Device for Surfacing Parts of Agricultural Machinery

Irina Gorlova

a

and Iroda Tadjibekova

b

Tashkent State Agrarian University, 100140, University str. 2, Tashkent, Uzbekistan

Keywords: Hydrogen-Oxygen Cladding, Agricultural Machinery, Wear-Resistant Coating.

Abstract: In increasing labor productivity, improving product quality and saving raw materials, the surfacing method

plays an important role in the production of industrial equipment, its operation and repair. During active

operation, parts of machines and mechanisms fail due to shock loads, abrasion, etc. Modern technology has

various methods for restoring and strengthening parts to increase their service life. One of the modern

technological processes for restoring parts is surfacing. Surfacing is the application of a layer of metal to the

surface of a work piece or product through fusion welding. The proposed device for surfacing parts in a

hydrogen-oxygen environment is a solution to the problems of the technological process of repair and

restoration welding and surfacing

.

1 INTRODUCTION

During active operation parts of machines and

mechanisms fail due to shock loads, abrasion, etc.

Modern technology has various methods of

restoration and hardening of parts to increase their

service life (Avdeev et al., 1986; Gorlova &

Tadjibekova, 2010; Khudayorov et al., 2023;

Khaliknazarov et al., 2024; Khaliknazarov &

Ibrokhimov, 2024).

One of the modern technological processes of

parts restoration is cladding. Cladding is the

application of a layer of metal on the surface of the

workpiece or product by means of fusion welding.

At repair works of any kinds of technics mainly

the restorative surfacing is used. Restorative

surfacing is used to obtain the original dimensions of

worn or damaged parts. In this case, the clad metal is

similar in composition and mechanical properties to

the base metal. Cladding is most widely used in repair

work to restore housing parts of various internal

combustion engines, camshafts, crankshafts, valves,

pulleys, flywheels and wheel hubs. Cladding can be

performed by almost all known methods of fusion

welding. The most important requirements for

cladding are as follows:

• minimum penetration of the base metal;

• minimum value of residual stresses and metal

a

https://orcid.org/0009-0002-4497-9663

b

https://orcid.org/0009-0005-8093-1968

deformation in the cladding zone;

• reduction of allowances for post-processing of

parts to acceptable values.

2 MATERIALS AND METHODS

Rational method of repair of machinery and

equipment is determined by the choice of surfacing

method and is determined by the possibility of

obtaining a clad layer of the required composition and

mechanical properties, as well as the nature and

permissible amount of wear. The choice of cladding

method is influenced by the size and configuration of

parts, productivity and the share of base metal in the

clad layer. The main types of surfacing: argon-arc

with a non-melting electrode, melting electrode in a

protective gas, manual arc welding with coated

electrodes, arc welding with self-shielded wire,

plasma powder.

Cladding work is carried out by various methods

of welding arc, gas, plasma, electronic, etc. Cladding

process can be mechanized and automated. Special

cladding units with automation of the main operations

are produced. The device presented in this article

belongs to the field of agricultural engineering, in

particular to devices for surfacing new or used worn-

out machine parts.

50

Gorlova, I. and Tadjibekova, I.

Device for Surfacing Parts of Agricultural Machinery.

DOI: 10.5220/0014044100004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 50-54

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

The most commonly used cladding devices

contain a nozzle, channels for supplying cladding

powder, oxygen, conveying and combustible gas. The

disadvantage is excessively high plasma temperature,

which reaches 7000-15000 0C, because of which it is

impossible to use easily fusible polymer powders or

non-ferrous metal powders, which limits the

technological capabilities of the devices.

The standard device is a prototype and for plasma-

arc surfacing, consisting of a plasma-forming head,

with a non-fusible electrode and with a cooling cavity

and side channels of tubes for supplying coolant and

powder materials, a mechanism for feeding long

metal or polymer materials, vaporizing manifold and

hinge mechanism. The disadvantage of such a device

is the complexity of the vapor-forming system and the

use of inert gas to obtain the plasma-forming medium,

which leads to an increase in the cost of clad parts, as

well as to an increase in air pollution at the workplace,

high energy and metal consumption of the cladding

process, increased losses of clad materials due to the

formation of large droplets of cooling medium

(Muhammadiev et al., 2020; Khaliknazarov et al.,

2021; Bokiev et al., 2021; Alimova et al., 2022;

Djiyanov et al., 2022; Saidova et al., 2023; Djiyanov

et al., 2024a; Djiyanov et al., 2024b; Isakova et al.,

2024; Irisov, 2024).

In addition, burnout occurs under the influence of

high temperatures, and due to burnout of easily

fusible, both metal, polymer and powder materials,

the range of cladding parts of machines is reduced.

The task of the presented device useful model, is

to expand the technological possibilities of cladding

device, increase the range of clad parts and reduce

harmful emissions into the environment. The set task

is achieved by the fact that the device for surfacing

parts in hydrogen-oxygen medium, consisting of a

plasma-forming head with a non-fusible electrode

and with a cooling cavity and side channels, tubes for

supplying coolant and powder materials, a

mechanism for supplying long material and a hinge

mechanism, is distinguished by the fact that the

plasma-forming head is additionally equipped with a

mixing chamber and a system for forming a

hydrogen-oxygen combustible mixture, that the

plasma-forming head is additionally equipped with a

mixing chamber and a system for the formation of

hydrogen-oxygen combustible mixture, and the non-

fusible electrode is mounted symmetrically on the

back side of the perforated flap, the hinge mechanism

is made multilink, one end of which is connected to

the body of the plasma-forming head, and with the

other to the mouthpiece of the mechanism for feeding

long-size surfacing rods, and the device is equipped

with an exhaust system.

3 RESULTS AND DISCUSSION

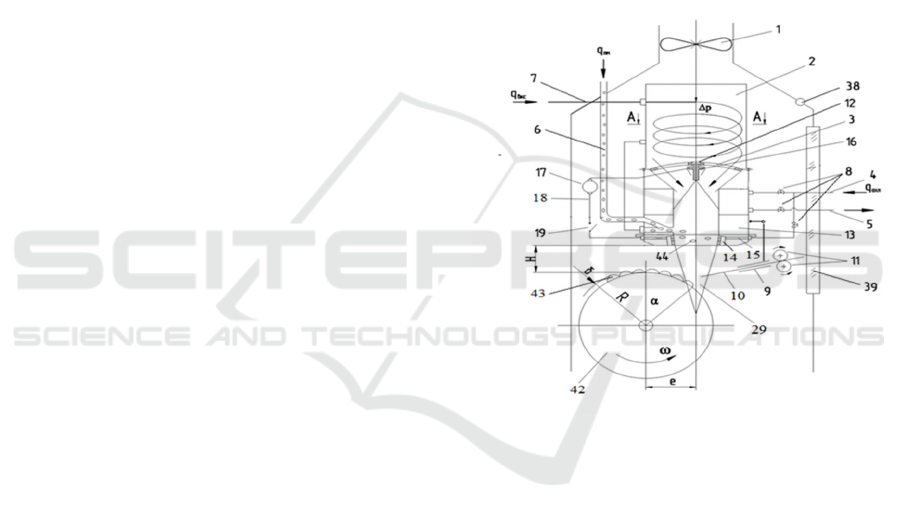

Figure 1 shows the proposed device for cladding parts

in hydrogen-oxygen medium (where: ω - rotation

frequency of the clad part; α - angle of plasma torch

touch; R - radius of the part; δ - thickness of cladding;

H-height of plasma-forming head nozzle

(plasmatron) installation; e - eccentricity; Δp -

working pressure drop; qohl - flow rate of cooling

medium; q51Bvx - flow rate of hydrogen-oxygen

medium. hydrogen-oxygen medium.

Figure 1: Schematic diagram of the device for surfacing

parts in hydrogen-oxygen medium.

The device for surfacing parts in hydrogen-

oxygen medium consists of a mixing chamber 1

(Fig.1 ), with perforated flap 2, cooling cavity 3 with

supply 4 and withdrawal 5 tubes, providing

continuous supply and withdrawal of coolant, side

channel 6 for powder material supply and tube 7 for

supply of local portion of hydrogen-oxygen

combustible mixture formed in the system, three

valves 8, mouthpiece 9 for feeding a long rod 10, feed

rollers of a multi-link hinge mechanism 11, plasma-

forming head 12 of a perforated flap, nozzle of the

plasma-forming head, which is equipped with a

vapor-forming system consisting of a perforated ring-

shaped working chamber 13 with feed channels 14

and 15. The perforated flap is equipped with a non-

fusible tungsten electrode 16, a generator 17, an

electric circuit 18 with a switch 19. The device is

Device for Surfacing Parts of Agricultural Machinery

51

additionally equipped with a viewing window 38 and

exhaust system 39.

Figure 2: A-A cross section of the mixing chamber (where

rk is the radius of the mixing chamber).

Fig. 2 shows the cross-section of the mixing

chamber along A-A (where rk - radius of the mixing

chamber), in which the perforated flap is made

replaceable and has the shape of a confuser.

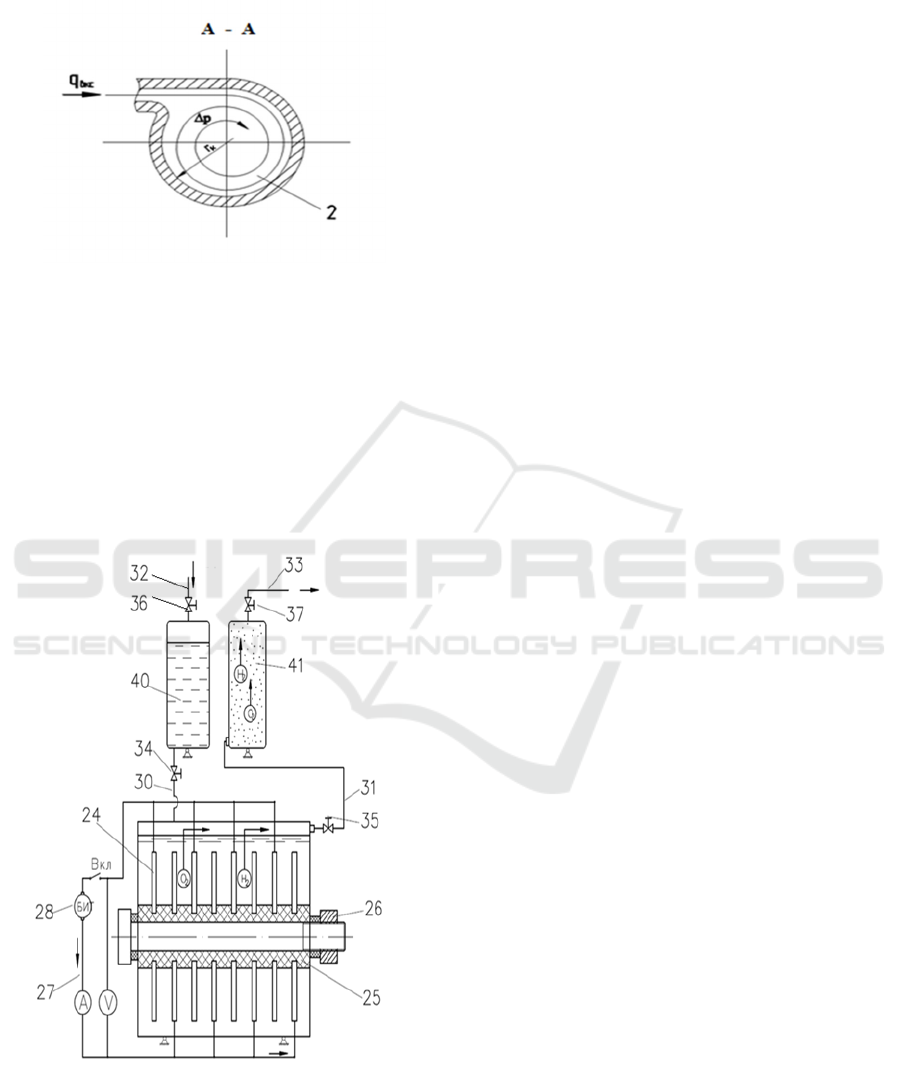

Fig. 3 shows the schematic diagram of hydrogen-

oxygen combustible mixture formation (where: A -

ammeter; V - voltmeter; O2 - oxygen; H2 - hydrogen;

BIT – pulse current block).

Figure 3: Principal scheme of hydrogen-oxygen

combustible mixture formation (HOCM).

The proposed device is also equipped with an

autonomous system for the formation of hydrogen-

oxygen combustible mixture (Fig. 3) and consists of

a number of flat disks 24, rigidly mounted in a

horizontal dielectric axis 25 and tightened on both

sides of the nut 26 in a single monoblock, and flat

disks 24 are connected to the electrical circuit 27

pulse current block (PIB) 28.

A small portion of liquid, enters through the

perforated ring-shaped working chambers 13 under

the influence of a high temperature gradient of the

torch 29 of the electric arc. The self-contained system

is provided with a system of tubes 30, 31, 32, 33 with

valves 34, 35, 36 and 37. The system includes a tank

40 for distilled water and a broiler 41 for collecting

the hydrogen-oxygen mixture. The plasma-forming

head 12 is connected to the multi-link hinge

mechanism 11 in the lower part. The inner wall of the

nozzle of the plasma-forming head is perforated.

The device for surfacing parts in hydrogen-

oxygen medium works as follows. In the process of

cladding new or worn parts 42 with fusible metal or

polymer powders, the hydrogen-oxygen combustible

mixture supplied through the chamber is ignited from

the electric arc of the tungsten electrode 16 and

further, flowing around the electric arc, forms a high-

temperature plasma torch 29, which is transported at

high speed to the cladding zone. Powdered metallic

polymeric materials 44 fed through the side channel

6 are injected into the plasma torch structure and

transformed into liquid droplets 43 and further

applied to the surface of the workpiece 42, forming a

wear-resistant thin metal or polymer coating of

thickness “δ”. Pulsed current (IT), intensively acting

on the walls of spherical disks 24, increases the

WCGS productivity. With the growth of the reactor

WCGS productivity, the pressure drop Δp and the rate

of WCGS feeding into the mixing chamber 1 of the

plasma-forming head 12 increase. Under the action of

IT there is a local expansion of distilled water (DW)

to atomic hydrogen (H2 ↑) and oxygen (O2 ↑), which

in the form of a swarm of bubbles, floating above the

level (DW) of the working fluid and further, through

broiler 41 and supply tube 33, are transported into the

cavity of mixing chamber 1, providing stability of

formation of high-temperature plasma, providing

surfacing of a large range of new or worn machine

parts. The coolant flow rate and VKGS are regulated

through valves 8, and the cladding mode is regulated

by setting the height H of the nozzle of the plasma-

forming head relative to the surface of the part to be

restored 42. When cladding light-melting metal or

polymer powders, it is sufficient to select the optimal

dose of coolant supplied through the tube 4 by

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

52

adjusting the valve. In the process of using long

lengths of fusible metal or polymer rods, the supply

of powder materials through the side channel 6 is

temporarily suspended, and the hinged rod feeding

mechanism 11 is put into operation. Long-length

fusible rod 10 under the action of plasma torch

temperature melts, forming small metal or polymer

liquid droplets 43, which under the action of high

velocity of plasma torch of plasma electric arc are

applied to the surface of the clad part 42, forming a

cladding thickness equal to (δ).

Selection of the optimum plasma torch height 29

and cladding quality is achieved by adjusting the

plasma torch height H and the working pressure Δp

of the plasma arc in the mixing chamber 1. Exhaust

system 38 with a viewing window 39 provides

periodic process control over the process of cladding

and reliable protection of the breathing zone of the

operator from harmful chemical components emitted

during the cladding process. Turning off the supply of

powder materials through the side channel 6 of the

plasma-forming part, as well as the metal rod 10,

through the mouthpiece 9 can be carried out and heat

treatment of the working surface of the part without

cladding, thereby increasing its wear resistance. The

multi-link hinge mechanism ensures optimum plasma

torch height. By varying the coolant flow rate through

the perforated side working chamber, the optimum

cladding and heat treatment mode can be selected

depending on the type and size of the materials to be

clad.

Due to adjustable supply of VKGS to the cladding

zone, in comparison with the temperature of electric

arc, relative to the temperature of hydrogen-oxygen

combustible mixture, the optimal mode for cladding

of both low-melting powders or rods and refractory

powders or rods is created, which significantly

increases the nomenclature of clad parts, thus

expanding the technological capabilities of the

proposed device. The coolant supplies through the

perforated wall of the nozzle of the plasma-forming

head creates optimal conditions for reliable

deposition of harmful components emitted in the

process of cladding parts. By reducing the

temperature gradient of the plasma plume formed by

the supplied working mixture, burnout of easily

fusible metal or polymer materials is excluded. The

method of heat treatment significantly reduces the

cost of restored parts. All this in general will give the

national economy of the country a significant

technical and economic effect.

4 CONCLUSIONS

In comparison with other methods of surface

treatment of metal, the use of the device for surfacing

of parts in hydrogen-oxygen environment has a

number of advantages:

1. the possibility of applying a metal coating of

large thickness; it gives a significant effect in

the restoration of severely worn parts, which is

more economical compared to the previously

used technology of manufacturing similar

vessels from clad steel obtained by rolling;

2. high productivity;

3. relative simplicity of design and

transportability of equipment adapted for

outdoor work, for example, cladding of parts of

earthmoving and agricultural machinery in the

field;

4. no limitations on the size of the cladding

surfaces of the products; e.) have a significant

limitation on the size of the processed products;

5. ease of performance, especially in automatic or

semi-automatic cladding mode;

6. the possibility of applying a wear-resistant

coating on the base metal of any composition;

7. the possibility of increasing the efficiency of

cladding by combining it with other methods of

surface treatment.

This device is aimed at maintaining and restoring

the resource of agricultural machinery and is

recommended for use in repair and restoration work

at repair enterprises.

The method of heat treatment significantly

reduces the cost of restored parts and all this in

general will give the national economy of the country

a significant technical and economic effect.

REFERENCES

Alimova, F.A., Primkulov, B.Sh., Saidova, M.T. &

Boboniyozov, E.A., 2022. Combined aggregate for

strip tillage and simultaneous sowing of re-crops. IOP

Conference Series: Earth and Environmental Science,

1112, 012021. https://doi.org/10.1088/1755-

1315/1112/1/012021.

Avdeev, M.V., Volovik, E.P., Ulman, I.E., 1986. Device for

plasma metallization. Technology of repair of machines

and equipment. M: Agropromizdat, 126-127.

Bokiev, A., Nuralieva, N., Sultonov, S., Botirov, A.,

Kholiknazarov, U., 2021. Diversification of energy

supply to the agricultural sector in the conditions of

Uzbekistan. E3S Web of Conferences, 264, 04022.

https://doi.org/10.1051/e3sconf/202126404022.

Device for Surfacing Parts of Agricultural Machinery

53

Djiyanov, M., Tadjibekova, I. & Temirkulova, N., 2022.

Development of models for functioning of a universal

service center in agriculture of Uzbekistan. IOP

Conference Series: Earth and Environmental Science,

1068, 012004. DOI: 10.1088/1755-

1315/1068/1/012004.

Djiyanov, M., Xalilov, R., Isakova, F. 2024a. Justification

of commercialization of export-oriented harvesting

apparatus for intensive processing of cotton boxes. BIO

Web of Conferences, 85, 01034.

https://doi.org/10.1051/bioconf/20248501034.

Djiyanov, M., Tadjibekova, I., Temirkulova, N.,

Kholmuradov, O., 2024b. Lecture Notes in Networks

and Systems, 733: 565–571.

Gorlova I.G., Tadjibekova I.E., 2010. Plasmatron for

surfacing of new and worn parts of machines. Booklet

“Uz EXPOCENTER”.

Irisov, K., Gorlova, I. & Khudaev, I. 2024. The method of

dispersion analysis of droplets using mini droplet cards

for resource-saving agricultural technologies. BIO Web

of Conferences, 105, 01016. DOI:

https://doi.org/10.1051/bioconf/202410501016.

Isakova, F., Tadjibekova, I., Kurbonov, F., 2024.

Improvement methods of feeding of aquaculture. BIO

Web of Conferences, 85, 01037.

https://doi.org/10.1051/bioconf/20248501037.

Khaliknazarov, U., Akbarov, D., Tursunov, A., Gafforov,

S., Abdunabiev, D., 2021. Existing problems of drying

cocoon and making chrysalis feeble, and their solutions.

IOP Conf. Series: Earth and Environmental Science,

939, 012020. DOI: 10.1088/1755-1315/939/1/012020.

Khaliknazarov, U., Ibrokhimov, U. 2024. Design of a water

pump-solar source system for drinking water supply.

BIO Web of Conferences, 85, 01004.

https://doi.org/10.1051/bioconf/20248501004.

Khaliknazarov, U., Tursunov, A., Jalilov, N., Dinikulov,

D., 2024. Lecture Notes in Networks and Systems, 733,

573–579.

Khudayorov, Z., Khalilov, R., Gorlova, I., Mirzakhodjaev,

S., Mambetsheripova, A., 2023. Mathematical model of

water drop trajectory in artificial rainfall. E3S Web of

Conferences, 365, 04011

https://doi.org/10.1051/e3sconf/202336504011.

Muhammadiev, A., Yunusov, R., Bayzakov, T., Sattarov,

N., Yusupov, Sh., Xaliqnazarov, U. & Sattarov, M.,

2020. Liner motor drive of cattle farm feeders. IOP

Conference Series: Earth and Environmental Science,

614, 012013. DOI: 10.1088/1755-1315/614/1/012013.

Saidova, M., Alimova, F., Tursunbaev, S., Kulmuradov, D.

& Boltaeva, M., 2023. Influence of the shape of the disc

slots of the seeder on the suction force of the vacuum

for precise sowing of seeds. IOP Conference Series:

Earth and Environmental Science, 1284, 012014.

https://doi.org/10.1088/1755-1315/1284/1/012014.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

54