begin to interact. The

efficiency of the cotton harvesting apparatus largely

depends on the rationality of this interaction.

Optimization of Bush-Guiding Efficiency in Vertical-Spindle Cotton Pickers Through Elliptical Drum Design: A Simulation-Based Study

95

To simulate the movement of the spindles and the

pressing sector, we used the open-source dynamic

mathematics software "GeoGebra." This software

allows simulating the movement of the spindle and

the drum's pressing sector by adjusting the

dimensions of the ellipse's major and minor axes and

other structural elements. By changing the

dimensions of the axes, it is possible to achieve the

trajectory of the spindles along the circumference (the

circumference being a special case of the ellipse).

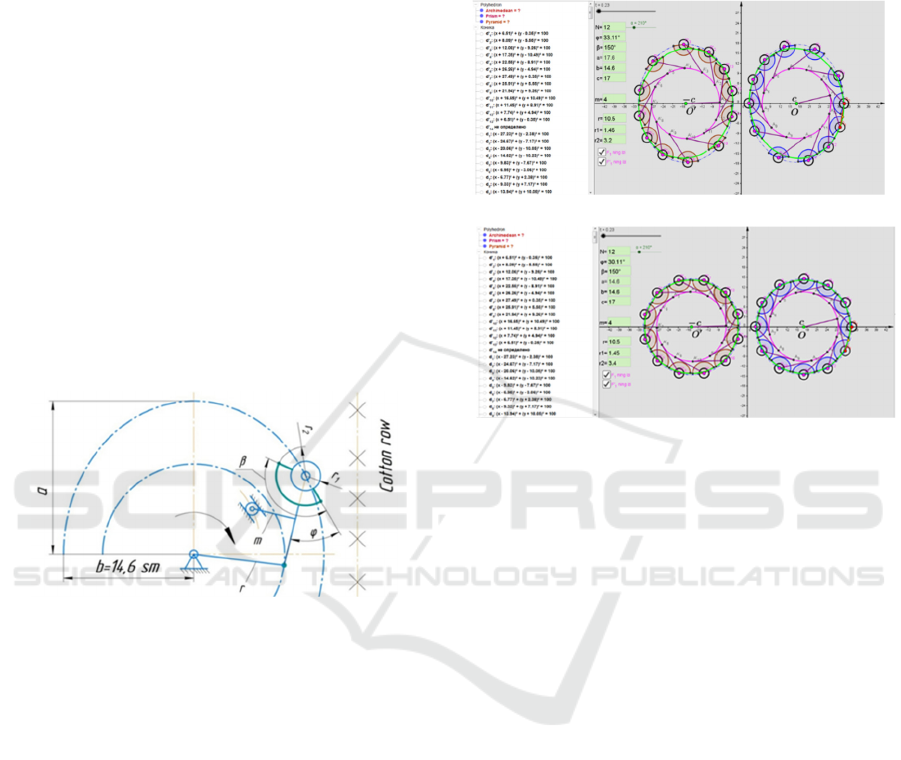

For convenience in comparing the movement

characteristics of the spindles and pressing sectors of

the serial and elliptical drums, as well as for reasons

of unifying the dimensions and construction of the

serial apparatus, the main dimensions of the elliptical

drum are identical to those of the serial drum: the

number of spindles for both drums is the same—

N=12 units; the minor axis of the ellipse b=14.6 cm,

equal to the radius of the serial drum (Rb=14,6 cm);

the radius of the spindle r1=1,45 cm; the radius of the

pressing sector r2=3,2 cm; the coverage angle of the

pressing sector β=1500 (Figure 1).

Figure 1: Parameters of the elliptical drum.

The GeoGebra program allows for varying the

dimensions of any link in the elliptical drum

mechanism and conducting visual observations of

changes in technologically important output

parameters. In our simulation experiment, only the

angle φ, determining the position of the pressing

sector, and the major axis a of the elliptical drum were

varied. By decreasing the size of a, a circle with a

radius equal to the radius of the serial drum can be

obtained, аmin=b=Rb=14,6 cm. To simulate the

orientation of the bolls to the working parts during the

process of introducing cotton plants into the working

chamber, primary attention was paid to observing the

movement characteristics of the spindle and the front

edge of the pressing sector (Figure 2).

As a result of the simulation, it can be noted that

when the spindle center moves along the ellipse, the

front edge of the pressing sector moves along a line

different from the ellipse (quasi-ellipse - shown in

Figure 2, green line). The size and shape of this line

depend on the angle φ and the major axis a. The

GeoGebra program allows simulating the effects of

the spindles and the pressing sector on the plants for

any possible values of these factors.

a)

b)

Figure 2: Simulation fragments of spindle and pressing

sector movement using GeoGebra dynamic mathematics

software; a - elliptical drum; b - drum view at

аmin=b=Rb=14,6 cm (serial drum); dashed line – trajectory

of spindle center movement; green line – trajectory of the

front edge of the pressing sector movement; numbers on the

left green background – controlled geometric parameters of

the mechanism.

From Figure 2a, it can be observed that with the

elliptical trajectory of the spindle in the entry part of

the working chamber, the front edges of the pressing

sectors form projections. After the central part of the

working chamber is passed, these projections move

away from the cotton row into the internal contour of

the drum. As the angle φ and the major axis a

increase, the size of the projection and the intensity of

its impact on the plant elements also increase. With a

rational choice of parameters φ and a, such activity of

the pressing sector can facilitate the pulling of cotton

plant elements during machine operation.

In contrast, on the serial drum, the trajectory of the

pressing sector edge forms a circle concentric with

the spindle center trajectory, meaning that the edges

of the pressing sector remain passive relative to the

cotton row. In this case, the shape and size of the

trajectory of the pressing sector edge depend only on

the angle φ (Figure 3b).

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

96

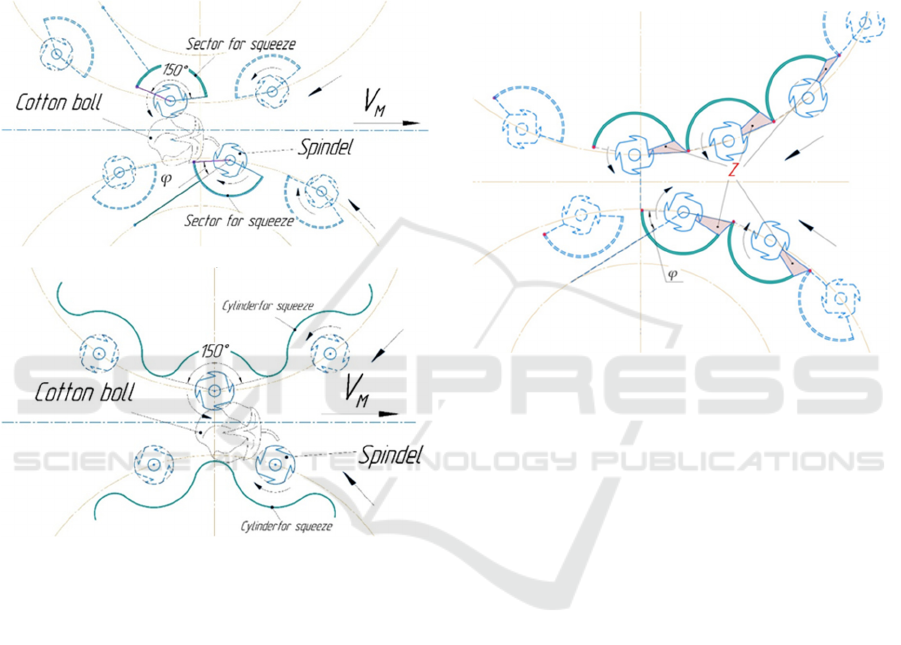

Figure 3 shows a schematic of the interaction

between the pressing sector of the elliptical drum and

a cotton boll. It is easy to see from the diagram that

the edge of the pressing sector of the right drum, with

its complex movement, tends to compress the boll

towards the spindle of the left drum, creating an

additional condition for the reliable penetration of the

spindle tooth into the cotton segment. The simulation

using GeoGebra clearly demonstrates this process.

a)

b)

Figure 3: Diagram of the impact of the pressing sector of

elliptical and serial drums on a cotton boll: a - Apparatus

with elliptical drums; b - Apparatus with serial drums.

3 RESULTS AND DISCUSSION

Based on the visual observation of the spindle and

pressing sector movement characteristics, it was

determined that the approach or departure of the

sector edge from the central line of the working slot

in the transverse direction is related to changes in the

angle φ and the major axis of the ellipse a.

Specifically, increasing the angle φ can increase the

extent of the projection of the front edges of the

pressing sector towards the working slot. In this case,

adjacent spindles and the front edge of the pressing

sector of opposite drums create a zigzag space (zones

Z) in the entry part of the working chamber, which

positively affects the process of introducing the

cotton plants into the working zone (Figure 4). A

similar effect can be achieved by increasing the major

axis a of the ellipse; however, unlike the parameter φ,

changing this parameter significantly impacts the

spindle speed modes, especially in transitional zones

(Yakubov et al., 2024). It should be noted that in the

serial apparatus, the effect of forming zones Z, which

would facilitate the introduction of plants into the

working chamber in a vertical position, is absent.

Figure 4: Formation of the zigzag space Z in the working

slot of the apparatus with elliptical drums.

4 CONCLUSIONS

1. Ensuring the introduction of cotton plants into

the working chamber in a vertical position within

the design of a serial vertical-spindle apparatus is

challenging. Introducing additional devices or

other structural changes into the drum design

may complicate the drum structure or reduce the

machine's performance.

2. The movement characteristics of the pressing

sectors of the elliptical drum, in terms of

interaction with cotton plants in the working

zone, are significantly advantageous compared to

the serial drum. The front edges of the pressing

sectors of the elliptical drum are more active in

the working chamber, and this phenomenon can

be utilized to facilitate the introduction of plants

into the working chamber in a vertical position.

3. The degree of activity of the pressing sector of

the elliptical drum depends on the size of the

major axis of the ellipse 𝑎 and the angle of the

pressing sector's position φ.

Optimization of Bush-Guiding Efficiency in Vertical-Spindle Cotton Pickers Through Elliptical Drum Design: A Simulation-Based Study

97

REFERENCES

Abdazimov, A.D., Sadriddinov, A.S., & Tulaev, A.R.,

2011. Phase discrete modeling of harvesting apparatus

processes during controlled movement of cotton bolls.

Tashkent: Izdat. Nas. Library of Uzbekistan named

after A. Navoi.

Amanov, A., Sembiring, J.P.B.A., & Amanov, T., 2019.

Experimental investigation on friction and wear

behavior of the vertical spindle and v-belt of a cotton

picker. Materials, 12(5), 773.

https://doi.org/10.3390/ma12050773.

Bahadirov, G., Ravutov, S., Abdukarimov, A., &

Toshmatov, E., 2021. Development of the methods of

kinematic analysis of elliptic drum of vertical-spindle

cotton harvester. IOP Conference Series: Materials

Science and Engineering, 1030(1), 012160.

https://doi.org/10.1088/1757-899X/1030/1/012160.

Ravutov, S.T., 2019. Problems of increasing the efficiency

of the vertical spindle cotton picker. Problems of

Mechanics, Tashkent, 4, 51-55.

Ravutov, Sh.T., Rizayev, A.A., & Rajapbaev, U.A., 2023a.

Enhancing cotton harvesting efficiency through

elliptical drum design: A comparative analysis of

spindle performance in the working area. IOP

Conference Series: Earth and Environmental Science,

1231, 012005. https://doi.org/10.1088/1755-

1315/1231/1/012005.

Ravutov, Sh.T., Ibragimov, G.I., Shokirov, S.Sh., &

Komilov, Sh.J., 2023b. Synthesis of the contour and

dimensions of the guiding channel of an elliptical drum

according to the operation conditions and kinematic

regimes. IOP Conference Series: Earth and

Environmental Science, 1284, 012015.

https://doi.org/10.1088/1755-1315/1284/1/012015.

Ravutov, Sh.T., Rizayev, A.A., & Rajapbaev, U.A., 2022.

On the issue of increasing the efficiency of the spindles

of a vertical-spindle cotton picker. IOP Conference

Series: Earth and Environmental Science, 1112,

012043. https://doi.org/10.1088/1755-

1315/1112/1/012043.

Rizaev, A.A., 2017. Research and creation of worker

organs of a cotton cleaner with high efficiency.

Tashkent: FAN.

Rizayev, A., Alimova, D., & Alimov, B., 2022. Modeling

spindle drive device of the cotton harvester. IOP

Conference Series: Earth and Environmental Science,

1112, 012042. https://doi.org/10.1088/1755-

1315/1112/1/012042.

Sablikov, V.M., 1985. Cotton pickers. Moscow:

Agropromizdat.

Shoumarova, M., Abdillayev, T., & Yusupov, S. A., 2022.

Parameters of the stabilizer of the poly-V belts of the

drive of vertical spindles for stable cotton harvesting

performance. IOP Conference Series: Earth and

Environmental Science, 1076(1), 012020. DOI:

10.1088/1755-1315/1076/1/012020.

Shoumarova, M., Abdillayev, T., Duskulov, A.A., &

Yusupov, Sh.A., 2023. The need for instrumental

measurement of the traction force of the friction drive

of the vertical spindles of the cotton harvesting

machine. E3S Web of Conferences, 443, 04014. DOI:

10.1051/e3sconf/202344304014.

Turanov, K., Abdazimov, A., Shaumarova, M., & Siddikov,

S., 2021a. Type analysis of a multiloop coulisse

mechanism of a cotton harvester. Advances in

Intelligent Systems and Computing, 1258, 290–305.

https://doi.org/10.1007/978-3-030-57450-5_27.

Turanov, K., Abdazimov, A., Shaumarova, M., & Siddikov,

S., 2021b. Mathematical modeling of a multiloop

coulisse mechanism of a vertical spindle cotton

harvester. Advances in Intelligent Systems and

Computing, 1258, 306–321.

https://doi.org/10.1007/978-3-030-57450-5_28.

Yakubov, K., Ravutov, S., Masharibov, A., Kadirov, İ.,

2024a. Theoretical substantiation of the parameters of

the Debris removal device of the cotton picker

apparatus. BIO Web of Conferences, 116, 01017.

https://doi.org/10.1051/bioconf/202411601017.

Yakubov, K., Ravutov, S., Atakhanov, İ., Radjabov, R.,

2024b. Theoretical justification of the parameters of the

improved transport corridor of the cotton harvester

apparatus. BIO Web of Conferences, 116, 01013.

https://doi.org/10.1051/bioconf/202411601013.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

98