Advances in Silicon Anode Morphology for Enhanced Lithium-Ion

Battery Performance: Current Status and Future Perspectives

Siyuan Zhou

School of Physics & Electronics, Hunan University, Hunan, 410082, China

Keywords: Lithium Battery, Silicon Anode, Morphology.

Abstract: Lithium-ion batteries with high energy density are regarded as highly promising electrochemical energy

storage systems. However, traditional liquid electrolytes present significant safety risks due to their propensity

for leakage and flammability. In contrast, solid-state electrolytes have garnered extensive attention for their

enhanced safety performance, high energy density, and superior stability with lithium anodes. Consequently,

research on solid-state electrolytes has become increasingly prominent. Despite this, the development of solid-

state electrolytes remains in an exploratory phase, primarily hindered by issues such as high solid-state

impedance and side reactions with electrodes. Moreover, the challenge lies in integrating the performance

advantages of various solid-state electrolytes. The primary obstacle is the poor compatibility between solid-

state electrolytes and electrodes. Current strategies to address these issues include electrode modification,

electrolyte recombination, and the introduction of interface layers. Nevertheless, solid-state electrolytes have

not yet achieved the level of development necessary to fully replace liquid electrolytes. This article provides

a comprehensive review of the status of organic polymer and inorganic solid-state electrolytes and discusses

the future development trends of these materials.

1 INTRODUCTION

Today, the problems of energy supply and the

environment are becoming increasingly prominent

and have become the focus of global attention. With

the development of industrialisation and urbanisation

and the gradual depletion of traditional energy

resources, the energy crisis has become an urgent

problem. In order to meet this challenge, people have

turned to electrification technology and are constantly

exploring innovations in the field of new energy

sources. As an important energy storage and release

device, lithium-ion batteries are gradually becoming

the mainstream choice for electric vehicles,

renewable energy systems and other fields. In the

research field of automotive batteries, lithium-ion

batteries are favoured for their high energy density,

long cycle life and low self-discharge rate. However,

conventional carbon anode materials are restricted in

terms of capacity and energy density, making it

difficult to meet the growing market demand for

electric vehicles. Therefore, the search for new anode

materials has become one of the hotspots of current

research (Deng et al., 2020 & Manzetti and Mariasiu,

2015).

Silicon, as a potential high-capacity anode

material with advantages such as abundant resources,

high theoretical specific capacity, and good electrical

conductivity, is widely regarded as an ideal

alternative to traditional carbon anode materials.

Silicon materials are characterised by their ability to

hold more lithium ions and therefore have a higher

specific capacity, which is expected to significantly

increase the energy density and range of batteries.

However, there are some challenges associated with

silicon anode materials. Firstly, silicon materials

undergo volume expansion and contraction during

charging and discharging, leading to problems such

as electrode particle fatigue and electrode structure

damage, affecting the cycle life and stability of the

battery. Second, the low conductivity and high

surface area of silicon materials also increase

electrode polarisation and charge transport resistance,

reducing the charge and discharge rate and power

performance of the battery (Speirs et al., 2014).

Recently, silicon electrodes have garnered

significant research interest. Strategies like

nanostructure engineering, composite development,

electrolyte additives, and novel polymer binders have

been extensively developed, leading to notable

improvements in the electrochemical performance of

Zhou, S.

Advances in Silicon Anode Morphology for Enhanced Lithium-Ion Battery Performance: Current Status and Future Perspectives.

DOI: 10.5220/0013932900004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 297-302

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

297

silicon materials. Nanostructure engineering, in

particular, has demonstrated significant potential for

enhancing cycling stability and rate capability.

Various silicon nanostructures, including

nanoparticles, nanowires, thin films, and porous

structures, have been extensively studied. These

nanostructures significantly improve the

electrochemical performance of silicon materials by

efficiently accommodating volume expansion,

increasing active surface area, shortening lithium-ion

diffusion paths, and reducing electron and ion

transport distances. These advances provide new

ideas to address the practical applications of silicon

anode materials (Li et al., 2022).

This paper reviews and analyses the research

progress on the morphology of silicon anode

materials for lithium-ion batteries, and summarizes

the current research progress of silicon anode

morphology regulation in the field of lithium batteries

based on the existing research background and status

quo, pointing out its potential application prospects in

improving the energy storage performance of the

batteries, prolonging the battery life and improving

the safety. In view of the problems and shortcomings

of the current research, the possible future research

directions and development trends are proposed, and

the future research prospects of silicon anode

materials are envisioned.

2 RESEARCH PROGRESS OF

SILICON ANODE FOR

LITHIUM-ION ELECTRODE

2.1 Block Silicon

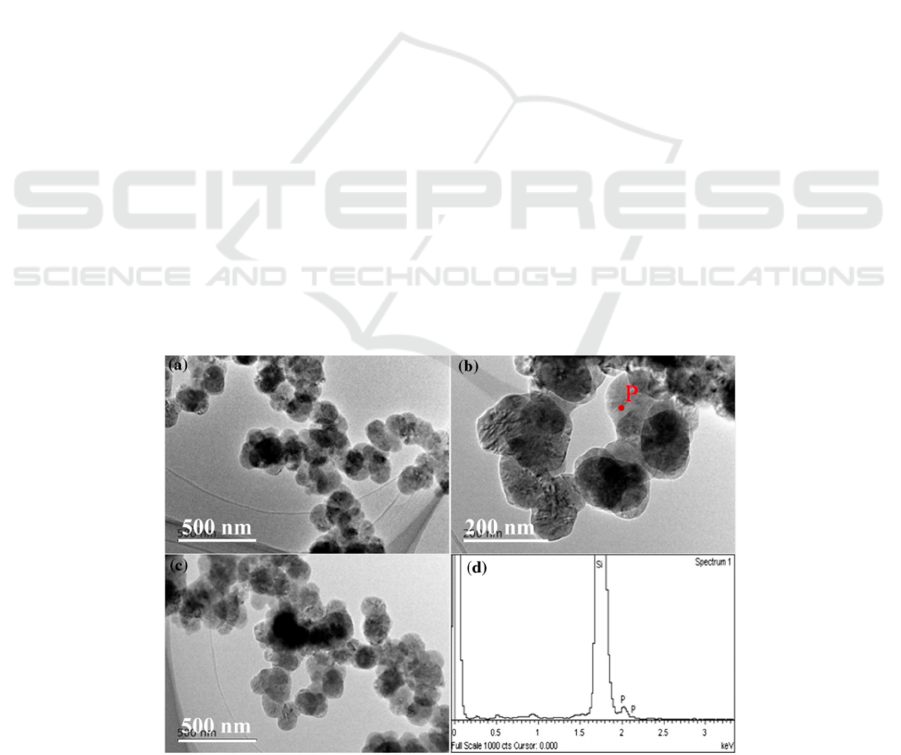

Lumpy silicon refers to large-size silicon particles or

lumpy silicon negative electrode materials, as shown

in Figure 1. Under the consideration of the influence

of morphology on energy storage performance,

lumpy silicon is used as a common silicon negative

electrode material morphology, which has its unique

superior high specific capacity and can achieve higher

energy density. The volume expansion is relatively

small, which is conducive to maintaining the stability

of the electrode structure. The preparation method is

relatively simple and can be mass-produced.

The high specific capacity of bulk silicon is

mainly due to its large volume and relatively small

surface area. This allows bulk silicon to store more

lithium ions, thereby increasing the energy density of

the battery. However, the volume expansion of bulk

silicon during charging and discharging may lead to

the destruction of the electrode structure. This is

because the silicon undergoes volume expansion as

lithium ions react with the silicon during charging and

discharging. Although the volume expansion of bulk

silicon is relatively small, it may still lead to structural

damage and performance degradation during long-

term cycling. Therefore, improving the cycling

stability and suppressing the volume expansion of

bulk silicon is the focus of current research.

Figure 1: TEM images of P-Si (Rajaeifar et al., 2022)

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

298

2.2 Silicon Nanoparticles

In nanostructure engineering, nanoparticles are one of

the most common silicon nanostructure.

Nanoparticles have the advantages of high specific

surface area and short ion diffusion paths, which are

beneficial to improve the cycling stability and rate

performance of batteries. In addition, nanoparticles

can be modified with suitable surface modifications

to improve the interfacial properties between them

and the electrolyte, thereby inhibiting SEI formation

and improving the cycle life of the battery.

Particle-forming silicon materials, with sizes

spanning the micron to nanometer scale, are of great

interest in commercial mass production and are

considered as one of the most promising candidates

for next-generation lithium-ion battery (LIB) anode

materials. The particle size of silicon materials has a

substantial influence on the battery's lifespan and

stability of the electrodes. In particular, when the

particle size is reduced to the nanoscale, mechanical

stresses can be released quickly, thus exhibiting

greater resistance to structural fracture compared to

larger particle sizes. The results of Kim et al. showed

that the particles do not continue to grow when the

particle diameter is below 10 nm, which also applies

to lithium metal. Similar results were found in tin-

based electrodes, where further fracture of the

particles does not occur when the particle diameter is

below a certain critical size.

The technology for engineering silicon

nanoparticles is fairly well established, with the main

methods including chemical vapour deposition

(CVD), ball milling, molten salt electrolysis and

ferrothermal (carbothermal) reduction. Silicon

nanoparticles synthesised by CVD usually have a

uniform size distribution, however, the method

suffers from the high cost of precursors and

complexes, harmful silane gases, and low yields,

which limit its application in large-scale production.

In contrast, the ball milling method has the

advantages of high production capacity, low cost, and

easy doping with other elements, so it is widely used

in the preparation of silica nanoparticles. Wang et al.

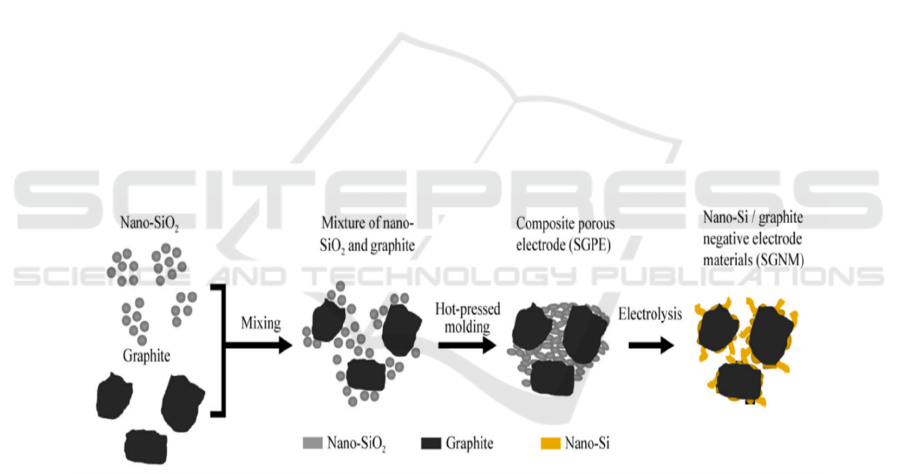

The morphology of silica nanoparticles as a raw

material is shown in Figure 2. From this figure, it can

be seen that there is an aggregate of spherical particles

with diameters between 20 and 70 nm, and its average

particle size is about 30 nm. In addition, the FESEM

images of the three graphites used in this study are

shown in Figure 2b-d.

Figure 2: The SGNM preparation process (Wang et al., 2022)

Recently, Zhu et al. proposed a simple and

scalable method to prepare silicon nanomaterials by

high-energy mechanical milling. This method

produces silicon nanoparticles of about 100 nm size,

which exhibit an exceptionally stable and reversible

capacity when coated with carbon, with a capacity

drop of less than 3% after 100 cycles. Although this

method is commercially available, there are still

many challenges in the process, such as large amounts

of impurities, surface oxidation, and size variation

(Tang et al., 2022).

In addition to ball milling and CVD, molten salt

electrolysis and ferrothermal (carbothermal)

reduction are also commonly used methods to obtain

silicon nanoparticles. Although these methods are

carried out at high temperatures, recently Lin et al.

proposed a strategy for the synthesis of silicon

nanocrystals at lower temperatures, which was

achieved in aluminium chloride molten salt.

However, silicon nanoparticles are seldom chosen as

anode materials because they tend to fragment during

repeated charge/discharge cycles, resulting in a loss

of electrical contact with the collector and a rapid

decay in capacity. To address these issues, various

additives such as carbonaceous materials, graphene,

conductive polymers, and metallic materials have

Advances in Silicon Anode Morphology for Enhanced Lithium-Ion Battery Performance: Current Status and Future Perspectives

299

been incorporated into silicon nanoparticles.

(Palomares et al., 2022).

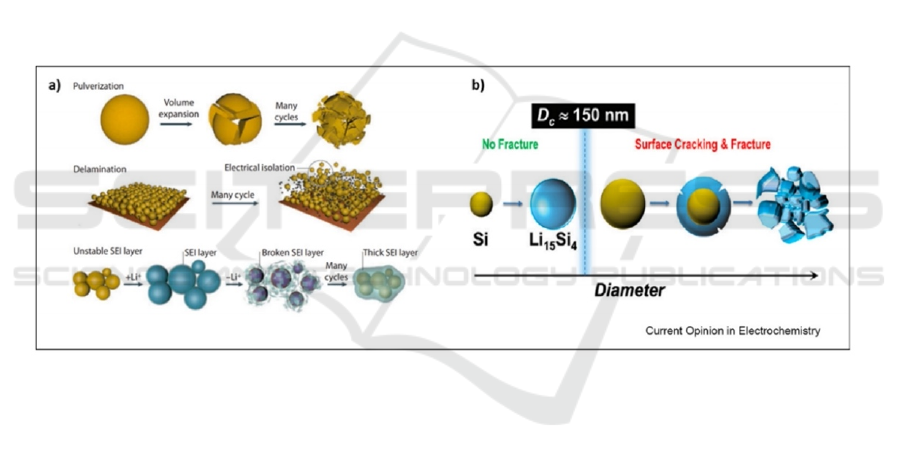

2.3 Silicon Nanoparticles

Silicon nanotubes have a larger surface area and

smaller volume due to their hollow tubular structure,

so they can effectively slow down the volume

expansion of silicon when it alloys with lithium, thus

improving the stability and cycle life of the electrode.

As shown in Figure 3, the walls of the silicon

nanotubes can provide more electron transport

channels and reduce the transport distance of

electrons inside the material, and thus have higher

electron conductivity, which helps to improve the

conductivity and power performance of the electrodes

(Moyassari et al., 2022). The hollow structure and

nanoscale size of the silicon nanotubes facilitates the

rapid diffusion of lithium ions inside the tubes, and

therefore improves the lithium-ion diffusion rate of

the electrodes, which in turn improves the charging

and discharging rate and cycling performance of the

batteries. Silicon nanotubes have better deformability

due to their flexible tubular structure, which can

better adapt to the volume change during the alloying

reaction between silicon and lithium and reduce the

structural damage of the electrode material (Roland et

al., 2022; Sanad and Shenouda, 2023 & Li et al.,

2023). Overall, silicon nanoparticles and silicon

nanotubes, as an important form of silicon anode

materials, have unique advantages in enhancing the

efficiency and reliability of batteries, and controlling

the parameters of silicon nanotubes, such as tube

diameter and wall thickness, can further regulate their

electrochemical properties. However, the preparation

of silicon nanotubes usually requires more complex

processes, and thus there may be some challenges in

terms of cost and process control (Patel et al., 2023 &

Ishii et al., 2024).

Figure 3: The mechanisms of Si electrodes (Patel et al.., 2023)

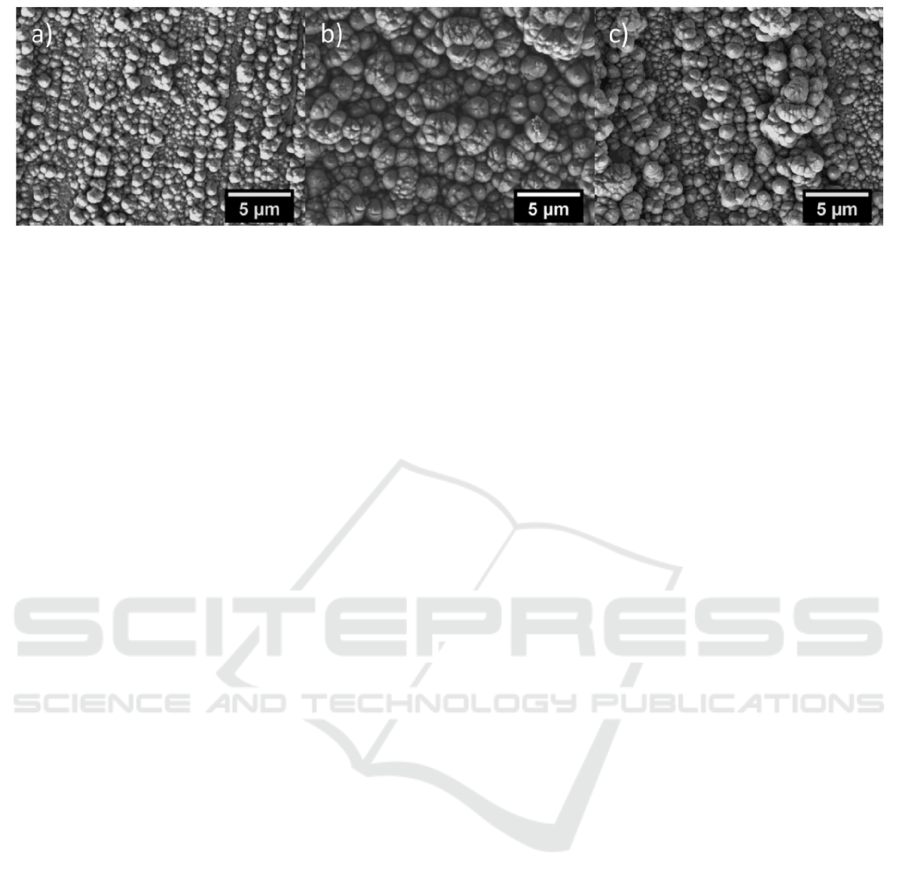

2.4 Thin Film Silicon

The main feature of thin-film silicon as a battery

anode material is to form a thinner silicon layer by

precisely controlling the thickness of silicon to cope

with the problems caused by the volume expansion of

the traditional bulk silicon material during the

charging and discharging process. As shown in

Figure 4, thin-film silicon can mitigate the volume

expansion problem more effectively than bulk silicon.

Due to its smaller thickness, the volume expansion

will be more uniform, resulting in less damage to the

electrode structure (Ishii et al., 2024). Thin-film

silicon usually has a large surface area, which is

conducive to increasing the contact area between the

electrodes and the electrolyte, thus improving the

charge transfer rate and electrochemical capability of

the cell. By controlling the preparation process of thin

films, precise modulation of their microstructure can

be achieved to further optimise their electrochemical

performance (Bonkile et al., 2024). Thin-film silicon

also has some relative technical limitations.

Compared to bulk silicon, the preparation of thin-film

silicon is typically more complex and requires more

sophisticated processes and equipment, which can

increase costs and reduce production efficiency.

Although thin-film silicon can mitigate volume

expansion, it may still face poor cycling stability

during long-term cycling, which requires further

improvement and optimisation (Li et al., 2023 & Yao,

2023).

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

300

Figure 4: SEM images of Si electrode (Lukin et al., 2023)

The mechanism of slowing down the volume

expansion of thin-film silicon mainly stems from its

smaller thickness, which makes the volume change

more uniform and thus reduces the stress

concentration in the electrode structure and prolongs

the life of the cell. The large surface area, on the other

hand, helps to improve the contact between the

electrode and the electrolyte, which facilitates the

rapid transport of electrons and ions, and thus

improves the performance of the cell (ElKhamisy et

al., 2024). However, the complexity of the

preparation process and the challenge of cycling

stability still need to be addressed through process

optimisation and material design to drive further

application and development of thin-film silicon in

batteries. These advantages and challenges make

thin-film silicon a promising area in the study of

battery materials and provide important directions

and challenges for future research (Ette et al., 2020).

3 OUTLOOK OF SILICON

ANODE

Currently, for the technological innovation aspect of

silicon negative electrode, researchers should further

explore the properties of silicon negative electrode

materials with different morphologies and optimise

their electrochemical properties, especially the rod-

shaped nano-silicon materials which have great

potential to increase the capacity and energy density,

improve the cycling performance, and increase the

charge transfer rate. At the same time, the challenges

of complex and costly preparation processes need to

be focused on, and efforts should be made to develop

low-cost and large-scale preparation technologies for

silicon anode materials, and to use renewable

materials or waste resources to reduce the preparation

cost (Haneke et al., 2023).

In terms of the development trend, the mechanism

of the effect of morphology modulation on the energy

storage performance needs to be explored in depth

through experimental and theoretical analyses to

reveal the mechanism of its action at both the macro-

and microscopic levels. The experimental results and

discussion should focus on the performance

differences of different morphology silicon anode

materials in lithium batteries, and explore the

influence of morphology modulation on energy

storage performance and the possible direction of

improvement. Meanwhile, in terms of application

prospects, this paper predicts the application

prospects of silicon anode materials in electric

vehicles and energy storage systems, and explores the

research and application of multifunctional silicon

anode materials, such as silicon nanowire anode

materials with self-repairing ability or porous

structure.

4 CONCLUSION

In this paper, the impact of silicon anode morphology

on the energy storage performance of Li-ion batteries

is reviewed, and several ideas are put forward in

terms of technological innovation, cost reduction and

development trends. In addition, comprehensive

analyses have been conducted to consider how to

overcome the volume expansion and contraction of Si

anode materials during charge/discharge cycles, how

to improve the cycling stability and capacity retention

of Si anode materials, how to increase the

conductivity of Si anode materials to enhance the

charge/discharge performance of batteries, and how

to reduce the interfacial problems between the Si

material and the electrolyte to enhance the battery's

durability and safety.

Advances in Silicon Anode Morphology for Enhanced Lithium-Ion Battery Performance: Current Status and Future Perspectives

301

REFERENCES

Deng, J., Bae, C., Denlinger, A., & Miller, T.

2020 Joule 4(3) 511-515

Manzetti, S., & Mariasiu, F. 2015 Ren. Sust. Energ.

Rev. 51 1004-1012

Speirs, J., Contestabile, M., Houari, Y., & Gross, R.

2014 Ren. Sust. Energ. Rev., 35, 183-193.

Li, P., Xia, X., & Guo, J. 2022 Sep. Purif. Technol. 296

121389

Rajaeifar, M. A., Ghadimi, P., Raugei, M., Wu, Y., &

Heidrich, O. 2022 Res. Conserv. Recy. 180,106144

Wang, N., Liu, Y. Y., Shi, Z. X., Yu, Z. L., Duan, H. Y.,

Fang, S., 2022 Rare. Metals. 41(2) 438-447

Tang, F., Tan, Y., Jiang, T., & Zhou, Y. 2022 J. Mater.

Sci. 57(4) 2803-2812

Palomares, V., Nieto, N., & Rojo, T. 2022 Curr. Opin.

Electroche. 31 100840

Moyassari, E., Roth, T., Kücher, S., Chang, C. C., Hou, S.

C., Spingler, F. B., & Jossen, A. 2022 J. Electrochem.

Soc. 169(1) 010504

Roland, A., Fullenwarth, J., Ledeuil, J. B., Martinez, H.,

Louvain, N., & Monconduit, L. 2022 Battery.

Energy 1(1) 20210009

Sanad, M. M., & Shenouda, A. Y. 2023 J. Mater. Sci-

Mater. el. 34(14) 1146

Li, X., Zhang, Z., Gong, L., Fu, K., Yang, H., Wang, C., &

Tan, P. 2023 Chem. Eng. J. 470 144188

Patel, Y., Vanpariya, A., & Mukhopadhyay, I. 2023 J.

Solid. State. Electr. 27(2) 501-510

Ishii, N., Kakinuma, N., & Morimoto, H.

2024 Electrochemistry 92(1) 017006-017006

Bonkile, M. P., Jiang, Y., Kirkaldy, N., Sulzer, V., Timms,

R., Wang, H., ... & Wu, B. 2024 J. Power. Source. 606

234256

Li, X., Zhang, Z., Gong, L., Fu, K., Yang, H., Wang, C., &

Tan, P. 2023 Chem. Eng. J. 470 144188

Yao, Y. 2023 In MATEC Web of Conferences (Vol. 382,

p. 01017) EDP Sciences

Lukin, D. M., Guidry, M. A., Yang, J., Ghezellou, M., Deb

Mishra, S., Abe, H., ... & Vučković, J. 2023 Phys. Rev.

X. 13(1) 011005

ElKhamisy, K., Abdelhamid, H., El-Rabaie, E. S. M., &

Abdel-Salam, N. 2024 Plasmonics. 19(1) 1-20

Ette, P. M., Bhargav, P. B., Ahmed, N., Chandra, B.,

Rayarfrancis, A., & Ramesha, K. 2020 Electrochim.

Acta. 330 135318

Haneke, L., Pfeiffer, F., Bärmann, P., Wrogemann, J.,

Peschel, C., Neumann, J., ... & Placke, T. 2023

Small. 19(8) 2206092

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

302