Analysis of Operational Load of Flat-Parallel Moving Movable

Frame of Cotton Harvesting Apparatus

Ulugbek Saytov

a

, Anvar Abdazimov

b

and Bakhtiyor Azimov

c

Tashkent State Technical University, 100095, University str. 2, Tashkent, Uzbekistan

Keywords: Movable Frame, Cotton Harvesting, Plane-Parallel Dynamics.

Abstract: The article provides a brief description and a basic diagram of a new flat-parallel moving movable frame of a

vertical-spindle cotton harvesting apparatus. The nature of the forces acting on the frame is analyzed taking

into account changes in the design of the suspension of the movable sections on the frame by the suspension

and the drive of the spindle drums and brush pullers. Calculation schemes of the new design of the movable

frame under the action of reaction forces from the interaction of the frame with the surfaces of the bed, with

elements of cotton bushes, inertial and load forces of the drive elements of the working bodies are developed.

Based on the developed calculation schemes, equations of the forces acting on the flat-parallel moving

movable frame with a new design of the suspension are compiled.

1 INTRODUCTION

The process of economic modernization in the

Republic of Uzbekistan shows the further

advancement of society towards liberalization,

expressed in the transformation of economic relations

and the formation of an innovative model for the

development of the country's economy. Today, as a

result of the rapid development of the "new

economy", the strengthening of the connection

between the capital market and new technologies, the

increase in their mobility and the growth in the scale

of the creation and use of knowledge, technologies,

products, services, real conditions have arisen for

solving the tasks set in the Development Strategy for

five priority areas of development of the Republic of

Uzbekistan in 2017-2021 (Decree of the President of

the Republic of Uzbekistan PF-4947, 2017). The

place of a given country in the world economic

community, its level of competitiveness in the world

arena of countries significantly depends on the system

of formation of new knowledge and technologies. It

should be noted that 80-95% of the growth of GDP of

developed countries of the world falls on knowledge-

intensive industries implementing innovations for

their development, in other words, in these countries

a

https://orcid.org/0009-0004-5502-2095

b

https://orcid.org/0000-0003-2846-2736

c

https://orcid.org/0009-0000-5600-4033

the innovative economy is widely developing (Decree

of the President of the Republic of Uzbekistan UP

3416, 2017).

Agricultural engineering of the Republic of

Uzbekistan is one of the key industries and is focused

mainly on the production of tractors and machines for

cultivating and harvesting cotton and has great

potential for exporting them to neighboring and

distant countries. Currently, there are 18 enterprises

operating in it, including 5 joint-stock companies

(JSC), 13 joint ventures (JV) with leading global

companies such as CNH, CLAAS, Lemken, John

Deere, etc. (Matchanov, 2023). Domestic semi-

mounted vertical-spindle (VS) cotton harvesting

machines (CHM) on a tractor, manufactured by JSC

TTP, are inferior in productivity and completeness of

harvesting to American self-propelled horizontal-

spindle (HS) machines. But it is not profitable for

farms to purchase an expensive self-propelled CHM,

which operates only 20-30 days a year. They find it

convenient and profitable to use a mounted or semi-

mounted CHM, the power source (tractor) of which

can be used during the year for other agricultural

work. According to calculations by Research Institute

of Agricultural Mechanization Uzbekistan, the

efficiency of a mounted CHM is twice as high as that

12

Saytov, U., Abdazimov, A. and Azimov, B.

Analysis of Operational Load of Flat-Parallel Moving Movable Frame of Cotton Harvesting Apparatus.

DOI: 10.5220/0014041300004738

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 4th International Conference on Research of Agricultural and Food Technologies (I-CRAFT 2024), pages 12-17

ISBN: 978-989-758-773-3; ISSN: 3051-7710

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

of a self-propelled one (Khojiev et al., 1994). The

comparatively low cost and operating costs of the

semi-mounted VS CHM, high selective capacity for

crop maturity and the ability to harvest at 55-60% boll

opening, as well as the ability to quickly (in 2-3

hours) mount it on a tractor and dismount it after the

end of the harvesting season for use in other

agricultural work, determine their potential not only

for Uzbekistan and the countries of Central Asia, but

also for other cotton-producing countries in the

northern belt, starting to harvest at a low boll opening

(Abdazimov et al., 2011).

One of the factors reducing the technical level of

serial semi-mounted tractors VS CHM series MX is

the insufficient stability of technological adjustments

(width of the working gap, staggered arrangement of

the spindles of adjacent drums) of the harvesting

apparatus (HA), resulting from the failure to improve

the design of the frame and drive of the spindle drums

of the movable section (Abdazimov et al., 2014), is

that when changing the width of the working gap HA,

the staggered arrangement of the spindles of adjacent

drums is disrupted, leading to deterioration of the

agrotechnical indicators (ATI) of the CHM. In this

case, the magnitude of the disruption of the staggered

arrangement of the spindles of adjacent drums

consists of two components - from a change in the

position of the frame of the movable section in space

and from an additional rotation of the spindle drum of

the movable section due to the presence of a dog

(tooth-lever) mechanism for driving the drums of the

movable section. That is, the division of the HA into

movable and fixed sections and the presence of a

gear-lever (drive) mechanism in the drive design and

ensuring the width of the working gap by moving

only one outer section, during which additional turns

of the spindle drum of the movable section occur, lead

to a violation of the staggered arrangement of the

spindles of adjacent drums and, as a consequence, to

a deterioration in the quality and reliability of the

machine.

The above-mentioned shortcomings have been

eliminated in the new design of the cotton harvesting

apparatus movable frame developed at the

Department of Ground Transport Systems at Tash

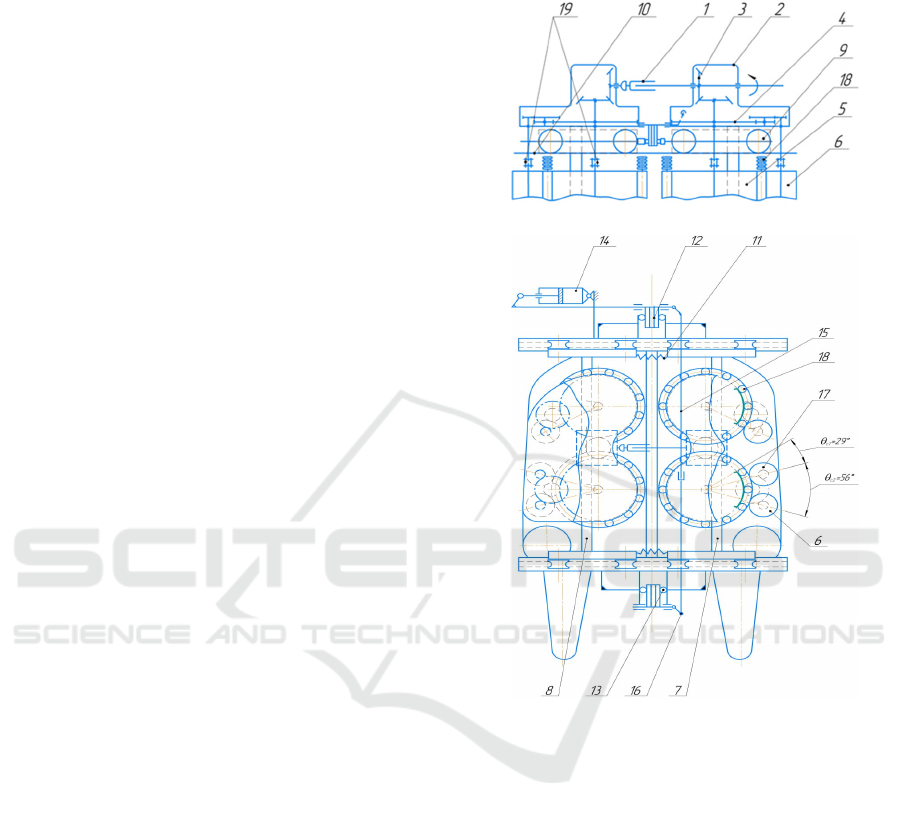

STU (Abdazimov et al., 2021), the diagram of which

is shown in Figure 1, a-front view, b-top view.

In the new design of the movable frame of

sections (Abdazimov et al., 2021), the drive of the

spindle drums 5 and strippers 6 (see Fig. 1, a and b)

of the movable frames of sections 7 and 8 is carried

out using bevel 3 and cylindrical gears 4 located in

the reducer 2. The reducers of the left 7 and right 8

movable sections are connected to each other by an

inter-section splined cardan shaft 1.

а

b

Figure 1: Schematic diagram of a cotton harvesting

apparatus with plane-parallel moving movable frames.

The movable frames of the section contain rollers

9, by means of which they can move on the transverse

bars of the guides 10 of the apparatus frame, are

pulled together by springs 11 and symmetrically

plane-parallel move apart relative to the axis of the

cotton row when their projections with rollers 13 of

the cams 12 of the working gap adjustment

mechanism act on them, containing a hydraulic

cylinder 14, kinematically connected by a rod 15 and

a lever 16 of the axis of the cams 12. To increase

reliability and reduce energy consumption, the bevel

and cylindrical transmissions of the reducer of the

movable section are made helical. To ensure

maintainability and technical maintenance, the shafts

in the working members - spindle drums 5 and

strippers 6 are made composite - part in the reducer

with drive gears, the other part in the working

Analysis of Operational Load of Flat-Parallel Moving Movable Frame of Cotton Harvesting Apparatus

13

members and are connected to each other by sleeve

couplings 19. If technical maintenance or repair is

necessary, the said working members can be

dismantled from the movable section by removing the

couplings.

Due to the changes made in the design of the

suspension of the movable frames on the frame and

the drive of the working bodies (the exclusion from

the design of the vertical hinged suspension of the

movable frame to the frame and the toothed-lever

mechanism of the drive), the stability and reliability

of the technological adjustments of the HA are

ensured, which contributes to an increase in the ATI

and productivity of the CHM. The purpose of this

work is to develop theoretical and experimental

foundations for substantiating the main parameters of

the new design of the movable section of the cotton

harvesting apparatus, taking into account its

operational load in real conditions. For this purpose,

an analysis of the forces acting on the movable frame

during the operation of the machine in cotton rows is

necessary.

2 MATERIALS AND METHODS

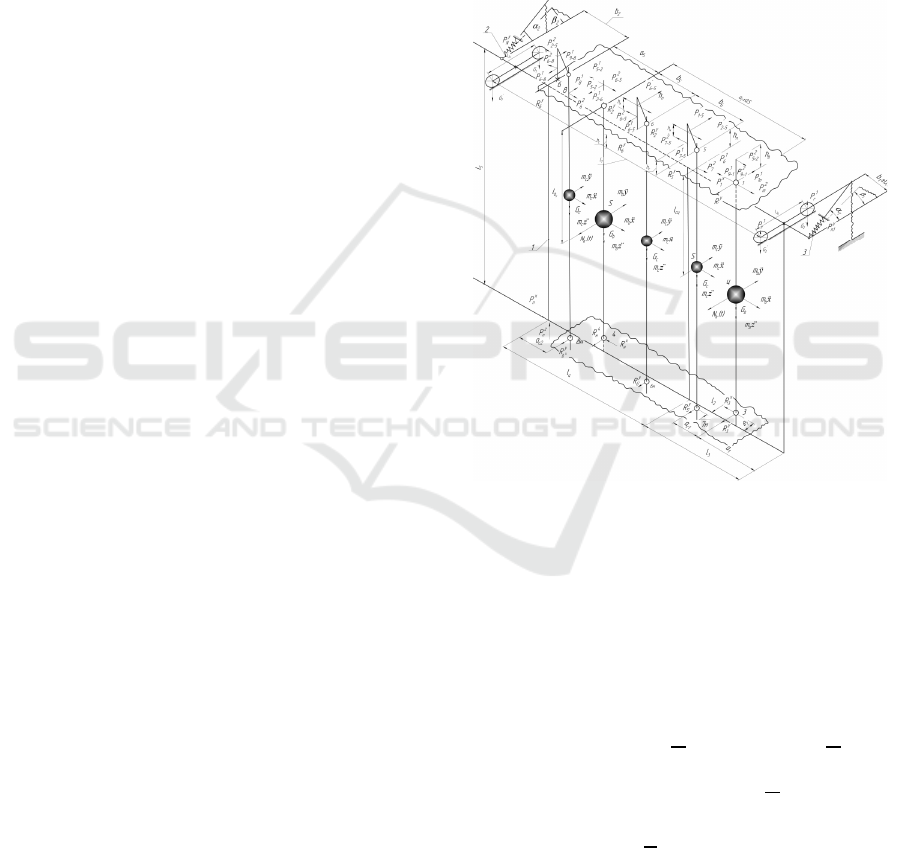

When the HA is operating in the field, the following

forces act on the movable frame (Fig. 2):

1. Inertial forces - 𝑚

х, 𝑚

𝑦, 𝑚

𝑧 and 𝑚

с

х,

𝑚

𝑦, 𝑚

с

𝑧, which act on the frame through the upper

and lower supports of the spindle and removable

drums, and the forces 𝑚

𝑧 and 𝑚

с

𝑧 only through

the upper supports (since the outer races of the

bearings of the drum shaft supports are seated in

supports with a sliding fit, which allows the lower

ends of the drum shafts to move relative to the lower

rods of the frame, and the upper part of the drum

shafts is stationary in the vertical direction relative to

the upper beam of the frame). These forces arise at

the center of gravity of the spindle and removable

drums during oscillations of the cleaning apparatus on

the suspension mechanisms.

2. The weights of the spindle 𝐺

and removable

𝐺

с

drums, which are applied to the upper supports of

the drums (the weight forces of the gear blocks were

neglected due to their insignificance).

3. Bush pressures 𝑁

(

𝑡

)

, directed perpendicular

to the xoz plane and transmitted to the upper and

lower supports of the spindle drums.

4. Compression springs 𝑃

х

, 𝑃

у

, 𝑃

and 𝑃

х

,

𝑃

, 𝑃

transmitted to the frames.

5. Soil pressures 𝑃

х

and 𝑃

(Fig. 3, a), acting on

the lower front part of the frame. These forces arise

due to the unevenness of the furrow, when driving

over ditch-irrigations with lowered devices, etc.

6. Soil pressure on the lower frame rod. These

forces arise due to the interaction of the lower surface

of the frame with the soil during the process of

harvesting raw cotton (Fig. 3, b).

7. Soil pressure on the lateral surface of the lower

frame rod (not shown in Fig. 2 and 3). Lateral forces

arise due to the interaction of the lateral surface of the

lower frame with the bed when the CHM exits onto

the headland with lowered devices.

Figure 2: Diagram of forces acting on the movable frame of

the HA.

To determine the inertial forces 𝑚

х , 𝑚

𝑦 , 𝑚

𝑧

and 𝑚

с

х , 𝑚

𝑦 , 𝑚

с

𝑧 , it is necessary to

experimentally establish the values of the

accelerations х, 𝑦, 𝑧 of the center of gravity of the

apparatus during its oscillations. Then the actions of

the latter on the supports are determined from the

following relationship (see Fig. 2).

𝑃

.

х

=±𝑚

х(

1−

𝑙

ц

𝑙

), 𝑃

н.

х

=±𝑚

х

𝑙

ц

𝑙

,

𝑃

.

=±𝑚

𝑦(

1−

𝑙

ц

𝑙

),

𝑃

н.

=±𝑚

𝑦

ц

, 𝑃

.

=±𝑚

𝑧 +𝐺

𝑙

where l

n

is the distance between the supports of the

spindle drums and pullers.

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

14

The bush pressure is determined by the formula

(Glushchenko, 1985):

𝑁

(

𝑡

)

=

∑

𝑁

,

𝑐𝑜𝑠𝑖𝜔

𝑡, (1)

where 𝑁

− amplitude of the “i” harmonic;

𝜔

=

𝑖

− number of the last harmonic taken into

account;

𝑉

− driving speed of the CHM;

𝑆

− average distance between adjacent cotton nests

(𝑆

depends on the planting pattern of the bushes).

The forces of the tension springs are equal

𝑃

=𝑘

∆𝑙

и 𝑃

=𝑘

∆𝑙

,

where 𝑘

and 𝑘

− spring stiffness coefficients,

respectively, ∆𝑙

and ∆𝑙

− deformations of the

springs accordingly.

The projections of the forces of the tension springs on

the x, y, and z axes will be equal to (Fig. 2)

(Abdazimov et al., 2022):

𝑃

х

=𝑃

𝑠𝑖𝑛𝛽

, 𝑃

у

=𝑃

𝑐𝑜𝑠𝛼

, 𝑃

=

𝑃

𝑠𝑖𝑛𝛼

𝑃

х

=𝑃

𝑠𝑖𝑛𝛽

, 𝑃

=𝑃

𝑐𝑜𝑠𝛼

,

𝑃

=𝑃

𝑐𝑜𝑠𝛼

. (2)

The force of soil pressure on the front part of the

lower frame is determined by the formula (Handbook,

1968):

𝑃

= 𝜀𝜌𝑎ℎ𝑣

(3)

where ε – dimensionless coefficient depending on the

frame shape and soil properties;

ρ – soil density, kg/m

3

;

υ – driving speed of the cotton harvesting apparatus,

m/s;

h – height of soil unevenness;

a – rod width;

𝛼− rod elevation angle.

The projections of the soil pressure force 𝑃

on the x

and z axes are equal to

𝑃

х

=𝑃

𝑠𝑖𝑛𝛼 𝑃

п

=𝑃

𝑐𝑜𝑠𝛼, (4)

The pressure of the soil on the lower and lateral

surfaces of the lower frame rod can be replaced by a

uniformly distributed load applied along the length of

the lower frame rod, i.e.

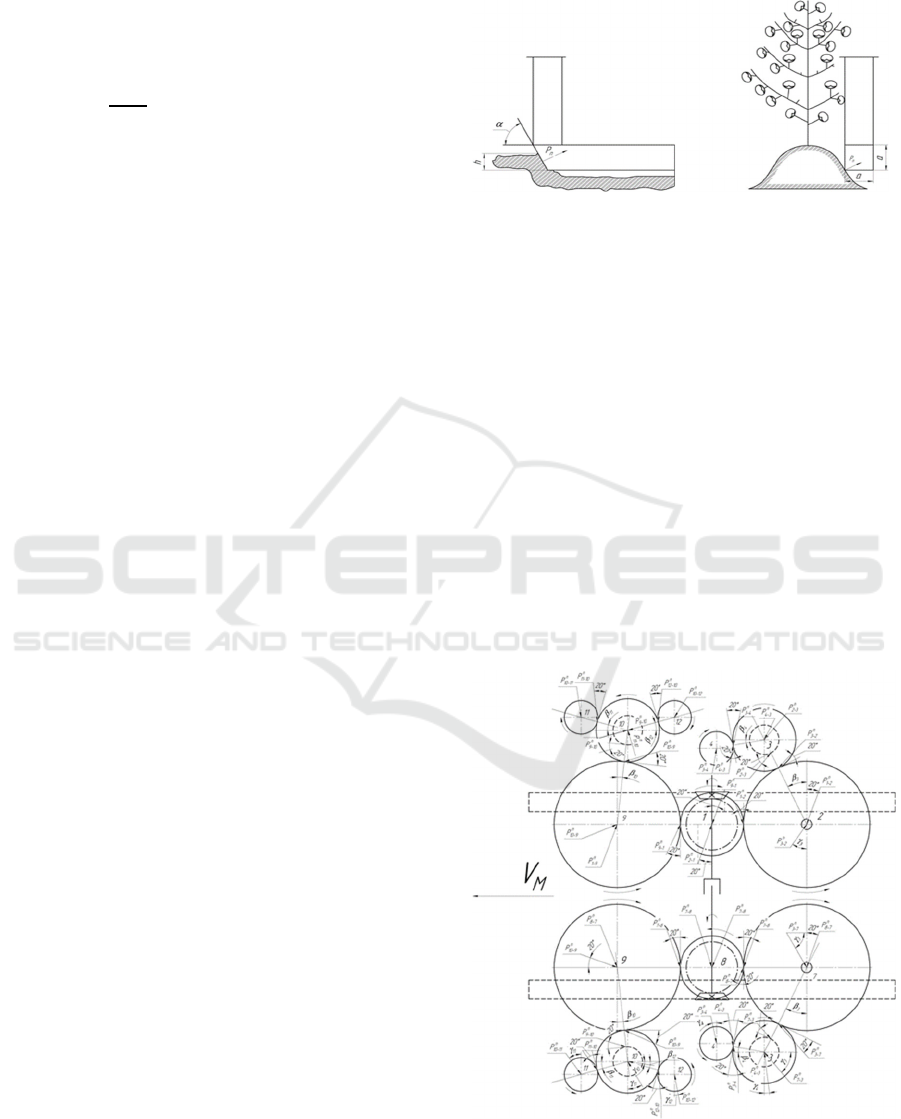

а b

Figure 3: Scheme of the action of soil pressure on frames

when moving a CHM across an arrow ditch with lowered

devices

𝑁=𝑓∙𝑃

(5)

where f – coefficient of friction;

a – height of the lower rod (see Fig. 2).

To determine the forces from the gear transmissions

acting on the frame, let us consider the drive diagram

of the spindle and removable drums of the HA with a

new design of the movable section (Abdazimov et al.,

2021).

To determine the load on the shaft or on the

cantilever axis, it is necessary to draw a diagram for

each drive gear. Fig. 4 shows a diagram for

determining the loads on the spindle and removable

drums and on cantilever axles of parasitic gears.

Figure 4: Scheme for determining loads from gear

transmissions.

Analysis of Operational Load of Flat-Parallel Moving Movable Frame of Cotton Harvesting Apparatus

15

Considering that the values of torque on the

spindle shafts and removable drums are known, we

determine the values of torque on the drive gears:

𝑀

=𝑀

, 𝑀

=

, 𝑀

=

+

𝑀

ш

, 𝑀

=

+

, 𝑀

=

+

𝑀

ш

, (7)

𝑀

=𝑀

, 𝑀

=

, 𝑀

=

,

where 𝑀

and 𝑀

ш

are the torques on the shafts of the

removable and spindle drums.

Let us consider the action of the 𝑍

puller gear on

the 𝑍

gear block gear. The action of the 𝑍

gear on

the 𝑍

gear is replaced by the force 𝑃

∙

, directed

along the engagement line “ab” (see Fig. 4.).

The total pressure on the tooth is determined by

the formula

𝑃

∙

, (8)

where 𝑀

− torque on puller shaft 8;

𝐷

− diameter of the pitch circle of the gear

𝑍

;

𝛼 = 20° −

engagement angle.

Since gear 𝑍

of the gear block rests on axis 6, the

action of gear 𝑍

on this axis can also be replaced by

force 𝑃

∙

.

Similarly, we get

𝑃

∙

=

, 𝑃

∙

=

, 𝑃

∙

=

, (9)

𝑃

∙

=

, 𝑃

∙

=

, 𝑃

∙

=

, 𝑃

∙

=

.

The projections of these forces along the Y and X

axes will be equal to

𝑃

∙

=𝑃

∙

𝑠𝑖𝑛𝛾

, 𝑃

∙

=

𝑃

∙

𝑐𝑜𝑠𝛾

, 𝑃

∙

=𝑃

∙

𝑡𝑔𝛼 ,

𝑃

∙

=𝑃

∙

𝑐𝑜𝑠𝛼 , 𝑃

∙

=𝑃

∙

𝑡𝑔𝛼 ,

𝑃

∙

=𝑃

∙

𝑐𝑜𝑠𝛼 ,

𝑃

∙

=𝑃

∙

𝑐𝑜𝑠𝛾

, 𝑃

∙

=

𝑃

∙

𝑠𝑖𝑛𝛾

, 𝑃

∙

=𝑃

∙

𝑐𝑜𝑠𝛼, (10)

𝑃

∙

=𝑃

∙

𝑡𝑔𝛼, 𝑃

∙

=𝑃

∙

𝑐𝑜𝑠𝛾

,

𝑃

∙

=𝑃

∙

𝑠𝑖𝑛𝛾

,

𝑃

∙

=𝑃

∙

𝑡𝑔𝛼 , 𝑃

∙

=

𝑃

∙

𝑐𝑜𝑠𝛼 , 𝑃

∙

=𝑃

∙

𝑐𝑜𝑠𝛾

,

𝑃

∙

=𝑃

∙

𝑠𝑖𝑛𝛾

,

where 𝛾

=𝛽

−𝛼; 𝛾

=𝛽

−𝛼; 𝛾

=𝛽

−

𝛼; 𝛾

= 90°− (𝛽

+𝛼).

The obtained expressions of forces acting on the

movable frame are typical for the static mode. In the

dynamic mode, the load of the movable frame of the

cotton harvesting apparatus section as such has not

been studied as a whole. Although the dynamics of its

working elements, such as spindles, spindle and

stripper drums, as rotation units were studied in

sufficient detail in the works (Glushchenko, 1985;

Glushchenko, 1990; Turanov, 1989). Analytical

expressions of bending, torsional, pendulum and axial

oscillations of the spindle, bending and torsional

oscillations of the spindle drum shaft and the stripper

shaft were obtained, approximate methods for solving

systems of equations describing the specified

processes were proposed. Calculation and

experimental studies have established that the

working elements of the drum-type CHM themselves

are sources of excitation of dynamic loads, leading to

the failure of individual connections of the parts of

these working elements due to their design

imperfections (Turanov, 1989). The specified loads

are transferred to some extent by the frames that carry

them, but their values in relation to technological ones

(impacts from the surfaces of the ridges of the bed and

the bush mass in the row) are significantly less

(Turanov, 1989). Consequently, it is of great

importance to determine the values of external

impacts on the movable frame under operating

conditions.

3 RESULTS AND DISCUSSION

The obtained expressions of forces acting on the

movable frame are typical for the static mode. In the

dynamic mode, the load of the movable frame of the

cotton harvesting apparatus section as such has not

been studied as a whole. Although the dynamics of its

working elements, such as spindles, spindle and

stripper drums, as rotation units were studied in

sufficient detail in the works (Glushchenko, 1985),

(Glushchenko, 1990), (Turanov, 1989). Analytical

expressions of bending, torsional, pendulum and axial

oscillations of the spindle, bending and torsional

I-CRAFT 2024 - 4th International Conference on Research of Agricultural and Food Technologies

16

oscillations of the spindle drum shaft and the stripper

shaft were obtained, approximate methods for solving

systems of equations describing the specified

processes were proposed. Calculation and

experimental studies have established that the

working elements of the drum-type CHM themselves

are sources of excitation of dynamic loads, leading to

the failure of individual connections of the parts of

these working elements due to their design

imperfections (Abdazimov et al., 2022). The

specified loads are transferred to some extent by the

frames that carry them, but their values in relation to

technological ones (impacts from the surfaces of the

ridges of the bed and the bush mass in the row) are

significantly less (Handbook, 1968). Consequently, it

is of great importance to determine the values of

external impacts on the movable frame under

operating conditions.

4 CONCLUSIONS

The conducted studies substantiated the methodology

for drawing up calculation schemes for determining

the loads acting on the elements of the new HA

structures with plane-parallel moving movable

frames. The developed calculation methodology

allows determining the values of bending and torque

moments in the sections of movable frames taking

into account individual values determined based on

the results of planned experiments.

REFERENCES

Abdazimov A.D., Atajanova M.M., Azimov B.M. and

Saytov U.A.. Modelling movement of pull-up spring of

cotton harvesting apparatus. AEGIS-2022 IOP Conf.

Series: Earth and Environmental Science 1076 (2022)

012004 doi:10.1088/1755-1315/1076/1/012004.

Abdazimov A.D., Sadriddinov A.S. Ulzhaev E. et al.

Movable frame of a section of a vertical-spindle cotton

harvesting apparatus. Patent for Utility Model No. FAR

01580 dated 09.02.2021.

Abdazimov A.D., Sadriddinov A.S., Tulyaev A.R. Phase

discrete modeling of processes in harvesting devices

with controlled movement of cotton bolls. Tashkent:

Publishing house of the National Library of Uzbekistan

named after A. Navoi, 2011, -180 p.

Abdazimov A.D., Ulzhaev E., Ubaydullaev U.M., Omonov

N.N. Fundamentals of automation of control and

management of technological parameters of cotton

harvesting machine. Tashkent: TashSTU, 2014, -164 p.

Decree of the President of the Republic of Uzbekistan PF-

4947 of February 7, 2017 “On the development strategy

in five priority areas of the Republic of Uzbekistan in

2017-2021”.

Decree of the President of the Republic of Uzbekistan UP

3416 of November 30, 2017 “On the formation of the

Ministry of Innovative Development of the Republic of

Uzbekistan”.

Glushchenko A.D. Dynamics of Drive Mechanisms of

Spindle Drives of Cotton Harvesting Machine

Harvesting apparatuss. Tashkent: Fan, 1985, -154 p.

Glushchenko A.D., Tashboltayev M.T. Dynamics of

Rotation Units of Cotton Harvesting Machine

Harvesting apparatuss. Tashkent: Fan, 1990, -138 p.

Handbook of the designer of agricultural machinery. Edited

by Candidate of Technical Sciences M.I. Kletskin.

Moscow: Mechanical Engineering, 1968. – 744 p.

Khojiev A., Norkulov S., Pavlov G., Khakimov A. What

are machines capable of? // “Khalk sozi” newspaper,

September 2, 1994.

Matchanov R. D. Chronicle of domestic agricultural

machinery. Tashkent: “Zamin nashr”, 2023, -334 p.

Turanov H.T. Dynamics of Working Bodies of Drum-Type

Cotton Cleaning and Cleaning Machines. Tashkent:

Fan, 1989, -112 p.

Analysis of Operational Load of Flat-Parallel Moving Movable Frame of Cotton Harvesting Apparatus

17