A Review of the Application of Nitrogen Doping in LiFePO

4

Cathode

Materials for Lithium-Ion Batteries

Wanting Chang

C

ollege of Chemistry, Jilin University, Changchun 130000, China

Keywords:

Nitrogen Doping, Lithium Iron Phosphate, Synthesis Method, Nitrogen and Sulfur Dualdoped Carbon.

Abstract: Lithium phosphate is a commonly used material for lithium battery-positive electrode materials, with high

energy density, high stability, and long service life. Still, it also has disadvantages such as poor conductivity

and heavy weight. Discussion based on the structure and electrochemical properties of lithium iron phosphate,

this review focuses on the modification methods of carbon-coated, nitrogen doping, and nitrogen-sulfur co-

doping. It analyzes the electrochemical properties after doping through impedance tests, EIS, SEM, and other

methods. It can be found that these methods can effectively reduce the charge transfer resistance and increase

initial discharge capacity, making the battery have a higher and more stable capacity. This review also

discusses the synthesis method of doped lithium iron phosphate. Two methods are introduced: using sucrose

and melamine as carbon sources and using polydopamine as a precursor. Also shows the synthetic advantages

and improvement principles. Both methods can indicate good electrochemical performance of lithium iron

phosphate doped with nitrogen.

1 INTRODUCTION

Lithium batteries are the most popular type of

batteries used nowadays. It can be utilized for storing

energy using natural resources (such as integrated

lithium-ion battery power source, marginal website

lithium-ion battery power source), etc. Among them,

lithium iron phosphate which is used as a common

material has attracted much attention. Lithium iron

phosphate (LiFePO

4

) has an alternating layer

structure of octahedral-coordinated iron and

octahedral-coordinated lithium mixed with phosphate

tetrahedrons (Malik et al, 2013). Compared to

LiMO

2

, lithium cobalt oxide (LiCoO

2

, LCO) other

traditional lithium-ion batteries, LiFePO

4

has

advantages in energy density, working cycles,

stronger durability, and excellent safety and

environmental protection (Li et al, 2016).

Furthermore, LiFePO

4

has many excellent

electrochemical properties. Such as high cycle

stability, safety, platform potential, and good high-

temperature performance.

However, LiFePO

4

still has some disadvantages,

such as heavy weight, low energy density, poor

conductivity, and easy mixing between Li-Fe sites.

To overcome these problems, a common approach is

to nanosize LiFePO

4

to reduce the risk of blockage

(Yang et al, 2016). In addition, scientists have

proposed a series of improvement methods, including

doping, nitrogen-doped carbon layers, high

conductivity coatings, morphology optimization, and

nanosize (Li et al, 2016), (Cech et al, 2013, Chen et

al, 2023, Zhang et al, 2013). This article will review

nitrogen-doped carbon layers, focusing on

improvement strategies for nitrogen-doped carbon

layers and specific methods for the electrical

characteristics of the electrolyte LiFePO

4

.

2 THE CHARACTERISTICS AND

STRUCTURE OF LiFePO

4

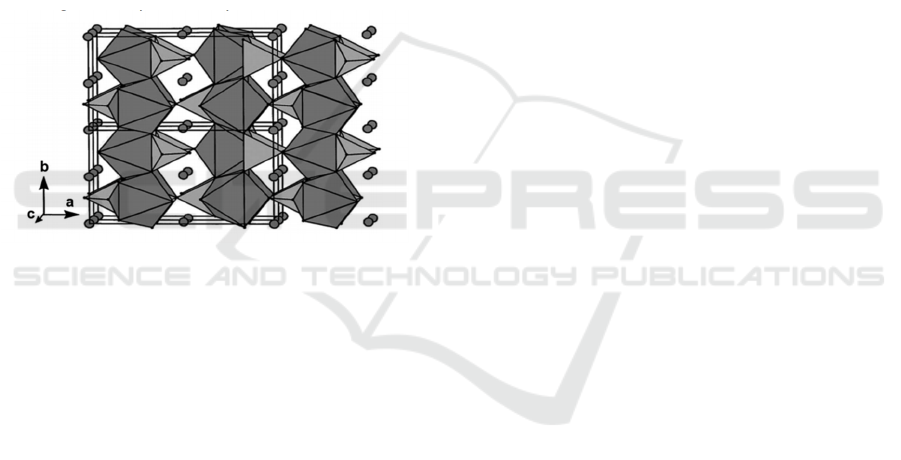

2.1 The Structure of LiFePO

4

LiFePO

4

is commonly used in lithium-ion batteries.

Its crystal structure has a unique alternating layer of

octahedral-coordinated iron and octahedral-

coordinated lithium mixed with phosphate

tetrahedrons. This unique structure gives LiFePO

4

material stable chemical properties (Yang et al,

2016),(Eftekhari, 2017). During the electrochemical

reaction of LiFePO

4

materials, as lithium ions are

inserted and removed, their crystal structure will

undergo certain changes. The conversion from

314

Chang, W.

A Review of the Application of Nitrogen Doping in LiFePO4 Cathode Materials for Lithium-Ion Batteries.

DOI: 10.5220/0013935600004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 314-318

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

LiFePO

4

to FePO

4

is a minor phase transition that

corresponds to different lattice parameters. In the

phase transition of this decay process, we can see that

LiFePO

4

has limited electronic and ionic conductivity

relative to lithium ions.

A notable feature of LiFePO

4

is its low electronic

and ionic conductivity. This is mainly because the

mobile lithium ions are restricted to 1D channels

along the b-axis, and their movement is restricted by

phosphate ions (Gabrisch et al, 2003). In addition, the

strong covalent bond between oxygen and P5 ions

forms a stable (PO

4

)

3-

unit, and this structural stability

enhances the safety of the material. To improve the

conductivity of LiFePO

4

, a common method is to

enhance its electronic conductivity by introducing

nitrogen atoms into the carbon structure. This

modification measure can improve the properties of

LiFePO

4

in lithium-ion batteries while maintaining

their high stability and safety characteristics.

Figure 1. LiFePO4 crystal structure of (Bi et al, 2013)

.

2.2 Electrochemical Properties

LiFePO

4

has many excellent electrochemical

properties as the electrode, which provides a good

basis for improving the performance and expanding

the applications of lithium-ion batteries.

First, the platform potential is relatively flat. The

insertion/extraction potential platform of LiFePO

4

is

relatively flat, which gives it relatively stable

discharge voltage and charge voltage, which it is

advantageous to the battery’s energy density and

cycle performance. The long platform of the voltage

curve of charging and discharging LiFePO

4

is about

3.4 V (0.2 C). When the temperature reaches 5°C, the

LiFePO

4

discharge capacity decreases from 139.6

mAh/g to 77.6 mAh/g (Kim et al, 2008).

Second is the high cycle stability. Because the

oxygen atoms in the LiFePO

4

structure are tightly

bound to the Fe and P atoms, it performs better at

higher temperatures compared to LiCoO

2

and other

layered electrode materials. The high lattice stability

enables LiFePO

4

to maintain its structural integrity

during long-term cyclic charge and discharge, thereby

ensuring the cycle life of the battery.

Third is safety. Golubkov et al showed that,

under adiabatic conditions, a heating element placed

around an 18650 LFP cell with 100% SOC can

provide constant power, the maximum temperature of

the cell during TR was between 400° C-450° C

(Bugrynice et al, 2008). This shows that compared

with other lithium-ion battery-positive electrode

materials, LiFePO

4

has a lower risk of thermal

runaway and explosion, making lithium-ion batteries

safer and more reliable.

Fourth is the low self-discharge rate. By using in

situ Raman spectroscopy to study the performance of

LiFePO

4

particles of different sizes and morphologies

during charging and self-discharging, it can be found

that LiFePO

4

has a low self-discharge rate, and the

battery suffers less loss during storage and idleness,

so it can maintain relatively long battery life.

Finally, there is the good high-temperature

performance. LiFePO

4

has good stability and cycle

performance in high-temperature environments and

can remain stable even at 400°C. It makes it suitable

for various high-temperature environments, such as

electric vehicles.

3 MODIFICATION STRATEGY

Materials with a larger surface area to volume ratio

can provide shorter paths for ions to travel, thereby

achieving higher power and energy density.

However, the increased surface area may also have

adverse effects, because the increased electrolyte

exposure promotes electrolyte decomposition, the

formation of unstable interfaces, and the dissolution

of transition metals (Quilty, 2023). Poorly performing

binders can negatively impact the cycling

performance of lithium batteries. Therefore,

structures containing highly π-conjugated polymer

chains should be considered when designing and

synthesizing polymer binders.

3.1 Carbon-Coated

Carbon coating is a good way to increase the

conductivity of the electrode. The addition of N, S, B,

P, F and other heteroatoms into the carbon network

further enhances the electrochemical activity.

Heteroatoms can act as electron donors, increase

carbon electron transfer, break down graphite’s

ordered structure, and promote the diffusion of

lithium ions. Simultaneously, a lot of defects will be

A Review of the Application of Nitrogen Doping in LiFePO4 Cathode Materials for Lithium-Ion Batteries

315

generated to promote the transmission of lithium in

the carbon layer.

The reversible capacity of carbon-coated

LiFePO

4

at 0.2C is about 140 mAhg

−1

. After the

cycle, it can maintain its capacity. And the capacity is

much greater than naked LiFePO

4

. By studying the

capacity of carbon covering LiFePO

4

of different

materials, it can be found that compared with other

carbon sources, graphite-covered LiFePO

4

has better

power chemical performance. After the impedance

measurement for different materials, the LiFePO

4

covered with graphite has a lower lithium-ion

migration resistance, and it also has a lower charge

transfer resistance. From this, we can conclude that

the addition of carbon will significantly reduce the

size of LiFePO

4

particles. The reduction of grain size

of LiFePO

4

and the enhancement of carbon electrical

contact will significantly improve the

electrochemical performance (Shin et al, 2006).

Bai N et al. (2016) studied Hierarchical porous

LiFePO

4

/C. Not only is the synthetic vegetable

protein pollution-free and easy to extract, but it also

has a circulation capacity of up to 166.8 mAhg

−

1

.

LiFePO

4

/C has a high capacity at different rates. At

high rates, the discharge capacity of carbon-coated

LiFePO

4

is twice that of the original LiFePO

4

, and the

capacity retention rate also is high.

Xiao Q.C et al. (2014) studied Li

1·2

(Mn

0.54

Co

0.13

Ni

0.13

)O

2

@AlF

3

/C (LMSAC) which is

prepared by AlF

3

and the carbon hybrid layer of

LMSS. The LMSS coated with AlF

3

/C has an initial

coulombic efficiency of more than 85%. Therefore,

carbon-coated improves the rate performance and

cycle performance. Impedance experiments show that

the electrode has a lower R

ct

and better conductivity

after carbon-coated.

3.2 Nitrogen Doping

The particle size of LFP/C-N (LiFePO

4

/N doped C)

materials prepared by nitrogen doping technique is

about 143 nm, in which LiFePO4 contains N. The

specific capacity of the material is 160.7 mAhg

-1

(0.1

C). It was demonstrated that the capacity of the

LiFePO

4

/C cathode did not decay after a long period

of operation, while the core-shell structure improved

its cycling performance.

Through the SEM image of LFP/C-N, it can be

found that the N element is distributed in the LiFePO

4

particles and surface carbon membranes. In addition,

it can be found from the structure of N doped that the

N doped in the carbon coating can expand the gap,

effectively increase the density of the carrier, and

increase the conductivity. When measuring 0.1C, the

charging and discharge voltage of each material can

obtain the conclusion that the discharge capacity

gradually increases with the increasing carbon

covering and N doped. After performing impedance

experiments, it can be found that materials with a

nuclear shell structure have lower charge transfer

resistance, and the N doped can further reduce the

transfer resistance. This also illustrates that the

nuclear shell structure and N-doped have a synergy

effect (Zhang et al, 2022).

Wang p et al. (2016) uses polybenzoxazine to

make LiFePO

4

nitrogen-doped material. Nitrogen

doping can provide a fast transport path for Li

+

. The

insertion process of Li

+

has a flat platform potential,

indicating that the battery is stable. It can maintain

75.8% of the initial discharge capacity, and through

continuous charge and discharge tests, it can be found

that it has stable cycle performance and excellent

recyclability.

Figure 2. (a) SEM image of LFP/CN. (b) LiFePO4

granules (Bai et al, 2016)

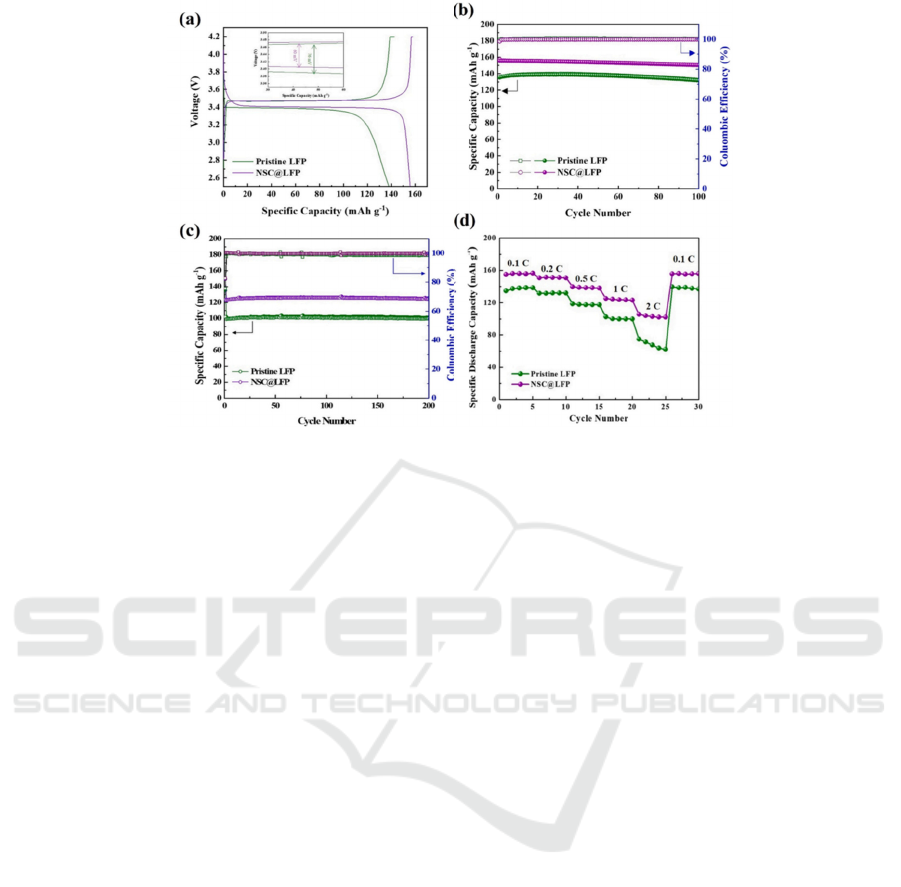

3.3 Nitrogen and Sulfur Dualdoped

Carbon

Double-doped carbon materials are carbon-doped

with nitrogen and sulfur. Compared with single-

doped materials, double-doped carbon materials have

better electrochemical properties. The heteroatom is

an electron donor, which can enhance the electron

transfer, and destruction of C, and facilitate the

diffusion of lithium ions. Moreover, doping with NSC

can create more defects, which can be used as the

active site. The cathode discharge capacity of LFP

doping by NSC was 155 mAhg

-1

and showed no

significant decay with cycling, which was

significantly higher than that of LFP. Furthermore,

NSC@LFP has 126 mAh·g-1 in the first period of 1

C. Heteroatom-doped carbon layer is an effective

method to modify the electrode (Xiao et al, 2014).

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

316

Figure 3. (a) the potential profile, (b) cycle efficiency, (c) cycle performance (d) the ability of pure LFP to NSC@LFP (Xiao

et al, 2014)

.

4 THE SYNTHESIS METHOD OF

LiFePO

4

4.1 Synthesis of Nitrogen-Doped

LFB-C with Sucrose and Melamine

as Carbon Sources

Nitrogen-doped LFB-C can be synthesized using

sucrose and melamine as the carbon source. The

addition of melamine helps in the appearance of

active surfaces. The effect of nitrogen content on

particle size was not significant due to the low

nitrogen content. The coating was formed uniformly

on the lithium iron phosphate surface. The nitrogen-

doped carbon layer and lithium iron phosphate

formed a "core-shell" conductive network, which

would greatly facilitate electron transfer and thus

improve electrochemical performance.

After measuring the EIS, the EIS is composed of

a straight line in the low-frequency area and a half in

the high-frequency area. The Warburg impedance is

used to measure the linear relationship in the low-

frequency range, and it can reflect the diffusion

ability of the lithium-ion in iron phosphate/lithium

iron phosphate. The half-circle diameter of the

modified sample was smaller than that of the

modified one. The reason for this is that nitrogen

provides a lot of conductive carriers for the carbon

layer particles in the LFP/C, so the LFP/C resistance

is reduced, and the slope of the inclined portion of the

nitrogen-modified sample is higher than that of the

untreated sample, which indicates that the Warburg

impedance is decreased, and the doping of LiFePO

4

is advantageous to the improvement of the

electrochemical property.

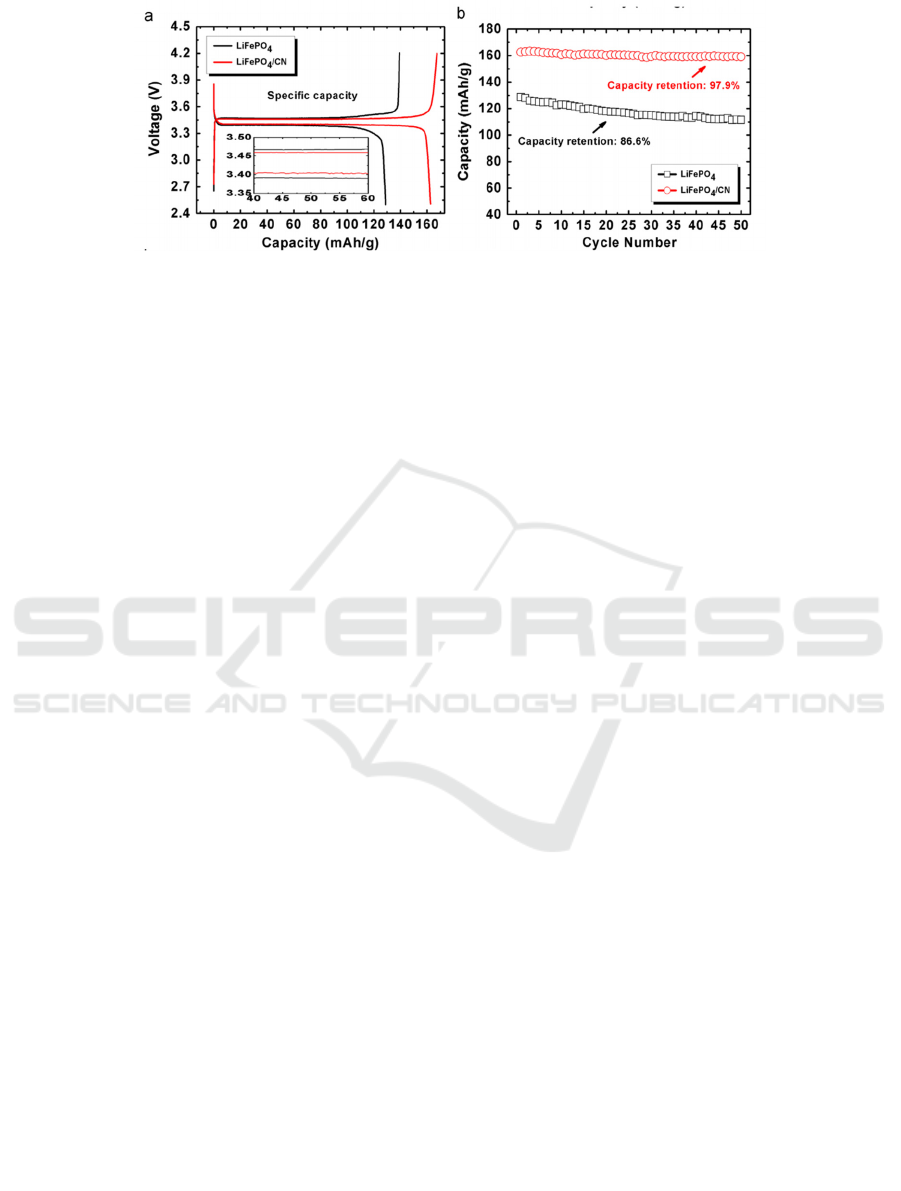

4.2 Synthesis of Nitrogen-Doped

LiFePO4 by Microwave Heating

with Polydopamine as Precursor

Carbon-Nitrogen

LiFePO4 and Tris buffer were mixed with dopamine

and stirred for 2 h. The weight ratio of

dopamine/LiFePO4 was 1:9, and then nitrogen-doped

lithium iron phosphate was synthesized by

microwave heating. Generally speaking, the particle

size of the electrode material has a great influence on

its electrochemical properties, but the microwave

heating method makes the product particles

homogeneous and small in size, so the influence is

small. The LiFePO4/CN synthesized by this method

has better cycling and electrochemical properties, as

shown in Figure 3 (Zhang et al, 2022).

A Review of the Application of Nitrogen Doping in LiFePO4 Cathode Materials for Lithium-Ion Batteries

317

Figure 4. (a) capacity and (b) cycling properties (Zhang et al, 2022).

5 CONCLUSIONS

In summary, doping with C, N, and S can effectively

improve the energy properties of the cathode.

Moreover, compared with single doping, nitrogen and

sulfur dual doping can make lithium iron phosphate

have better electrochemical properties. Double

doping materials can enhance the electron transfer of

carbon, damage the ordered structure of graphite,

increase the edge defect, form small pores, and

accelerate the diffusion of lithium ions.

In addition, this review also introduces two

methods for synthesizing nitrogen-doped LiFePO

4

:

mixing the LiFePO

4

sample with sucrose and

melamine and synthesizing nitrogen-doped LiFePO

4

was carried out by using polydopamine as a precursor

of carbon-nitrogen, and by microwave heating.

As a common lithium battery cathode material,

LiFePO4 has a longer service life and stronger

durability. However, LiFePO4 also has a lower

energy density, so how to improve its shortcomings

with cheaper materials is an important challenge.

REFERENCES

Bai N et al. 2016 Mater Technol 32 203

Bi Z, Zhang X, He W, Min D and Zhang W 2013 RSC Adv.

3 19744

Bugrynice P.J, Davidson J.N and Brown S.F 2018 Energy

Procedia 151 74

Cech O, Thomas J. E, Sedlarikova M, Fedorkova A,

Vondrak J, Moreno M. S and Visintin A 2013 Solid

State Sci. 20 110

Chen Q, Liu H, Hu J, Wang L, Li Y and Yao Y 2023 Ionics.

29 4537

Eftekhari A 2017 J. Power Sources. 343 395

Gabrisch H, Yazami R and Fultz B 2003 J. Power Sources.

119-121 674

Han B, Meng X, Ma L and Nan J 2016 Ceramics

International 42 2789

Kim H.-S, Kong M, Kim K, Kim I.-J and Gu H.-B 2008 J.

Electroceram. 23 219

Li S, Liu X, Liu G, Wan Y and Liu H 2016 Ionics. 23 19

Malik R, Abdellahi A and Ceder G 2013 J. Electrochem.

Soc. 160 A3179

Quilty C et al. 2023 Chem Rev 123 1327

Shaji N et al. 2023 J. Electrochem. Energy Convers.

Storage 72 108710

Shin H. C, Cho W. I and Jang H 2006 Electrochimica Acta

52 1472

Wang P et al. 2016 ACS Appl .Mater.Interfaces 40 26908

Xiao Q.C et al. 2014 Mater Technol 29 A70

Yang Z, Dai Y, Wang S and Yu J, 2016 J. Mater. Chem. A.

4 18210

Zhang B, Wang S, Liu L, Li Y and Yang J 2022 Materials

15 4738

Zhang H, Deng Q, Mou C, Huang Z, Wang Y, Zhou A and

Li J 2013 J. Power Sources. 239 538

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

318