Experimental Field Studies to Determine the Parameters of an

Improved Pneumatic Seeder Apparatus

Mukhayyokhon Saidova

1a

, Surayyokhon Khasanova

1

b

, Dinara Yadgarova

2

c

,

Elyorjon Gapparov

3d

and Gavxaroy Tadjibaeva

3

e

1

Tashkent State Technical University, 100095 Tashkent, Uzbekistan

2

Urgench State University, 220100 Urgench City, Uzbekistan

3

Namangan State University, 160107 Namangan, Uzbekistan

Keywords: Pneumatic Seeder, Seed Spacing, Planting Accuracy.

Abstract: In the article, the authors analyzed the results of field experiments of a pneumatic seeder that accurately plants

a bare cotton seed. The field experiments were conducted on earth with 2 different conditions, namely on a

test site and on an inclined plane. The experiment was carried out with a change in the speed of the unit. The

article presents the parameters of the planting disc used for slot sowing of seeds. The interval between slots,

the number of seeds that got into each slot, as well as the degree of elongation of the slots were taken as an

evaluation criterion when planting seeds in the slot. The results obtained on the basis of experiments have

been analyzed, and the authors' conclusion is given in the article

1 INTRODUCTION

The world is leading in the development of energy-

resource technologies and modern technical means

for growing cotton. The volume of cotton fiber

cultivation on a global scale is 23477 thousand tons,

including in India - 6205, China - 5987, USA - 4555,

Brazil - 1895, Pakistan - 1785, Australia - 1045,

Turkey - 871, Uzbekistan - 838 and Turkmenistan -

296 thousand tons (Kathirvel et al., 2005; Javellonar

et al., 2016; Xiangdong et al., 2017; Alimova et al.,

2022). Seeder one of the important tasks is considered

to be the improvement and development of new

scientifically based energy-resource-saving ones that

ensure high quality of work and efficiency. In this

regard, certain successes have been achieved in

developed foreign countries, including the USA,

Turkey, India, China and other countries, with great

attention being paid to the development and

application of pneumatic sieves that accurately sow

a

https://orcid.org/0009-0007-0870-4802

b

https://orcid.org/0009-0007-0758-3922

c

https://orcid.org/0000-0008-6154-2453

d

https://orcid.org/0000-0005-0337-0871

e

https://orcid.org/0009-0002-3937-5523

seeds (Singh et al., 2005; Ramesh et al., 2015;

Veerangouda et al., 2020; Alimova, 2023).

The pneumatic seeder, which precisely sows bare

seeds, is suspended and aggregated with tractors of

class 0.9-1.4. It consists of a suspended structure, a

frame, 4 sections for landing. Each section for

planting will be equipped with a pneumatic seeding

device. The seeding machine consists of an improved

vertical disk, a housing, a feed chamber (seeding), a

separator, a thinning chamber, an air duct, and round

linings (Byler, 2003; Karimov et al., 2020; Saidova et

al., 2024a; Djiyanov et al., 2024).

The distribution of seeds in rows (seeding step) is

studied in seeders, which plant clearly and punctually.

The implementation of an even distribution of seeds

is emphasized in special standards. In this case, the

distances between the sown seeds are determined by

recording (measuring) (Norchayev et al., 2022; Irisov

& Bekmurodov, 2023; Norchayev et al., 2024;

Saidova et al., 2024b).

64

Saidova, M., Khasanova, S., Yadgarova, D., Gapparov, E. and Tadjibaeva, G.

Experimental Field Studies to Determine the Parameters of an Improved Pneumatic Seeder Apparatus.

DOI: 10.5220/0014044600004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 64-67

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

2 MATERIALS AND METHODS

During the tests, a seeder equipped with a pneumatic

seeding machine that accurately planted lint-free

seeds was aggregated with a tractor TTZ-80.11 (Fig.

1) (Aslonov & Irisov, 2023; Tukhtakuziev et al.,

2024a; Djiyanov et al., 2024; Tukhtakuziev et al.,

2024b).

Figure 1: General view of an experimental instance of a

pneumatic seeder that precisely seals seeds without feathers

into a tractor.

3 RESULTS AND DISCUSSION

The parameters of the planting disc used to plant

seeds in the slot, throwing 2 seeds into each slot: the

diameter of the suction holes is 3.5 mm, the diameter

of the circle in which the holes are located is 180 and

200 mm, the number of holes is 32x2 (32 groups, 2

holes in each group). In this case, the interval between

the seeds in the planted row should be equal to 12.5

cm.The intervals between slots as an evaluation

criterion for slotting seeds, the number of seeds that

got into each slot, as well as the degree of elongation

of the slots, was obtained. Besides, In field

experiments, the depth of seeding was determined. To

do this, 7 days after sowing the seeds, the sprouted

seedlings were dug out and the depth of instillation

was measured along the ethyl part of the roots.

Figure 2: View of the landing gear assembled (the landing

disc is not installed; the bottom cover is open): a) side view;

b) bottom view: 1-fastener housing; 2-fastener cover; 3-

gear adjustment mechanism; 4-cover of the hole for

removing hardware; 5-hole for removing hardware.

Figure 3: Assembled state of the landing discs (the landing

disc is not installed): 1-the body of the device; 2-the cover

of the device; 3-the central unloader; 4-radial unloaders.

Figure 4: Planting disc.

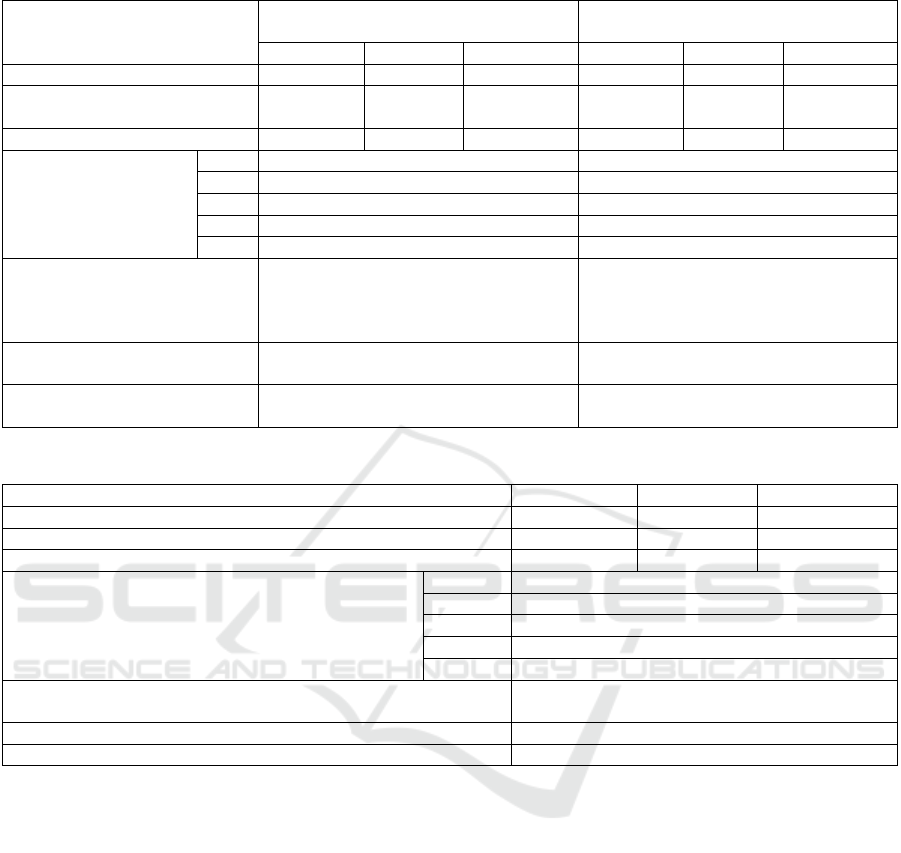

Table 1 shows the results of experiments

conducted at a unit speed of 1.45 m/s.

V

med

= 1.45

m/s; d

1

= 200 mm; d

2

= 180 mm; z = 32x2 pieces; d

m

= 3.5 mm; P = 40 mbar; i = 0.389; l

y

= 12.5 cm; The

variety of seeds is "Sultan".

As can be seen from the data in the table, when

the unit was operating at a speed of 1.45 m/s, the

distances between the slots averaged 11.9-12.0 cm,

the coefficients of their variation were 12.4-13.2%.

With a given number, i.e. the proportion of slots sown

in two, 67.4-74.5%, the proportion of slots sown in 2

± 1 pieces was almost 98%. The length of the nests

ranged from 0.6 to 1.0 cm, and the proportion of nests

no longer than 2 cm was about 77.6-89.4%. All these

indicators meet the preliminary time requirements.

The results obtained in the variants with a total

velocity of 2.1 m/s are shown in Table 2.V

med

= 2,1

m/s; d

1

= 200 mm; d

2

= 180 mm; z = 32x2 pieces; d

m

= 3.5 mm; P = 40 mbar; i = 0.389; l

y

= 12.5 cm; The

variety of seeds is "Sultan".The place where the

experiment was conducted: Inclined plane.

Experimental Field Studies to Determine the Parameters of an Improved Pneumatic Seeder Apparatus

65

Table 1: The results of experiments conducted at a unit.

Specification

n = 31,5 rpm;

l

у

= 12,5 c

m

n = 19,7 rpm;

l

у

= 20 c

m

М

med

±

σ

V

, %

М

med

±

σ

V

, %

Interval between slots, c

m

12,0 1,49 12,4 11,9 1,56 13,2

Number of seeds falling into the

slots,

p

cs

1,9 0,37 19,9 1,9 0,39 19,9

Stretching of the slots, c

m

0,6 0,76 118,9 1,0 1,03 102,3

Distribution of slots by

seed, %:

0 2,1 2,0

1 17,0 16,3

2 74,5 67,4

3 6,4 14,3

4 0 0

Planting accuracy (the amount

of slots in which the number of

seeds corresponds to standard

(

2±1

p

cs.

)

, %

97,9 98,0

Share of slots no more than 2 cm

in len

g

th, %

89,4 77,6

The amount of slots falling

b

etween the intervals, %

2,1 2,0

Table 2: Results of sowing seeds in two slot fields.

S

p

ecification

М

med

±

σ

V

, %

Interval between slots, c

m

12,1 1,72 14,3

Number of seeds falling into the slots,

p

cs 1,7 0,54 32,4

Stretching of the slots, c

m

0,4 0,63 146,3

Distribution of slots by seed, %:

03,7

1 30,4

2 59,3

35,9

40,7

Planting accuracy (the amount of slots in which the number of seeds

corres

p

onds to standard

(

2±1

p

cs.

)

, %

95,6

Share of slots no more than 2 cm in len

g

th, % 83,2

The amount of slots falling between the intervals, % 3,7

As can be seen from the table data, in this case,

the distances between them on average are 12.1 cm,

the coefficient of variation has become equal to

14.3%. The proportion of nests sown in 2 ± 1 pieces,

i.e., the sowing accuracy was 95.6%.The lengthening

of the nests turned out to be better than the previous

version – 0.4 cm, and the proportion of nests no

longer than 2 cm was 83.2%. These indicators also

meet the preliminary time requirements.

4 CONCLUSIONS

1. For cotton seeds, the optimal parameter is that the

holes in the pneumatic planting disc have a

diameter of 3.5 mm.

2. The pneumatic seeding machine fully meets the

temporary initial requirements for timely sowing

of seeds one at a time: the seeding accuracy was

more than 95% in laboratory and field

conditions.

3. The performance indicators of the pneumatic

seeding machine during nest planting correspond

to the temporary initial requirements. The

coefficient of variation of the actual values of the

intervals between the slots was 10.0-10.4% in

laboratory conditions, 14.3% in the field. The

percentage of nests in which the number of seeds

in the nest met the initial requirements (2 ± 1

pcs.), that is, the planting accuracy, was 95.2-

98.4% and 95.6%, respectively. The degree of

elongation of the formed nests was about 0.4-0.9

cm, and this corresponded to the initial

requirements.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

66

REFERENCES

Alimova, F.A., 2023. Mathematical modeling of small soil

channel laboratory stand drive and evaluation of its

energy state. IOP Conference Series: Earth and

Environmental Science, 1284, 012031. DOI:

10.1088/1755-1315/1284/1/012031.

Alimova, F., Primqulov, B., & Boboniyozov, E., 2022.

Parametres of the strip-tilling working bodies for re-

crops sowing. AIP Conference Proceedings, 2637(1),

050007. https://doi.org/10.1063/5.0118617.

Aslonov, N., & Irisov, K., 2023. Mathematical model of

resistance to spreading forces using a bulldozer blade.

E3S Web of Conferences, 390, 01032.

https://doi.org/10.1051/e3sconf/202339001032.

Byler, R.K., 2003. Moisture restoration for seed cotton, two

approaches. In Proc. Beltwide Cotton Conf, 767-771.

Djiyanov, M., Tadjibekova, I., Temirkulova, N., &

Kholmuradov, O., 2024. Development of rational

composition of assessment indicators of small technical

tools. In Lecture Notes in Networks and Systems, 733,

565–571. https://doi.org/10.1007/978-3-031-37978-

9_55.

Irisov, K. D., & Bekmurodov, I. R., 2023. Theoretical

aspects of substantiating the parameters of the working

body of an environmentally comfortable spraying unit.

IOP Conference Series: Earth and Environmental

Science, 1284, 012041. https://doi.org/10.1088/1755-

1315/1284/1/012041.

Javellonar, R. P., Delaraga, L. V., & Alegato, O. R., 2016.

Design, development and evaluation of a disc-type corn

seeder. Ilocos Journal of Science, 61.

Karimov, R., Bobojanov, M., Tairova, N., Xolbutayeva, X.,

Egamov, A., & Shamsiyeva, N., 2020. Non-contact

controlled voltage stabilizer for power supply of

household consumers. IOP Conference Series:

Materials Science and Engineering, 883(1), 012120.

DOI: 10.1088/1757-899X/883/1/012120.

Kathirvel, K., Reddy, A., Manian, R., & Senthilkuamr, T.,

2005. Performance evaluation of planters for cotton

crop. Agricultural Mechanization in Asia Africa and

Latin America, 36(1), 61.

Norchayev, D.R., Gaybullyev, B.Sh., Khayitov, A.N.,

Khusainov, B.S., & Khudaykuliev, A.A., 2024. Using

modern technologies to improve the vegetable

cultivator. BIO Web of Conferences, 105, 01023.

https://doi.org/10.1051/bioconf/202410501023.

Norchayev, D.R., Xaliqulov, M.A., Turkmenov, X.I.,

Shermuxamedov, X.P., & Ibragimova, G.N., 2022.

Acceptable solutions for harvesting root crops in the

soil climate of the Republic of Uzbekistan. IOP

Conference Series: Earth and Environmental Science,

1076(1), 012029. https://doi.org/10.1088/1755-

1315/1076/1/012029

Ramesh, B., Reddy, B.S., Veerangoud, M., Anantachar, M.,

Sharanagouda, H., & Shanwad, U.K., 2015. Properties

of cotton seed in relation to design of a pneumatic seed

metering device. Indian Journal of Dryland

Agricultural Research and Development, 30(1), 69-76.

http://dx.doi.org/10.5958/2231-6701.2015.00011.1.

Saidova, M., Tursunbaev, S., Boltaeva, M., Ismoilov, T., &

Gilijova, A., 2024a. Analysis of a pneumatic seeder

equipped with an improved planting disc. BIO Web of

Conferences, 105, 01024.

https://doi.org/10.1051/bioconf/202410501024

Saidova, M., Tursunbaev, S., Boltaeva, M., & Isakulova,

N., 2024b. Comparison of pneumatic sowing machines

by the number of seeds in the slots of the discs and the

distance between the slots. BIO Web of Conferences,

105, 01004.

https://doi.org/10.1051/bioconf/202410501004.

Singh, R.C., Singh, G., & Saraswat, D.C., 2005.

Optimisation of design and operational parameters of a

pneumatic seed metering device for planting

cottonseeds. Biosystems Engineering, 92(4), 429-438.

https://doi.org/10.1016/j.biosystemseng.2005.07.002.

Tukhtakuziev A., Barlibaev S., Rasuljonov A., Kholikulov

J., 2024a. Determining the depth of immersion of

combined machine ridge harvesters and the dimensions

of the ridges produced by them. BIO Web of

Conferences, 105, 01025.

https://doi.org/10.1051/bioconf/202410501025.

Tukhtakuziev A., Rasuljonov A., Azizov S., Temirkulova

N., 2024b. Substantiation of the parameters of the

double flat disc seeder for directly sowing repeated

crops in the soil after wheat crop harvesting in

Uzbekistan. BIO Web of Conferences, 105, 01015.

https://doi.org/10.1051/bioconf/202410501015.

Veerangouda, M., Maski, D., Desai, B.K., & Doddagoudar,

S.R., 2020. Study on some engineering properties of

cotton seeds in relation to the development of a tractor

operated seed dibbler. Journal of Pharmacognosy and

Phytochemistry, 9(5), 1836-1839.

Xiangdong, N.I., Guojie, X.U., Qi, W.A.N.G., Xiaorui,

P.E.N.G., Jian, W.A.N.G., & Bin, H.U., 2017. Design

and experiment of pneumatic cylinder array precision

seed-metering device for cotton. Nongye Jixie

Xuebao/Transactions of the Chinese Society of

Agricultural Machinery, 48(12).

Experimental Field Studies to Determine the Parameters of an Improved Pneumatic Seeder Apparatus

67