Development Testing and Energy Efficiency Assessment of

Electrotechnology for Resiving Mulberry Silkworm Sponge

Urolboy Khaliknazarov

a

, Bobur Kamilov

b

, Abbas Tursunov

c

, Ulugbek Ibrokhimov

d

and Bekzod Choriev

e

Tashkent State Agrarian University, 100140, University str. 2, Tashkent, Uzbekistan

Keywords: Electrotechnology, Silkworm Processing, Energy Efficiency.

Abstract: Since the cocoon and the dome inside it have different electrical absorption capacity, treatment with an

ultrahigh frequency electromagnetic field during degreasing of the silkworm dome of the silkworm makes it

possible to achieve higher efficiency compared with other electrical physical influences. Because the ultrahigh

frequency electromagnetic field is absorbed only in the dome, almost not being absorbed by the cocoon shell.

As a result, the dome inside the cocoon is burned by heating at high temperature for a short period of time

.

1 INTRODUCTION

Today, new technologies are being applied in the

world for growing, storing and processing cocoons.

In particular, scientific-research works aimed at

developing new scientific and technical solutions of

resource-saving technology and techniques of cocoon

devitrification are being carried out. In this regard,

special attention is paid to the use of energy and

resource-saving methods, which ensure complete

inanimation of the cocoon without cracking,

compared to heat and chemical treatment. Therefore,

it is an important task to develop an electrotechnology

that ensures the complete death of the cocoon without

adversely affecting the quality of the cocoon, as well

as to justify its technological parameters and

operating modes.

In the cocoon processing enterprises in our

country, the silkworm inside the cocoon is killed by

hot air treatment to kill the cocoon during the drying

process. In this process, the high energy consumption,

low productivity and 7-8 hours of re-drying after

processing lead to deterioration of the quality index

of the obtained silk product. Therefore,

a

https://orcid.org/0009-0003-8775-5333

b

https://orcid.org/0000-0003-1430-5029

c

https://orcid.org/0000-0003-1430-4489

d

https://orcid.org/0009-0008-6732-9915

e

https://orcid.org/0009-0005-4806-1982

comprehensive measures are being implemented to

gradually provide the silk industry with modern,

energy-efficient technologies (Khaliknazarov et al.,

2021; Khaliknazarov & Turdiboyev, 2021; Radjabov

et al., 2021; Turdiboyev et al., 2022; Khaliknazarov

et al., 2024; Khaliknazarov & Ibrokhimov, 2024;

Mirzakhodjaev et al., 2024).

The demand for natural silk and silk fabrics in

Jakhan bazaar is increasing day by day. In the world,

more than 630,000 tons of cocoons are grown

annually by more than 35 countries, and they are

primarily processed into raw silk. China, India,

Uzbekistan, Thailand, Brazil, Vietnam, North Korea

and Iran are among the advanced countries engaged

in cocoon preparation and processing (Khaliknazarov

& Turdiboyev, 2021; Radjabov et al., 2021;

Turdiboyev et al., 2022; Khaliknazarov &

Ibrokhimov, 2024).

One of the important issues is the modernization

and technical re-equipment of silk industry

enterprises, the introduction of modern energy-saving

innovative technologies and developments that can

ensure the improvement of the quality of natural silk

products.

Khaliknazarov, U., Kamilov, B., Tursunov, A., Ibrokhimov, U. and Choriev, B.

Development Testing and Energy Efficiency Assessment of Electrotechnology for Resiving Mulberry Silkworm Sponge.

DOI: 10.5220/0014043900004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 45-49

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

45

2 MATERIALS AND METHODS

Requirements for technical and technological

indicators of animized and dried cocoons.

According to GOST 8417-57, depending on the

quality of the dead and dried cocoons and the yield of

raw silk, the cocoons are divided into 1 and 2 grades.

(Turdiboyev et al., 2022).

According to the characteristics of the shell

surface, each type of cocoon must meet the following

requirements:

Table 1: Classification of the cocoon into classes depending

on the characteristics of the shell surface.

Varieties

of

cocoons

Characteristics of the surface of the

cocoon

1

Clean, unshelled cocoons. A batch with no

spots on the surface or spots with a total

diameter of no more than 5 mm, each scar

no more than 10 mm, and spots with

smooth shiny spots no longer than 10 mm

in len

g

th is allowed.

2

A cocoon with a spot or a total spot on the

surface not exceeding 25% of the shell

surface, each spot not exceeding 15 mm in

length, a batch of spots with smooth shiny

areas not exceeding 15 mm, deformed,

thin-walled, forms characteristic of this

variety, or hybrid and thin transparent

cocoons.

If there are several scars or smooth shiny areas on

the surface of the cocoon, its variety is determined by

the largest size of one of the scars or smooth shiny

area (Khaliknazarov & Turdiboyev, 2021).

Varieties include undifferentiated cocoons,

cocoons with spots on the cocoon surface more than

25% of the total cocoon shell surface, scar more than

15 mm, smooth shiny area more than 15 mm. The

entire length of the shell is strongly deformed and the

bark is sticky, the surface of the shell is covered with

spots, twining, leaking, moldy, hardened,

underdeveloped, and the shape is sharply distorted

(Khaliknazarov & Turdiboyev, 2021; Radjabov et al.,

2021; Turdiboyev et al., 2022; Khaliknazarov &

Ibrokhimov, 2024; Mirzakhodjaev et al., 2024).

A whole cocoon that is of high quality in terms of

shell surface characteristics and meets the

requirements of Level 2 cocoons, but has a raw silk

yield of less than 23%, is classified as substandard.

The productivity of cocoons of grade 1 should be

-35.7%, the productivity of cocoons of grade 2 -

28.8% (Turdiboyev et al., 2022).

Moisture content for all types of cocoons is set at

10.0%.

No more than 10.0% of the cocoon content of

black pods and live specimen pods, separated into

varieties, is allowed.

Moisture content of raw silk is allowed up to

11.0%.

The moisture content of cocoons supplied to

sericulture factories should be less than 4%

(Khaliknazarov & Ibrokhimov, 2024).

3 RESULTS AND DISCUSSION

An ultra-high frequency electromagnetic field

treatment device in killing mulberry silkworm

cocoons.

On the basis of the above results obtained in

laboratory conditions, a technical assignment was

developed for the design of an electrical technological

device for the death of the mulberry silkworm

cocoon.

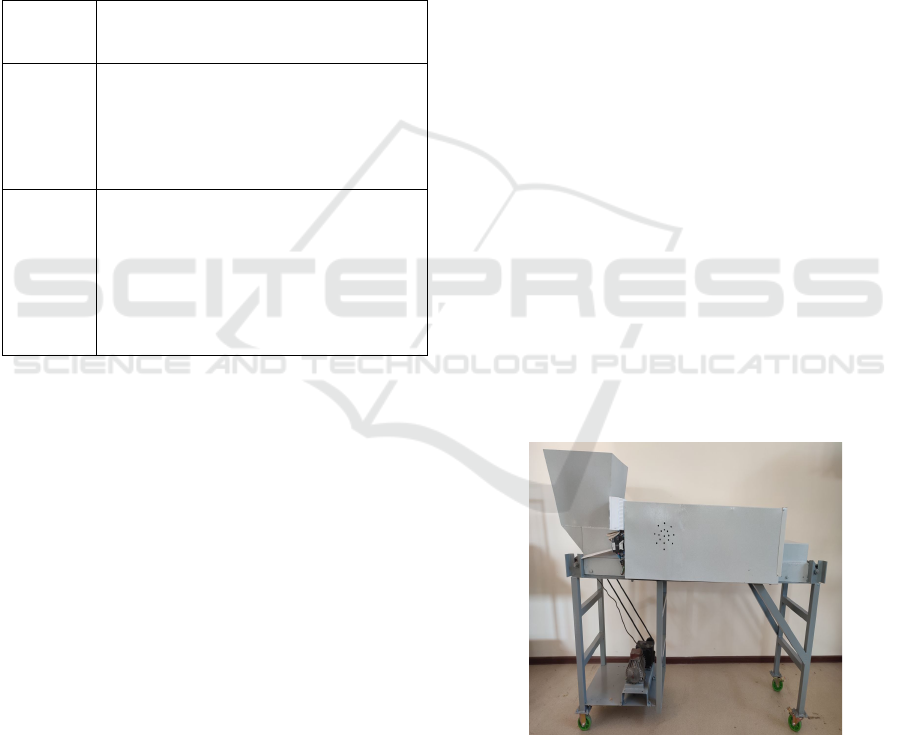

Figure 4.1 shows an overview of the ultra-high-

frequency electro-magnetic field treatment device

used to kill the mulberry silkworm cocoon. The first

processed cocoons are placed in a hopper with a

distributing iron box. From the hopper, the cocoons

are transferred to the processing chamber by means

of a moving belt conveyor. The belt conveyor is

driven by a 1.1 kW asynchronous electric motor and

a reduction gear. The drive of the belt conveyor

through the reducer is carried out with the help of

pulleys and a belt.

Figure 1: An overview of the first ultra-high-frequency

electric magnetic field treatment device for cocoons.

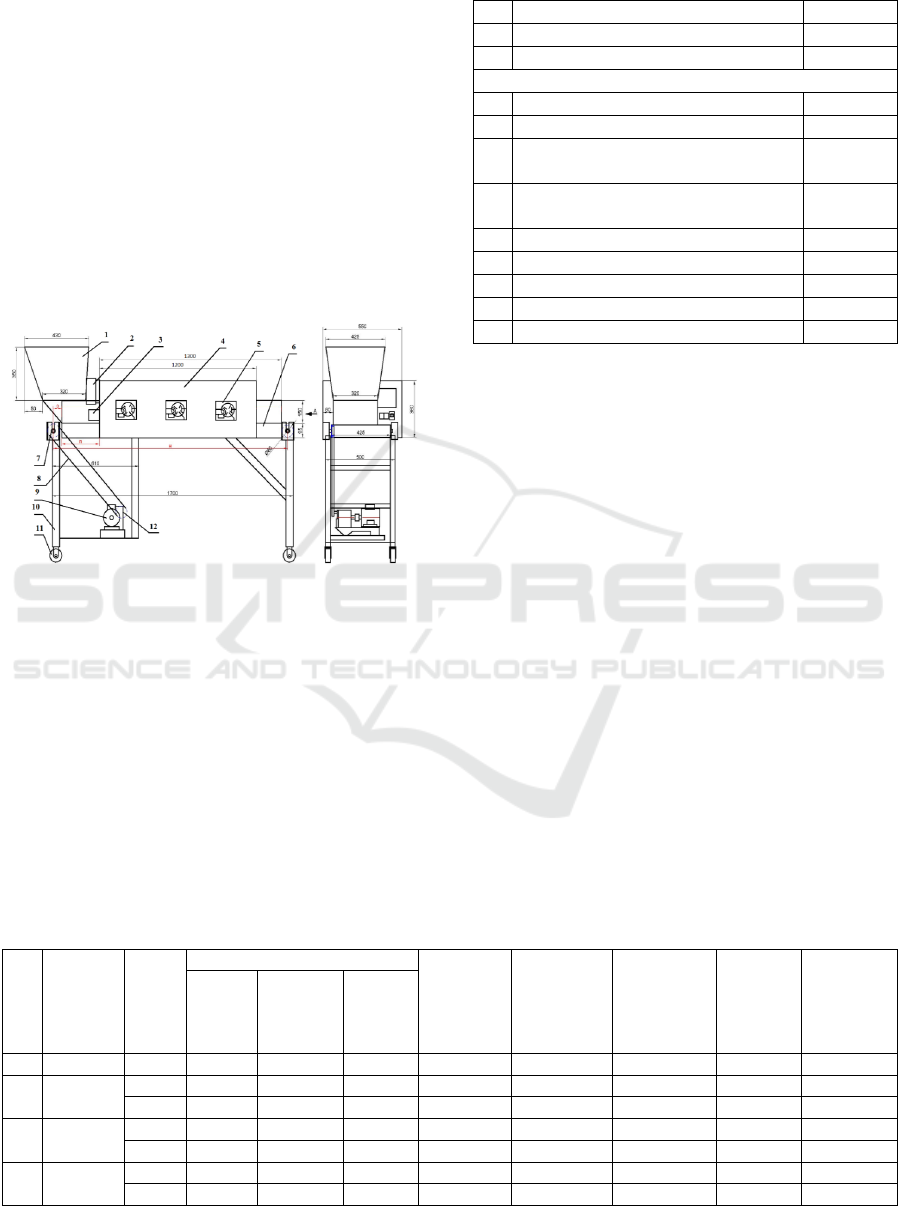

The device consists of three working cameras.

Three 1000 W magnetrons are installed on the side

walls of the working chamber. (Figure 2). The

cocoons are placed in a hopper with a distributing iron

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

46

box. Device start-up electrical control box 2 and 3

(shchiti). From the hopper, the cocoons are

transferred to the processing chamber 4 by means of

a moving belt conveyor. On the sides of the working

chambers, 5 magnetrons with 1000 W of power for

primary processing of the cocoon are installed. The

dead cocoons are introduced into the working

chamber through a conveyor belt 6. The conveyor

with a moving belt is driven by the drive shaft 7, the

electric motor 9 with a power of 1.1 kW.

The principle circuit diagram of the cocoon

pretreatment device with an ultra-high frequency

electric magnetic field is shown in Figure 2. The

device is protected by a circuit breaker (QF) to protect

it from short circuit and overload currents.

a) Main view b) Side view

Figure 2: Scheme of arrangement of the elements of the

pretreatment device with an ultra-high frequency electric

magnetic field in the cocoon. 1. Iron cell bunker 2. Electric

control box that starts the device 3. Programmable time

relay 4. Working camera 5. Ultra high frequency

electromagnetic wave scattering magnetron 6. A cocoon

conveyor with a moving belt 7. Belt conveyor drive shaft 8.

Belt drive belt conveyor 9. Electric motor 10. Device

support 11. Wheels of the device.

An M1 electric motor is used to rotate the

conveyor belt.

The main technical indicators of the device are

presented in Table 2.

Table 2: Technical indicators of the device.

№ Productivity Value

1 During the death of the cocoon, kg∙h 60

2 During semi-drying, kg∙h 12

Device parameters

1 Number of working chamber, piece 3

2 Width of the working chamber, mm 320

3 The thickness of the processed

cocoon layer, mm

30

4 Movement speed of conveyors,

m/min

0,68

5 Installed electric motor capacity, kW 1,1

6 Power of magnetrons, kW 3∙1=3

7 Fan power for cooling, kW 0,075

8 Total energy consumption, kWh 2.1

9 Service worker 1 person

The structural indicators of the cocoon obtained

for the experiment are presented in Table 3.

Results of an experiment conducted under

production conditions of a mulberry silkworm cocoon

deactivation device.

The following were taken as the main factors

representing the effect of an extremely high

frequency electric magnetic field: Power of

processing device (R), Processing time (t), and

thickness of the processed product layer (h). In order

to evaluate the effectiveness of the ultra-high

frequency electromagnetic field and to characterize

the processed product, the degree of inactivation of

the sponge inside the cocoon (W) was adopted.

The following parameters were adopted in order

to achieve the maximum level of inanimation during

treatment with an extremely high frequency electric

magnetic field before inanimation of the mulberry

silkworm cocoon: R=950-1000 W; t = 29-30 minutes;

h = 30mm.

In killing the silkworm cocoon: the cocoon is

treated with an extremely high frequency electric

magnetic field.

Table 3: Structural indicators of the cocoon taken for the experiment.

№ Cocoon

Class

Class The size of the cocoon, % Average

weight of

the

cocoon, g

The

average

weight of

the

cocoon,

g

Average

silkiness of

cocoons,%

Average

flatness

of silk

Metric

number

of cocoon

fiber, m/g

Small

(14-15

мм)

Medium

(16-19

мм)

Large

(20-22

мм)

1 2 3 4 5 6 7 8 9 10 11

1. China

I 4,50 78,26 17,24 2,.23 0,417 41,78 0,274 3650

II 4,10 77,15 16,33 1,94 0,389 40,28 0,238 3592

2.

Ipakchi-

1

I 4.48 77.33 16.67 2.22 0.497 50.90 0.272 3676

II 4,36 76,83 16,12 1,99 0,415 50,56 0,242 3601

3.

Ipakchi

-2

I 4.31 78.21 16.85 2.21 0.424 42.25 0.269 3595

II 4,25 76,28 16,61 2,18 0,422 41,85 0,253 3498

Development Testing and Energy Efficiency Assessment of Electrotechnology for Resiving Mulberry Silkworm Sponge

47

By first treating the cocoon with an ultra-high

frequency electromagnetic field, the degree of

inactivation of the cocoon bubble was increased to

96-100%. The duration of electrical treatment, the

thickness of the cocoon layer, the amount of slime on

the surface of the cocoon, the type of cocoon, and the

intensity of the electric field affect the death of the

mulberry silkworm cocoon. The duration of electrical

treatment, the thickness of the cocoon layer, the

amount of slime on the surface of the cocoon, the type

of cocoon, and the intensity of the electric field affect

the death of the mulberry silkworm cocoon.

The following varieties of cocoons were taken for

research.

"China" - I, II class

"Ipakchi 1" - I, II class

"Ipakchi 2" - I, II class

As a result of the tests conducted under production

conditions, it was determined that the cocoon

processing device with an ultra-high frequency

electric magnetic field is suitable for providing the

parameters and modes of the technological process

under the production conditions of the laboratory

copy.

A study was conducted to check the technological

mode and parameters of mulberry silkworm cocoons

in the production line of the cocoon primary

processing enterprise belonging to "TST Agrocluster"

LLC, Kuyichirchik district, Tashkent region.

In order to conduct experiments under production

conditions, the structural indicators of cocoons were

analyzed in the laboratory of the primary cocoon

processing enterprise belonging to "TST Agroklaster"

LLC.

The results of the experiment on killing the

mulberry silkworm cocoon with an extremely high

frequency electric magnetic field are presented in

Table 4.

From the experimental tests carried out under

production conditions, we can say that the yield of

defective cocoons when killing the mulberry

silkworm cocoon according to the proposed

technology is up to 4-5%, while in the current

technology it is 10-11%. Compared to the current

technology, the output of defective cocoons is

reduced to 5-6%. As a result, it is possible to improve

the quality indicators of the silk obtained from the

cocoon.

Evaluating the efficiency of electrotechnology

for killing the mulberry silkworm cocoon.

The ultra-high frequency (UHF) electric magnetic

field treatment device for killing the mulberry

silkworm cocoon was tested at the cocoon processing

enterprise of "TST Agrocluster" LLC, Lower

Chirchik district. Economic efficiency was calculated

on the basis of the current technology used in killing

the mulberry silkworm and the results obtained with

ultra-high frequency (UHF) electromagnetic field

treatment. Table 5 lists the names of the equipment

used in the death of mulberry silkworm cocoons and

the amount of electricity and heat energy used to

process 1 ton of the product.

Based on the table given above, we determine the

relative amount of electricity and fuel used for the

processing of 1 ton of the product and the amount of

processed product of the equipment used in the

process of killing the mulberry silkworm through the

following expression.

tons

hourkW

,

⋅

=

i

i

i

A

P

W

(1)

Here Р

i

– power of the equipment;

А

i

– Product

processing efficiency of the equipment in 1 hour;

We calculate the relative electricity and diesel fuel

consumption for killing 1 tons of mulberry silkworm

cocoon in the SK-150K device.

tons

96

3625,0

8,34

yelectricit

hourкW

W

⋅

==

tons

liter

100

3625,0

5,36

diesel

==W

Table 4: The technological process of killing the mulberry silkworm cocoon and the amounts of energy used for it.

№

Technological

process

Device name Productivity

Electricity consumption in

1 hour for cocoon

p

rocessin

g

; kWh

Diesel fuel consumption

in 1 hour for cocoon

p

rocessin

g

; l.

1

Killing the mulberry

silkworm cocoon

SK-150K 8,7 tons/day 34,8 36,5

2

Killing the mulberry

silkworm cocoon

Very high

frequency

electric fiel

d

0,288

tons/day

2,1 -

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

48

We calculate the relative electricity consumption

for killing 1 tons of mulberry silkworm cocoons in the

proposed ultra-high frequency electric magnetic field

treatment device.

tons

175

012,0

1,2

yelectricit

hourкW

W

⋅

==

Considering that the price of 1 kW∙s of electricity

for production enterprises today is 450 soums, 43200

soums for processing 1 ton of live cocoons in the SK-

150K device;

Considering the price of diesel fuel is 5800 soums,

580000 soums will be spent.

78750 soums will be spent if the proposed ultra-

high-frequency electric magnetic field is treated.

We determine the difference in comparative costs

for killing 1 ton of mulberry silkworms according to

the current and proposed technology.

tons

Э

soum

544450

7875058000043200

=

−+=Δ

If an average capacity cocoon processing plant

processes 60 tons of cocoons in one season;

soum32667000

54445060

seasonseason

=

⋅=Δ⋅=Δ ЭАЭ

38925000 soums are saved in one season.

If we subtract 5825000 soums from this profit, the

expected economic efficiency per season is 26842000

soum

.

4 CONCLUSIONS

According to the results of experimental tests carried

out in production conditions, the level of deactivation

of the sponge increases up to 96% with the initial

treatment of the cocoon with an extremely high

frequency electric magnetic field. The duration of

treatment with electric physical action in killing the

sponge inside the cocoon affects the type of cocoon,

its physical-mechanical properties and processing

power, and allows up to 41% energy saving compared

to the current technology. As a result, the cost of the

silk obtained from the cocoon is reduced. Because the

high-frequency electric magnetic field is almost not

absorbed in the cocoon, but only in the mushroom. As

a result, the fungus inside the cocoon becomes dead

due to heating at high temperature in a short period of

time

.

REFERENCES

Khaliknazarov U.А. & Turdiboyev А.А., 2021. Using the

Ultrahigh Frequency Effect (UFEF) Electromagnetic

Field During Dehydration of Silkworm. International

Journal of Advanced Research in Science, Engineering

and Technology, 8(7), 17623-17625.

Khaliknazarov, U. & Ibrokhimov, U., 2024. Design of a

water pump-solar source system for drinking water

supply. BIO Web of Conferences, 85, 01004

https://doi.org/10.1051/bioconf/20248501004

Khaliknazarov, U., Tursunov, A., Jalilov, N., Dinikulov,

D., 2024. Lecture Notes in Networks and Systems, 733,

573.

Khaliknazarov, U., Akbarov, D., Tursunov, A., Gafforov,

S., Abdunabiev, D., 2021. Existing problems of drying

cocoon and making chrysalis feeble, and their solutions.

IOP Conference Series: Earth and Environmental

Science, 939(1), 012020. DOI: 10.1088/1755-

1315/939/1/012020.

Mirzakhodjaev, S., Djiyanov, M., Nurmikhamedov, B.,

Mamasov, S., 2024. Results of Frontal Plug Tests

Combined with Active Working Body. BIO Web of

Conferences, 85, 01035

https://doi.org/10.1051/bioconf/20248501035.

Radjabov A., Ibragimov M., Eshpulatov, N., 2021. The

study of the electrical conductivity of Apples and

Grapes as an object of electrical processing. E3S Web

of Conferences, 226, 00002.

https://doi.org/10.1051/e3sconf/202122600002.

Turdiboyev, A., Khaliknazarov, U., Akbarov, D.,

Kholiyarov, M., Abdullaeva, S., Butaev, T., 2022.

Study on the energy efficiency issues in extracting fat

and oils from cotton seeds. AIP Conference

Proceedings, 2686 (1), 020019. DOI:

HTTPS://DOI.ORG/10.1063/5.0112950

Development Testing and Energy Efficiency Assessment of Electrotechnology for Resiving Mulberry Silkworm Sponge

49