Development of Technology for the Production of a New Lightweight

Composite Using Recycled Aluminum and Mineralized Wood Waste

Simonetta L. Pagliolico

1a

, Shirinkhon Turakhujaeva

2b

, Graziano Ubertalli

1c

,

Abdutolib Parmonov

3d

and Madina Safarova

4e

1

Department of Applied Science and Technology, Politecnico di Torino, Italy

2

Department of Mechanical and Aerospace Engineering, Turin Polytechnic University in Tashkent, Uzbekistan

3

Jizzakh branch of the National University of Uzbekistan, Jizzakh, Uzbekistan

4

Jizzakh State Pedagogical University, Jizzakh, Uzbekistan

Keywords: Composite Materials, Lightweight Structures, Recycled Aluminum.

Abstract: This paper presents the development of an innovative technology for producing a lightweight composite

material utilizing recycled aluminum and mineralized wood waste. The primary objective is to create an

environmentally sustainable material that offers significant weight reduction and enhanced mechanical

properties for various industrial applications. The process involves the amalgamation of aluminum, reclaimed

from post-consumer products, with wood waste that has undergone mineralization to improve its durability

and compatibility with metal matrices. Key aspects of the development include optimizing the mineralization

process, ensuring uniform dispersion of wood particles within the aluminum matrix, and achieving strong

interfacial bonding. Preliminary results demonstrate that the new composite exhibits superior strength-to-

weight ratios and thermal stability compared to traditional materials. This advancement holds potential for

widespread applications in automotive, aerospace, and construction industries, promoting both resource

efficiency and environmental conservation.

1 INTRODUCTION

The management of waste and by-products from

manufacturing and agricultural activities represents a

great challenge for the circular economy and

sustainable development.

The European Commission adopted the new

Circular Economy Action Plan (CEAP) in March

2020 (European Commission, 2020) as part of the

European Green Deal to improve the benefits of the

circular economy on carbon reduction and carbon

removals, also through long term storage in wood

construction and re-use and storage of carbon in

products such as mineralization in building material.

While specific regulations regarding the reuse of

wood waste from agricultural activities are not

explicitly outlined, the European Green Deal

a

https://orcid.org/0000-0003-4390-8345

b

https://orcid.org/0009-0004-2069-9362

c

https://orcid.org/0000-0002-4628-7639

d

https://orcid.org/0000-0002-2423-5299

e

https://orcid.org/0009-0002-7872-8872

emphasizes sustainability, circularity, and resource

efficiency across various sectors, including

agriculture and forestry. Initiatives and policies aim

to reduce waste, enhance resilience, and promote

sustainable practices throughout the entire lifecycle

of products (European Commission, 2020).

The Republic of Uzbekistan is reforming its

legislation to have a sustainable wastes management.

The State Committee on Ecology and Environmental

Protection of the Republic of Uzbekistan organized in

2019 a roundtable discussion on the “Strategy for

solid waste management in the Republic of

Uzbekistan for 2019-2028” (State Committee on

Ecology and Environmental Protection of the

Republic of Uzbekistan, 2019), which promoted,

among other topics, the secondary resource

utilization, encompassing both reusing and recycling

40

Pagliolico, S. L., Turakhujaeva, S., Ubertalli, G., Parmonov, A. and Safarova, M.

Development of Technology for the Production of a New Lightweight Composite Using Recycled Aluminum and Mineralized Wood Waste.

DOI: 10.5220/0014043500004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 40-44

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

of materials, with the aim of an overall energy savings

and energy reduction to create new items, and

recovery using wastes as alternative energy sources

(State Committee on Ecology and Environmental

Protection of the Republic of Uzbekistan, 2019).

In the hierarchy of sustainable waste

management, waste reduction or minimization comes

first. When we reduce waste, we consume fewer raw

materials, helping to preserve natural resources. In the

central part of the pyramid which represents the

hierarchy of sustainable waste management we find

recycling, i.e. the processing of waste materials to

create new products. This can reduce the energy

needed to create new items and conserve raw

materials, avoiding waste disposal in landfill. Energy

recovery is a step lower and allows to generate energy

and reduce the use of landfills. At the base of the

pyramid we find landfill disposal, which involves a

significant use of land and the risk of methane

emissions and leachate formation. The best approach

involves a combination of these strategies,

prioritizing waste reduction and promoting a circular

economy.

Wood waste is commonly either downcycled for

use as biomass fuel or upcycled into engineered wood

products that exhibit superior properties compared to

solid wood. These products are typically created by

bonding fragmented wood using organic

thermosetting adhesives, including plywood, OSB

(oriented strand board), MDP (medium-density

particleboard), MDF (medium-density fiberboard),

and HDF (high-density fiberboard) (Bianco et al.,

2021).

Mineralized wood (MW) can be derived from

woodworking waste. One of the authors of this study

utilized wood chips, mineralized with spherical,

silicon-rich, aluminosilicate particles, as coarse

aggregate to create an innovative structural

lightweight concrete specifically designed for

insulated lightweight building envelope applications,

as discussed by (Becchio et al., 2009). Several

benefits were achieved, including improved

durability, as silica reinforces cell walls, making them

more resistant to decay, increased fire resistance, as

silica could be a protective layer reducing wood

flammability, enhanced strength, due to the

impregnation process strengthening the wood

structure, and reduced swelling and shrinkage in

damp conditions.

One crucial focus within engineering materials

science involves developing novel, efficient, and

promising alloys for use in foundry production. The

utilization of wood waste from agricultural activities,

sawmills, and processing industries (which produce

panels, building components, and furniture) presents

an innovative opportunity for creating lightweight

aluminum components reinforced with natural wood

fibers. Omoniyi et al. (2022) created aluminum and

wood composites by incorporating wood particles

into the aluminum alloy matrix using the stir casting

technique. These aluminum-based wood composites

offer solutions for structural challenges in large roof

and floor spans. Characterization results indicate that

increasing the wood particle content in the

composition, up to a certain percentage in weight,

leads to reduced composite density while enhancing

impact strength and tensile strength compared to

unreinforced aluminum alloys.

In a prior study (Ubertalli et al., 2023), the authors

of this research started to explore the feasibility of

creating aluminum-mineralized wood (AMW)

composites materials as the core for lightweight

aluminum components by incorporating mineralized

wood chips into an aluminum alloy matrix using a

casting process.

Aluminum alloys are the second most used

metallic alloys in buildings (skirting, roof, cladding,

window and door frame, solar panel, staircase, air

conditioning system, heat exchange system, furniture,

curtain wall) and constructions (consumer electronic,

power line, thermal and electrical engine, spacecraft

component, component of land and sea vehicle)

thanks to their low density, high ductility and specific

strength, higher corrosion resistance than plain

carbon steels in environmental atmospheric

conditions, and could be 100% recycled, thus

reducing the environmental footprint and ecological

impact. Furthermore, aluminum is considered non-

combustible (A1-Euroclass reaction to fire) because

it does not sustain combustion. Some recent research

works proposed the use of aluminum foams to

produce core cavity in stiffer cast products for

automotive and aerospace, with increased stiffness,

damping properties, vibration absorption, and

acoustic and thermal insulation characteristics, even

if the wide pore size distribution and the non-

homogeneous localization of pores in the component

cause anisotropy in material properties (Ubertalli &

Ferraris, 2020; Ubertalli et al., 2020; Ferraris et al.,

2021; Ferraris et al., 2022).

In this research it is crucial to focus on improving

the efficiency of component materials (Turakhujaeva

et al., 2023). Additionally, we investigated the macro

and microstructure of the composite samples.

Aluminum alloy components are manufactured using

sand casting process. Sand casting is one of the oldest

and most popular methods that allowing for the

production of small batches. The process involves

Development of Technology for the Production of a New Lightweight Composite Using Recycled Aluminum and Mineralized Wood Waste

41

pouring liquid aluminum alloy into sand molds that

contain Mineralized Wood (MW) chips inside

cylindrical permeable cages, which serve as the core

volume inside the component. The liquid aluminum

infiltrates the spaces between the wood chips

resulting, after solidification, in a continuous,

interconnected metal structure, connected to the

aluminum skin of the component.

This approach may allow the production of thick-

walled components with superior bending and

torsional properties compared to thin-walled, ribbed

components, while still maintaining a lower overall

density. The characterization of the micro and macro

structure of Aluminum Mineralized Wood (AMW)

composites involved techniques such as optical and

electron scanning microscopy and CT-scan. In an

ongoing works we will explore how the inclusion of

mineralized wood chips impacts the properties of the

samples, including vibration and sound absorption

(Cottone et al., 2023; Tursunbaev et al., 2023;

Tursunbaev et al., 2024).

2 MATERIALS AND METHODS

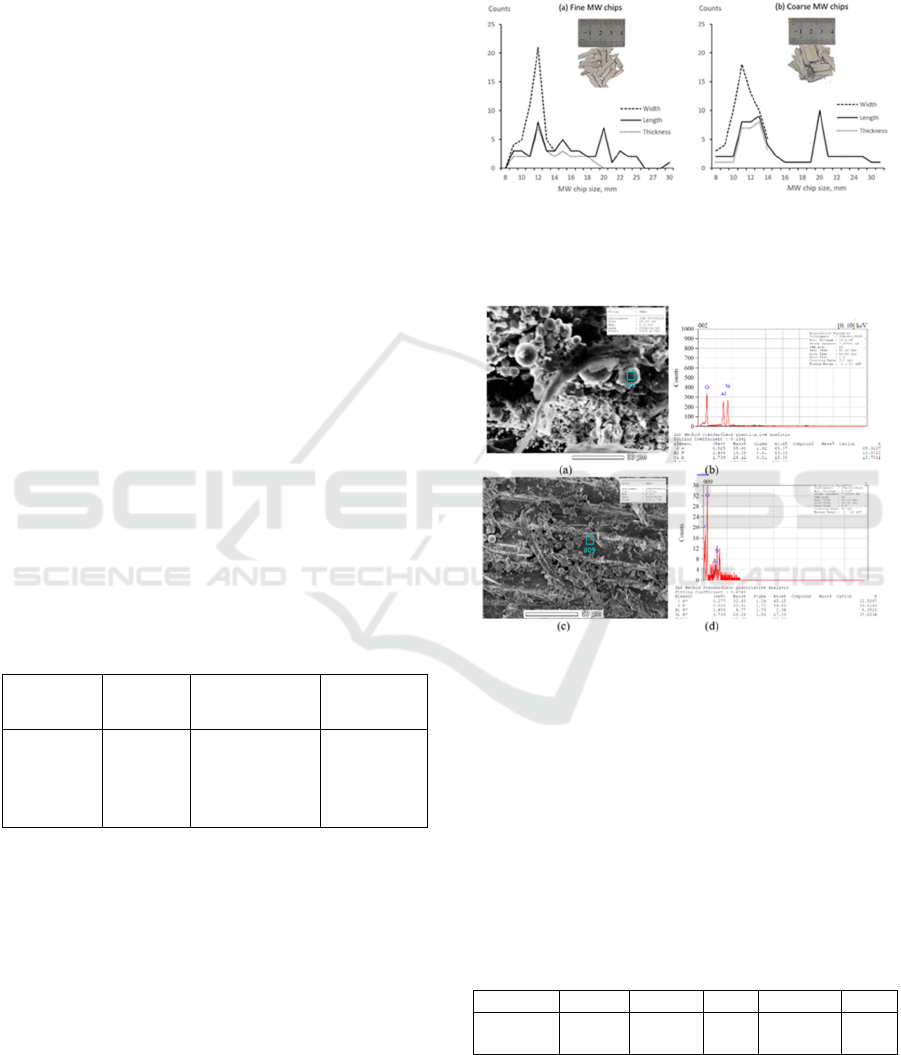

Four samples have been prepared. Mineralized Wood

(MW) chips were selected based on two different size

distribution, fine and coarse (Figure 1), oven dried at

103°C until a constant mass was reached, weighed

and proportioned for each sample as reported in the

Table 1.

Table 1: MW weight and weight percent of coarse and fine

chips used in the AMW composite samples (#).

Sample ID MW

wtg

Coarse MW

wt

%

Fine MW

wt

%

1 3.18 79% 21%

2 3.16 62% 38%

3 3.27 55% 45%

4 3.55 40% 60%

In Figure 2 are reported the SEM micrographs of

the spherical, silicon-rich, aluminosilicate particles

formed in mineralization process (a) and the

associated EDS spectra (b). These particles have a

slight variation in Al, Si and O proportions and

significantly differ in size. The morphology and

elemental analysis indicated that the particles were

composed of aluminosilicate spheres and probably

traces of iron.

The micrographs of wood (c) associated with the

EDS spectra (d) highlights the morphology of the

long tubular wood cells and the deposition on wood

cell walls of spherical, silicon-rich, aluminosilicate

particles. EDS analysis on wood walls showed the

presence of carbon and oxygen, which are the main

elements in wood, and, possibly, also the

impregnation of the walls by silicon-rich compounds.

Figure 1: Mineralized wood chips: particle size distribution

(length, width and thickness) of fine (a), and coarse chips

(b).

Figure 2: Micrographs of MW chips: SEM image (x1000)

(a) and EDS elemental spectra of the spherical, silicon rich,

aluminosilicate particles (b); SEM image (x600) (c) and

EDS elemental spectra of wood (d).

The recycled aluminum alloy used for casting is

the AK5M2, according to the GOST designation

(GOST 1583-93, 1993) Tursunbaev et al., 2023;

Ubertalli and Ferraris, 2020; Ubertalli et al., 2023). It

is a foundry alloy of the system Al-Si-Cu used to

manufacture shaped castings by various casting

techniques, including sand casting, and having the

chemical composition reported in table 2.

Table 2: Chemical composition of samples.

Standar

d

Si Cu Fe Ti Al

GOST

1583-93

4-6 1.5-3.5

≤1

0.05-0.2 Rest

Four permeable cylindrical aluminum mesh cages

(Figure 3a) containing the MW chips have been

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

42

placed inside the molds (Figure 3b). Sand molds are

formed by packing sand around a pattern, which

replicates the external shape of the desired cylindrical

casting. These cages formed the core of AMW

samples (Figure 3c). Molten AK5M2 alloy is heated

up to 750 °C, and it is than poured into the molds

containing mineralized wood chips (Figure 3c).

Figure 3: Permeable cylindrical aluminum mesh cages

containing the MW chips (a); cylindrical aluminum mesh

cages containing the MW chips are placed inside the molds

(b); pouring of aluminum into the mold (c).

3 RESULTS AND DISCUSSION

After solidification, the axial section of the samples

showed that the mineralized wood chip had become

black in color (Fig. 4a) undergoing a pyrolysis

process with marked development of fume (observed

during casting) and that the aluminum metal cage had

melted, allowing to charred wood to float on liquid

aluminum. The interface between wood and

aluminum appears to copy the shape of the chips, but

there is an almost continuous gap between the two

materials, also due to the poor wettability of the

wood. In the metallographic image of a cross-section

(Figure 4b) some bubble-like cavities and nodule-like

particles appear. We can assume that they have been

generated by bubble gas developed during casting (cf.

Figure 5a).

The morphology and the elemental composition

of spherical aluminosilicate particles (Figure 4c and

Figure 4d) seems not to be changed after casting. On

the contrary, the composition of wood (Figure 4c and

Figure 4e) varied sensibly (cf. Figure 2d and Figure

4e) because of wood pyrolysis in contact with the

molten alloy at high temperature and burning of wood

in contact with air. The elemental analysis highlights

that the percentage of oxygen is noticeably decreased.

Figure 4: Sample 1 after casting: macro image (a);

metallographic image (b); SEM image of MW surface after

casting (c); EDS analysis of spherical aluminosilicate

particles; EDS analysis of MW after casting (e).

Sample 1 was analyzed by CT-scan showed wood

chips on top of the sample, due to the dissolution of

the aluminum cage containing the MW chips, the

difference of density between metal and wood and the

gases developed from wood during casting which did

not allow the rapid formation of a skin of solid

aluminum on the top of the sample (Figure 5a). It is

also evident the high amount of pores and nodule-like

particles in the aluminum-based matrix (Figure 5b)

due to the delivering of gases before solidification.

Gases are produced during partial combustion but

mainly wood pyrolysis of the chips wood at high

temperature due to hot liquid aluminum.

Figure 5b shows the size distribution of AMW

composite void and/or nodule-like particles

calculated by the add-on Foam/powder analysis

module of CT-scan VGStudio Max 3.5 software

(Volume Graphics, Heidelberg, Germany). The void

(and/or nodule-like particles) equivalent diameter for

any single unit, i.e. the diameter of a sphere that has

the same volume as the single unit cell, has been

calculated. The equivalent diameter distribution

appears bimodal with two mean diameter values,

respectively 110 µm and 475 µm. Majority of voids

(and/or nodule-like particles) of sample 1 shows high

sphericity (φ = 0.80-0.92) and the largest voids show

the lowest sphericity.

Figure 5: Sample 1 after casting: CT-scan images (a); pore

and/or nodule-like particles size distribution (b).

4 CONCLUSIONS

In this initial research, the feasibility of casting

aluminium-mineralized wood composites was

Development of Technology for the Production of a New Lightweight Composite Using Recycled Aluminum and Mineralized Wood Waste

43

evaluated. The wood chip can guarantee the

formation of a light component core, thanks to the

low reactivity of the wood, when pyrolyzed, with

liquid aluminium. The casting process highlighted

some critical issues that can be addressed by

improving the pouring step and optimizing the

architecture of the AMW-based components. Our

future efforts will focus on overcoming these

problems and, also, optimizing materials and

components.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the

Laboratory of Foundry Technologies of Tashkent

State Technical University for aluminum alloy

casting, and Prof. Sara Ferraris of GLANGE

Research Group of the Institute of Materials Physics

and Engineering, Department DISAT of Politecnico

di Torino, for SEM-EDS analysis.

REFERENCES

Becchio, C., Corgnati, S., Kindinis, A., & Pagliolico, S.,

2009. Improving environmental sustainability of

concrete products: Investigation on MWC thermal and

mechanical properties. Energy and Buildings, 41 (11),

1127-1134.

http://dx.doi.org/10.1016/j.enbuild.2009.05.013.

Bianco, I., Thiébat, F., Carbonaro, C., Pagliolico, S.,

Blengini, G.A, Comino, E., 2021. Life cycle assessment

(LCA)-based tools for the eco-design of wooden

furniture. Journal of Cleaner Production, 324, 129249.

https://dx.doi.org/10.1016/j.jclepro.2021.129249.

Cottone, R., Shtrepi, L., Serra, V., Pagliolico, S.L., 2023.

The recycling and reuse of natural materials: sound

absorbing box patterns that use waste from olive tree

pruning. Acoustics, 5(1), 177-192.

https://doi.org/10.3390/acoustics5010011.

European Commission, 2020. A new circular economy

action plan for a cleaner and more competitive Europe.

COM (2020) 98 final. Brussels, 11.3.2020. https://eur-

lex.europa.eu/legal-

content/EN/TXT/?qid=1583933814386&uri=COM:20

20:98:FIN.

Ferraris, S., Santostefano, A., Barbato, A., Molina, R.,

Ubertalli, G., 2021. Al-based foams as permanent cores

in al castings: effect of surface skin thickness and

composition on infiltration and core-shell bonding.

Metals, 11(11), 1715.

https://doi.org/10.3390/met11111715.

Ferraris, S., Santostefano, A., De Marco, F., Campagnoli,

E., Matteis, P., Barbato, A., Molina, R., Ubertalli, G.,

2022. Co-Casting of Al and Al-Foams. Advanced

Enginnering Materials, 24(9), 1-13.

https://doi.org/10.1002/adem.202200116.

GOST Standard 1583-93, 1993. Alloys aluminum casting.

Omoniyi, P., Adekunle, A., Ibitoye, S., Olorunpomi, O.,

Abolusoro, O., 2022. Mechanical and microstructural

evaluation of aluminium matrix composite reinforced

with wood particles. Journal of King Saud University –

Engineering Sciences, 34(6), 445–450.

https://doi.org/10.1016/j.jksues.2021.01.006.

State Committee on Ecology and Environmental Protection

of the Republic of Uzbekistan, 2019. Roundtable

discussion on “solid waste management strategy for the

period 2019-028”. https://uza.uz/posts/145784.

Turakhujaeva, Sh., Karimov, K, Turakhodjaev, N.,

Akhmedov, A., 2023. Mathematical modeling of

quantitative changes in hydrogen and oxide inclusions

in aluminum alloy. E3S Web of Conferences, 365,

05016. https://doi.org/10.1051/e3sconf/202336505016.

Tursunbaev, S., Turakhodjaev, N., Mardonakulov, S., &

Toshmatova, S., 2024. Effect of germanium oxide on

the properties of aluminum casting details in

agricultural machinery. BIO Web of Conferences, 85,

01024. https://doi.org/10.1051/bioconf/20248501024.

Tursunbaev, S., Turakhodjaev, N., Odilov, F.,

Mardanokulov, S., & Zokirov, R., 2023. Change in

wear resistance of alloy when alloying aluminium alloy

with germanium oxide. E3S Web of Conferences, 401,

05001. https://doi.org/10.1051/e3sconf/202340105001.

Ubertalli, G., Ferraris, S., 2020. Al-Based Metal Foams

(AMF) as Permanent Cores in Casting: State-of-the-Art

and Future Perspectives. Metals, 10(12), 1592.

https://doi.org/10.3390/met10121592.

Ubertalli, G., Turakhujaeva, S., Pagliolico, S.L., 2023.

Aluminium-Mineralized Wood Composites: exploring

a new possibility for the lightening of structural

components. International Scientific and Scientific-

Technical Conference on "Resource and Energy-

Saving Innovative Technologies in the Field of

Foundry" (Tashkent, Uzbekistan), pp. 46-49.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

44