Enhancing Lithium-Ion Battery Performance: Silicon-Carbon

Composite Anodes

Yihao Yin

School of Physical Science and Technology, Shanghaitech University, Shanghai, 201210, China

Keywords: Lithium-Ion Batteries, Anode, Silicon-Carbon Composite.

Abstract: With the growth of global energy concerns, lithium-ion batteries (LIBs) are at the forefront of research for

efficient energy storage solutions. The objective of this study is to explore the potential of silicon anodes,

which can theoretically hold up to 4200 mAh/g, far exceeding the 372 mAh/g of traditional graphite anodes.

Significant volume expansion and instability during lithiation prevent the practical application of silicon

anodes. To address these issues, various carbon materials, including graphite, carbon nanotubes (CNTs), and

graphene, are integrated with silicon to enhance capacity, stability, and cyclability. In addition, research on

graphite, carbon nanotube, and graphene composite anodes suggests that hybrid approaches can capitalize on

the strengths of each material, potentially surpassing the performance of single-material anodes. As graphene

production technology improves and becomes more cost-effective, graphene-silicon anodes may eventually

become the optimal solution for high-performance lithium-ion batteries. This paper provides a systematic

review of the mainstream silicon-carbon composite anode materials at the present stage, and makes an outlook

on the future development trend of silicon-carbon composites.

1 INTRODUCTION

In recent years, nations around the world have

become increasingly concerned about energy issues.

Solutions to energy depletion and the energy crisis are

in the spotlight. A mass of policies are proposed in

order to save energy and encourage renewable energy

exploitation. These policies all point to the same core,

which is electricity. Research on batteries, especially

LIBs, has been carried out extensively to be able to

better utilize and store electricity. The development

of LIBs is mainly focused on several aspects like

capacity, stability, and charging and discharging

efficiency. Among these, capacity is of the most vital

significance, and countless works have been carried

out to increase the capacity of LIBs. LIBs transform

chemical energy into electrical energy via an

electrochemical redox reaction. In every cell, the area

that experiences oxidation is referred to as the anode,

and the area that experiences reduction is referred to

as the cathode. Lithium atoms and lithium ions are

stored and received at the anode and cathode.

The silicon anode instead of the traditional

graphite anode is thought to be promising because the

theoretical maximum capacity is 4200 mAh/g. The

silicon anode has a specific capacity that is over ten

times larger than that of graphite's theoretical

maximum capacity of 372 mAh/g

(Min et al, 2024).

In fact, in the last five years, research on silicon

anodes has kept growing. However, when the lithium

ions enter the silicon anode, the silicon-lithium alloy

will be formed, and the volume will expand

dramatically. It not only leads to instability of the

lithium-ion battery itself but also makes silicon

anodes unsuitable for solid-state lithium-ion batteries

because the two solid-phase interfaces collide and

crush each other, leading to damage. This property

seriously affects the actual capacity and service life

of silicon anode LIBs and raises the risk of using

silicon anode lithium-ion batteries as well.

Many studies are being carried out to solve this

problem, such as using nanoprecipitation,

redesigning the structure, and doping silicon with

other atoms. Carbon doping now turns out to be

effective and low-cost. But carbon doping will

inevitably decrease the capacity. Thus, researchers

are trying to find a way to get a composite of silicon

and carbon with optimal capacity and volume

extension. This study will review different types of

carbon-silicon anodes, compare the performance of

various composite materials, and provide guidance

for further research.

262

Yin, Y.

Enhancing Lithium-Ion Battery Performance: Silicon-Carbon Composite Anodes.

DOI: 10.5220/0013913300004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 262-267

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

2 CLASSIFICATION AND

COMPARISON OF

CARBON-SILICON

COMPOSITES

2.1 Graphite-Silicon Anode

The advantages of using graphite are obvious. The

cost of graphite is low, the specific surface area is

low, the tap density is high, and graphite itself is eco-

friendly. Another thing of interest is that graphite-

silicon anodes are made in a very diverse and

sophisticated process. Based on these properties,

graphite is promising to be processed into a graphite-

silicon anode. However, the performance of the

graphite-silicon anode is not satisfying for many

reasons, such as specific capacity and aging. The

performance of graphite-silicon anodes through

different preparation methods can vary a lot.

There’re quite a lot of preparation methods to

get graphite-silicon anodes. Peng Li et al. concluded

that several methods, like mechanical ball milling, the

spraying method, chemical vapor deposition, and the

and the wet processing method, were the most

commonly used preparation methods. Among these,

ball milling and CVD are the most widely used and

easy to adjust for the final product (Peng et al, 2021).

Zhao et al. (2022) synthesized a high-performance Si-

G-C-15 anode material using a cost-effective routine.

The resulting composite showed a specific capacity

of 965 mAh/g as well as retained over 70% capacity

after 100 cycles. The small particle size and uniform

distribution of components in the composite play a

crucial role in promoting the rapid diffusion of

lithium ions within the electrode. This uniform

distribution contributes to the overall performance

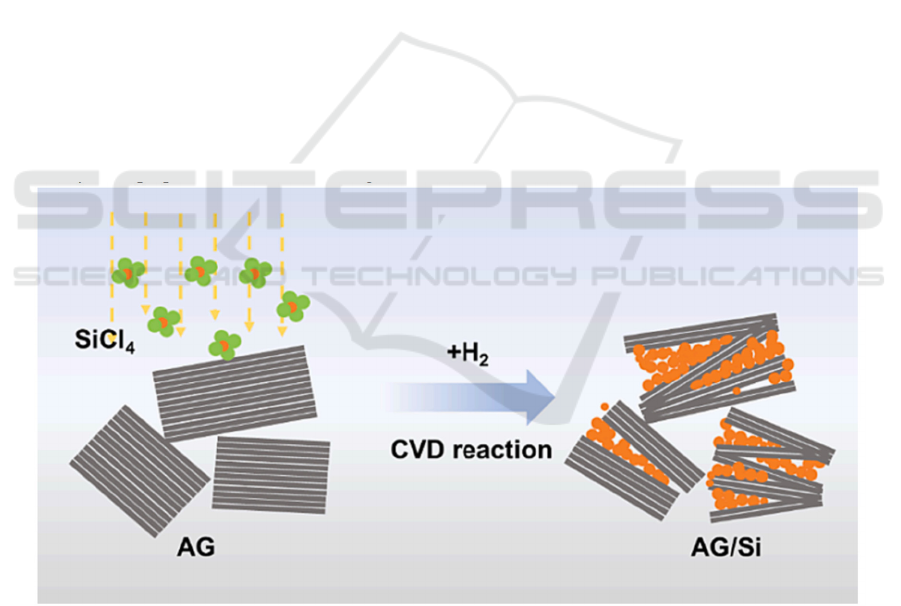

and stability of the battery. Hu et al. (2023) prepared

a graphite-silicon composite using chemical vapor

deposition (CVD). They grew nano-sized silicon on

HCl-purified graphite in a CVD chamber with SiCl4

in an argon atmosphere and hydrogen. The CVD

anode showed better capacity retention and specific

capacity at high current density compared to one

prepared by ball milling. In the composite, the

graphite matrix acts as a semi-enveloping structure

around the silicon particles, providing confinement

that buffers the volume growth of silicon during

electrochemical cycles, which is shown in Figure 1.

This confinement helps to protect the silicon particles

from breaking away from the conductive network,

thereby enhancing the life span of the anode.

Figure 1: The composite was prepared using CVD (Hu et al., 2023)

The content of silicon in graphite-silicon

composites is relatively low (around 10% to 20%) to

prevent anode damage. In order to reduce the side-

effects of volume expansion in anodes, lots of space

should be spared for silicon particles to grow up.

Since the volume expansion is constant as long as the

silicon content is constant, what can be improved is

the unoccupied space. So, it’s definitely accessible to

better disperse silicon atoms in the graphite or make

the micro-silicon smaller. However, the performance

of the graphite anode is not satisfying. The ball

milling method, which is the most applied preparation

process, turned out to be inefficient. The lifespan and

specific capacity of the composite prepared through

Enhancing Lithium-Ion Battery Performance: Silicon-Carbon Composite Anodes

263

ball milling are greatly inferior to the ones made

through CVD (Hu et al., 2023). Though the specific

capacity of graphite-silicon anodes has reached a high

level. Its lifespan is still worrying, as the retention has

fallen to 70% only after 100 cycles.

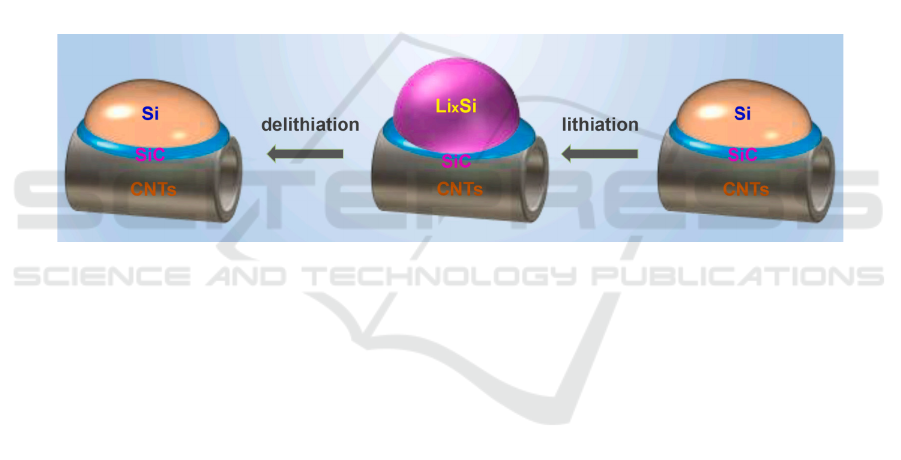

2.2 Carbon Nanotube-Silicon Anode

Carbon nanotubes (CNTs) is famous for its

outstanding mechanical properties and its stability. It

’s as strong as a diamond, while its ductility is also

great. Its tensile strength is up to 60 GPa and the

tensile strain is up to 15% (Daoyang et al., 2018).

Carbon nanotubes are categorized into single-walled

(SWCNTs) and multi-walled (MWCNTs) varieties.

Both exhibit excellent electrical and thermal

conductivity. So, they can also work equally well as

electrodes and conductors. The working mechanism

of Si/CNTs composite electrodes is shown in

Figure.2. Carbon nanotubes possess a large specific

surface area, providing ample space for hosting

nanoparticles and enhancing the performance of

energy storage devices (Ha et al., 2024). In the case

of cost, CNTs are relatively low-priced because they

have been able to be mass manufactured. But some

difficulties need to be overcome for the carbon

nanotube-silicon anode. The specific surface area of

a carbon nanotube is quite high since it is actually the

rolling of several carbon atom layers. The high

specific surface area contributes to the van der Waals

force, so the carbon nanotubes tend to form clusters.

Thus, the preparation of a carbon nanotube-silicon

anode is trickier than that of a that of a graphite-

silicon anode. How to design a high-performance

anode obtained through one-step synthesis or simple

methods is the main problem. Several one-step

syntheses have now been developed. The products

turned out to have a higher specific capacity and a

longer service life.

Figure 2: The working mechanism of Si/CNTs composite electrodes (Guo et al., 2024)

Guo et al. (2024) developed a practical method to

prepare Si/CNTs composites. SiO

2

, Mg powder, and

CNTs were mixed in argon, enclosed in carbon paper,

and heated for hours. The samples were treated with

HCl and HF solutions to remove impurities, resulting

in purified Si/CNTs composites. The SiO

2

to CNT

weight ratio is critical in shaping the interface

between silicon nanoparticles and carbon nanotubes.

When the ratio is high, silicon nanoparticles react

with CNTs, forming Si-C bonds that enhance

interaction and improve electrochemical

performance. Thus, adjusting the SiO

2

weight ratio

controls Si-C bond formation can alter the

performance of the carbon nanotube-silicon anode.

The composite they synthesized has outstanding

performance. Si/CNTs-2 with enhanced interfacial

bonding through Si-C chemical interactions has high

specific capacity and duration. At 0.2 A/g, it has an

initial reversible capacity of 1100.2 mAh/g and

maintains a capacity retention rate of 83.33% after

200 cycles. Gonzalez et al. (2022) created silicon-

doped carbon nanotubes (Si-CNTs) using metal-

catalyzed chemical vapor deposition (M-CVD) at 800

℃and 900 ℃ separately, producing two different Si-

CNT anodes, Si-CNT8 and Si-CNT9. The Si-CNT

anodes were treated with nitric acid before

characterization and electrochemical assessment. Si-

CNT8 demonstrated a consistent capacity of

approximately 400 mAh/g throughout 120 cycles. In

contrast, Si-CNT9 delivered 360 mAh/g over 120

cycles. It indicates that the Si/CNT composite should

better be synthesized in at 800 ℃. The synthesis

temperature influenced the resistance to oxidation of

the Si-CNT samples, with Si-CNT9 showing higher

resistance compared to Si-CNT8. At a higher

temperature, the Si-C bond formation was observed,

suggesting that higher temperatures favor make it

easier to insert silicon in the CNTs network.

According to these researches, it is rational to get

the conclusion that the specific capacity of carbon

nanotube-silicon anodes is much higher than

traditional graphite anodes and the graphite-silicon

anodes mentioned above. Though the carbon

nanotube-silicon anodes created by Isaías Zeferino

Gonzalez et al. is not impressive enough, it proves

that CVD can be applied in both graphite anodes and

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

264

carbon-nanotube anodes. Based on these cases, the

upper limit of carbon nanotube-silicon anode is very

high, with extremely superior specific capacity and

life time, but also due to its own difficult-to-process

characteristics, the performance gap will be very

large in different processing, and perhaps even under

slightly different processing conditions, which

requires a very mature preparation process for carbon

nanotube-silicon anode.

2.3 Graphene-Silicon Anode

Graphene possesses high electrical conductivity,

excellent stability, outstanding mechanical

properties. Besides these advantages, graphene is

more beneficial to the anode duration than CNT

(Poonam et al., 2021). This is because graphene

layers can alleviate the stress caused by volume

expansion, buffering the damage to the anode as long

as graphene can uniformly cover the carbon-silicon

particles. It’s also essential to address the problem of

its large specific surface area. Li et al. (2024)

developed a method to create high-performance

silicon/graphene carbon composites. They dispersed

graphene oxide (GO) with silicon nanoparticles in a

solvent, added coal tar pitch, evaporated the solvent,

and carbonized the composite at a certain temperature

under nitrogen. This formed multi-interface

structures, enhancing the composite's performance as

an anode material for LIBs. The composite is

beneficial for the formation of a homogeneous solid

electrolyte interphase (SEI) film and lithium-ion

transport, reducing resistance and improving

electrochemical properties. The graphene-silicon

anode exhibits outstanding service life and high

specific capacity, with a specific capacity of 820.8

mAh/g at 50 mA/g and 93.6% capacity retention after

1000 cycles at 2 A/g. These results demonstrate its

excellent performance and stability, surpassing all

previously mentioned anode materials. Graphene’s

specific capacity and longevity make it the best

material for carbon-silicon anodes, highlighting its

potential in lithium-ion batteries.

But unlike the CNTs which can be mass-

produced, the graphene mass production has not been

established. Even if high performance graphene can

be produced in some certain ways like mechanical

peeling, reduced graphene oxide (rGO) methods and

so on, few graphene-silicon anode are produced and

applied into practice, let alone the usage in business.

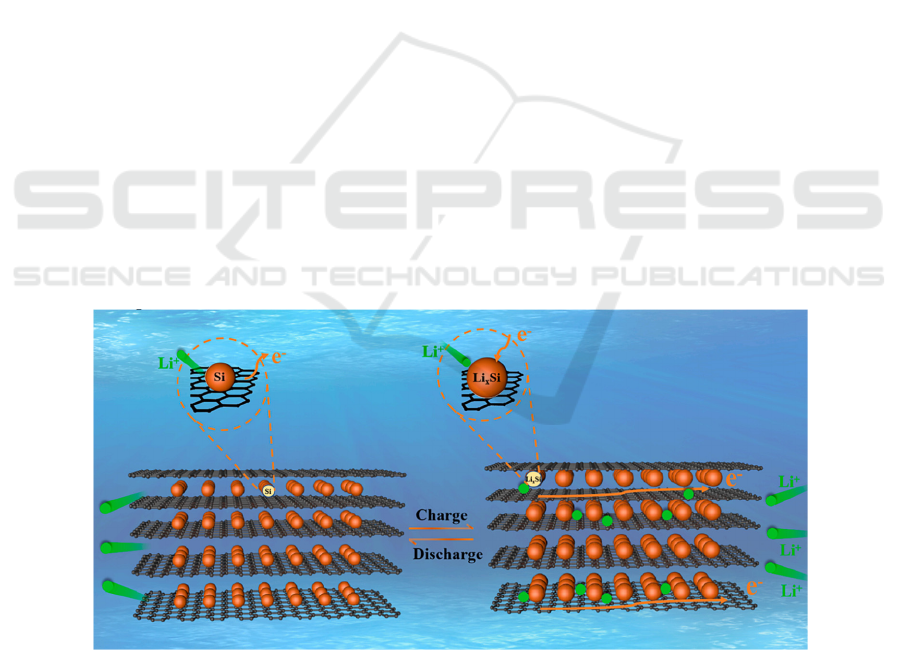

To address this problem, Zhang et al. (2024)

introduced a novel method to mass-produce oriented

Si/rGO films. They utilized a layer assembly

technique with GO as a binding agent. Nano-Si

particles were dispersed, sonicated, and combined

with GO to form a nano-Si/GO composite. In Figure

3, the high-order layer and dense structure formed by

the nano-Si embedded into the gap between layers of

graphene is clearly visible. In this case, the Si/rGO

composite exhibits an initial specific capacity of

1222.5 mAh/g at 200mA/g. Notably, this capacity

remains consistent over 1000 mAh/g after 200 cycles,

highlighting the electrode's exceptional cycling

stability.

Figure 3: The layer-to-layer structure and its working mechanism (Zhang et al., 2024)

It's a fact that there are numerous high-performing

graphene-silicon anodes that can hold more than

2300mAh/g at 210 mA/g after 50 cycles (Fei et al.,

2014). However, most of the preparation methods are

time-consuming and not eco-friendly. Though the

performance of Zhang ’ s product needs to be

improved, its preparation method inspires others to

invent more methods to obtain graphene-silicon

anodes with mass production. Though the cost is not

affordable now, with more and more researches

Enhancing Lithium-Ion Battery Performance: Silicon-Carbon Composite Anodes

265

realizing the promising performance of graphene and

graphene-silicon anode, the price will definitely

decrease in near future.

3 PROSPECTS FOR SILICON-

CARBON ANODES

In recent years, the integration of carbon materials

with silicon has offered a viable solution to mitigate

the challenge. Carbon, such as graphite, carbon

nanotubes, and graphene, brings a suite of desirable

properties to the composite, including high electrical

conductivity, mechanical robustness, and the ability

to accommodate volume changes during lithiation.

By synergistically combining silicon with carbon,

researchers aim to develop composite anode materials

that offer enhanced capacity, stability, and cyclability

compared to traditional graphite-based anodes.

One thing that has been mentioned many times in

so many studies and is considered crucial is

homogeneity. How the silicon particles are arranged

between the individual carbon layers can greatly

affect the properties of the composite. when the

silicon particles can be uniformly distributed, the

carbon layers can best buffer the damage caused by

the increase in volume and maximize the contact area,

which is beneficial to improving the specific capacity.

Therefore, this paper argues that CVD is a highly

desirable material for preparing carbon-silicon

anodes because CVD allows for precise control of

film thickness, composition, and properties by

adjusting process parameters such as temperature,

pressure, precursor concentration, and gas flow rate.

This level of control allows for customization of the

film to meet the specific requirements of various

applications. Defects are minimized and the overall

performance and reliability of the deposited material

is improved.

Another important case is about the carbon

content. With the content of carbon increases, the

specific capacity of carbon-silicon anode will

inevitably decrease because the specific capacity of

silicon is much higher than carbon. It’s not rational to

criticize a specific processing of carbon-silicon anode

for a single reason that in one’s research, the capacity

of anode is lower than another research without

taking carbon content into account. So, if we can get

the ideal performance of carbon-silicon composite at

any particular carbon doping level, then the

difference between the ideal performance and actual

performance can be computed. We can also try to get

an optimal proportion of carbon and silicon to get a

relatively high specific capacity ensuring the service

life as well. Wu. et al. (Min et al, 2024) has showed

the ideal volume expansion and capacity in different

doping concentration using first-principles study.

They compute the anode volume expansion and

specific capacity at different Li embedding ratio and

different carbon concentration. Their work can be an

indication, but quite a lot factors will be omitted as

it’s a first-principles study, so the calculated data is

not able to be realized.

By comparing the performance of graphite,

carbon nanotubes and graphene, it is clear that carbon

nanotubes stand out at the moment with better

performance, moderate cost and no longer

cumbersome fabrication process. But this does not

mean that the future development can only be

centered around carbon nanotubes, now there are also

researchers began to explore the graphite / carbon

nanotubes / graphene composite carbon silicon anode

preparation and performance, through the nature of

each material, the cost of complementary to achieve

a better state. And in the future, once graphene can be

mass-produced, better performance of graphene can

replace the current status of carbon nanotubes.

Therefore, the future development of carbon silicon

anode should be centered on graphene and carbon

nanotubes or graphite composite carbon doping to

carry out research.

4 CONCLUSIONS

In conclusion, combining carbon materials with

silicon anodes is a viable approach to improving the

performance of lithium-ion batteries. The study

provides a comprehensive comparison of different

types of carbon-silicon anodes, including graphite-

silicon, carbon nanotube-silicon, and graphene-

silicon composites. Each type offers unique

advantages and challenges. Graphite-silicon anodes,

while cost-effective and environmentally friendly,

have issues with capacity and stability. On the other

hand, carbon nanotube-silicon anodes show excellent

specific capacity and mechanical properties but

require precise and often complex preparation

methods to overcome their tendency to agglomerate.

Graphene-silicon anodes exhibit excellent electrical

conductivity and mechanical stability with

outstanding specific capacity and lifetime, but large-

scale production remains a major obstacle.

It has been shown that a uniform distribution of

silicon particles in the carbon matrix is essential to

maximizing anode performance. Methods such as

chemical vapor deposition allow precise control of

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

266

the fabrication process to produce high-quality

carbon-silicon composites with optimal properties.

Furthermore, the ratio of carbon to silicon can have a

significant impact on the capacity and stability of the

anode, suggesting that an optimal balance must be

achieved to ensure high performance and long life.

Current research advances indicate that carbon

nanotube-silicon anodes are leading the way in terms

of performance and utility. However, continued

research on graphite, carbon nanotube, and graphene

composite anodes suggests that hybrid approaches

can capitalize on the strengths of each material,

potentially surpassing the performance of single-

material anodes. As graphene production technology

improves and becomes more cost-effective,

graphene-silicon anodes may eventually become the

optimal solution for high-performance lithium-ion

batteries.

In the search for a sustainable energy future,

carbon-silicon anodes are a beacon of hope for the

transformative potential of advanced materials and

engineering solutions. By harnessing the power of

carbon and silicon, we can open up new possibilities

for energy storage, transportation, and electrification,

thereby creating a brighter and cleaner tomorrow for

future generations.

REFERENCES

Daoyang H, Hui M, Shanshan X, Konstantinos G D, Laifei

C 2018 J.Eur.Ceram.Soc. 38 Pages 3695-3708

Fangfang Z, Min Z, Yanru D, Lei M, Yu Z, Sulin N and

Liangming W 2022 Powder Technol. 404 117455

Fei L, Hongwei Y, Zhibo Y, Xiuwan L, Yanli Q and Deyan

H 2014 Mater. Lett. 128 Pages 132-135

Ha E K, Jaehwan K, Sung G S, Young S Y 2024 Carbon

219 118800

Isaías Z G, Hsien-Chieh C, Raynald G, George P. D,

Ysmael V 2022 Mater. Today Commun. 30 103158

Mengfei H, Houzheng W and Guo-Jun Z 2023 Chemical

Physics Letters 833 140917

Min W, Guangkai C, Zhe L, Lan Y and Cen W 2024

Vacuum 225 113222

Peng L, Hun K, Seung-Taek M and Yang-Kook S 2021

Energy Storage Mater. 35 Pages 550-576

Poonam S, Abgeena S, Abid, Julien C M and Islam S S

2021 J. Power Sources 501 229709

Xiaobei G, Zhongtang Y, Wei W, Yi Z, Nengfei Y,

Chunhua L 2024 Surf. Interfaces 48 104223

Xin L, Kun L, Man Y, Jiapeng Z, Haiyan L, Ang L,

Xiaohong C and Huaihe S 2024 J. Colloid Interface Sci

667 Pages 470-477

Yanlin Zhang, Dafang He, Junhong Lu, Jie Huang,

Haoyang Jiang, Junfeng Rong, Guolin Hou and

Haiqun Chen 2024 Chem. Eng. J 487 150564

Enhancing Lithium-Ion Battery Performance: Silicon-Carbon Composite Anodes

267