Determination of the Parameters of the Working Bodies of the Drum

of a Horizontal Spindle Cotton Harvesting Apparatus

Nabijon Omonov

a

, Mubarakhan Atadjanova

b

, Odiljon Kholikulov

c

and Sobirjon Sherkobilov

d

Tashkent State Technical University, 100095, University str. 2, Tashkent, Uzbekistan

Keywords: Spindle Drum, Cotton Harvesting Apparatus, Disk Separator.

Abstract: This paper presents the development of an innovative technology for producing a lightweight composite

material utilizing recycled aluminum and mineralized wood waste. The primary objective is to create an

environmentally sustainable material that offers significant weight reduction and enhanced mechanical

properties for various industrial applications. The process involves the amalgamation of aluminum, reclaimed

from post-consumer products, with wood waste that has undergone mineralization to improve its durability

and compatibility with metal matrices. Key aspects of the development include optimizing the mineralization

process, ensuring uniform dispersion of wood particles within the aluminum matrix, and achieving strong

interfacial bonding. Preliminary results demonstrate that the new composite exhibits superior strength-to-

weight ratios and thermal stability compared to traditional materials. This advancement holds potential for

widespread applications in automotive, aerospace, and construction industries, promoting both resource

efficiency and environmental conservation

1 INTRODUCTION

In recent years, in our republic, at the Tashkent

Tractor Plant JSC (Agrotech cluster), the high-

performance company "Djon-Dir" has been

producing cotton picking machines (CPM) with a

horizontal spindle (HS) equipped with picking

devices, and until now, hundreds of machines have

been delivered to clusters and farms. gave It is known

that the HS CHM was produced in the USA and is

mainly adapted to the soil-climate conditions and

agronomy of this country. Currently, more than 30

types of cotton varieties are regionalized in our

country, of which early varieties, mid-ripening and

promising varieties are considered, in addition, it is

recommended to plant new varieties. In our republic,

cotton varieties are now planted at 60, 76 and 90 cm

between rows (Matchanov, 2023).

The analysis of the work efficiency of HS and

vertical spindle (VS) CHM in the conditions of

a

https://orcid.org/0000-0001-8618-5808

b

https://orcid.org/0000-0002-9753-816X

c

https://orcid.org/0009-0001-4446-0645

d

https://orcid.org/0000-0002-6446-562X

Uzbekistan showed that the ATCs of HS machines

are on average 6...9% higher than those of VS, and

the work efficiency is almost twice as large. Based on

the results of experiments, analysis and calculations

of experts, HS CHM yield is higher than 30 t/ha,

especially in fields with high yield (43...51 t/ha) and

the degree of furrow opening is high (90% and

above), reliability indicators are also showed that it

will be high. It was shown that these HS CHMs are

not fully adapted to the conditions of Uzbekistan

(Glushenko et al., 2004; Abdazimov et al., 2014;

Abdazimov et al., 2019).

In order to eliminate the above-mentioned

shortcomings, in-depth study of the technological

process of picking this GS CHM, especially the

research of the process of pulling and wrapping the

cotton in the groin of GSh, and establishing the

dimensions and modes of the cotton picking

apparatus (CHA) suitable for the conditions of our

republic, carrying out constructive and technological

36

Omonov, N., Atadjanova, M., Kholikulov, O. and Sherkobilov, S.

Determination of the Parameters of the Working Bodies of the Drum of a Horizontal Spindle Cotton Harvesting Apparatus.

DOI: 10.5220/0014043300004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 36-39

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

adaptation works based on the suitability criteria

requires going.

2 MATERIALS AND METHODS

In our ongoing research work, the number of spindles

in the drum, spindle location parameters, spindle

material and tooth sizes were studied based on the

type of regionalized and promising varieties, the size

of cotton branches, structure and bolls, yield, planting

scheme, which are considered the main working

organs of HS CHM (Petre, 2015).

Cotton varieties have their own pattern of

formation depending on the shape and type of bush,

which pattern was determined based on the statistical

processing of the results of experiments on each

zoned cotton variety. Experiments were conducted on

the dynamics of boll opening, arrangement and

elasticity of boll elements (branches, bolls, leaves,

etc.).

Usually, it is noted that the axis of the drum and

separator should be 120-125 mm in the longitudinal

direction and 220 mm in the transverse direction

(Glushenko et al., 2004; Abdazimov et al., 2014). It

is desirable for the disk separator to be located near

the colosnik grid, that is, near the exit of the spindle

from the working chamber, but it is difficult to turn

the cassette with the spindle into the separation zone

at a short distance and in a short time. This is achieved

by choosing the most optimal variant of the guideway

profile, in which it is necessary to take into account

the increase in pressure on the guideway of the roller

when the spindle cassette turns.

It is important that the drum of the cotton picker

with horizontal spindles completely and qualitatively

separates the cotton wrapped around the spindles, that

is, it does not damage the cotton fibers and seeds. If

even a small amount of cotton pieces remain on the

spindle after passing through the disc separator, the

cotton piece of the spindle at 3000-4125 rev/min will

be wrapped in plaster and will be stuck to the cotton

in the groin in the working chamber, and the quality

of wrapping the cotton piece will be negatively

affected. Spindles in each tier should pass under the

separator disks at a distance of 0.1...1.0 mm, if this

gap is larger than this, the cotton will be wrapped

around the spindle (Omonov et al., 2021; Omonov &

Tulaev, 2021).

It is known that the horizontal spindles are

mounted on the curved-shaft cassette, and under the

action of the curved-shaft cassette through the sliding

bearing on the guideway, there are 4 complex

kinematic movements, that is, advancement with the

machine, rotation along with the spindle drum, the

curved-shaft cassette under the influence of the

guideway and the spindle fixed to it according to a

certain law around the axis of the cassette. turns and

the spindle rotates around its axis. In this case, under

the influence of the profile of the guideway, the

spindles must enter and exit the working chamber in

a forward-reciprocating motion perpendicular to the

row of yarn, enter the disk separator sideways, and

exit the separator zone at least 4 times completely,

and the spindle must also complete one full revolution

around its axis in the wetting washer zone. rotation

conditions must be ensured and these conditions are

achieved on the basis of the guideway profile and the

curved cassette. The completeness of separation of

cotton wrapped on the spindle depends on the

structural and technological parameters of the picking

apparatus, as well as on the physical and mechanical

properties of the cotton crop (Abdazimov et al., 2022;

Omonov et al., 2022; Rizaev et al., 2023).

In the study of high-quality and reliable separation

of cotton wrapped from a horizontal spindle, first of

all, development of the optimal design parameters of

the disc separator by taking into account the direction

of movement of the separator in relation to the spindle

and speed indicators, the effect of the separator

wrapped on the spindle on the cotton, as well as the

factors determining the surface of the spindle on the

working part and can be put into production. When

determining the outer diameter of the disk, L0-n+m,

where: L0 is the length of the working part of the

spindle processed by the separator, L0 - n is the length

of the working part of the spindle in the separation

zone, where the axis of the separator shaft intersects

with the axis of the spindle; m is the distance from the

end of the spindle to the separator shaft, mm

(according to the research data of M.V. Sablikov,

m=32...36 mm was considered sufficient) (Glushenko

et al., 2004).

3 RESULTS AND DISCUSSION

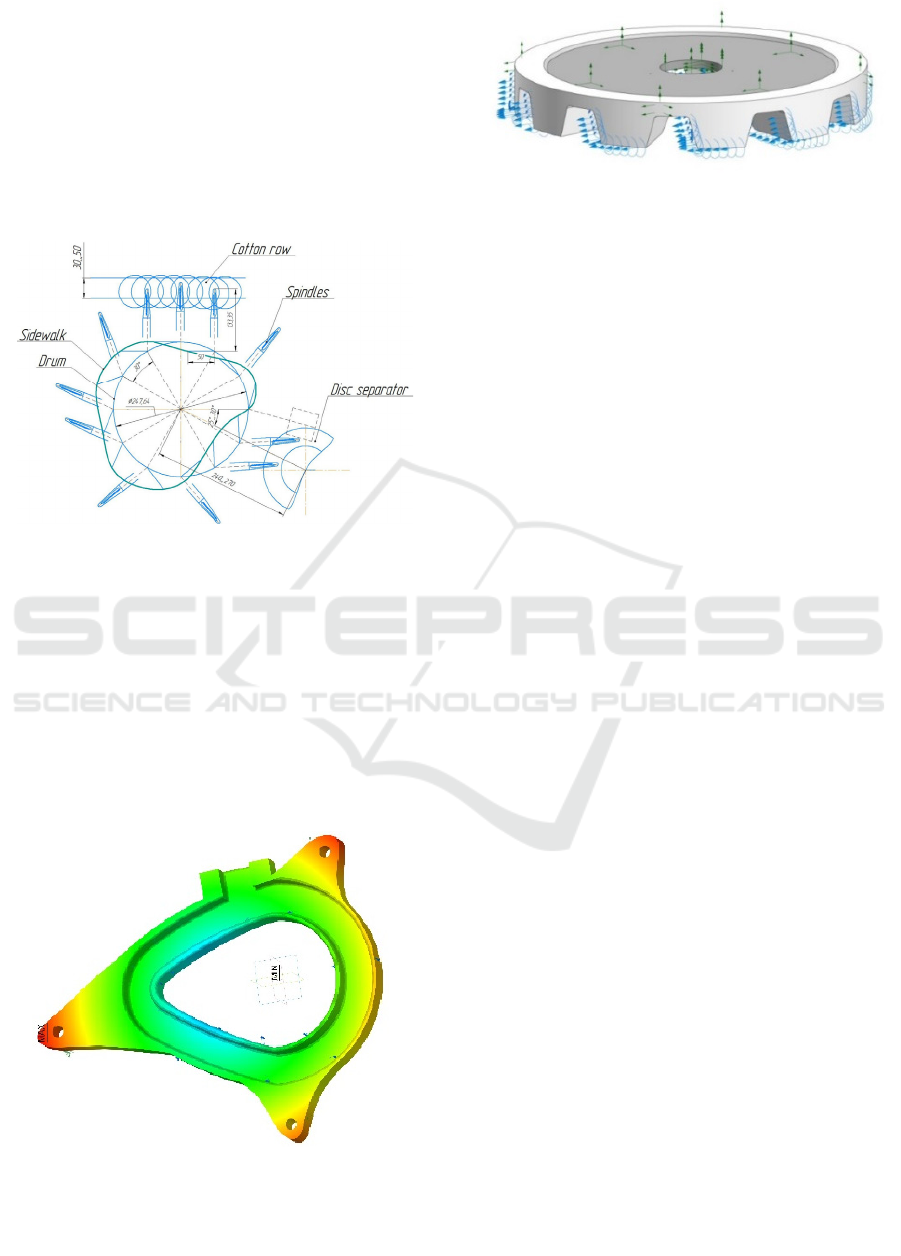

Work was carried out to determine the optimal

technological and structural parameters of the

guideway and the disk separator for the HS CHM sine

dialing apparatus. In the picking chamber, the

condition must be met that the spindles do not allow

the yarn to bend in the direction of CHM movement,

and for this it is necessary to achieve that the

component of the speed of the spindle center in the

picking zone in the direction of CHM movement

speed Vm=0 (Fig. 1). When determining the optimal

diameter of the disk separator, first of all, the length

Determination of the Parameters of the Working Bodies of the Drum of a Horizontal Spindle Cotton Harvesting Apparatus

37

of the spindle working part (50-80 mm, the length of

the working part of the CHM spindle used in our

country is 52 mm) was taken into account, as well as

the spindle and the separator to the mutual kinematic

movement trajectory, which in turn is the spindle

cassette curvature depends on the structural

characteristics of the guideway profile. The

arrangement scheme and dimensions of the guideway

profile and disk separator on the spindle drum of the

HS machine dialing apparatus are given in Fig. 1.

Figure 1: The layout and dimensions of the working bodies

in the dialing apparatus.

A 3D model of the construction of the guideway

of the spindle drum was developed in the Compass

program, in which dynamic forces were applied to the

walls of the guideway along the X, Y, Z coordinates,

and the stability was checked (Fig. 2). In this case, the

known spindle-cassette curve ship is forced to move

along the profile of the guideway with the help of a

sliding bearing, and dynamic forces are applied to the

walls of the guideway.

Figure 2: 3D model of a spindle drum guideway.

Figure 3: 3D model of a disc separator and the forces acting

on it.

A 3D model of the disc separator was also

developed and subjected to dynamic forces and tested

for robustness. For reference, a disc separator consists

mainly of two parts: a metal alloy and a polymer

product (Figure 3).

4 CONCLUSIONS

The guide rail material is Steel 3 according to GOST

R 52246-2016, the total mass is 6.64 kg. The

coefficient of loss of stability of the newly designed

guideway (coefficient zapasa poteri ustoychivosti)

was 0.000305, the stability coefficient was 1.85...10,

the coefficient zapasa po predelu tekuchesti was

1.06...10.

The diameter of the disk separator is D=159 mm,

the total thickness is 24 mm, the diameter of the disk

of the metal part is d=137 mm, the thickness is S=4

mm, the total mass is 525 grams. The composition of

the disc separator metal alloy: Fe 96.87%, Si 1.6%,

Mn 0.96%, Ti 0.35%, Cr 0.04%, V 0.03%, Sb 0.01%,

Pb 0.01%, Sn 0.01%, P 0.01% and Niobium 0.01%.

organizes.

It was found that the structure of guideway and

disc separator in the new structure meets the

requirements of stability and durability.

REFERENCES

Abdazimov, A.D., Omonov, N.N., & Khudayorov, M.T.,

2022. Justification of the parameters of the information

model of the automatic guidance system of the cotton

harvester. IOP Conference Series: Earth and

Environmental Science, 1076, 012002. DOI:

10.1088/1755-1315/1076/1/012002.

Abdazimov, A.D., Radjabov, S.S., & Omonov, N.N., 2019.

Automation of agrotechnical assessment of cotton

harvesting machines. IOP Conference Series: Journal

of Physics: Conference Series, 1260(3), 032001. DOI:

10.1088/1742-6596/1260/3/032001.

Abdazimov, A.D., Uljaev, E., Ubaidullaev, U.M., &

Omonov, N.N., 2014. Fundamentals of automation of

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

38

control and control of technological parameters of

cotton harvesting machines. TSTU (Technical

University, Tashkent), 11–24.

Glushenko, A.O., Matchanov, R.D., Rizaev, A.A.,

Toshboltaev, M.T., & Khudoykulov, R.R., 2004.

Simulation of dynamic processes in horizontal-spindle

cotton pickers. Science, 7–39.

Matchanov, R.D., 2023. Development of a cotton

harvesting machine for selective cotton harvesting.

Science, Tashkent, 6–34.

Omonov, N.N. & Tulaev, B.R., 2021. Evaluation of the

degree of processing of the stalks on the basis of the

analysis of the trajectory of the spindle of the horizontal

spindle cotton harvesting machin. IOP Conference

Series: Earth and Environmental Science, 868, 012072.

DOI: 10.1088/1755-1315/868/1/012072.

Omonov, N.N., Abdazimov, A.D., Shodiyev, J.G., &

Atadjanova, M.M., 2021. Investigation of spindle

activity of horizontal spindle cotton harvesting

machine. IOP Conference Series: Earth and

Environmental Science, 868, 012073. DOI:

10.1088/1755-1315/868/1/012073

Omonov, N.N., Masharibov, A.R. & Atadjanova, M.M.,

2022. Universal row-crop tractor with a variable base:

calculation of the links of the tractor base change

mechanism. IOP Conference Series: Earth and

Environmental Science, 1076, 012006. DOI:

10.1088/1755-1315/1076/1/012006.

Petre, M., 2015. Combine Harvesters: Theory, Modeling,

and Design (USA), 4-55.

Rizaev, A.A., Alimova, D.B., Omonov, N.N., &

Mamatmurodov, I.A., 2023. About rational number of

spindles on drums of cotton harvester. E3S Web of

Conferences, 401, 04013.

https://doi.org/10.1051/e3sconf/202340104013.

Determination of the Parameters of the Working Bodies of the Drum of a Horizontal Spindle Cotton Harvesting Apparatus

39