Calculation of the Amount of Grain Moving Inside the Grinding

Chamber

Farmon Mamatov

1a

, Fakhridin Karshiev

2b

, Bogdagul Karshieva

2c

, Abdisalim Kenjabayev

2d

,

Yigitali Shamayev

2e

and Alim Axmedov

2f

1

Karshi Engineering-Economics Institute, 225, Mustakillik str., 180100, Karshi, Uzbekistan

2

Termez State University, 43, Barkamol avlod str., 190111, Termez, Uzbekistan

Keywords: Grain Grinding Process, Hammer Mill, Air-Particle Dynamics.

Abstract: In the world, resource-saving technologies for grinding grain feed and preparing full-value feed from it and

technical means for their implementation are being produced. In particular, special attention is paid to high-

quality grinding, energy and resource-saving devices by bringing grain feedstuffs such as wheat, barley, corn

grain and soot to the same granulometric composition. From this point of view, in this research work, it is

important to process cereal feed by mechanical grinding method, to develop devices that implement it, to

justify their technological work process and parameters of working parts. The purpose of the research is to

develop devices that grind grain feed at the level of the specified requirements at low costs and justify their

parameters. Based on this, the amount of grain moving in the "air-particle ring" in the grinding chamber was

calculated, and the amount of grain particles moving in the "air-particle ring" was calculated to be msl=0.025

kg. When the hammer of the hammer mill is working, the amount of fractions up to 1 mm in the crushed

grains is 3%, the amount of fractions up to 1-2 mm is 87.6%, and the amount of fractions larger than 2 mm is

9.4%. .

1 INTRODUCTION

Currently, the state attaches great importance to the

development of livestock breeding in our republic. In

the strategy of agricultural development of the

Republic of Uzbekistan for 2020-2030, the

establishment of family livestock and poultry farms

and strengthening of their feed base is defined as one

of the main tasks (Astanakulov et al., 2021a;

Astanakulov et al., 2021b; Kovalev et al., 2023a;

Kovalev et al., 2023b; Kovalev et al., 2024). It is

known that with the establishment of livestock and

poultry farms, the demand for concentrated feed

increases (Astanakulov et al., 2022; Astanakulov et

al., 2023; Kovalev et al., 2023a; Kovalev et al.,

2023b; Ikonnikova et al., 2023; Yablokova et al.,

a

https://orcid.org/0000-0002-8916-4225

b

https://orcid.org/0009-0003-3067-7418

c

https://orcid.org/0009-0003-3067-7418

d

https://orcid.org/0000-0000-2038-0028

e

https://orcid.org/0000-0001-7172-1866

f

https://orcid.org/0009-0001-5927-1329

2024). Because one of the main ways to increase the

productivity of livestock is to feed them with soft

fodder, that is, fodder obtained by processing

nutritious grains (Sattarov et al., 2023; Borotov et al.,

2023a; Borotov et al., 2023b).

The 2022-2026 program for the development of

the livestock industry and its industries in the

Republic of Uzbekistan is a priority goal of the rapid

development of the livestock industry and its

industries, the stable supply of food products to the

population of the republic, and the expansion of

production opportunities. and focusing on setting

tasks (Shomirzaev et al., 2022; Маmatov et al., 2022).

Today, there are a total of 18,032 livestock farms in

our republic, of which 7,614 cattle farms, 3,263 sheep

and goat farms, 142 sheep farms, 52 camel farms,

Mamatov, F., Karshiev, F., Karshieva, B., Kenjabayev, A., Shamayev, Y. and Axmedov, A.

Calculation of the Amount of Grain Moving Inside the Grinding Chamber.

DOI: 10.5220/0014042700004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 27-30

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

27

1,163 poultry farms, 4,829 fish farms, 715 1 was

established in the field of beekeeping and 254 in the

direction of rabbit breeding.

Ensuring food safety at the expense of increasing

the production of livestock products, wide

introduction of modern methods of production,

thereby creating an added value chain, development

of the livestock industry and its branches, as well as

modern information and communication technologies

in this field and organization of effective use of

scientific achievements, rapid development of the

livestock industry, providing the population with

cheap and high-quality meat and other food products,

preparation of high-quality feed is an integral part of

efficient livestock farming.

2 MATERIALS AND METHODS

According to the research methodology for the

theoretical study of the technological process of the

hammer grain crusher, the interaction between the

hammer and the grain inside the grinding chamber

should be modeled. The results of theoretical studies

and one-factor experiments to determine the factors

affecting the working process of a hammer grain

crusher device, which performs grinding, showed that

the number of revolutions of the hammer with a lever,

the working surface of the hammer, as the size of the

grinding chamber is affected by the diameter of the

sieve mesh and the gap between the sieve and the

hammer.

Based on the above analysis, the combined effect

of the recorded parameters and operating modes of

the grain grinder on the grain grinding process and,

on this basis, determining their optimal values was

carried out using the methods of mathematical

planning of multifactorial experiments.

3 RESULTS AND DISCUSSION

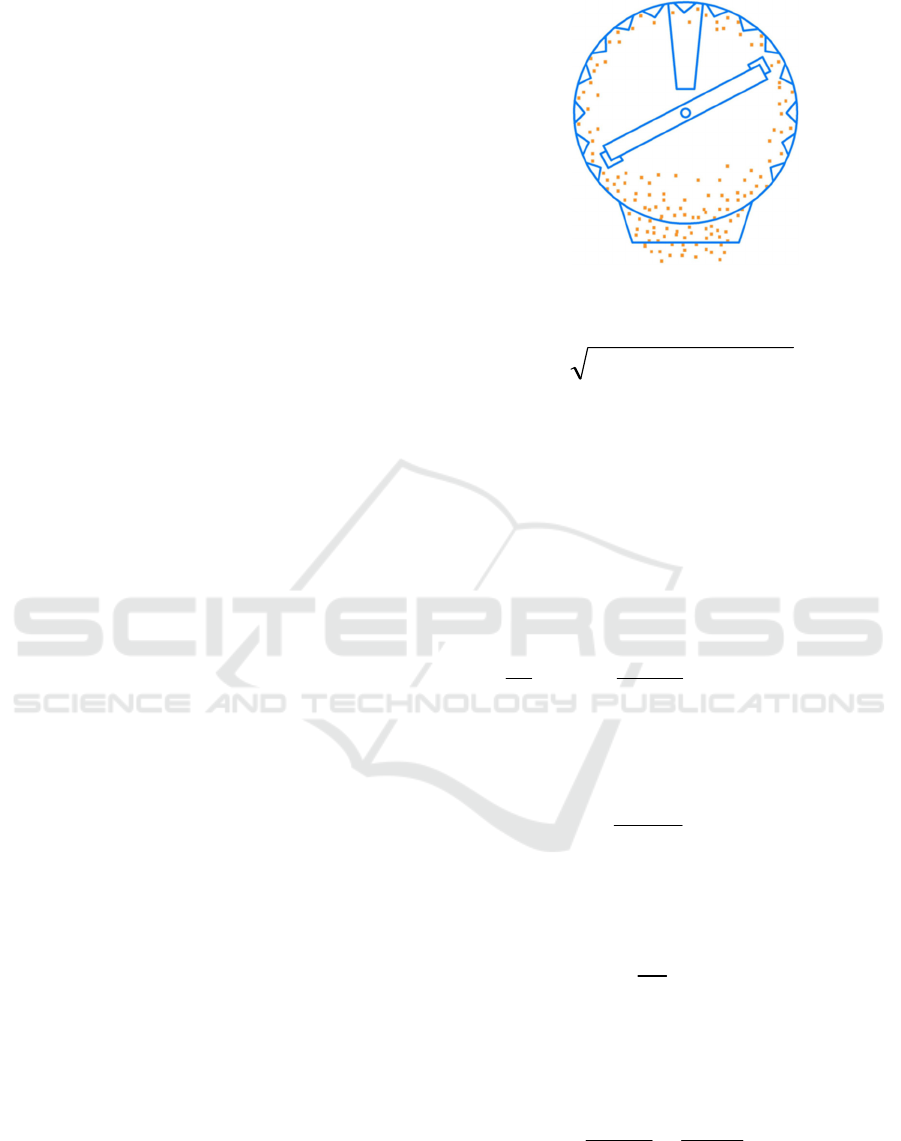

The amount of grain moving in the "air-particle ring"

in the crushing chamber can be determined as

follows, according to the expression recommended by

S.V. Melnikov, the speed of hammers that ensures

crushing in one stroke (Fig. 1).

Figure 1: Grain grinding process.

./)/ln(

1

ρσ

xakv

chdud

=

(1)

here

a – grain length, m;

x

1

– length of the undeformed part of the grain after

impact, m;

– grain density, kg/m

3

;

k

d

– dynamic grinding coefficient of the grain,

k

d

=1,6-2,0

σ

ch

– grain strength limit, N/m

2

.

We can reduce the above expression to the

following form

=

chd

ud

k

v

x

a

σ

ρ

2

1

exp

(2)

Based on the specified impact speed, we express

the following relation

=

chd

ud

k

v

σ

ρ

λ

2

1

exp

(3)

In this case, the deformation of the grain under the

influence of the free impact of the mallet

−=−

1

1

1

1

λ

axa

(4)

Based on this, the number of blows that should be

given to ensure complete grinding of the grain is as

follows.

1

1

1

1

−

=

−

=

λ

λ

xa

a

z

ud

(5)

According to the calculation according to this

expression, the grain receives 3 blows in sections II

ρ

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

28

and III in the first half revolution of the hammer after

entering the grinder.

Ungrinded grain particles move in additional

circulation along the "air-particle ring" inside the

grinding chamber. In this case, the grain particles

receive 2 blows from the hammers of the grinder for

each additional rotation. If the grain needs to receive

9 shocks for complete grinding, then the grain

particles need to rotate 3 more times along the "air-

particle ring".

In turn, the grain particles rotate in the following

amount while they are inside the grinding chamber

2

2−

=

ud

dz

z

n

(6)

In that case, the amount of grain particles moving

in the "air-particle ring" is equal to the following

sl

ud

sl

zq

m

ω

π

)2( −

=

(7)

here ω

sl

– angular velocity of the "air-particle"

layer, m/s;

– the speed at which grains are transferred

to the grinding chamber, kg/s.

4 CONCLUSIONS

The optimal values of the parameters of the working

parts and operating modes of the food grain grinding

device are as follows.

1. For barley grains σch=7MPa; ρ=1300kg/m

3

, the

speed of the hammer to crush them u=40,2 m/s; its

radius of gyration r=0,215 m; the radius of the

grinding chamber and kd =1,8; q=0,03 kg/s if there is,

then the speed that ensures crushing of grains in one

stroke of the mallet vud=20,1m/s, angular velocity of

the "air-particle" layer ωsl=83,75rad/s, the number of

blows that ensure complete grinding of the grain

zud=25 and the amount of grain particles moving in

the "air-particle ring" should be equal msl=0,025kg.

2. During the hammer rotation of the hammer

mill, the amount of fractions up to 1 mm in the

crushed grains is 3%, the amount of fractions up to 1-

2 mm is 87.6%, and the amount of fractions larger

than 2 mm is 9%. 4%, and the grinding model was

1.34.

REFERENCES

Astanakulov K.D., Umirov A.T., Sultanbekova P.S.,

Alpamyssova G.B., 2021a. Determination of working

indicators of New Holland TS-5060 combine for soy

bean harvesting. IOP Conference Series: Earth and

Environmental Science (Biodiversity and Ecosystem

Stability), 839(5), 052048. DOI: 10.1088/1755-

1315/839/5/052048.

Astanakulov, K.D., Ashurov, N.A., Turdibekov, A.R.,

2023. Straw harvesting equipment for combine

harvesters in dry land harvesting. IOP Conference

Series: Earth and Environmental Science, 1231(1),

012023. DOI: 10.1088/1755-1315/1231/1/012023.

Astanakulov, K.D., Babaev, Kh.M., Eshankulov, Kh.M.,

Turdibekov, I.M., 2022. Development of technology

and equipment for harvesting mung bean crops. IOP

Conference Series: Earth and Environmental Science,

1112, 012008. DOI: 10.1088/1755-

1315/1112/1/012008.

Astanakulov, K.D., Baimakhanov, K.A., Alpamyssova,

G.B., Babojanov, A.B., 2021b. Development of a

pneumatic drum-type seeding apparatus for two-row

seeding soybean and mung bean. IOP Conference

Series: Earth and Environmental Science (Biodiversity

and Ecosystem Stability), 839(5), 052062. DOI:

10.1088/1755-1315/839/5/052062.

Borotov, A., Bekzhanov, S., Nurjan, D., Tursunov, J.,

Tursunov, Sh., Boykulov, U., Ernazarov, K., &

Karshiev, F.U., 2023b. Development of the

construction of the feed mixer device of granulation

line. IOP Conference Series: Earth and Environmental

Science, 1284, 012013. DOI: 10.1088/1755-

1315/1284/1/012013.

Borotov, A., Choriev, R., Boykulov, U., & Khatamov, A.,

2023a. A theoretical method of the reception of blue

stem feed by the feeders and transfer to the grinding

drum. E3S Web of Conferences), 390, 04038.

https://doi.org/10.1051/e3sconf/202339004038.

Ikonnikova, M., Kovalev, D., Astanakulov, K.,

Voroshilova, A., 2023. Digitalization of the

organizational structure of an agro-industrial enterprise

based on the GERT-network computational model. E3S

Web of Conferences, 390, 03024.

https://doi.org/10.1051/e3sconf/202339003024.

Kovalev I., Kovalev D., Astanakulov K., Podoplelova A.,

Voroshilova A., Shaporova Z., 2024. Cost-

effectiveness analysis of the implementation of

transport and technological cycles in the swarm use of

agricultural UAVs. E3S Web of Conferences, 471,

04017. https://doi.org/10.1051/e3sconf/202447104017

Kovalev, I., Kovalev, D., Astanakulov, K., Podoplelova,

V., Borovinsky, D. & Efa, S., 2023a. Conceptual basis

for digitalization of specifications of transport and

technological cycles of agricultural UAVs. E3S Web of

Conferences, 443, 06014.

https://doi.org/10.1051/e3sconf/202344306014

Kovalev, I., Kovalev, D., Astanakulov, K., Podoplelova,

V., Borovinsky, D., Shaporova, Z. & Efa, S., 2023b.

Digitalization of UAV transport and technological

q

Calculation of the Amount of Grain Moving Inside the Grinding Chamber

29

cycles in smart agriculture. E3S Web of Conferences,

390, 03014.

https://doi.org/10.1051/e3sconf/202339003014.

Kovalev, I.V., Kovalev, D.I., Astanakulov, K.D.,

Podoplelova, V.A., Borovinsky, D.V., Shaporova, Z.E.,

2023a. Productivity analysis of agricultural UAVs by

field crop spraying. IOP Conference Series: Earth and

Environmental Science, 1284, 012026. DOI:

10.1088/1755-1315/1284/1/012026.

Kovalev, I.V., Kovalev, D.I., Astanakulov, K.D.,

Voroshilova, A.A., Podoplelova, V.A. & Borovinsky,

D.V., 2023b. Analysis of system parameters in a

microprocessor performance model of a swarm of

agricultural spraying UAVs. IOP Conference Series:

Earth and Environmental Science, 1284, 012030. DOI:

10.1088/1755-1315/1284/1/012030.

Mamatov, F.M., Karimov, R., Gapparov, Sh., &

Musurmonov, I.E., 2022. Study of the parameters of the

field of the cone-shaped working body straw chopper.

IOP Conference Series: Earth and Environmental

Science, 1076, 012026. DOI: 10.1088/1755-

1315/1076/1/012026.

Sattarov, N.E., Borotov, A.N., Choriev, R.K., 2023. Meat

productivity of bull-calves of the red steppe breed with

various methods of keeping. IOP Conference Series:

Earth and Environmental Science, 1231, 012036. DOI:

10.1088/1755-1315/1231/1/012036.

Shomirzaev, M.Kh., Astanakulov, K.D., Babaev, Kh.M.,

2022. Research into the perforated surface of the double

staged grinder-crusher. IOP Conference Series: Earth

and Environmental Science, 1076, 012035. DOI:

10.1088/1755-1315/1076/1/012035.

Yablokova, A., Kovalev, D., Kovalev, I., Podoplelova, V.,

Astanakulov, K., 2024. Environmental safety problems

of swarm use of UAVs in precision agriculture. E3S

Web of Conferences, 471, 04018.

https://doi.org/10.1051/e3sconf/202447104018.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

30