Research Progress on Solid-State Electrolytes for Lithium-Ion

Batteries

Hanning Ma

Leicester International Institute, Dalian University of Technology, Panjin, 124000, China

Keywords: Lithium Battery, Solid-State Battery, Solid-State Electrolyte.

Abstract: Lithium-ion batteries with high energy density are regarded as highly promising electrochemical energy

storage systems. However, traditional liquid electrolytes present significant safety risks due to their propensity

for leakage and flammability. In contrast, solid-state electrolytes have garnered extensive attention for their

enhanced safety property, high energy density, and superior stability with lithium anodes. Consequently,

research on solid-state electrolytes has become increasingly prominent. Despite this, the development of solid-

state electrolytes remains in an exploratory phase, primarily hindered by issues such as high solid-state

impedance and side reactions with electrodes. Moreover, the challenge lies in integrating the property

advantages of various solid-state electrolytes. The primary obstacle is the poor compatibility between solid-

state electrolytes and electrodes. Current strategies to address these issues include electrode modification,

electrolyte recombination, and the introduction of interface layers. Nevertheless, solid-state electrolytes have

not yet achieved the level of development necessary to fully replace liquid electrolytes. This article provides

a comprehensive review of the status of organic polymer and inorganic solid-state electrolytes and discusses

the future development trends of these materials.

1 INTRODUCTION

Human productivity increased significantly after the

Industrial Revolution, and energy demand reached an

unprecedented height. Industrial production mainly

relies on fossil fuels such as coal, natural gas, and oil,

which are non-renewable and lead to serious

environmental pollution, such as global warming

caused by greenhouse gas emissions. Therefore, the

search for renewable new energy has become a huge

challenge for human development at this stage.

Currently, known renewable energy sources include

wind, solar, geothermal, tidal, etc. However, these

renewable energy sources are unstable and

intermittent, and how to integrate these intermittent

energy sources into a stable and efficient large-scale

electric energy storage system is the key to solving

the energy crisis today (Tao et al, 2022). Lithium-ion

batteries stand out in many electrochemical energy

storage systems because of their advantages of high

working voltage, high energy density, low self-

discharge rate, long cycle life, and no memory effect.

However, the widely used traditional lithium-ion

batteries have gradually exposed several problems

due to using liquid electrolytes. The organic

components in liquid electrolytes are prone to

decomposition, combustion, and even explosion

under high temperatures and currents. In addition,

these organic components may decompose at high

voltages, making liquid lithium-ion batteries used

now difficult to match cathode materials with high

electrode potentials. Therefore, one of the alternatives

with the highest expectations is all-solid-state

lithium-ion batteries prepared with solid-state

electrolytes.

It is worth noting that the solid-state electrolyte

currently is the main innovation which replaces the

diaphragm and electrolyte in the liquid electrolyte. In

this way, unnecessary chemical reactions between

electrodes to dissolve active substances can be

effectively inhibited, and the safety of batteries can be

also improved (Janek and Zeier, 2023). Meanwhile,

the solid electrolyte can be matched to the anode of

lithium metal with a high theoretical specific

capacity. Even better, this kind of anode can match

the cathode material with a high specific capacity,

thus comprehensively improving the energy density

(400Wh/kg&1000Wh/L) (Aspinall et al., 2024). To

pursue high energy density, the solid-state electrolyte

Ma, H.

Research Progress on Solid-State Electrolytes for Lithium-Ion Batteries.

DOI: 10.5220/0013915200004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 273-279

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

273

layer needs to be thin enough, and the material needs

to be thin and flexible, further broadening its

application prospects. In addition, batteries with

solid-state electrolytes also have the advantages of

strong endurance, wide temperature range and fast

charging speed.

Currently, the solid-state electrolyte is mainly

divided into organic polymer solid-state electrolytes

and inorganic solid-state electrolytes two categories.

The inorganic solid-state electrolyte can be divided

into oxide, halide and sulfide solid-state electrolyte.

In this article, the current research progress of

mainstream solid-state electrolytes is reviewed, and

the future development direction of solid-state

batteries is prospected.

2 SOLID-STATE ELECTROLYTE

2.1 Organic Polymer Solid-State

Electrolyte

Organic polymer solid-state electrolyte is mainly

composed of lithium salt with low dissociation energy

and a polymer matrix with a high dielectric constant

(Wang et al., 2023). According to the types of

conductive particles, the organic polymer solid-state

electrolyte can be divided into two categories: single-

ion polymer solid-state electrolyte and double-ion

polymer solid-state electrolyte. Single-ion polymer

solid-state electrolyte is mainly composed of single-

ion lithium salt and polymer matrix, in which anions

are usually fixed on the polymeric main chain or

provided to the polymer as an acceptor, so only cation

migration in this kind of solid-state electrolyte.

However, this causes anions to accumulate near the

anode, which increases the resistance and affects the

overall property of the battery. Double-ion polymer

solid-state electrolyte is mainly composed of double-

ion lithium salt and polymer matrix. The anions

usually move faster than the cations. Therefore,

double-ionic polymer solid-state electrolytes

generally have higher ionic conductivity, while

single-ionic polymer solid-state electrolytes have

higher cation migration numbers.

The organic polymer electrolyte matrix material is

usually a polymer with polar functional groups to

promote the dissociation and ion transfer of lithium

salts so that it can have a relatively lower interface

impedance (Wang et al., 2023). Simultaneously,

polymer solid-state electrolytes are more suitable for

large-scale production because of their good

flexibility and elasticity, easy processing and low

cost. However, its organic composition results in

limited thermal stability and a low electrochemical

window (<4V). At the cathode interface, there are

many factors contributing to the instability of the

interface, such as the oxidation decomposition of the

polymer, the side reaction between the polymer and

the cathode, and the ageing of the battery interface in

the long cycle. At the anode interface, because of the

high reducibility of lithium metal, the polymer is

reduced, and structural changes occur, thereby

reducing the overall property of the solid-state

battery.

To solve the above problems of organic polymer

solid-state electrolyte, the researchers proposed the

following solutions: 1) Improve the cathode material:

By combining the cathode material with the organic

polymer, the interface impedance can be effectively

reduced, the ion transfers much faster, and the

interface instability of the cathode can be solved

effectively. 2) Introduction of the interface layer:

reduce the physical contact between the polymer

solid-state electrolyte and the electrode, reduce the

interface impedance from the source and restrain the

side reaction between the cathode and the electrolyte.

The interfacial layer between the electrolyte and the

anode can also restrain the reduction reaction and the

growth of lithium dendrites.

2.2 Inorganic Solid-State Electrolyte

2.2.1 Oxide Solid-State Electrolyte

Oxide solid-state electrolytes are composed of metal

oxides containing lithium, which are mainly divided

into calcareous, garnet and NASICON types

according to their different structural forms (Yao et

al., 2023). The calcareous type has the structural

formula ABO

3

, where A is the larger cation (usually

rare earth ions), and B is the smaller cation (usually

transition metal ions). However, the calcareous type

of oxide solid-state electrolyte has large grain

boundary impedance and small ionic conductivity,

especially at low potential, thereby reducing the

conductivity of lithium ions (Luo et al., 2024).

Garnet-type (LLZO) oxide solid-state electrolytes

(such as Li

5

La

3

M

2

O

12

, M = Ta and Nb) are composed

of lithium, lanthanum, and transition metal elements,

as shown in Figure 1. This kind of oxide solid-state

electrolyte has high electrochemical stability to the

metal lithium anode and has a higher electrochemical

window, which can match the high voltage cathodes.

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

274

However, the main challenge is the interface

compatibility between the electrolyte and cathodes

and anodes.

NASICON-type oxide solid-state electrolyte, also

known as sodium superionic conductor, its structural

formula is AM

2

(PO

4

)

3

. Where A represents alkali

metal ions (Li

+

\Na

+

), M represents Ti, Ge, Zr and

other elements. By substituting lithium for sodium,

lithium-ion conductors with higher ionic conductivity

can be obtained. The typical NASICON-type oxide

solid-state electrolyte is LiTi

2

(PO

4

)

3

(LTP). This kind

of electrolyte is stable in air and water and is not easy

to react to. However, its cost is high, and it is difficult

for large-scale production. In addition, due to the

presence of Ti4+ ions, like calcareous oxide solid-

state electrolytes, these electrolytes are also easy to be

reduced by lithium metal anode at low potential,

thereby reducing the overall property of the battery.

To solve the problem of an oxide-solid-state

electrolyte, the researchers proposed the following

solutions: 1) the introduction of a buffer layer: for the

interface impedance problem between the solid-state

electrolyte and the cathode, a layer of aluminium

oxide can be deposited to reduce the interface

impedance; for the reduction reaction between several

particular solid-state electrolytes and the lithium metal

anode, the lithium-ion conductor can be used as the

buffer layer between the solid-state electrolyte and the

electrode to inhibit the reduction reaction. 2) Improve

the electrode: on the one hand, lithium alloy electrodes

can be manufactured to reduce adverse reactions. On

the other hand, the electrolyte component can be

compounded with the cathode active component by

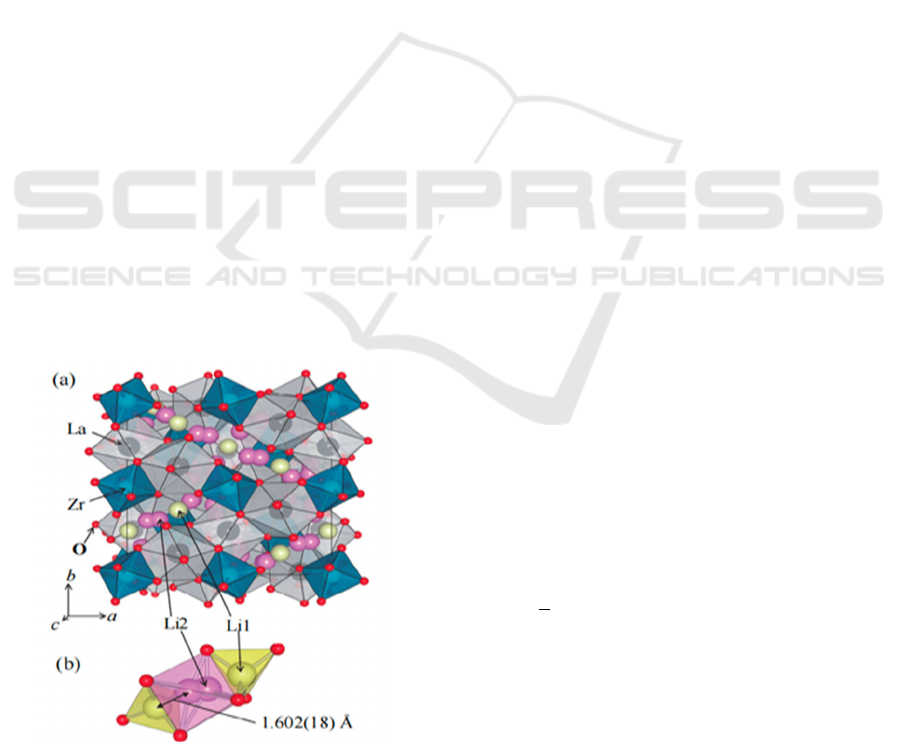

Figure 1: (a)Cubic Li7La3Zr2O12 crystal structure(b)

Coordination polyhedral around Li1 and Li2 sites (Yao et

al., 2023).

heating and other methods to achieve a good

electrolyte-electrode contact interface, thereby

reducing the interface impedance. 3) Ion doping: The

skeleton of sodium superionic conductors can be

modified by intercalating cations of different valence

states and ionic radii, thereby causing lattice distortion

and improving ionic conductivity (Luo et al., 2024).

2.2.2 Halide Solid-State Electrolyte

Halide solid-state electrolyte is mainly composed of

lithium, transition metal elements and halogen

elements, and its structure is determined by the

coordination number determined by the atomic radius

ratio of metal elements and halogen atoms. According

to the coordination number, halide solid-state

electrolytes can be divided into three categories: 1)

Li

a

-M-Cl

6

; 2) Li

a

-M-Cl

4

, 3) Li

a

-M-Cl

8

. Among them,

Li

a

-M-Cl

8

is unstable at room temperature, and its

conductivity is lower than Li

a

-M-Cl

6

and Li

a

-M-Cl

4

.

Therefore, Li

a

-M-Cl

6

electrolytes and some Li

a

-M-

Cl

4

electrolytes have been studied more at present

(Chen et al., 2023).

Li

a

-M-Cl

6

halide solid-state electrolytes are

mainly composed of group IIIB metal ions. The

common crystal structures of this kind of solid-state

electrolyte include the tripartite crystal system of the

P3m1 space group (hcp-T), the orthogonal crystal

system of the pnma space group (hcp-O) and the

cubic crystal system of C2/m space group (ccp).

Among them, the Li

a

-M-Cl

6

halide solid-state

electrolyte has better conductivity in the C2/m

structure. Lia-M-Cl

4

halide solid-state electrolytes are

mainly composed of trivalent and other valence metal

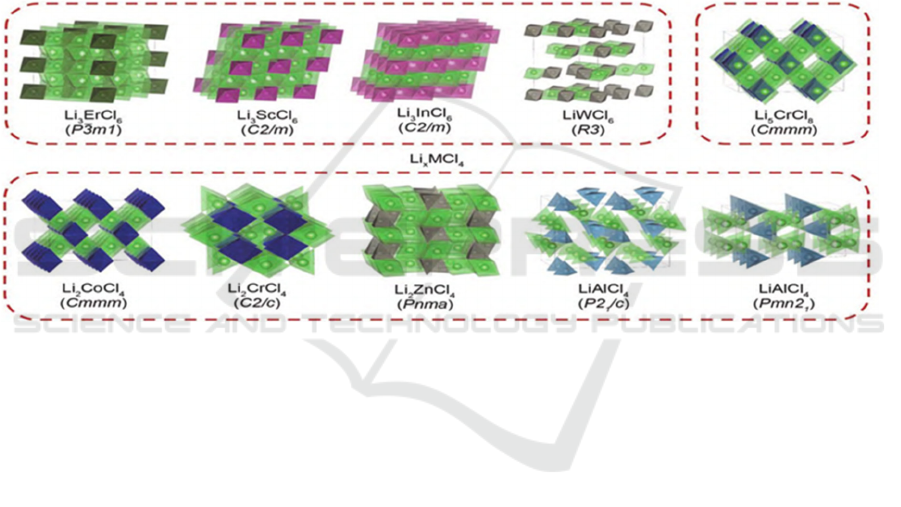

ions, as shown in Figure 2. The defect anti-spinel

structure has the highest electrical conductivity. Due

to the introduction of higher-priced cations, more

vacancies are created to maintain electrical neutrality,

and this structure is beneficial to the transport of

lithium ions.

Currently, halide solid-state electrolytes generally

have low phase transition temperatures, and a high

crystallinity phase can be obtained by the low

reaction temperature. In addition, fluoride and

chloride electrolytes have special advantages like

electrochemical windows (Yu et al., 2023). However,

halide-solid-state electrolytes have poor humidity and

air stability. This is because halogen salts are easy to

form into crystalline hydrates, and the more obvious

the polarization of the metal cation of halogen salts in

water, the easier it is to form a crystalline hydrate.

These crystalline hydrates will undergo a hydrolysis

reaction after heating, which makes it easy to form

metal oxide double salts that hinder the migration of

Research Progress on Solid-State Electrolytes for Lithium-Ion Batteries

275

lithium ions. However, some studies have shown that

halides show good stability in dry air, and after a

strictly controlled dehydration process, the hydrate

can be reversely converted to return to its structure

and electrochemical properties before water

absorption.

In addition, the instability of halide solid-state

electrolytes and lithium metal mainly depends on the

type of transition metal element in the halide

composition. For example, the Li

3

HoCl

6

electrolyte

can realize the stable cycle of assembled Lin-

symmetric batteries, but it is easy to short-circuit

when assembled with Li metal symmetric batteries.

In contrast, Li

3

HoCl

6

has better stability against Li

metal, which may be because the products formed by

fluoride contact with lithium metal can better fill the

vacancies and defects located in the solid-state

electrolyte and related interfaces, forming a denser

intermediate layer, thereby preventing the

development of further reactions.

In response to the above halide solid-state

electrolyte problems, the researchers proposed the

following improvement methods: 1) solid-phase

reaction synthesis: through ball milling to improve

the uniformity of raw material mixing and refine the

electrolyte particles, to improve the point contact

problem, reduce the interface impedance. 2) Liquid

phase synthesis: This method can save time and

improve efficiency, the halide is uniformly

distributed in the solid-state electrolyte, and it is

easier to obtain samples with uniform grain size after

crystallization.

Figure 2: Structure diagram of the third-class halide solid-state electrolyte (Chen et al., 2023)

2.2.3 Sulfide Solid-State Electrolyte

Sulfide solid-state electrolyte is mainly composed of

lithium, sulfur, phosphorus and other elements.

According to its crystal structure, it can be divided

into glass phase, glass ceramic phase and crystal

phase (Chen, 2021). Compared with the glass phase

and glass ceramic phase, crystalline sulfide solid-state

electrolyte has higher ion transport efficiency due to

its unique structure, and thus exhibits higher ionic

conductivity at indoor temperature (Qin and Gu,

2021). However, this kind of sulfide solid-state

electrolyte is prone to reduction and oxidation

reactions with lithium metal anode, which leads to the

instability of the interface between anode and

electrolytes. The sulfide solid-state electrolyte has

good mechanical strength, mechanical flexibility, and

high ionic conductivity, and its overall property is

greater than other types of solid-state electrolytes. For

example, the relatively low hardness of sulfide makes

it easy to deform during extrusion, thereby improving

the contact problem with the cathode through

deformation, which also makes it easier to process.

However, the material also has many shortcomings.

At the cathode interface, 1) insufficient ion and

electron penetration leads to a low utilization rate of

the cathode material; 2) There is a space charge effect.

Due to the large gap between the chemical potential

of lithium ions in the cathode and the electrolyte,

lithium ions tend to diffuse from the sulfide electrode

to the cathode, and an area with a low concentration

of lithium ions is easily formed on the sulfide side of

the interface, thereby reducing the ionic conductivity

and improving the interface impedance; 3) The

volume change of the cathode material leads to poor

contact and increased impedance. At the anode

interface, 1) the growth of lithium dendrites is a

problem, and 2) the interface is unstable, which

makes it easy to form a conductive phase layer mixed

with ions and electrons. In addition, due to the

sensitivity of sulfide to water vapour, it is easy to

react with water to produce toxic hydrogen sulfide

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

276

gas, resulting in a decrease in ionic conductivity (Yu

et al., 2023).

In response to the above sulfide solid-state

electrolyte problem, the researchers proposed the

following solutions: 1) Add a small amount of

electrolyte: Add a small amount of electrolyte

between the solid-state electrolyte and the electrode

or inside the solid-state electrolyte, so that it cannot

flow freely in the battery, choose the electrolyte that

does not react with the sulfide solid-state electrolyte

but can dissolve lithium salt. Alternatively, a glass

fibre diaphragm containing electrolyte can be

introduced into the cathode and the sulfide solid-state

electrolyte to improve the ionic conductivity and

solve the contact problem, thereby reducing the

interface impedance. 2) Composite with polymer

electrolyte: the polymer can act as a binder,

conductive network or skeleton material in the

composite to effectively inhibit the space charge

effect. 3) oxide-doped sulfide: can effectively absorb

H

2

S and inhibit the formation of H

2

S.

3 PROSPECTS FOR SOLID-

STATE ELECTROLYTES

The main factors contributing to the properties of

solid-state electrolytes are contact failure and

instability between electrodes and electrolytes. First,

the contact failure problem is that the electrolyte and

the electrode are both solid and the contact between

the two is point contact. The liquid electrolyte used

before like ethylene carbonate and diethyl carbonate

can fill all the pores caused by the charge and

discharge of the electrode. Additionally, the periodic

volume change of the electrode is unable to affect it.

Lithium tends to deposit in pores and rough edges of

grain boundaries, resulting in uneven deposition.

Therefore, the problem of the lithium dendrites

occurs. This non-uniformity of deposition will further

cause the contact between the solid-state electrolyte

and the cathode to decrease, thus the more lithium

depositing, the lithium dendrites will puncture the

electrolyte and connect the two electrodes, causing

the battery to short-circuit. Second, the presence of a

large solid interface impedance contributes to the

instability between the solid-state electrolyte and the

electrode. To improve the power density of solid-state

batteries, reducing the impedance can effectively

improve the transform efficiency of lithium ions.

Sufficient power density can achieve the

requirements of commercial mass-produced

production of power storage systems. The causes of

solid impedance at the interface include reduction

side reaction between electrolyte and electrode,

formation of space charge layer and periodic volume

change of electrode. When the solid-state electrolyte

matches the cathode, the mismatch of the

electrochemical windows results in the oxidation

decomposition of the solid-state electrolyte itself and

the anion replacement between the electrolyte and the

electrode. Those two kinds of reactions generally

occur simultaneously. When the solid-state

electrolyte matches the metal lithium anode, due to

the strong reduction of lithium itself, some cations

with high valency in the electrolyte are easy to have

reduction reactions, forming a new high-impedance

interface, which hinders the transmission of lithium

ions and makes the overall property of the battery

decline.

All kinds of solid-state electrolytes have their

property advantages, but there is no solid-state

electrolyte that can have all the property advantages

simultaneously and achieve inexpensive expenditure

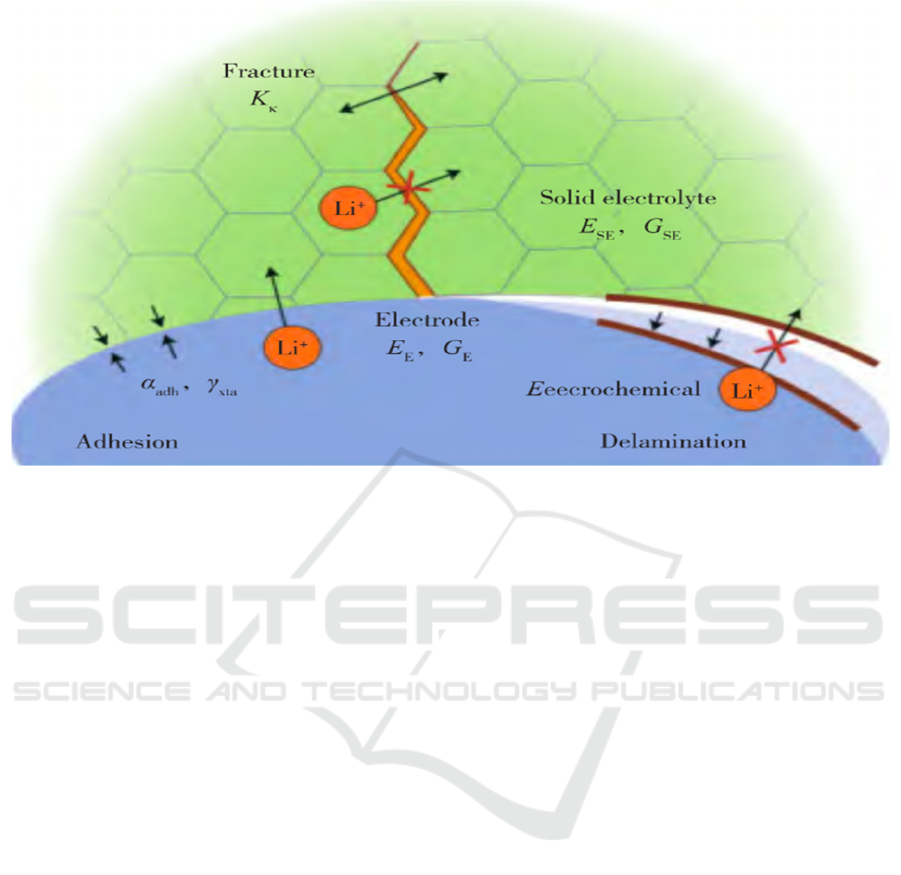

and easy production, as shown in Figure 3. The real

problem facing solid-state electrolytes is that if it is to

replace traditional liquid lithium batteries in large-

scale commercial production, simply having high

ionic conductivity (such as the high cost of high-

property sulphide solid-state electrolyte) is not

enough to support its position in the industrial

application of all-solid-state batteries. Therefore,

researchers have developed composite solid-state

electrolytes, aiming to get a kind of comprehensive

one with various advantages to form an electrolyte

system with high ionic conductivity, good

processability, cycle stability and low cost (Zhan et

al., 2023). For example, in the oxide/sulphide

complex electrolyte, increasing the oxide content is

conducive to achieving uniform dispersion of the

oxide solid-state electrolyte, and improving the

interface bond between the oxide and the sulphide,

thereby increasing the migration rate of lithium ions.

In addition, organic polymers can also be combined

with sulphide solid-state electrolytes. The organic

polymer can be used as a binder to disperse the

sulphide in the composite film, to improve the

interface impedance. At the same time, the polymer

can also act as a skeleton, improve the flexibility of

the sulphide, and due to its low-cost characteristics,

large-scale preparation can be achieved. Through

these composite methods, the advantages of different

solid-state electrolytes can be effectively integrated,

and the limitations of a single material can be

overcome, to promote the industrial application of all-

solid-state batteries.

Research Progress on Solid-State Electrolytes for Lithium-Ion Batteries

277

Figure 3: Contact diagram at the interface between the solid-state electrolyte and the electrode (FAMPRIKIST et al., 2019)

4 CONCLUSION

This study reviews the various types of solid-state

electrolytes, including oxide, halide, sulfide, and

organic polymer solid-state electrolytes, and analyses

their application potential and challenges. Each type

of solid-state electrolyte has its unique property

advantages, but there is no solid-state electrolyte that

can have comprehensive property advantages and

meet the requirements of low cost and easy

production. Although sulfide-solid-state electrolyte

has high ionic conductivity and good mechanical

properties, it is expensive and sensitive to water

vapour. Although oxide-solid-state electrolyte is

stable in air and water, it has the problem of large

interface impedance and insufficient ionic

conductivity. Halide-solid-state electrolytes have

advantages in terms of electrochemical windows, but

their humidity stability is poor and unstable with

lithium metal. Although the polymer solid-state

electrolyte has excellent machining properties and

low cost, its electrochemical window is narrow, and

its thermal stability is insufficient. The development

of a composite solid-state electrolyte has become an

effective solution to single limitations. Using

combination and doping, the advantages of various

solid-state electrolytes can be combined to form an

electrolyte system with high ionic conductivity, low

cost, good machining properties, and cycle stability.

For example, the oxide/sulfide composite electrolyte

can improve the interface bonding by increasing the

oxide content, thus increasing the migration rate of

lithium ions. The combination of organic polymer

and sulfide can improve the interface impedance and

flexibility by using the bonding and skeleton action

of the polymer and achieve low-cost, large-scale

preparation. In summary, the research on composite

solid-state electrolytes provides a new path for the

commercial application of all-solid lithium-ion

batteries. Future research should continue to explore

the combination strategy of different solid-state

electrolytes to optimize property, reduce production

costs, and promote the commercialization of all-solid-

state battery technology.

REFERENCES

Tao C, Ouyang B, Fan X, Zhou W, Liu W, Liu W 2022 J.

Carbon Energy 4(2) 170-199

Janek, J, Zeier W.G 2023 J .Nat Energy 8 230–240

Aspinall J, Sada K, Guo H. et al. 2024 J. Nat Commun 15

1-12

Wang L, Li C, Liu X.et al. 2023 J. Journal of Chemical

Engineering of Chinese Universities 37(1) 22-27

Yao Z, Sun Q, Gu Q. et al. 2023 J. Advances in New and

Renewable Energy 11(1) 76-84

Luo Q, Wu J and Li J 2024 J. New Chemical Materials 1-6

Chen S, Yu C, Luo Q. et al. 2023 J. Acta Phys-Chim Sin

39(08) 7-24

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

278

Yu T, Shao Z, Liu Y.et al. 2023 J. Mining and Metallurgy

32(4) 64-71

Chen M 2021 J. Information Recording Material 22(7) 29-

31

Qin Z, Gu Z 2021 J. Chinese Battery Industry 25(6) 329-

335

Zhang G, Zhang Z and Ma Y 2023 J. Acta Chim Sin 81(10)

1387-93.

FAMPRIKIST, CANEPAP, DAWSON JA, et al 2019 J.

Nat Materials 42(1) 163-175

Research Progress on Solid-State Electrolytes for Lithium-Ion Batteries

279