Analysis on Development of Plasma Gasification for Waste

Treatment

Yike Liu

School of Environmental Engineering and Science, Dalian Maritime University, Dalian, Liaoning, 116014, China

Keywords: Plasma, Municipal Waste, Environmental Effect.

Abstract:

China's waste disposal business is now dealing with several significant issues. There are still constraints in

the building, large-scale, and kitchen waste treatment processes. A solution combining high resource

utilization, low cost, and promotion value of kitchen trash treatment has not yet been discovered. In the central

and western regions, there are deficiencies in the handling of household garbage; in particular, the issue of

waste disposal in county areas requires immediate attention. Plasma gasification technology can quickly

decompose garbage at high temperatures and convert it into combustible gas and vitreous and other substances

with high processing efficiency. The technology is carried out in the case of hypoxia, can reduce the

generation of nitrogen oxides, and can remove toxic and harmful substances, and the pollution to the

environment is small. The combustible gas produced in the gasification process can be used to generate

electricity or converted into other fuels to achieve energy recovery. Plasma gasification can greatly reduce the

volume of waste, thus reducing the need for landfill disposal. In this paper, principle of plasma gasification

waste treatment, advantages, efficiency and application in life are analyzed.

1 INTRODUCTION

Compared with foreign countries, the research of

plasma gasification technology in China started late,

but developed rapidly. Many domestic universities,

scientific research institutions and environmental

industry companies have successively set up key

laboratories for plasma gasification technology and

research institutes related to plasma gasification to

actively explore and develop plasma gasification

technology. Some research institutions have

developed pilot-scale plasma gasification devices. In

a word, plasma gasification technology is developing

rapidly in China and is gradually moving towards

industrial application.

Plasma waste treatment technology is relatively

new. At present, it is still in the stage of research and

preliminary application, and there is still a certain

distance from large-scale commercial application.

Energy consumption problem: Plasma disposal of

garbage requires a lot of electricity, which may lead

to high operating costs. Equipment investment:

Plasma waste disposal equipment is usually

expensive, and for some small or medium-sized

garbage disposal projects, the return on investment

may not be ideal. Processing efficiency: Although

plasma treatment can achieve the harmless treatment

of garbage, its treatment efficiency may not be as

efficient as traditional incineration methods,

especially when handling a large amount of garbage.

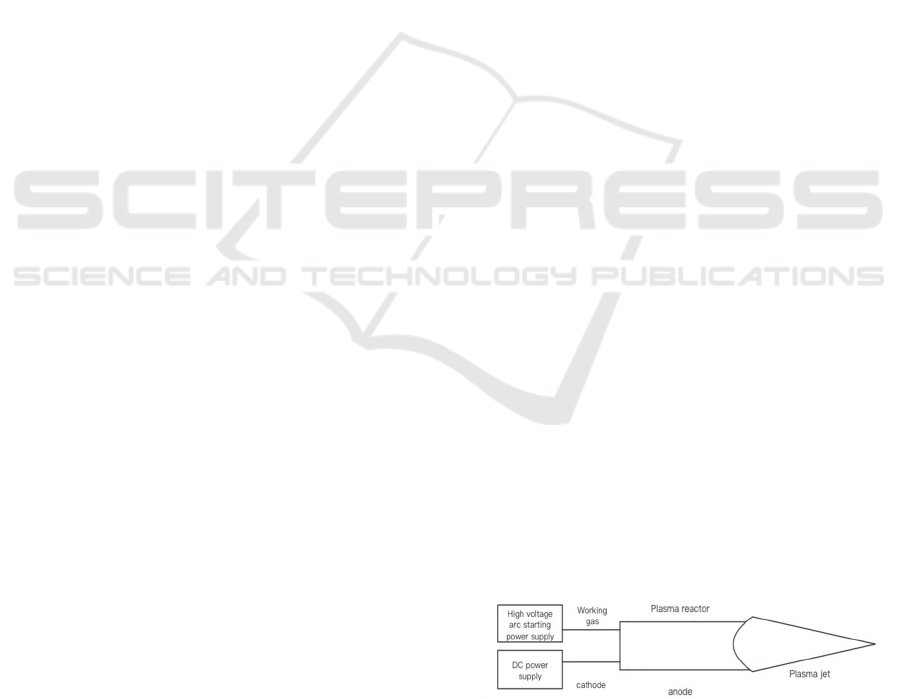

The core equipment of plasma gasification

technology is the plasma reactor. Its main working

principle is: use high-voltage breakdown of working

gas to form a discharge path, and further ionize the

breakdown working gas through a high-power DC

power supply, and inject it into the plasma

gasification furnace to form a high-temperature and

high-speed plasma jet with a core temperature of

10,000 degrees and a surface temperature of

thousands of degrees as shown in figure 1 (Diao et al,

2024). Eventually, the treated material will be melted

or even gasified through the plasma jet.

Figure 1. Principle of DC arc plasma reactor technology

(Picture credit :Original )

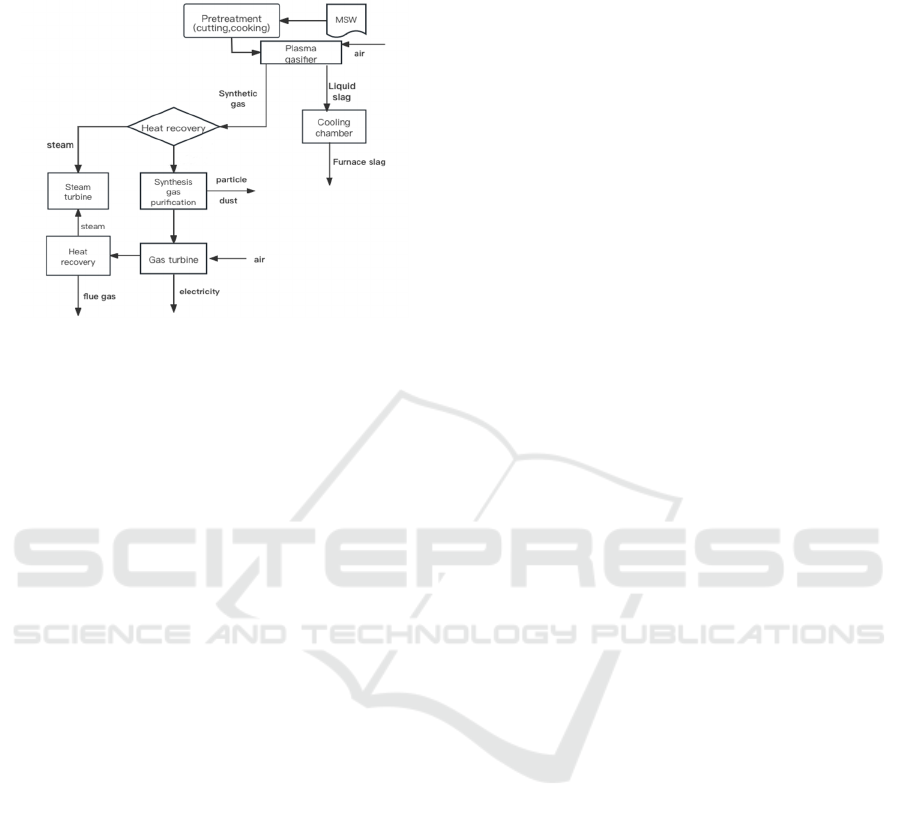

As can be seen from figure 2, the whole process is

divided into five parts: waste pretreatment, plasma

292

Liu, Y.

Analysis on Development of Plasma Gasification for Waste Treatment.

DOI: 10.5220/0013926000004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 292-296

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

gasification MSW, syngas cooling, syngas

purification, and syngas power generation.

Figure 2. Process schematic of MSW to electricity via

plasma-assisted pyrolysis and gasification (Picture credit :

Original )

The MSW is pre-treated before entering the

plasma gasifier, and the MSW is cut to a diameter of

less than 15 cm (Mai et al, 2016). 4% of coke and

MSW mixed into the gasifier, coke can absorb and

maintain the heat released by the plasma torch,

improve the calorific value of the combustion, and in

the gasification process, MSW into syngas and liquid

slag will lead to MSW continuous decline, at this

time, coke can also play a "support" role.

In the gasifier, the plasma torch is placed at the

bottom of the gasifier as a heat source, ionizing the

medium (air or oxygen) into plasma, and directly

acting on the MSW to convert the organic matter in

the garbage into syngas, and discharged from the top

of the gasifier. The ash and metal in the gasifier are

converted into slag and run out of the bottom of the

gasifier and extracted using a magnetic separator. The

molten slag after the metal is sent to the cooling

chamber for cooling, and finally forms glass particles.

The cooled syngas is sent to the purification

system for purification, which mainly removes

particles, dust, chlorine, sulfur, lead, cadmium, zinc,

mercury and other substances in the syngas. Finally,

the gas-steam combined cycle power generation

method is used for power generation, that is, the

purified syngas is sent to the gas turbine for

combustion and power generation, while the waste

heat of the syngas cooling process and the waste heat

of the high temperature flue gas discharged by the gas

turbine is recovered to produce steam for the steam

boiler to generate power and improve the power

generation.

2 MAIN TYPES OF GARBAGE TO

BE DISPOSED OF BY PLASMA

At present, foreign plasma gasification melting

treatment technology has been commercialized, from

the initial application of direct treatment of low-level

radioactive waste and medical waste, gradually

developed to the treatment of solid waste field. There

are many kinds of e-waste, including used printed

circuit boards, used tantalum capacitors, used

lithium-ion batteries, used liquid crystal displays and

used light-emitting diodes. Compared with

incineration, the pyrolysis temperature is higher and

less air pollutants such as dioxins (Sheng & Li, 2023)

and PBdes are generated.

Therefore, plasma thermolysis technology is

commonly used to treat hazardous waste

contaminants. Medical waste refers to direct or

indirect infectious, toxic and other hazardous waste

generated by medical and health institutions in

medical treatment, prevention, health care and other

related activities. Because medical waste contains

pathogens, heavy metals and organic compounds, it

will pollute surface water, groundwater and soil when

accumulated and decomposed in the open

environment. Common medical waste treatment

methods mainly include incineration treatment, high

temperature and high-pressure steam sterilization,

plasma treatment technology, microwave

disinfection, chemical disinfection, safety landfill

method and so on. However, there are some problems

in medical waste incineration treatment. The fly ash

formed by medical waste incineration contains toxic

metals and organic pollutants, which poses a serious

threat to the environment.

In the main treatment technology of medical

waste, gasification technology can convert various

solid substances into gaseous fuel, with high energy

conversion efficiency, clean and environmental

protection characteristics, is generally considered to

be an important means to achieve clean and efficient

energy production (Yang et al, 2018).

3 PERFORMANCE OF PLASMA

GASIFICATION

Although the plasma gasification process of

municipal solid waste is more complicated, it is

economically feasible. Waste disposal facilities can

charge a certain amount of waste disposal fees for the

waste being treated, and have income from the sale of

electricity. The current output is mainly electricity,

Analysis on Development of Plasma Gasification for Waste Treatment

293

but liquid fuels, hydrogen, synthetic natural gas, etc.,

may be sold in the future. Sorting and recycling

valuable commodities such as metals and high-value

plastics from municipal household waste is also a

source of income; Another source of revenue includes

the sale of slag and sulfur, which could potentially be

recycled as building materials, rockwool and building

bricks. And by avoiding landfills and reducing the

transportation of waste, plasma technology can also

save some additional costs. In addition, the use of

plasma gasification technology to treat municipal

solid waste can also enjoy government subsidies for

renewable energy and carbon emission credits.

However, in terms of economic considerations,

there are still some problems in using plasma

pyrolysis/gasification technology for direct solid

waste treatment. Firstly, the plasma reaction system

uses high-grade electrical energy as energy, and high-

power consumption is required to maintain the

equilibrium hot plasma state. Secondly, the ultra-high

temperature of equilibrium hot plasma will cause heat

loss and low energy utilization rate. Finally, the reuse

value of gas products and the utilization rate of solid

product carbon are low.

Since plasma is only used as a high-intensity heat

source in the melting furnace, and does not participate

in gasification reaction and gasification process

control as a gasification agent, the comprehensive

thermal efficiency of plasma melting is low, and the

operation rate of the batch batch in the plasma melting

furnace is low. At the same time, the fluctuation of

process conditions and parameters in gasification

process will cause the carbon content of gasification

residue to increase, and even macromolecular organic

matter to appear. The process fluctuation of

gasification process will cause drastic changes in the

process mode and operating conditions of the melting

furnace, resulting in the melting process deviating

from the intention and requirements of the melting

process. Under the comprehensive treatment mode of

hazardous waste, the separation furnace needs to be

further improved in terms of thermal efficiency,

material universality and process reliability.

4 ENVIRONMENTAL IMPACT

Harmful substances in wastewater can lead to

eutrophication of the water body, so that aquatic

organisms such as algae over reproduce, consume

oxygen in the water, and thus make other aquatic

organisms die due to lack of oxygen. This not only

destroys the diversity of aquatic life, but also

seriously affects the balance and stability of aquatic

ecosystems.

Agricultural use of sewage will lead to crop

production, quality reduction, and even harm people

and livestock, large areas of farmland are polluted,

reducing soil quality. The consequences of Marine

pollution are also very serious, such as oil pollution,

causing the death of seabirds and Marine life. After

water pollution, through drinking water or the food

chain, pollutants enter the human body, causing acute

or chronic poisoning. Arsenic, chromium,

ammonium, benzo and pyrene, etc., can also cause

cancer. Water contaminated with parasites, viruses or

other pathogens can cause a variety of infectious and

parasitic diseases. Water polluted by heavy metals is

harmful to people's health (Anubhav et al, 2012).

Pollutants such as sulfur oxides, nitrogen oxides

and volatile organic compounds contained in exhaust

gases will form acid rain, haze and other bad weather

after chemical reactions in the atmosphere, seriously

worsening air quality. Intensification of the

greenhouse effect: Greenhouse gases such as carbon

dioxide and methane in some exhaust gases cause the

Earth's surface temperature to rise, which leads to

global climate change and an increase in extreme

weather events. The deterioration of air quality

affects plant growth and leads to disruption of the

food chain in the ecosystem, which in turn threatens

biodiversity (Ren , 2011).

5 THE CURRENT PROBLEMS

5.1 Cost

Reduced (increased) equipment refers to the

equipment that is mainly different between the waste

incineration power plant and the plasma gasification

plant, and it is assumed that the cost of the

gasification plant and the rest of the equipment in the

incineration plant is the same except for the increased

and reduced equipment.

Compared with the equipment composition of

ordinary incineration plants, plasma gasification

plants mainly increase the gasifier, plasma torch,

water cooling equipment, generators and other

equipment, and reduce the electricity cost of plasma

torches of incinerators, steam cycles (boilers,

generators, condensers) and exhaust pipes and other

equipment. Although the plasma gasification process

is complicated, it is economically feasible. Receiving

garbage can charge a certain garbage disposal fee, and

the electricity produced can be sold to the power grid;

Metals and valuable plastics can also be recovered

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

294

from recycled waste, and the slag after gasification

can be used to produce building materials, which can

almost all the ash; The plasma method is very

efficient in generating electricity. Plasma gasification

technology can also save the cost of transporting

garbage, and plasma gasification technology can

enjoy government subsidies and tax exemptions. For

example, the construction of a plasma gasification

plant requires about $150 million (Ahmed et al,

2024). With the continuous development of plasma

gasification technology, the power consumption of

the plasma torch has been reduced (Galaly, 2022).

5.2 Processing Conditions and

Equipment Duration

The thermal efficiency of the plasma torch is higher

than 90%, and the service life is as long as 5000

hours, which is much higher than the level of

domestic and foreign counterparts (Rutberg et al,

2013). The owner can shorten the production cycle,

reduce production costs, with unified quality and

inspection standards, streamlined operation mode to

produce high-quality products to meet the needs of

the market. The calorific value of domestic waste is

low, and it is necessary to mix coal for combustion in

fluidized bed, so the flue gas discharge is large and

the operation cost is high. The plasma torch

incinerator can directly treat domestic waste, solid,

semi-solid and liquid waste. The plasma torch

incinerator passes into excess air, and the domestic

waste is fully incinerated to generate CO2, H2O and

other elemental substances, among which mercury,

zinc, lead, tin, copper and other heavy metals are

discharged with the flue gas in the form of oxides, and

the activated carbon injection device is used to spray

activated carbon enrichment and post-treatment (Hu

& Jiang, 2022).

6 FUTURE DEVELOPMENT

TRENDS

At present, the domestic plasma technology to treat

hazardous waste also needs to further improve and

optimize its process reliability, energy consumption,

and comprehensive operating cost. For example,

relying on the existing hazardous waste rotary kiln

incineration and disposal in collaboration with

plasma gasification and melting technology,

hazardous waste is classified and classified, coupled

with wind, light and other renewable energy sources,

and waste heat recovery is used for turbine power

generation. High value utilization of syngas after

purification reduces energy consumption and

operating costs.

7 CONCLUSION

Plasma waste treatment technology is generally

considered to be a relatively environmentally friendly

treatment method because of its ability to convert

harmful substances in waste into harmless or less

harmful substances. For example, plasma technology

can decompose harmful substances in medical waste

at high temperatures and transform them into

harmless small molecules or solidify inorganic

pollutants such as heavy metals in the glass. In

addition, pollutants such as exhaust gases and dioxins

generated during plasma treatment can be treated

through specialized flue gas purification systems to

meet relevant emission standards. However, there are

potential risks associated with any waste disposal

technology, especially if it is not handled properly or

equipment fails. In general, plasma waste treatment

technologies have been designed and implemented

with the reduction of hazardous substances in mind

but need to be continuously monitored and improved

to ensure long-term environmental safety.

REFERENCES

Ahmed R. G., Guido V. O., Nagia D. A. O. 2024

Sustainable Plasma Gasification Treatment of Plastic

Waste: Evaluating Environmental, Economic, and

Strategic Dimensions Acs Omega 9 21174−21186

Anubhav Ojha , Abhishek Clement Reuben, Durgesh

Sharma, et al . 2012 Solid waste management in

developing countries through plasma arcgasification-an

alternative approach APCBEE Procedia 1 193-198

Diao Z. Q., Zhu S. Q., Su X. Y., et al. 2024 Research

progress in plasma gasification technology for solid

waste disposal Environmental Protection of Chemical

Industry 1-7

Galaly, A. R. 2022 Sustainable Development Solutions for

the Medical Waste Problem Using Thermal Plasmas

Sustainability 14 11045

Hu C. Y., Jiang T. B. 2022 Discussion on the Application

of Plasma Treatment Technology for Hazardous Waste

Dongfang Electric Review 36 5-10

Mai W. Y., Tang L., Zhao K. M., et al. 2016 Economic

analysis of synthesis gas electricity generation of

plasma-assisted pyrolysis and gasification for

municipal solid waste Renewable Energy Resources 34

771-779

Analysis on Development of Plasma Gasification for Waste Treatment

295

Ren Yifeng. 2011 New technology of waste disposal power

generation and its application Power Generation

Equipment 25 370-373

Rutberg P G., Kuznetsov V. A., Serba E. O. et al. 2013

Study of electric arcs in an air-steam mixture in AC

plasma torches High Temperature 51 608-614

Sheng H Z., Li Y J. 2023 Development of Waste Treatment

by Thermal Plasma Technology Chinese Journal of

Theoretical and Applied Mechanics 55 2981-2996

Yang Z., Tang S., Zhang Z., et al. 2018 Characterization of

PM 10 surrounding a cement plant with integrated

facilities for co-processing of hazardous wastes Journal

of Cleaner Production 186 831-839

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

296