Applications of Metal-Organic-Frameworks in Electrodes of

Lithium-Ion Batteries

Yongrui Zhang

School of Energy and Chemical Engineering, Xiamen University Malaysia, 43900 Sepang, Malaysia

Keywords:

Lithium-Ion Battery, Electrode Materials, MOFs.

Abstract: Metal-organic frameworks (MOFs), with their unique structure and chemistry, are at the forefront of lithium-

ion battery (LIB) technology development. This paper reviews recent advancements and applications of

MOFs in LIB cathode and anode materials. As cathode materials, MOFs offer high specific surface areas and

tunable pore sizes, ensuring fast lithium-ion diffusion and improved capacity retention after multiple charge-

discharge cycles. Examples include nickel-based MOFs with an initial discharge capacity of 182 mAh/g and

cobalt-based MOFs with stable capacities for over 200 cycles. Additionally, MOFs enhance the conductivity

of traditional cathode materials like LiCoO2 significantly improving their electrochemical performance and

thermal stability. On the anode side, MOFs improve cycling stability and capacity retention by addressing the

volume expansion issues of high-capacity materials like silicon and hard carbon. Silicon-MOF composites

have achieved preliminary capacities over 2100 mAh/g with good retention rates. MOF-modified graphite

and hard carbon anodes also show improved initial coulombic efficiency and prolonged cycle life. Future

developments will focus on simplifying and reducing the cost of MOF synthesis, addressing safety and

environmental issues, and applying MOFs to new battery technologies. This collaboration aims to accelerate

the commercialization and sustainable energy storage applications of MOF-based LIBs.

1 INTRODUCTION

The global energy crisis represents one of the most

pressing challenges faced by humanity today. With

the highly development of humans' technology on

different fields, like the new energy vehicles (e.g.

Electrical Vehicles EVs), industrial production, and

hydrogen storage technology et. which will rescue

our nature mother from the risk of various types of the

pollutions which are caused by the over usages of

traditional fossil fuels. Traditional fossil fuels, that

have been an essential component of production of

energy for decades, are not only limited but also

contribute greatly to environmental degradation and

climate change (e.g., the greenhouse effect). The shift

to renewable energy sources, such as solar and wind,

will be essential for long-term stability. However, the

temporary nature of these renewable energy sources

needs modern energy storage technology to maintain

a reliable and steady energy supply. The development

of energy storage technology plays an essential role

in tackling the energy problem and reducing

environmental pollution. Effective energy storage

systems can close the distance between energy supply

and demand, stable grids and improve the efficiency

of renewable energy usage. Among the various

energy storage technologies, batteries have emerged

as a promising solution due to their ability to store and

release energy on demand. The ongoing research and

advancements in battery technology are critical to

overcoming the limitations associated with renewable

energy sources (Chen et al, 2018). Currently, storage

of electricity research is mostly focused on improving

battery performance, capacity and efficiency.

lithium-ion batteries, also known as LIBs, are at the

forefront of this study because to their high energy

density, extra cycle life, and low self-discharge rates

(Chen & Belcher, 2017). However, LIBs are not

without disadvantages. Issues such as restricted

resource availability, safety issues, and the

environmental effect of lithium mining present huge

challenges. Additionally, while LIBs provide greater

amounts of energy than many other battery types,

they still fall short of pleasing the demands for high-

energy applications as electric vehicles and large-

scale grid storage.

Metal Organic Frameworks (MOFs) have more

recently attracted an abundance attention in the field

of energy storage, particularly for increasing the

280

Zhang, Y.

Applications of Metal-Organic-Frameworks in Electrodes of Lithium-Ion Batteries.

DOI: 10.5220/0013922200004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 280-285

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

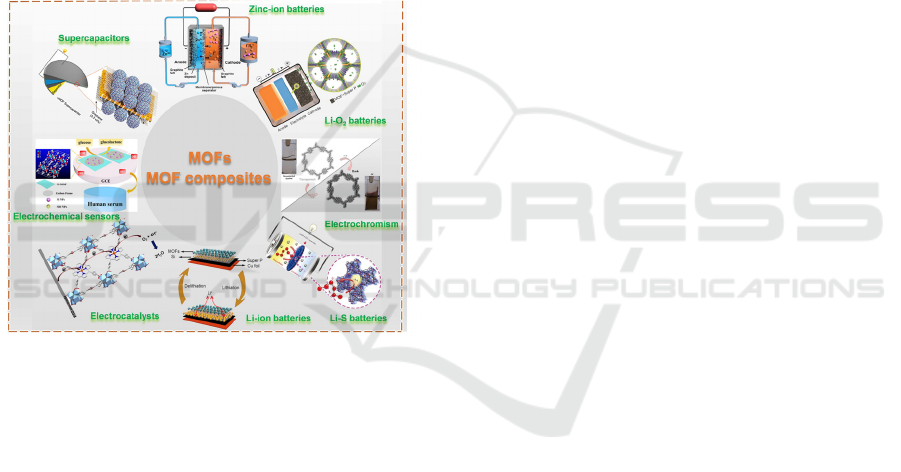

performance of LIBs, as shown in Figure 1. The

MOFs are crystalline materials comprised of ions of

metal or clusters which coordinate with organic

ligands to produce hollow structures (Férey et al,

2005). Metal-organic frameworks (MOFs) possess

incredibly vast surface areas, changeable pore sizes,

strongly thermal and chemical stability, structural

diversity, and functioning surfaces. The above

characteristics make them appropriate for storage of

gases, the adsorption molecular sieving, chemical

reactions, and an extensive number of industrial

applications. MOFs can potentially be customized to

offer different features via the addition of alternate

ions of metals and ligands that are organic, plus the

outer layer can be changed to optimize performance

in specific fields (Furukawa et al, 2013, Gao et al,

2020, Goodenough & Park, 2013).

Figure 1. Schematic diagram of descriptions for MOFs

materials’ applications in electrochemical field

(Goodenough & Park, 2013).

MOFs are an example of electrode materials that

can be applied or added in the electrolyte composition

of lithium-ion batteries to improve the

electroconductivity and battery stability. MOFs were

incorporated into LIBs and the results have been very

encouraging in that the energy-density and efficiency

of the batteries have been significantly elevated. The

reason is that MOFs can fasten the ions and therefore,

the reaction rates can be much higher. That's because

the MOF materials can offer more electrochemical

active sites and electron transportation, which are the

reasons for high storage capacity and fast

charge/discharge rates with the electrolyte of the

lithium-ion battery (Kim et al, 2018).

There is a higher structural variability of MOFs,

which makes it possible to build the very same

chemical compounds but with different properties

that may be best suited for battery optimum

performance. The plastics' structural changes are

minimized during the process. This is one of the

major features needed in the design of nearly the next

generation of batteries that is suitable for rapidly

increasing energy use while preserving

environmental integrity. In summary, energy storage

researchers must step up their efforts to address the

impending global energy crisis. However, among the

available storages, the batteries, mainly LIBs, come

forward prominently for their role in the transition

through the storage and conversion of renewable

energy with the highest efficiency. Despite the

statement that LIBs have weaknesses such the wealth

of certain materials is distributed, breakthroughs in

the use of lighter materials like MOFs are seen as a

certain advantage for a particular group of resolvers.

With MOFs being responsible for the enhancement of

energy density and thus, the overall performance of

the batteries, there is a contribution to the sustainable

energy solutions development. The future research

should remain focused on MOFs without disregards

to the fact that this direction is feasible to go since it

can significantly develop outstanding batteries

efficient of excessive capacity, and safer and less

pollution-emitting (Li et al, 2009).

The upcoming paragraphs will focus mostly on

the use of MOF materials as LIBs electrode materials

to enhance the existing performance of traditional

battery electrode materials.

2 MOFS ELECTRODE

MATERIALS APPLICATIONS

IN LIBs

Conventional lithium battery electrodes are

associated with many problems. For instance,

electrode materials degrade with repetitive charge-

discharge cycles, thereby decreasing the battery's

lifetime. Besides, different electrode materials not

only have unfavourable electrochemical properties at

high rates, but their energy density is also close to its

theoretical limit which means it is hard to make any

considerable improvements. Nevertheless, the

application of MOFs materials in electrode materials

is promising there will be the opportunity that new

type material will maximize the performance of

traditional LIBs.

Applications of Metal-Organic-Frameworks in Electrodes of Lithium-Ion Batteries

281

2.1 Pristine MOFs

Pristine MOFs are often described as such—that is,

they refer to the initial frameworks before any post-

synthetic treatments or functionalization. High purity

in pristine MOFs is essential for maintaining MOFs'

intrinsic properties: high surface areas, tunable

porosity, and diverse chemical functionality in

different applications, such as gas storage, separation,

catalysis, and sensing (Li et al, 2020). Pristine MOFs

have some properties that are very attractive to energy

storage researchers for use as electrode materials in

batteries. Most conventional battery materials suffer

from some problems, which include low capacity,

poor cycling stability, and slow kinetics. Pristine

MOFs, with their high surface areas and tunable pore

structures, offer promise for addressing these

challenges by providing more active sites for

electrochemical reactions and assisting in ionic

transport. Applications have been made with MOF in

LIB using their electrode materials.

MOFs can serve as both cathode and anode

materials. For instance, the high porosity of MOFs

can accommodate large volumes of lithium ions,

enhancing the battery's capacity. Additionally, the

structural flexibility of MOFs can mitigate the

volume changes during lithiation and DE-lithiation

processes, thus improving the cycling stability (Li et

al, 2019). Pristine MOFs such as MIL-101(Cr) and

MOF-177 have been explored for their excellent

capacity retention and rate performance as cathode

materials in LIBs (Liu et al, 2019).

A significant shortcoming of pristine MOFs as

electrodes in lithium-ion batteries is their relatively

low electrical conductivity. Generally, MOFs consist

of metal ions or clusters coordinated to organic

ligands with a high porosity configuration. This high

porosity is beneficial for ion transport. However,

bringing about an inner limitation in electron

transport due to the organic nature of the ligands and

significant possible separation between the metal

centers (Rao et al, 2021).

Above all, directly choosing pristine MOFs

materials to produce LIBs electrodes is not an

efficient method to enhance traditional LIBs

performance.

2.2 MOFs in Cathode Materials

One of the primary advantages of MOFs as cathode

materials is their high specific surface area, which

contributes to rapid lithium-ion diffusion and

improves the overall capacity and cycling

performance of the battery. The structure of MOFs,

consisting of metal nodes connected by organic

linkers, creates a highly porous network that can store

and release lithium ions efficiently. This

characteristic is particularly advantageous for

enhancing the energy density and power performance

of lithium-ion batteries.

Zhou et al., (2020) had studied on demonstrating

the effectiveness of a nickel-based MOF (Ni-MOF)

as a cathode material. The Ni-MOF showed a high

initial discharge capacity of 182 𝑚𝐴ℎ/𝑔 at 0.1 𝐶 ,

which remained at 155 𝑚𝐴ℎ/𝑔 after 100 cycles,

indicating excellent capacity retention. The high

capacity and good cycling stability were attributed to

the large surface area and uniform pore structure of

the Ni-MOF, which was helpful to efficient lithium-

ion transport and minimized structural degradation

during cycling. The specific surface area of the Ni-

MOF used in this researching was measured at

1320 𝑚²/𝑔 , significantly higher than that of

conventional cathode materials like LiCoO2, which

typically have surface areas below 50 m²/g (Sun et al,

2020).

Going through other literatures, it is found that a

cobalt-based MOF (Co-MOF) was employed as a

cathode material and showed promising results. The

Co-MOF delivered an initial capacity of 160 𝑚𝐴ℎ/𝑔

at 0.1 𝐶, maintaining 140 𝑚𝐴ℎ/𝑔 after 200 cycles.

This performance is attributed to the robust

framework of the Co-MOF, which helps maintain

structural integrity during the lithium-ion

intercalation/deintercalation process. The Co-MOF

used in this study also exhibited a high surface area

of 1250 𝑚²/𝑔 , which contributed to its superior

electrochemical performance (Tarascon & Armand,

2001).

MOFs can also act as conductive additives in

cathode composites. Traditional cathode materials

like LiCoO2 suffer from poor electrical conductivity,

which limits their rate capabilities. Incorporating

MOFs can address this issue by providing a

conductive matrix that enhances electron transport

within the electrode. For example, a study by Chen et

al. (2018) incorporated a conductive MOF into a

LiCoO2 cathode, resulting in a composite with

significantly enhanced conductivity. The

LiCoO2/MOF composite exhibited a discharge

capacity of 190 𝑚𝐴ℎ/𝑔 at 0.1 𝐶 , compared to

150 𝑚𝐴ℎ/𝑔 for pure LiCoO2. Moreover, the

composite retained 92% of its initial capacity after

500 cycles, compared to 80% for the pure LiCoO2.

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

282

The conductive MOF in this study had a specific

surface area of 1100 𝑚²/𝑔 and significantly

improved the electronic conductivity of the

composite (Wang et al, 2020).

2.3 MOFs in Anod Materials

MOFs materials can be considered as optimum anode

materials in LIBs as well due to their good

characteristics which are mentioned previously. By

applying MOFs anode materials in traditional LIBs,

the better performance does battery will have.

2.4 High Capacity and Stability

The use of MOFs in anode materials leverages their

high theoretical capacities and structural flexibility.

Silicon-based anodes, known for their high capacity

(up to 4200 mAh/g ), suffer from severe volume

expansion and contraction during charge/discharge

cycles, leading to rapid capacity fading. MOFs can

mitigate these issues by providing a flexible matrix

that accommodates volume changes, thereby

enhancing the durability and performance of the

anode.

A significant study by Zhang et al. (2019)

explored a silicon-MOF composite anode. The MOF

provided a flexible structure that mitigated the

volumetric expansion of silicon. This composite

anode achieved an initial capacity of 2100 mAh/g

and retained 85% of this capacity after 300 cycles at

0.5 C, demonstrating remarkable cycling stability

compared to pure silicon anodes, which typically

suffer substantial capacity loss within the first 100

cycles. The silicon-MOF composite benefited from

the high surface area of the MOF, measured at

1400 m²/g, which provided ample space for lithium-

ion storage and minimized mechanical stress during

cycling (Wang et al, 2019).

2.5 Composite Anode Materials

MOFs can enhance the performance of traditional

graphite anodes as well. Graphite, with a theoretical

capacity of 372 𝑚𝐴ℎ/𝑔 , is widely used in

commercial LIBs but faces limitations in rate

performance and capacity. By incorporating MOFs,

these limitations can be addressed. For example, a

hybrid anode composed of graphite and a copper-

based MOF (Cu-MOF) was studied by Sun et al.

(2020). The hybrid anode showed an enhanced

capacity of 450 𝑚𝐴ℎ/ g at 0.1 𝐶 and maintained

410 𝑚𝐴ℎ/𝑔 after 200 cycles. The MOF’s porous

structure facilitated lithium-ion diffusion and

accommodated volume changes, resulting in

improved performance. The Cu-MOF in this study

had a specific surface area of 1200 𝑚²/𝑔 , which

significantly enhanced the lithium storage capacity of

the hybrid anode (Xu et al, 2018).

Moreover, hard carbon anodes, which have higher

capacity than graphite but suffer from poor initial

coulombic efficiency, can also benefit from MOFs. A

study by Kim et al. (2018) incorporated a titanium-

based MOF (Ti-MOF) with hard carbon, resulting in

a composite that exhibited a higher initial coulombic

efficiency of 85%, compared to 70% for pure hard

carbon. The composite anode also demonstrated a

stable capacity of 450 𝑚𝐴ℎ/𝑔 over 300 cycles. The

Ti-MOF used in this study had a surface area of

1300 𝑚²/𝑔 , which contributed to the improved

electrochemical performance and stability of the

composite anode (Yaghi & Li, 1995).

3 LIMITATIONS OF MOFS

ELECTRODE MATERIALS IN

LIBs

Even though making use of MOFs electrode materials

in traditional LIBs can highly improve the

performance of battery, there are still some

limitations of MOFs electrode materials which are

discovered, like non-stable enough of structure, poor

conductivity, non-stable enough of electrochemical

properties.

3.1 Structural Stability and

Mechanical Integrity

One of the primary limitations of MOFs as battery

electrodes is their structural stability and mechanical

integrity. During the charge-discharge cycles, the

electrode materials undergo significant volume

changes. MOFs, characterized by their porous and

crystalline structures, often suffer from mechanical

degradation due to these volume fluctuations. This

degradation can lead to a loss of active material and a

decrease in electrical conductivity, ultimately

reducing the battery's overall performance (Yaghi et

al, 2003).

3.2 Conductivity Issues

Another significant challenge with MOFs is their

intrinsic low electrical conductivity. Most MOFs are

composed of metal ions coordinated with organic

Applications of Metal-Organic-Frameworks in Electrodes of Lithium-Ion Batteries

283

linkers, which are typically insulating. This poor

conductivity necessitates the incorporation of

conductive additives, such as carbon materials or

conductive polymers, to enhance electron transport

within the electrode. However, the addition of these

materials increases the complexity and cost of the

electrode fabrication process (Zhang et al, 2020).

3.3 Electrochemical Stability

The electrochemical stability of MOFs under

operating conditions is also a crucial concern. Many

MOFs exhibit instability in the presence of

electrolytes, particularly those that are aqueous or

have high ionic strengths. The dissolution of MOF

components or the breakdown of their frameworks

can lead to a rapid decline in battery performance. For

instance, the metal-ligand bonds in MOFs may be

susceptible to hydrolysis or redox reactions,

compromising the integrity of the material (Zhang et

al, 2019).

4 PROSPECT OF MOFs

ELECTRODE MATERIALS IN

LIBS

The integration of Metal-Organic Frameworks

(MOFs) into lithium-ion batteries (LIBs) represents a

burgeoning field with promising prospects. As

researchers continue to explore and optimize the

properties of MOFs, several key areas of

development and application emerge as crucial for

advancing battery technology.

Future research will be concentrated on enhancing

the electrochemical performance of MOF-based

electrodes by tailoring their structural and chemical

properties. One promising avenue is the design of

MOFs with precisely engineered pore sizes and

surface functionalities optimized for specific ion

interactions. This approach not only aims to

maximize ion diffusion rates but also to stabilize

electrode materials against structural degradation

during cycling. Advanced characterization

techniques, such as in situ spectroscopy and

microscopy, will have significant effect on

illustrating the dynamic behaviours of MOFs

electrodes under more types of operational

conditions.

To facilitate the widespread adoption of MOFs in

commercial LIBs, scalable synthesis methods that

ensure reproducibility and cost-effectiveness is very

important. Current synthesis routes often involve

complex procedures or require harsh reaction

conditions, limiting their scalability. Future efforts

will focus on developing environmentally benign

synthesis routes using readily available precursors

and optimizing post-synthetic treatments to enhance

MOF stability and performance. Moreover,

integration strategies that streamline the

incorporation of MOFs into existing battery

manufacturing processes without compromising

performance will be critical.

Addressing safety and sustainability concerns

associated with MOF-based LIBs will be an urgency

for future research. While MOFs offer significant

advantages in terms of performance enhancement,

their environmental impact, particularly concerning

metal leaching and disposal, requires careful

consideration. Research efforts will aim to develop

MOFs using non-toxic metals and biodegradable

organic linkers, as well as exploring recycling

technologies to minimize waste. Furthermore,

comprehensive studies on the long-term stability and

safety of MOF-based electrodes under extreme

conditions, including high temperatures and

mechanical stress, will be essential to ensure the

reliability of LIBs for diverse applications.

Beyond common LIBs, MOFs have the potential

to completely revolutionize battery technologies such

as sodium-ion cells (SIBs) and solid-state batteries

(SST). SIBs, which utilize sodium ions instead of

lithium ions, require electrode materials with

mechanical characteristics similar to those chosen by

LIBs. MOFs, with their configurable pore dimensions

and varied chemical compositions, can possibly be

adapted to accommodate greater sodium ions,

increasing their possibilities in future-oriented energy

storage devices. Similarly, the development of MOF-

based solid electrolytes and separators provides the

possibility of helping improve the safety and density

of energy of solid-state batteries by providing stable

ion transport pathways and effective barriers to

dendrite formation.

Collaborative efforts between academia, industry,

and government agencies will be crucial in advancing

the development and commercialization of MOF-

based battery technologies. Multidisciplinary

research initiatives that combine materials science,

chemistry, engineering, and computational modelling

will accelerate the discovery of novel MOF materials

and their integration into advanced energy storage

systems. Furthermore, initiatives aimed at

standardizing testing protocols and performance

metrics for MOF-based electrodes will facilitate

comparative studies and accelerate technology

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

284

transfer from lab-scale demonstrations to commercial

production.

5 CONCLUSION

The application of MOFs in lithium-ion batteries,

particularly as cathode and anode materials, presents

a promising avenue for enhancing battery

performance. The high surface area, tunable pore

size, and chemical versatility of MOFs contribute to

improved capacity, cycling stability, and safety of

lithium-ion batteries. Empirical data from recent

studies underscore the potential of MOFs to

revolutionize battery technology, offering significant

improvements over traditional materials.

However, challenges related to cost, scalability,

and integration into existing manufacturing processes

remain. Future research should focus on addressing

these challenges, developing more efficient synthesis

methods, and ensuring the environmental

sustainability of MOF materials. With continued

advancements, MOFs hold the potential to play a

pivotal role in the next generation of high-

performance lithium-ion batteries.

REFERENCES

Chen, X., Li, Y., Zhang, Z., & Yang, Y. 2018 J. Power

Sources 396,188-195

Chen, Z., & Belcher, A. M. 2017 Adv. Mater

29(44),1702860

Férey, G., Mellot-Draznieks, C., Serre, C., Millange, F.,

Dutour, J., Surblé, S., & Margiolaki, I. 2005 Science,

309(5743),2040-2042

Furukawa, H., Cordova, K. E., O’Keeffe, M., & Yaghi, O.

M. 2013 Science, 341(6149),1230444

Gao, Y., Zhang, X., & Zhou, W. 2020 Electrochim. Acta,

329, 135104

Goodenough, J. B., & Park, K. S. 2013 J. Am. Chem.

Soc.135(4), 1167-1176

Kim, J., Lee, S., Park, H., & Cho, J. 2018 Electrochim Acta,

268, 349-357

Li, J. R., Kuppler, R. J., & Zhou, H. C. 2009 Chem. Soc.

Rev. 38(5), 1477-1504

Li, S., et al. 2020 Nat. Rev. Mater. 5(2), 87-104

Li, Y., Yang, S., & Wu, X. 2019 J. Power Sources 410, 162-

173

Liu, Y., Xu, X., & Wang, Y. 2019 J. Power Sources 421,

60-66

Rao, S., Xu, H., & Jiang, D. 2021 Adv. Funct. Mater.

31(15), 2004878

Sun, Q., Wu, X., Li, W., & Wang, Y. 2020 Electrochim

Acta, 332, 135511

Tarascon, J. M., & Armand, M. 2001 Nature 414(6861),

359-367

Wang, H., Huang, Y., & Ding, S. 2020 Chem. Soc. Rev.

49(18), 5650-5698

Wang, P., Zhang, X., Li, X., & Zhao, Y. 2019 J. Alloys

Compd. 788, 1026-1032

Xu, Y., Li, Q., Xue, H., & Pang, H. 2018b Coord Chem Rev

376, 292–318

Yaghi, O. M., & Li, H. 1995 J. Am. Chem. Soc. 117(41),

10401-10402

Yaghi, O. M., O'Keeffe, M., Ockwig, N. W., Chae, H. K.,

Eddaoudi, M., & Kim, J. 2003 Nature 423(6941), 705-

714

Zhang, W., Wu, H., & Zhou, Y. 2020 J. Mater. Chem. A

8(5), 2335-2345

Zhang, Y., Zhao, H., & Li, J. 2019 Nano Energy 60, 245-

253

Applications of Metal-Organic-Frameworks in Electrodes of Lithium-Ion Batteries

285