Basing the Parameters of the Planting Machine for Semi-Automatic

Sherzodkhuja Mirzakhodjaev

1a

, Azzam Musurmonov

2b

, Khodzhimurod Shodiev

3c

and Giyosiddin Salimov

4d

1

Tashkent State Agrarian University, 100140, University str. 2, Tashkent, Uzbekistan

2

Scientific Research Institute of Horticulture, Viticulture and Winemaking Named after Academician M. Mirzayev,

Tashkent, Uzbekistan

3

Samarkand State University of Veterinary Medicine, Livestock and Biotechnology, Samarkand, Uzbekistan

4

Almalik Branch of Tashkent State Technical University named after Islam Karimov, 2, M. Ulugbek, Tashkent, Uzbekistan

Keywords: Planting Machine, Seedling Automation, Sand Afforestation.

Abstract: This article provides information on the necessary technologies and techniques for planting in our republic

and is devoted to the development of a device for increasing seedlings by further improving this recommended

method. At that time, the technology of aerozization was developed. Despite the diversity of requirements for

the use of forestry seedling machines, the latter was characterized by a general technological scheme of work.

Planting is carried out using standard seedlings (cuttings and seedlings) grown in forest nurseries. In the

following years, artificial forest plantations began to be created on large areas by planting large-sized

seedlings. In such conditions, tractor-mounted hole diggers, as well as special digging machines for planting

and transplanting large seedlings with soil, are aimed at widespread use.

1 INTRODUCTION

The results of research conducted in recent years on

the reclamation of sand forests show that planting

with granular seeds is more effective, as the safety

and germination of crops increases by 2-2.5 times,

which makes it possible to turn the developed sandy

areas into forestry areas and strengthen the mobile

sands of Arol and Kyzylkum and increase the speed

of afforestation. The positive features of granular

seeds include their less removal from the planted line

by wind-sand flow, less ingestion by field rodents,

ease of planting with existing forestry and agricultural

seeds, as well as ultra includes light aircraft. Note that

the "Hang planer" with a total load capacity of 200-

250 kg can carry out aerial planting at a speed of 40-

60 km/h, which is on average 10 times higher than the

speed of ground vehicles.

The problem of fixing and afforestation of shifting

sands is also complicated by the complexity of the

relief, high flow and the steepness of the slopes of the

a

https://orcid.org/0000-0001-8593-1450

b

https://orcid.org/0009-0003-2669-0973

c

https://orcid.org/0009-0007-9132-9459

d

https://orcid.org/0000-0001-8593-1450

dunes, which make the latter almost inaccessible to

existing vehicles (Nedashkovsky, 1977; Leontyev,

1962; Sabirov, 2011; Shatalov and Efimtsev, 1984;

Zima and Malyugin, 1976; Bartenev, 2015;

Mirzakhodjaev et al., 2024; Mirzakhodjaev et al.,

2024; Mirzakhodjaev et al., 2024; Khudayorov et al.,

2023; Khudayorov et al., 2023; Khudayorov et al.,

2023; Mirzakhodjaev et al., 2021; Mamatov et al.,

2021; Mirzaev et al., 2019; Khaliknazarov and

Ibrokhimov 2024 ; Khaliknazarov et al., 2024;

Turdiboyev et al., 2022; Khaliknazarov et al., 2021;

Bokiev et al., 2021; Muhammadiev et al., 2020;

Anarbaev et al., 2020; Yunusov et al., 2020;

Rakhmonov et al., 2020; Rakhmonov et al., 2020;

Turdiboyev et al., 2023; Davirov et al., 2020;

Akhmetov et al., 2024; Akhmetov et al., 2023;

Zhanikulov et al., 2022; Akhmetov et al., 2021;

Irgashev et al., 2021; Obidov et al., 2021; Eshpulatov

et al., 2021; Eshpulatov et al., 2021; Ashirov et al.,

2021; Farmonov et al., 2020; Djiyanov et al., 2024;

Djiyanov et al., 2024; Djiyanov et al., 2022; Isakova

Mirzakhodjaev, S., Musurmonov, A., Shodiev, K. and Salimov, G.

Basing the Parameters of the Planting Machine for Semi-Automatic.

DOI: 10.5220/0014042000004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 23-26

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

23

et al., 2024; Astanakulov et al., 2023; Irisov et al.,

2024; Aslonov and Irisov, 2023 ; Irisov and

Xamidov, 2023; Irisov and Bekmurodov, 2023;

Alimova et al., 2024; Saidova et al., 2023).

That is why in the 40s and 50s of the last century,

large-scale scientific and production experiments

were conducted on sowing saxovol seeds on sand

dunes with the help of PO-2 and AN-2 aircraft.

Overall positive results were achieved (Leontyev,

1962; Sabirov, 2011),

It should be noted that at that time the technology

of erotization was not fully developed. The difficulty

was that it was necessary to equip airfields or runways

at work sites for the aircraft. The high cost of flight

hours and the lack of runways, as well as

scientifically based developments, have been a

serious obstacle to the widespread use of aerosis in

forestry production.

2 MATERIALS AND METHODS

Planting machines are divided into the following

groups according to the type of planting areas in

forestry: on empty land, for specially established

forest plantations, sandy and stony soils, large-sized

tree planting and seedling planting (Shatalov and

Efimtsev, 1984).

Each type of afforestation area requires special

soil treatment, a certain type and size of seedlings for

planting, and a scheme for planting seedlings. It is

used in machines for planting forestry seedlings on

agrotechnical demand. The general requirements for

them are as follows: correct placement of seedlings

and the root part of seedlings in planting areas,

ensuring planting depth and density, maintaining the

specified distance between seedlings in a row

(planting stage) and seedlings including doing no

harm.

Despite the diversity of requirements for the use

of forestry seedling machines, the latter is

characterized by a general technological work

scheme (Bartenev, 2015). Planting is carried out

using standard seedlings (cuttings and seedlings)

grown in forest nurseries.

In the following years, artificial forest plantations

began to be created on large areas by planting large-

sized saplings. In such conditions, tractor-mounted

hole diggers, as well as special digging machines for

planting and transplanting large seedlings with soil

are widely used. The process of manual planting of

the planting material of the traditional type of forest

planter consists of the following three operations:

preparation of the planting area in the form of a

permanent furrow or hole, feeding plants to the

planting site at a certain time, intervals and thickens

the root system of planted plants (Shatalov and

Efimtsev, 1984; Zima and Malyugin, 1976; Bartenev,

2015). At the same time, it should be noted that in this

case, the intermediate process related to separate

separation (removal) of seedlings from the bunker

and feeding to seedlings is not taken into account.

This is because they perform this operation manually.

In the development of automatic planters, it is

necessary to take into account this intermediate

process, which can be carried out using a special

mechanism for individual separation and transfer to

the handles of the planter or to the receiving place.

3 RESULTS AND DISCUSSION

The technological process of automated seedling

planting is as follows. A special automatic device is

installed in the traditional type of seedling planter to

deliver the plants to the handles of the planter of the

machine. This device should deliver plants from

cassettes or directly from a pen. An automated planter

must be serviced by at least two workers: a tractor

driver and an operator who monitors the continuity of

the technological process. Existing mechanized

planters are serviced by workers, namely: tractor

operator, planter and spacer. Thus, the automation of

planting processes of sand-strengthening plant

seedlings should ensure reliable operation in

conditions of moving sand, increase the productivity

of planting operations by at least 1.3-1.5 times, and

reduce the number of service personnel from 4 to 2.

Significant economic benefits are achieved by

improving the quality of root systems, increasing the

survival rate of seedlings by 15-20% and saving fuel

and lubricants, and by avoiding repeated planting and

intercropping with existing crops by 20-30%.

Technology also achieves social benefits by

improving the working conditions of production

workers.

To achieve these goals, we use the principal

scheme of the seedling machine (Bartenev, 2015;

Mirzakhodjaev et al., 2024; Mirzakhodjaev et al.,

2024; Mirzakhodjaev et al., 2024; Khudayorov et al.,

2023; Khudayorov et al., 2023). The scheme of the

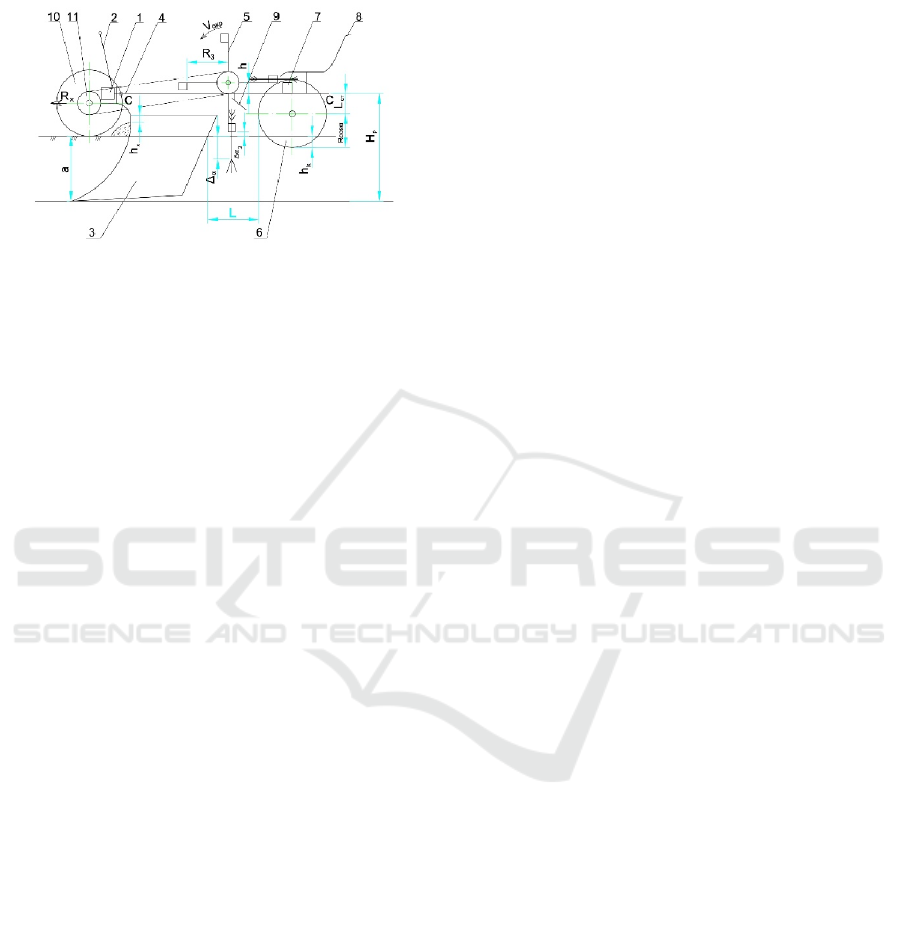

planter (Fig. 1) is the basis for the design of many

other types. It consists of a cross beam 1 with a

fastening mechanism 2, a main frame 4 with a landing

gear 5, compression rollers 6, a receiving table 7,

seats for seedlings 8, supports 9 includes. Soshnik 3

is attached to the frame above. The transmission is

carried out through the wheels of 10 chains 11. In this

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

24

construction, the movement is carried out from one of

the compression rollers equipped with a star.

Figure 1: Scheme of the planter.

Based on the general scheme, it is necessary to

understand the relative location of the working bodies

in the technological sequence and their kinematic

connection with the machine frame, which ensures

their reliability.

the 1st century it is as follows:

AA- soil surface

BB- the bottom of the planting furrow (crack)

a - planting depth, cm

H

p

- the height of the car frame above the bottom of

the nest, cm

H

c

- soil compaction height, cm

L - the distance between the roller ring and the back

edge of the machine in the projection on the

horizontal plane, m.

The height of the machine frame:

𝐻

=𝑎+𝑅

−𝐷ℎ

+𝐷𝑎

(1)

where: R

3

is the radius of the planting device, cm

Dh

p

- the height of the axle bearing of the planter

(constructive size), cm

Da

2

- the distance of the lower edge of the holder

(clamp) of the planting device to the soil surface, Da

2

= 2-4 cm.

Soshnik processing height:

𝐻

=𝐷+ℎ

+𝐷ℎ (2)

Here: h

x

is the height of the soil mound, cm

Dh is the reserve height of the pile to prevent the

soil from falling from the surface layer through the

upper edge.

In order to theoretically justify the main

parameters of the working parts of the developed

aggregate, their results are presented below.

4 CONCLUSIONS

The literature and patent sources on the existing

constructions of forest planting machines, the type

and parameters of the developed forest planting

machine, which most fully meet the agrotechnical

requirements for deep planting of sand seeds and

seedlings, are based.

- good host plants in conditions of moving sand.

As an optimal type, a box-shaped opener with a sharp

angle and parameters to the soil is offered.

REFERENCES

Akhmetov, A.A., Akhmedov, Sh.А., Allanazarov, M.A.,

Asamov, R.H. 2023, IOP Conference Series: Earth and

Environmental Science, 1138(1), 012047

doi:10.1088/1755-1315/1138/1/012047

Akhmetov, A.A., Allanazarov, M.A., Muratov, L.B.,

Kambarova, D.U. 2021, IOP Conference Series: Earth

and Environmental Science, 868(1), 012075

Akhmetov, A.A., Allanazarov, M.A., Rakhimboyeva, D.S.,

Rajabov, I.R. 2024, AIP Conference Proceedings,

3045(1), 040008 https://doi.org/10.1063/5.0198816

Alimova, F., Saidova, M., Boboniyozov, E., & Mirzayev,

B. (2024). Analysis of the state of mechanized sowing

of rice in seedlings. BIO Web of Conferences, 85.

https://doi.org/10.1051/bioconf/20248501032

Anarbaev, A., Zakhidov, R., Tursunov, O., ...Yusupov, Z.,

Kushev, A. 2020, IOP Conference Series: Earth and

Environmental Science, 614(1), 012015 DOI

10.1088/1755-1315/614/1/012015

Ashirov, M., Omonov, D., Khalilov, R., Rakhimov, U.

2021, E3S Web of Conferences, 244, 02018

https://doi.org/10.1051/e3sconf/202124402018

Aslonov, N., Irisov, K. 2023, E3S Web of Conferences, 390,

01032 https://doi.org/10.1051/e3sconf/202339001032

Astanakulov, K., Kurbonov, F., Isakova, F. 2023, E3S Web

of Conferences, 381, 01001

https://doi.org/10.1051/e3sconf/202338101001

Bartenev, I.M., 2015. Forest planting machines. Ed.

Ministry of Education and Science VSFLTU,

Voronezh.

Bokiev, A., Nuralieva, N., Sultonov, S., Botirov, A.,

Kholiknazarov, U. 2021, E3S Web of Conferences,

264, 04022

https://doi.org/10.1051/e3sconf/202126404022

Davirov, A., Tursunov, O., Kodirov, D., ...Baratov, D.,

Tursunov, A. 2020, IOP Conference Series: Earth and

Environmental Science, 614(1), 012039 DOI

10.1088/1755-1315/614/1/012039

Djiyanov, M., Tadjibekova, I., Temirkulova, N. 2022, IOP

Conference Series: Earth and Environmental Science,

1068(1), 012004 doi:10.1088/1755-

1315/1068/1/012004

Djiyanov, M., Tadjibekova, I., Temirkulova, N.,

Kholmuradov, O. 2024, Lecture Notes in Networks and

Systems, 733, 565–571

Djiyanov, M., Xalilov, R., Isakova, F. 2024, BIO Web of

Conferences, 85, 01034

https://doi.org/10.1051/bioconf/20248501034

Basing the Parameters of the Planting Machine for Semi-Automatic

25

Eshpulatov, N., Khalmuradov, T., Khalilov, R.,

...Nurmanov, S., Omonov, D. 2021, E3S Web of

Conferences, 264, 04086

Eshpulatov, N., Khalmuradov, T., Khalilov, R., Obidov, A.,

Allanazarov, M. 2021, E3S Web of Conferences, 264,

04072 https://doi.org/10.1051/e3sconf/202126404072

Farmonov, E., Lakaev, S., Khalilov, R., Gorlova, I. 2020,

IOP Conference Series: Materials Science and

Engineering, 883(1), 012097

Irgashev, A., Ishmuratov, Kh.K., Allanazarov, M.A.,

Ishmuratova, K.Kh. 2021, IOP Conference Series:

Earth and Environmental Science, 868(1), 012068

Irisov, K., Gorlova, I., Khudaev, I. 2024, BIO Web of

Conferences, 105, 01016

https://doi.org/10.1051/bioconf/202410501016

Irisov, K., Xamidov, G. 2023, E3S Web of Conferences,

386, 03003

https://doi.org/10.1051/e3sconf/202338603003

Irisov, K.D., Bekmurodov, I.R. 2023, IOP Conference

Series: Earth and Environmental Science, 1284(1),

012041 DOI 10.1088/1755-1315/1284/1/012041

Isakova, F., Tadjibekova, I., Kurbonov, F. 2024, BIO Web

of Conferences, 85, 01037

https://doi.org/10.1051/bioconf/20248501037

Khaliknazarov, U., Akbarov, D., Tursunov, A., Gafforov,

S., Abdunabiev, D. 2021, IOP Conference Series: Earth

and Environmental Science, 939(1), 012020 DOI

10.1088/1755-1315/939/1/012020

Khaliknazarov, U., Ibrokhimov, U., 2024. BIO Web of

Conferences, 85, 01004

https://doi.org/10.1051/bioconf/20248501004

Khaliknazarov, U., Tursunov, A., Jalilov, N., Dinikulov,

D., 2024. Lecture Notes in Networks and Systems, 733,

573–579

Khudayorov, Z., Khalilov, R., Gorlova, I., Mirzakhodjaev,

S., Mambetsheripova, A., 2023. E3S Web of

Conferences, 365, 04011

https://doi.org/10.1051/e3sconf/202336504011

Khudayorov, Z., Khalilov, R., Mirzakhodjaev, S.,

Nurmikhamedov, B., Mamasov, S. 2023. E3S Web of

Conferences, 376, 02013

https://doi.org/10.1051/e3sconf/202337602013

Khudayorov, Z., Mirzakhodjaev, S., Khalilov, R.,

Nurmikhamedov, B., Mamasov, S., 2023. E3S Web of

Conferences., 390, 01033

https://doi.org/10.1051/e3sconf/202339001033

Leontyev, A.A., 1962. Sandy deserts of Central Asia and

their reclamation development. Tashkent, 160 pp.

Mamatov, F., Mirzaev, B., Mirzahodzhaev, S., Uzakov, Z.,

Choriyeva, D., 2021. IOP Conference Series: Materials

Science and Engineering, 1030(1), 012164 DOI:

10.1088/1757-899x/1030/1/012164

Mirzaev, B., Mamatov, F., Ergashev, I., ...Kodirov, U.,

Ergashev, G. 2019. E3S Web of Conferences, 135,

01065 https://doi.org/10.1051/e3sconf/201913501065

Mirzakhodjaev, S., Allanazarov, M., Ishmuratov, K., 2024,

BIO Web of Conferences, 85, 01043

https://doi.org/10.1051/bioconf/20248501043

Mirzakhodjaev, S., Djiyanov, M., Nurmikhamedov, B.,

Mamasov, S. 2024, BIO Web of Conferences, 85,

01035 https://doi.org/10.1051/bioconf/20248501035

Mirzakhodjaev, S., Shodiev, K., Uralov, G., Badalov, S.,

Choriyeva, D., 2021. E3S Web of Conferences, 264,

04047 https://doi.org/10.1051/e3sconf/202126404047

Mirzakhodjaev, S., Utaganov, K., Musurmonov, A. 2024,

BIO Web of Conferences, 85, 01036

https://doi.org/10.1051/bioconf/20248501036

Muhammadiev, A., Yunusov, R., Bayzakov, T.,

...Xaliqnazarov, U., Sattarov, M. 2020, IOP Conference

Series: Earth and Environmental Science, 614(1),

012013 DOI 10.1088/1755-1315/614/1/012013

Nedashkovsky, A.N., 1977. Integrated mechanization of

work on growing forest plantations on sand. On Sat.

“Scientific works” VASKHNIL, M. Kolos

Obidov, A., Nuriev, K., Allanazarov, M., Kurbonov, E.,

Khudoyberdiev, R. 2021, E3S Web of Conferences,

284, 02012

https://doi.org/10.1051/e3sconf/202128402012

Rakhmonov, I., Berdishev, A., Khusanov, B.,

Khaliknazarov, U., Utegenov, U. 2020, IOP

Conference Series: Materials Science and Engineering,

883(1), 012104 DOI 10.1088/1757-

899X/883/1/012104

Rakhmonov, I., Berdishev, A., Niyozov, N., Muratov, A.,

Khaliknazarov, U. 2020, IOP Conference Series:

Materials Science and Engineering, 883(1), 012103

DOI 10.1088/1757-899X/883/1/012103

Sabirov, M.K., 2011. Consolidation and afforestation of

shifting sands of Kyzylkum using binders, Tashkent,

Publishing house. “Mekhnat”, 128 p.

Saidova, M., Alimova, F., Tursunbaev, S., Kulmuradov, D.,

& Boltaeva, M. (2023). Influence of the shape of the

disc slots of the seeder on the suction force of the

vacuum for precise sowing of seeds. IOP Conference

Series: Earth and Environmental Science, 1284(1),

012014. https://doi.org/10.1088/1755-

1315/1284/1/012014

Shatalov, V.G., Efimtsev, Yu.A., 1984. Mechanization of

forestry work, M, “Forest industry” 152 p.

Turdiboyev, A., Aytbaev, N., Mamutov, M., ...Toshev, T.,

Kurbonov, N. 2023, IOP Conference Series: Earth and

Environmental Science, 1142(1), 012027 DOI

10.1088/1755-1315/1142/1/012027

Turdiboyev, A., Khaliknazarov, U., Akbarov, D.,

...Abdullaeva, S., Butaev, T., 2022. AIP Conference

Proceedings, 2686, 020019

Yunusov, R.F., Bayzakov, T.M., Sattarov, N.E., ...Nazarov,

O.A., Diniqulov, D.U. 2020, IOP Conference Series:

Earth and Environmental Science, 614(1), 012017 DOI

10.1088/1755-1315/614/1/012017

Zhanikulov, S., Khalmuradov, T., Allanazarov, M. 2022,

IOP Conference Series: Earth and Environmental

Science, 1112(1), 012015 DOI 10.1088/1755-

1315/1112/1/012015

Zima, N.M., Malyugin, T.T., 1976. Mechanization of

forestry operations. M, "Forest industry", 416 p.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

26