Experimental Research Based on the Parameters of the Pneumatic

Seeder

Mukhayyokhon Saidova

1a

, Tunahan Erdem

2b

, Sarvar Tursunbaev

1c

, Temurbek Ismoilov

3d

and Sadbarxon Mavlanova

3e

1

Tashkent State Technical University, 100095 Tashkent, Uzbekistan

2

Cukurova University, 01250, Adana, Turkey

3

Namangan State University, 160107 Namangan, Uzbekistan

Keywords: Pneumatic Seeder, Seed Spacing, Planting Accuracy.

Abstract: In the article, the authors analyzed the results of laboratory tests of a pneumatic sowing apparatus that

accurately sows bare cotton seeds. The experiments were carried out on seeds of the “Sultan” variety. Tests

to change the number of revolutions of the sowing disks in 2 different variants, the distance between slots,

the coefficient of variation of the actual value of the interval between slots, the number of seeds falling into

each slot, their standard deviation. The number of slots without seeds, the percentage of slots with seeds, and

slot elongation were examined. The article presents conclusions based on the results obtained.

1 INTRODUCTION

In world practice, it has been proven that in

pneumatic diluents it is most acceptable to use

landing discs rotating along a vertically longitudinal

surface, and most companies producing pneumatic

diluents produce diluents equipped with just such

discs. The research paper considers the main

parameters of the landing disc, which rotates on a

vertically longitudinal surface, that is, on a horizontal

axis located transversely to the direction of movement

of the seal (QXA-3-001 practical project, 2018;

Ramesh et al., 2017; Xiangdong et al., 2017; Lu et al.,

2022; Li et al., 2023; Verma et al., 2024).

It is known that in order to obtain higher crop

yields, it is necessary to evenly distribute seeds

throughout the field, that is, plant them evenly to the

desired depth, ensuring a given range and distance to

the node. In world practice, when using seeds

prepared with high quality, seed sowing is used in a

clear norm, one seed per slot.

a

https://orcid.org/0009-0007-0870-4802

b

https://orcid.org/0000-0002-1595-6852

c

https://orcid.org/0000-0003-2516-3597

d

https://orcid.org/0000-0003-0414-2148

e

https://orcid.org/0009-0007-9824-8002

In addition to the general requirements, specific

planting requirements are developed according to the

climate and soil of each area. In particular, the soil

and climatic conditions of Uzbekistan are such that in

the spring sowing period, after precipitation, in most

cases tar appears in the soil, and seeds planted in one

grain risk getting stuck under it, failing to split the

resin.For this reason, when planting rotten seeds or

other seed materials, it is advisable to sow them in a

slot way, that is, laying 2-3 seeds in each slot (El-

Sayad, 2012; Javellonar et al., 2016; Veerangouda et

al., 2020; Alimova et al., 2022; Saidova et al., 2023;

Saidova et al., 2024).

2 MATERIALS AND METHODS

Experimental studies according to GOST 31345-

2017 "Agricultural machinery. Tractor tractors. Test

methods", as well as UzDst 3193:2017. "Testing of

agricultural machinery. The method of energy

68

Saidova, M., Erdem, T., Tursunbaev, S., Ismoilov, T. and Mavlanova, S.

Experimental Research Based on the Parameters of the Pneumatic Seeder.

DOI: 10.5220/0014044700004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 68-73

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

assessment of machines " (Uzdst 3193, 2017; GOST

31345-2017, 2018).

By changing the number of revolutions of the

sowing discs of 2 different variants of the bare cottons

seeds pneumatic sowing machine, the distance

between the hives, the coefficient of variation of the

actual value of the interval between the hives, the

number of seeds that fell into each slot, their standard

deviation, the proportion of slots into which the seed

did not fall, the proportion of slots into which the seed

fell were studied on a special stand, the length of the

slots.

The laboratory stand is a model of the planting

process, while in practice it moves across the field on

the surface of unobstructed soil, while the landing

device is freely accessible on the stand, and the "soil"

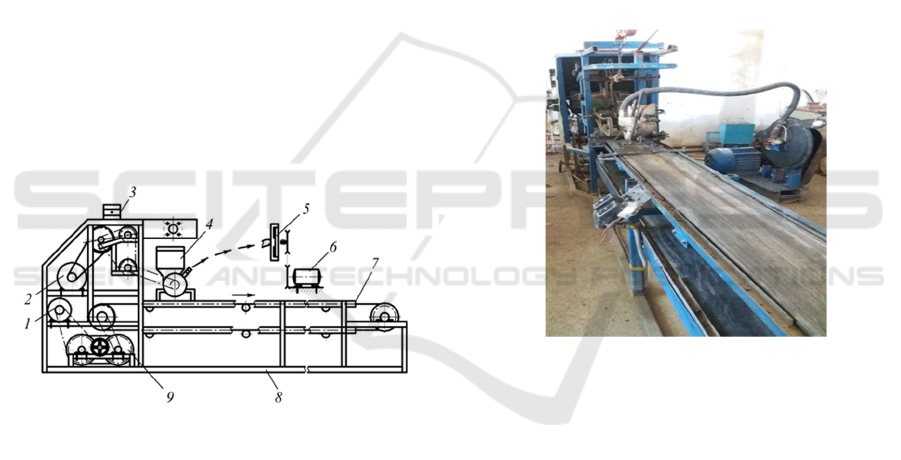

in the form of a conveyor belt is movable (Fig. 1).

A pneumatic landing device 4 was installed on

this test bench. To create a vacuum, an exhauster 5

was installed, which is powered by an electric motor

6. The pneumatic landing device is connected to the

exhauster by an air wire. The electric motor 2, which

is powered by direct current, and the circuit extension

act as a landing gear drive. Rheostat 3 allows you to

change the number of revolutions transmitted to the

lander.

Figure 1: Scheme of the laboratory stand for testing the

planting apparatus.1, 6 – AC electric motors; 2-DC electric

motors; 3-rheostat; 4-pneumatic landing apparatus; 5-

extractor; 7-conveying belt; 8-frame; 9-variator.

Experimental studies were carried out with a

single-row layout of the lander in the following order

(Fig. 2).

− the seeds are placed in the hopper of a

pneumatic seeding machine;

− solidol is applied to the conveyor belt so that

the seeds from the sowing machine can stick to

the tape;

− adjustment of the set values of the unit speed

was carried out using a variator;

− when adjusting or changing the distances

between the seeds in the slot, the number of

revolutions of the disc of the sowing machine

changed;

− the number of revolutions of the disc of the

seeding machine is determined using a

tachometer through the valve of the disc of the

seeding machine;

− the laboratory stand has been launched. From

the sowing machine, the seeds fell onto the

surface of the conveyor belt. The stand was

stopped when the surface of the tape was

completely covered with seeds along the

length;

− the number of seeds in the slots that appeared

on the surface of the tape, the distance between

the slots and their elongation were measured;

− counted the number of seeds that got into the

slots;

− the distance between the slots was measured

using an electronic vernier caliper.

Figure 2: General view of laboratory stand equipped with

improved pneumatic planting apparatus.

The set of numbers obtained as a result of

measurements was processed by mathematical

statistics methods and the average values of random

variables (Mmed), the mean square deviation (±σ)

and variational coefficients (V) were determined.

They were entered into the appropriate tables and

analyzed.

In the punched planting method, the accuracy of

sowing and the set distance between seeds (pitch)

were taken into account, which corresponded to the

criterion for evaluating the quality of sowing.If the

sowing step between the seeds was less than half of

the specified distance, then one seeder and two

seeders were accepted.It was believed that if the step

between the sown seeds is one and a half times larger

than the specified step, then empty slots remain.This

method was used to evaluate the performance of

various seeding machines (Testing of agricultural

Experimental Research Based on the Parameters of the Pneumatic Seeder

69

machinery, 1991; Testing of agricultural machinery,

2001; Karimov et al., 2020; Irisov et al., 2023). Using

this method of estimating the location of seeds, it is

possible to quantify the quality of the sown seeds and

visually assess the deviation for a given planting

accuracy. This method makes it much more difficult

to estimate the location of the seeds (Tukhtakuziev et

al., 2020; Norchayev et al., 2022; Alimova, 2023;

Aslonov & Irisov, 2023; Tukhtakuziev et al., 2023;

Djiyanov et al., 2024; Mirzakhodjaev et al., 2024).

3 RESULTS AND DISCUSSION

All studies were carried out with seeds of the “Sultan”

variety in good condition. The data obtained during

the experimental studies were processed in

accordance with the methods used in the study of

technological processes in agriculture.

Laboratory experiments were conducted

according to GOST 31345-2007, accepted among the

CIS countries, "Tractor seeders. The method was

carried out on the basis of the requirements

established in accordance with the "interstate

standard", in particular in standard 6.3.2

"determination of the quality indicators of the seeding

apparatus during bench tests" and 6.3.6

"determination of the distribution of seeds (slots) in a

row".

Experimental studies were carried out through the

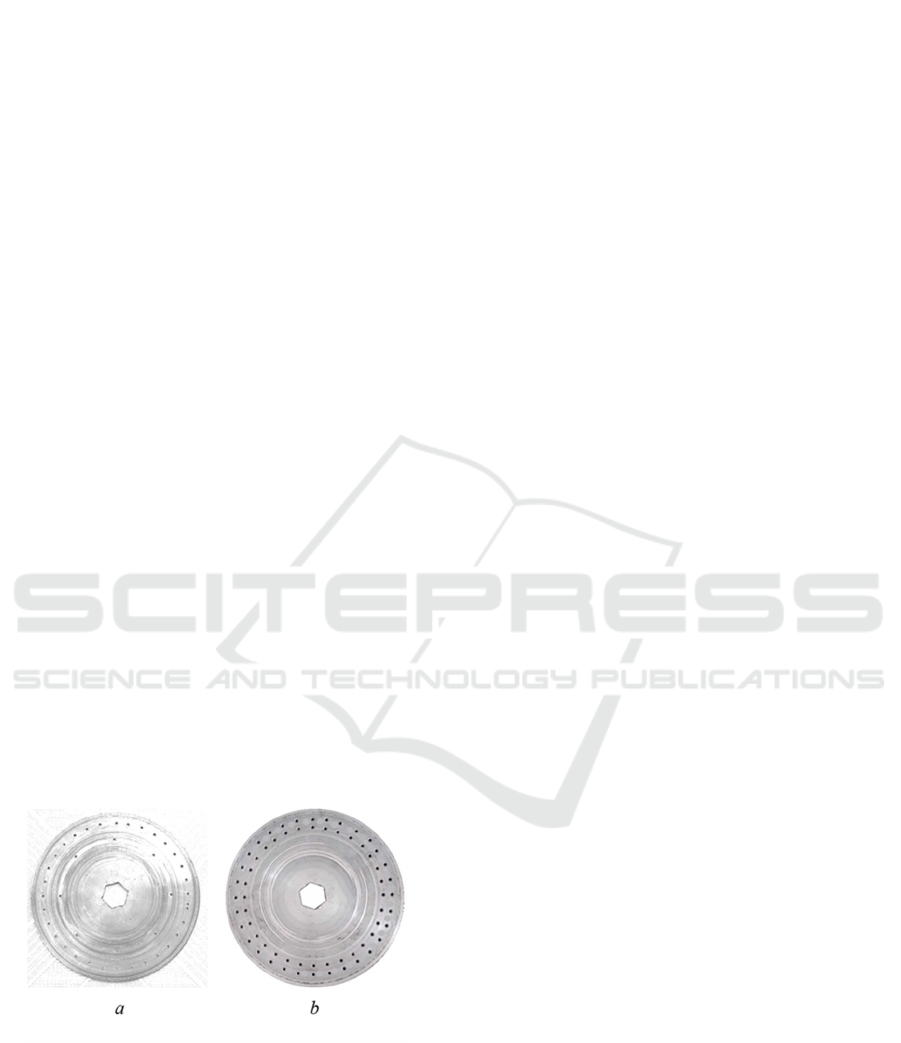

following planting discs.

Option 1 is a planting disc with a circular hole (3.5

mm in diameter);

Option 2 is a planting disc with two circular holes

(3.5 mm in diameter).

Figure 3: Planting discs with holes of different sizes.

The prepared a-shaped disk was mounted on an

additionally machined pneumatic landing gear and

mounted on a universal stand. During the

experiments, the linear speed of the conveyor belt was

increased to 2.1 m/s. This corresponds to the speed of

the unit in the field, equal to 7.57 km/ h (MTZ-80x5

tractor - reduced speed). The number of revolutions

of the sowing disc was adjusted depending on the

required value of the distance between the seeds.

The holes for planting seeds in one row have a

diameter of 3.5 mm, the diameter of the circle in

which the holes are located is 180 mm, the number of

holes is 32, the number of revolutions of the disk is

31.5 ail/min, the linear speed of the conveyor belt is

2.1 m/s, the degree of thinning in the pneumotype is

40 mbar. With these parameters, the distance between

the seeds in a row should be 10 cm.

Based on the initial temporary requirements,

when sowing seeds in rows and lowering one into

each slot, the coefficient of variation of the actual

values of the intervals between seeds should not

exceed 15%, the number of seeds laid per unit length

should be provided with an accuracy of at least 95%.

The results of experiments on sowing seeds in

one row are presented in Table 1. Vmed = 2,1 m/s; d

= 180 mm; z = 32 piece; dm = 3,5 mm; P = 40 mbar;

The variety of seeds is "Sultan".

The results obtained in experiments on planting

seeds in one row are as follows: the planting accuracy

was 97.1%, the coefficient of variation was 13.0%.

In the experiments, two cases of fertilization per

slot were noted, which amounted to about 8.1%.

Cases where there were two seeds in one slot instead

of one are also observed in modern overseas seeders,

and no restrictions are imposed on the initial

requirements. So we can say that at the Meyer level.

Further experiments were aimed at determining the

performance indicators of the pneumatic landing

device during slot landing. The intervals between

slots, the number of seeds dropped per slot, as well as

the degree of elongation of the slots were taken as

criteria for evaluating the slotting of seeds. In

accordance with the temporary preliminary

requirements, it is required that the coefficient of

variation of the actual value of the interval between

cells does not exceed 25%, that 85% of the generated

cells are filled at a given value and that the number of

cells is one more, equal or one less so that the cells

are filled, stretched, does not exceed the sum of the

seed lengths.

The experiments were carried out in the following

modes and parameters: the speed of movement of the

conveyor belt (seeder) is 2.1 m/s, the rotation speed

of the sowing disc is 31.5 and 19.7 rpm, the degree of

thinning in the pneumotype is 40 mb, the diameter of

the planting disc - circles with holes in the planting

disc are 180 and 200 mm, the number of holes - in this

case, the distance between the slots should be 12.5 cm

(31.5 rpm) and 20 cm (19.7 rpm).

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

70

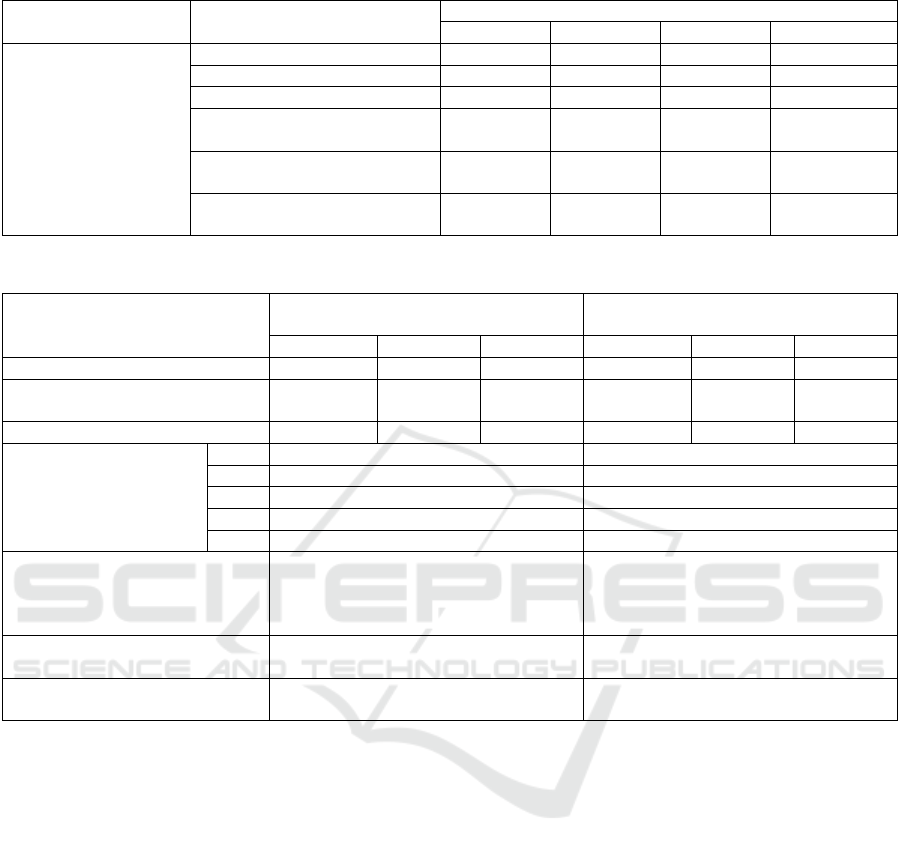

Table 1: Results of planting seeds in one row.

Working mode Specification

Distance between seeds, c

m

I II III Med.

n = 31,5 rpm

l

у

= 10 cm

М

med

, cм 10,1 10,5 10,4 10,3

b

±, cм 1,35 1,15 1,53 1,34

V, % 13,3 11,0 14,7 13,0

Share of seedless slots

(

≥ l

у

х 1,5

)

, %

2,9 2,0 2,7 2,5

Share of two-seeded slots

(

≤ l

у

/ 2

)

, %

2,6 12,5 9,3 8,1

Share of 3 seed slots and more,

%

0 0 0 0

Table 2: Results of slot seeds in two.

Specification

n = 31,5 rpm;

l

у

= 12,5 c

m

n = 19,7 rpm;

l

у

= 20 c

m

М

med

±

σ

V

, %

М

med

±

σ

V

, %

Interval between slots, c

m

13,1 1,37 10,4 19,2 1,91 10,0

Number of seeds falling into the

slots,

p

cs

2,1 0,33 15,7 2,1 0,38 17,6

Stretching of the slots, c

m

0,9 0,70 81,2 0,9 0,76 85,0

Distribution of slots by

seed, %

0 1,2

1 9,0 4,7

2 76,0 75,2

3 13,4 15,3

4 1,6 3,6

Planting accuracy (the amount of

slots in which the number of

seeds corresponds to standard

(2±1 pcs.), %

98,4 95,2

Share of slots no more than 2 cm

in len

g

th, %

93,4 91,6

The amount of slots falling

b

etween the intervals, %

4,1 4,7

The results of the experiments carried out are

presented in Table 2. V

med

= 2,1 m/s; d

1

= 200 mm;

d

2

= 180 mm; z = 32х2 piece; d

m

= 3,5 mm; P = 40

mbar; The variety of seeds is "Sultan".

4 CONCLUSIONS

According to the results of the experiment, the

following conclusion can be drawn:

1. The number of rotations of the planting disc

was 31.5 rpm, in the option where the specified

interval was 12.5 cm: the interval between the

slots was on average 13.1 cm, the vibrational

coefficient of the actual value of the interval

between the slots was equal to 10.4%. The

average number of seeds per slot was 2.1, with

an average quadratic deviation of 0.33. The

distribution of slots by seed was as follows: the

proportion of unfertilized slots – 0%, the

proportion of 1 – seeded slot – 9.0%, 2 –

76.0%; 3 – 13.4% and 4-1.6%. The share of

2±1 seed slots was 98.4% (according to the

standard should not be less than 80%). The

lengthening of the slots was on average 0.9 cm.

It is required that the lengthening of the slots

according to Standard does not exceed the sum

of the lengths of the seeds that actually fell on

them. Considering that the average length of

the seed we have is 9.1 mm, the length of the

slots should not exceed 1.82 cm or 2 cm when

rounded (in experiments, based on GOST

(standard), the measurement accuracy was

taken 0.5 cm). According to the results of the

experiment, the amount of slots no more than 2

cm in length was 93.4%.

2. The number of revolutions of the landing disc

was 19.7 rpm in the variant where the specified

interval was 20 cm: the interval between the

grooves averaged 19.2 cm, the coefficient of

Experimental Research Based on the Parameters of the Pneumatic Seeder

71

variation of the actual value of the interval

between the grooves was 10.0%. The number

of seeds in the slot in this variant also averaged

2.1 pieces, with an average square deviation of

0.38. The distribution of slots by seed was as

follows: the proportion of unfertilized slots –

1.2%, the proportion of 1 – seeded slots – 4.7%,

2 – 75.2%; 3 – 15.3% and 4-3.6%. The share of

2±1 seed slots was 95.2%. The lengthening of

the slots was on average 0.9 cm, the amount of

slots no more than 2 cm in length was 91.6%.

REFERENCES

Alimova, F.A., 2023. Mathematical modeling of small soil

channel laboratory stand drive and evaluation of its

energy state. IOP Conference Series: Earth and

Environmental Science, 1284, 012031.

https://doi.org/10.1088/1755-1315/1284/1/012031.

Alimova, F., Primqulov, B., & Boboniyozov, E., 2022.

Parametres of the strip-tilling working bodies for re-

crops sowing. AIP Conference Proceedings, 2637,

050007. https://doi.org/10.1063/5.0118617.

Aslonov, N., & Irisov, K., 2023. Mathematical model of

resistance to spreading forces using a bulldozer blade.

E3S Web of Conferences, 390, 01032.

https://doi.org/10.1051/e3sconf/202339001032.

Djiyanov, M., Xalilov, R., & Isakova, F., 2024. Justification

of commercialization of export-oriented harvesting

apparatus for intensive processing of cotton boxes. BIO

Web of Conferences, 85, 01034.

https://doi.org/10.1051/bioconf/20248501034.

El-Sayad, Y.A., 2012. Design and fabricate a metering

device of vacuum seeder to suit egyptian cotton.

Egyptian Journal of Agricultural Research, 90(4),

1723-1742. https://doi.org/10.21608/ejar.2012.164070.

GOST 31345-2017. Agricultural machinery. Tractor

seeders. Test methods. Moscow: Standartinform, 53 p.

Irisov, K.D. & Bekmurodov, I.R., 2023. Theoretical aspects

of substantiating the parameters of the working body of

an environmentally comfortable spraying unit. IOP

Conference Series: Earth and Environmental Science,

1284, 012041. https://doi.org/10.1088/1755-

1315/1284/1/012041.

Javellonar, R.P., Delaraga, L.V. & Alegato, O.R., 2016.

Design, development and evaluation of a disc-type corn

seeder. Ilocos Journal of Science, 61.

Karimov, R., Bobojanov, M., Tairova, N., Xolbutayeva, X.,

Egamov, A. & Shamsiyeva, N., 2020. Non-contact

controlled voltage stabilizer for power supply of

household consumers. IOP Conference Series:

Materials Science and Engineering, 883, 012120. DOI:

10.1088/1757-899X/883/1/012120.

Li, K., Li, S., Ni, X., Lu, B., & Zhao, B., 2023. Analysis

and experimental of seeding process of pneumatic split

seeder for cotton. Agriculture, 13(5), 1050.

Lu, B., Ni, X., Li, S., Li, K., & Qi, Q., 2022. Simulation and

experimental study of a split high-speed precision

seeding system. Agriculture, 12(7), 1037.

https://doi.org/10.3390/agriculture12071037.

Mirzakhodjaev, S., Djiyanov, M., Nurmikhamedov, B., &

Mamasov, S., 2024. Results of frontal plug tests

combined with active working body. BIO Web of

Conferences, 85, 01035.

https://doi.org/10.1051/bioconf/20248501035.

Norchayev, D.R., Xaliqulov, M.A., Turkmenov, X.I.,

Shermuxamedov, X.P., & Ibragimova, G.N., 2022.

Acceptable solutions for harvesting root crops in the

soil climate of the Republic of Uzbekistan. IOP

Conference Series: Earth and Environmental Science,

1076, 012029. https://doi.org/10.1088/1755-

1315/1076/1/012029.

QXA-3-001 Practical project, 2018. Development of an

energy resource-efficient pneumatic sealant that plants

seeds of crops in specific norms. Gulbahor, 97 p.

Ramesh, M.B., Veerangouda, M., Reddy, B.S., Anantachar,

M., & Sharanagouda, H., 2017. Simulation of Design

and Operational Parameters of Pneumatic Seed Planter

for Cotton Using ANSYS Software. Agricultural

Engineering Today, 41(4), 37-45.

Saidova, M., Alimova, F., Tursunbaev, S., Kulmuradov, D.,

& Boltaeva, M., 2023. Influence of the shape of the disc

slots of the seeder on the suction force of the vacuum

for precise sowing of seeds. IOP Conference Series:

Earth and Environmental Science, 1284, 012014.

https://doi.org/10.1088/1755-1315/1284/1/012014.

Saidova, M., Tursunbaev, S., Boltaeva, M., & Isakulova,

N., 2024. Comparison of pneumatic sowing machines

by the number of seeds in the slots of the discs and the

distance between the slots. BIO Web of Conferences,

105, 01004.

https://doi.org/10.1051/bioconf/202410501004.

Testing of agricultural machinery, 1991. Sowing machines.

The program and test methods. - RD.10.5.1.-91

//Official publication – Moscow. 100 p.

Testing of agricultural machinery, 2001. Sowing machines.

The program and test methods. - Uz RH 63.06: 2001

//The publication is official. - Tashkent, 95 p.

Tukhtakuziev, A., & Rasuljonov, A. R., 2020. Ensuring the

stability of the processing depth of suspended soil

mounted machines. IOP Conference Series: Earth and

Environmental Science, 614, 012156. DOI:

10.1088/1755-1315/614/1/012156.

Tukhtakuziev, A., Rasuljonov, A.R., Turkmenov, H.I.,

Irgashev, A.A., & Barlibaev, S., 2023. Ensuring the

stability of the suspended chisel-cultivator processing

depth. E3S Web of Conferences, 390, 01038.

https://doi.org/10.1051/e3sconf/202339001038.

Uzdst 3193: 2017. Testing agricultural techniques. Method

of energy evaluation of machines. - Tashkent, 21 p.

Veerangouda, M., Maski, D., Desai, B.K., & Doddagoudar,

S.R., 2020. Study on some engineering properties of

cotton seeds in relation to the development of a tractor

operated seed dibbler. Journal of Pharmacognosy and

Phytochemistry

, 9(5), 1836-1839.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

72

Verma, K., Mohanty, S. K., Dash, R. C., Mishra, J., Behera,

A., & Rath, I., 2024. Optimization of Power Tiller

Operated Pneumatic Planter under Laboratory

Conditions for Enhancing Cotton Planting Efficiency.

Journal of Experimental Agriculture International,

46(5), 526-537.

https://doi.org/10.9734/jeai/2024/v46i52407.

Xiangdong, N.I., Guojie, X.U., Qi, W.A.N.G., Xiaorui,

P.E.N.G., Jian, W.A.N.G., & Bin, H.U., 2017. Design

and experiment of pneumatic cylinder array precision

seed-metering device for cotton. Nongye Jixie

Xuebao/Transactions of the Chinese Society of

Agricultural Machinery, 48(12).

Experimental Research Based on the Parameters of the Pneumatic Seeder

73