Flow-Through Chrome Plating Technology for the Restoration of

Agricultural Machinery

Irina Gorlova

a

and Farida Isakova

b

Tashkent State Agrarian University, 100140, University str. 2, Tashkent, Uzbekistan

Keywords: Chrome Plating, Agricultural Machinery, Surface Hardening.

Abstract: During operation, machine parts are exposed to complicating factors: aggressiveness of the environment, high

content of gas and mechanical impurities. It is necessary to use various methods of hardening the surfaces of

the working bodies of machines. Work is constantly being carried out on the problem of improving the quality

of protective coatings of the main parts and mastering hardening technologies. The article presents a device

for flow-through chrome plating, where a chrome coating is applied to the surface of parts by maintaining

certain parameters of the carrier flow flowing through channels in a closed system. Chrome plating technology

is considered, which allows to restore worn surfaces of parts operating under conditions of increased specific

pressure, high temperature and lack of lubrication, in order to increase hardness, wear resistance, corrosion

resistance and reduce the coefficient of friction of machine parts

.

1 INTRODUCTION

Electric chrome coatings have high hardness and

wear resistance. Therefore, chrome plating restores

the wear-resistant surfaces of agricultural machinery

parts with small wear (plunger pairs, distributor

spool, piston pins, etc.).

Chrome plating is performed in baths lined with

lead, viniplast or other acid-resistant material. The

walls of the bath are made double. The space between

them is filled with water or oil, which is a coolant for

heating the electrolyte in the bath. The concentration

of the bath should include a hood to remove

evaporation products and gases released during

electrolysis. Rectifiers VAKG-12/6-300, VAKG-

12/600 M with a voltage of 12 V, a low-voltage

generator AND 500/250, etc. are used as direct

current sources. To intensify the electrolysis process,

a reversible direct current is used (the polarity

changes according to a certain program).

To obtain high-quality chrome coatings, it is

necessary to observe the ratio between the current

density and the temperature of the electrolyte. By

changing the electrolyte temperature and current

density (without changing the electrolyte

composition), three types of chromium precipitates

a

https://orcid.org/0009-0002-4497-9663

b

https://orcid.org/0000-0003-2342-8459

can be obtained: shiny (hardness- up to HB 900, high

wear resistance and brittleness), milky (hardness- HB

500-600, sufficient wear resistance and plasticity),

matte (the hardest and most brittle). The increased

fragility of the matte sediment reduces its wear

resistance, so this type of sediment is not used when

restoring parts. Shiny precipitation is used for

decorative purposes (Bogorad, 1984; Equipment for

electrochemical production, 2010; Khudayorov et al.,

2023a; Khudayorov et al., 2023b; Mirzakhodjaev et

al., 2024a; Mirzakhodjaev et al., 2024b).

The average current output value for chrome

plating is 13-15%, and the chromium deposition rate

is 0.03-0.06 mm/h.

Due to the poor wettability of the chrome coating

surface, the wear resistance of the parts decreases.

Therefore, when restoring parts operating under

conditions of increased specific pressure. Due to high

temperature and lack of lubrication (piston rings,

cylinder liners, etc.), porous chrome plating is used.

The porosity of the surface is obtained by mechanical,

chemical or electrochemical methods (Zakirov et al.,

1978; Vansovskaya, 1985; Vyacheslav & Shmeleva,

1985; Gorlova et al., 2010; Khudayorov et al., 2023;

Djiyanov et al., 2024; Isakova et al., 2024; Alimova

74

Gorlova, I. and Isakova, F.

Flow-Through Chrome Plating Technology for the Restoration of Agricultural Machinery.

DOI: 10.5220/0014045000004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 74-78

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

et al., 2024; Irisov et al., 2024; Astanakulov et al.,

2024).

2 MATERIALS AND METHODS

By changing the electrolysis mode, different types of

chromium precipitates can be obtained, differing in

their properties and, consequently, in the field of

application. The greatest technical and economic

effect is achieved when using wear-resistant and

flow-through chrome plating. It is important to note

that hardness does not always correlate with wear

resistance.

The diagrams in Figure 1 clearly demonstrate the

areas of obtaining hard and wear-resistant coatings

under standard chrome plating modes in "universal"

sulfate electrolytes.

Figure 1: Diagrams of the conditions for obtaining solid (S)

and wear-resistant (W) chromium coatings in dilute

electrolyte (a) and standard electrolyte (b).

The wear resistance of the coatings increases with

increasing temperature and, after passing through a

maximum at 55-65° C, decreases to a minimum at 75°

C. For precipitation obtained from a dilute electrolyte,

the maximum wear resistance is shifted to the region

of higher temperatures. The plasticity of electrolytic

chromium also significantly depends on the chrome

plating mode. Brittle chromium precipitates (shiny

and matte) are obtained at low electrolyte

temperatures and high current densities, more plastic

coatings are obtained at high temperatures and low

current densities.

Electrolytically precipitated chromium contains

oxygen, hydrogen and a small amount of nitrogen.

The mass fraction of oxygen is 0.2-0.5 mass fractions,

and hydrogen is 0.03-0.07 mass fractions. The

volume of gases included in the sediment depends on

temperature and current density: with increasing

temperature and decreasing current density, the

volume of gases in the sediment decreases slightly.

All chrome coatings are characterized by high

hardness, the hardness is determined by the

electrolysis mode.

Chromium is applied in a thin (0.25–0.8 microns)

layer on nickel to provide an economical and highly

corrosion-resistant coating. Most decorative chrome

coatings are produced using hexavalent chromium

electrolytes. Over the past two decades, trivalent

chromium-based processes have gained increasing

acceptance in the industry.

Shiny chrome can be applied in continuous

(regular) or intermittent layers. Intermittent deposits

are formed by applying chromium to a microporous

(or microcrack) nickel plate. The choice of a

continuous or discontinuous layer depends on the

required level of corrosion resistance. Failure of a

shiny chrome plate is often associated with deep pits

resulting from corrosion starting in random cracks or

pores on the chrome surface. Corrosion is an

electrochemical mechanism. Since these cracks or

pores are located relatively widely, the current

generated by the chromium/nickel pair is

concentrated at several points. Deep pits form at these

points, which quickly penetrate through the nickel

plaque and the substrate of the component. The

creation of micro-gaps (microcracks) on the surface

leads to the spread of corrosion current and a

slowdown in the rate of corrosion. Typically, a

conventional chrome plate is used for products with a

coating for operating conditions 1/2, whereas an

intermittent layer is used to cover operating

conditions 3 or higher (ASTM B456).

Four types of hexavalent chromium electrolytes

are commonly used:

• sulfate catalysts,

• sulfate-fluoride catalysts,

• sulfate-fluoride-organic catalysts

• and self-regulating high speed (SRHS).

The most common electrolytes used today are

based on a double sulfate fluoride catalyst. This

mixed catalyst has the advantages of increasing

cathode efficiency, coating ability and ability to apply

shiny nickel layers compared to a direct sulfate type

catalyst.

Over the past decade, the popularity of the triple

catalytic system has increased. This system has

characteristics similar to a dual catalyst, with the

advantages of higher cathode efficiency, a wider

operating window and improved coverability. The

operation of these systems requires regular analysis

of the concentration of chromic acid, sulfuric acid and

proprietary catalysts. The main differences between

the systems are shown in Table 1.

Flow-Through Chrome Plating Technology for the Restoration of Agricultural Machinery

75

Table 1: Hexagonal chromium electrolyte systems.

Type Single catalyst Double catalyst Triple Catalyst SRHS

Concentration Cr0

3

,

g

/

l 450-500 180-400 250 240

Ratio Cr0

3

:H

2

S0

4

100:1 200-300:1 160-170:1 260-270:1

Type of catalyst Sulfate only Mixed sulfate/fluoride Mixed sulfate /

fluoride

Mixed Sulfate/

Or

g

anic re

g

ulato

r

Cathodic efficiency factor, % 8 12-18 20-25 15

temperature, F 100 100-104 104 104-113

Cathodic Current densit

y

, asf 80-102 100-150 90-150 110-160

Level mixed oxides, g/l <22 10-20 <12 <12

Main Features Ease of Preparation.

Resistance to

pollution.

Good Chromability.

Good hiding ability

Wide Operating

parameters.

Excellent hiding

ability.

Tolerant to Sulfate

changes.

Easy to use.

The main factor affecting the coating time is the

cathodic efficiency of chrome plating solutions,

which is influenced by the following factors (This is

shown in Table I.):

− Type of electrolyte.

− The concentration of the solution.

− The current density used.

− The temperature of the solution.

− The composition of the solution.

During operation, parts of agricultural machines

are exposed to complicating factors: aggressiveness

of the environment, high content of gas and

mechanical impurities. As a result, manufacturers are

forced to use various methods of hardening the

surfaces of the working bodies of pumps. Specialists

are constantly working on the problem of improving

the quality of protective coatings of basic agricultural

parts and such hardening technologies as flow-

through chrome plating have been mastered.

For operation in an aggressive environment,

increased requirements are imposed on the surfaces

of agricultural machinery parts, which can be

achieved using chrome plating technology, which

allows to increase the surface properties of parts, such

as hardness, wear resistance, corrosion resistance and

reduce the coefficient of friction. The chrome coating

is applied to the inner surface of the parts by

maintaining certain parameters of the carrier flow

flowing through the inner channel in a closed system.

3 RESULTS AND DISCUSSION

To achieve this task, a device for flow-through

chrome plating of engine valves is proposed,

consisting of a vertical cone-shaped hollow body,

containing a cap with a threaded mount on top and a

prefabricated poppet bottom with a centering

protrusion, a ventilating element, powered by an

electric motor, an apron with an observation window,

a tank with a hydraulic mixer and a filter, a pump with

hydraulic communication, a pressure gauge, and The

hydraulic mixer is equipped with spraying tips facing

the bottom of the tank from below, In this case, the

device is mounted on roller wheels, and the conical

body is connected to the tank body through a multi-

hinged bracket, while the valve being restored

relative to the inner wall of the conical body is

mounted with a technological gap.

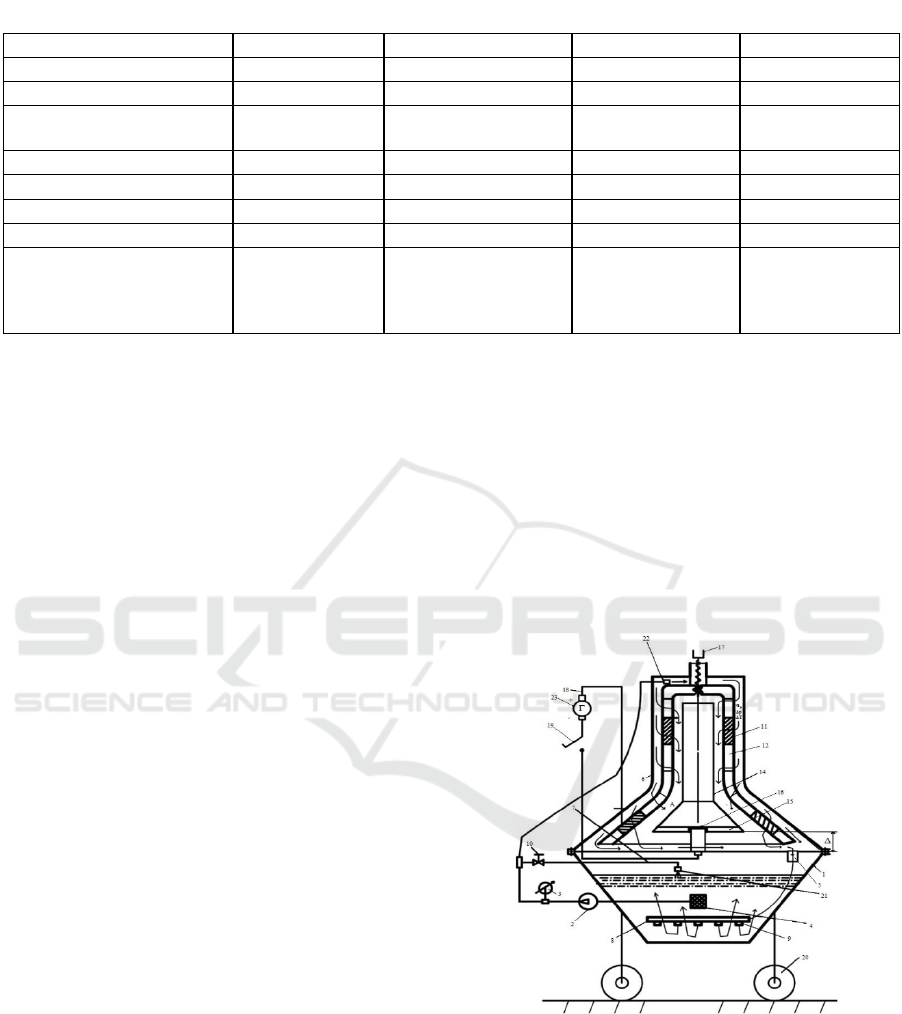

Figure 2: Schematic drawing of the device in the section.

Figure 2 shows a schematic drawing of the device

in section (ԛ

э

- electrolyte consumption; Δр, ΔТ -

operating pressure and temperature gradient of the

electrolyte in the working chamber A; "+", "-" -

positive and negative poles of the generator of the

electric network; Δ- technological gap).

The device for flow-through chrome plating of

engine valves (Fig. 2.) contains a reservoir 1 for

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

76

chrome electrolyte, pump 2, pressure gauge 3, filter

4, inlet 5, outlet 6 and return 7 tubes, a hydraulic

mixer 8 with sprayers 9, an adjustment valve 10, a

perforated tube 11 with radial channels 12 installed

inside the housing 13 which describe the shape of the

contour of the chrome-plated valve 14, plates 15 with

a central protrusion 16 forming a technological gap

equal to Δ. The body 13 and the perforated tube 11

are provided with an adjustment screw 17 from

above. The cavity formed between the perforated tube

11 and the valve 14 creates a chrome plating working

chamber "A". The technological gap Δ ensures

intensive circulation of the chromium electrolyte

around the valve 14. A positive electric charge is

connected to the valve 14, and a negative electric

charge is connected to the perforated tube. The

electrical network 18 of the device is controlled via a

switch 19. The device can be moved on roller legs 20.

The return tube 7 is equipped with a nozzle 21, and

the supply tube 5, with a nozzle 22, the electrical

network 18 is powered by a generator 23.

The operation of the proposed device is as

follows: with the start of the pump 2, the chromium

electrolyte through the filter 4, the supply tubes 5 and

the radial channels 12 of the perforated tube 11 enters

the working chamber A, where, due to the action of

positive and negative charges, intensive deposition of

chromium particles occurs on the working surface of

a new or extremely worn valve 14. The remaining

part of the chromium electrolyte, through the

discharge 6 and return 7 tubes, is returned back to the

reservoir 1, where a hydraulic mixer 8 with a spray

unit 9 provides high stability of the concentration of

the chromium electrolyte. The working pressure Δр,

the temperature gradient ΔТ and the electrolyte

consumption q

э

inside the working chamber A

ensures the optimal mode of the chrome plating

process. The installation of the roller leg 20 increases

its mobility of the proposed device. By increasing the

number of installations, it is possible to increase the

replaceable chrome plating performance of heat

engine valves. Due to the tightness of the design of

tank 1, atmospheric air pollution in the workplace is

excluded. The operating mode of the device is

regulated through the adjusting screw 1.

The working pressure in the hydraulic system of

the device is controlled by a pressure gauge 3. The

proposed device provides chrome plating, iron

plating, copper plating not only of extremely worn,

but also of new valves of various heat engines,

increasing its technological capabilities, eliminating

atmospheric air pollution in the workplace during

flow chrome plating, which will give a significant

technical and economic effect to the national

economy of the country.

A device for in-line chrome plating of engine

valves containing a reservoir, a housing, a pump, a

support plate, a hydraulic system, a perforated

conductive tube, a chrome plating chamber

characterized in that the internal contours of the

chrome plating chamber describe the external

contours of the shape of the chrome-plated valve, and

the support plate is equipped with a central

protrusion, and the discharge tube of the hydraulic

system is equipped with a hydraulic mixer with a

spray unit, as well as an adjustment valve and a tube

for returning the chromium electrolyte back to the

tank, while the device is mounted on roller legs.

4 CONCLUSIONS

The device relates to agriculture, in particular to

devices and apparatuses for flow-through chrome

plating of complex valves of engines and other parts

of agricultural machinery. Due to the proposed device

with an improved design, the application of chrome

coatings on worn or new parts of agricultural

machinery that are complex in shape is achieved by

expanding the technological capabilities of the

proposed device, which will give the national

economy of the country a significant technical and

economic effect.

REFERENCES

Alimova, F., Saidova, M., Primqulov, B., & Erdem, T.,

2024. Optimization of the parameters of the pneumatic

feed mechanism for precise clustered sowing. BIO Web

of Conferences, 85, 01026.

https://doi.org/10.1051/bioconf/20248501026.

Astanakulov, K., Kurbonov, F., Isakova, F., 2023.

Investigation of the rotation number of a fish feed

distribution device disc apparatus. E3S Web of

Conferences, 381, 01001.

https://doi.org/10.1051/e3sconf/202338101001.

Bogorad L.Ya., 1984. Chrome plating (5

th

ed.) Revised and

additional. L.: Mechanical Engineering.

Djiyanov, M., Xalilov, R., Isakova, F., 2024. Justification of

commercialization of export-oriented harvesting

apparatus for intensive processing of cotton boxes. BIO

Web of Conferences, 85, 01034

https://doi.org/10.1051/bioconf/20248501034.

Equipment for electrochemical production, 2010. Textbook

(2

nd

ed.), reprint. Angarsk: AGTA.

Gorlova, I.G., Tadjibekova, I.E., 2010. Plasmatron for

surfacing of new and worn parts of machines. Booklet

“Uz EXPOCENTER”.

Flow-Through Chrome Plating Technology for the Restoration of Agricultural Machinery

77

Irisov, K., Gorlova, I., Khudaev, I., 2024. The method of

dispersion analysis of droplets using mini droplet cards

for resource-saving agricultural technologies. BIO Web

of Conferences, 105, 01016.

https://doi.org/10.1051/bioconf/202410501016.

Isakova, F., Tadjibekova, I., Kurbonov, F., 2024.

Improvement methods of feeding of aquaculture. BIO

Web of Conferences, 85, 01037.

https://do.org/10.1051/boconf/20248501037.

Khudayorov, Z., Khallov, R., Gorlova, I., Mrzakhodjaev,

S., Mambetsherpova, A., 2023c. Mathematical model

of water drop trajectory in artificial rainfall. E3S Web of

Conferences, 365, 04011.

https://do.org/10.1051/e3sconf/202336504011.

Khudayorov, Z., Khallov, R., Mrzakhodjaev, S.,

Nurmkhamedov, B., Mamasov, S., 2023b. Theoretical

study of the influence of the changing environment on

the process of rainfall irrigation. E3S Web of

Conferences, 376, 02013.

https://doi.org/10.1051/e3sconf/202337602013.

Khudayorov, Z., Mirzakhodjaev, S., Khalilov, R.,

Nurmikhamedov, B., Mamasov, S., 2023a. Deflector

nozzles of rain irrigation machines. E3S Web of

Conferences., 390, 01033.

https://doi.org/10.1051/e3sconf/202339001033.

Mrzakhodjaev, S., Djyanov, M., Nurmkhamedov, B.,

Mamasov, S., 2024a. Results of Frontal Plug Tests

Combined with Active Working Body. BIO Web of

Conferences, 85, 01035.

https://doi.org/10.1051/bioconf/20248501035.

Mirzakhodjaev, S., Utaganov, K., Musurmonov, A. 2024b.

Field Tests of a Cultivator Proceeds between Row Soils

in Vineyards. BIO Web of Conferences, 85, 01036.

https://doi.org/10.1051/bioconf/20248501036.

Vansovskaya, K.M., 1985. Metal coatings applied by

chemical means. Edited by P.M. Vyacheslavov. L.:

Mechanical Engineering.

Vyacheslav, P.M., Shmeleva, N.M., 1985. Control of

electrolytes and coatings (2

nd

ed.), reprint. and

additional. L.: Mechanical Engineering.

Zakirov, S.Z., 1978. Hardening of machine parts by

electrodeposition of iron. Dushanbe: Irfon.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

78