Research Progress on the Safety of Lithium Ion Battery Materials

Yuting Dong

1

, Junrui Li

2,*

and Yurui Lu

3

1

School of Chemical Engineering, Northeast Electric Power University, Jilin, 132011, China

2

School of Chemical Engineering, Zhejiang University of Technology, Hangzhou, 310014, China

3

School of Materials Science and Engineering, Hubei University, Wuhan, 430062, China

Keywords: Lithium-Ion Batteries, Battery Safety, Material Design.

Abstract: Lithium-ion batteries have received much attention as one of the key technologies in energy storage

technology. With the development of the new energy field, the energy density carried by lithium-ion batteries

is also increasing, and users are paying more and more attention to battery safety. At present, there have been

many accidents related to lithium-ion battery fire and explosion around the world, some of which have caused

serious threats to human normal life activities and human health. These safety issues are a message to us -

ensuring that the use of batteries is safe is critical, especially before considering high energy density battery

systems for future applications, must address their safety issues. The purpose of this review is to summarize

the root principles of lithium-ion battery safety problems from the three aspects of electrolyte, positive and

negative electrode, and focus on the latest progress in the field of material design, aiming to further enhance

people's understanding of battery safety and further develop the battery market in the future through this

article.

1 INTRODUCTION

In recent years, in response to the scientific concept

of green environmental protection, lithium-ion

batteries (LIB) have been applied on a large scale in

many industries because of their advantages such as

high unit energy, fast discharge efficiency and long

working life (Tarascon and Armand, 2001;

Goodenough and Kim, 2010 & Armand and Tarascon,

2008). Typically, a lithium-ion battery consists of a

positive electrode, an anode, and a diaphragm. The

positive electrode is usually made of lithium cobaltate

(LiCoO2), the anode is made of graphite, and the

diaphragm is made of polymer materials such as

polypropylene (PP) and polyethylene (PE). The

electrolyte consists of LiPF6, ethylene glycol

carbonate (EC), consists of at least one phosphate

acid salt and one or more flame retardant additives.

The safety of the battery is an important

consideration, and although it performs well under

normal conditions of use, safety hazards such as

overcharging, short circuiting, and high temperatures

may occur under conditions of abuse (Balakrishnan et

al., 2006; Wang et al., 2012; Wen et al., 2012;

Bandhauer et al., 2011 & Doughty and Roth, 2012).

In order to ensure that the battery can run safely

and smoothly, it can usually be protected by two ideas:

external physical detection and internal micro-

regulation. External protection mainly relies on small

physical electronic monitoring equipment such as gas

sensors and pressure detectors, although these devices

are designed and manufactured as small and fine as

possible, but most sensors still need to be equipped

with specific functional devices (such as heating disks,

etc.), and the demand for these components also

increases the space occupied by the matched battery

and its weight. The out-of-control environment of hot

pressing often increases the risk of battery safety

accidents. The internal protection scheme is mainly

through design or reaction modification to provide an

intrinsically safe and structurally reasonable material

for the manufacture of battery components, and this

scheme is also considered to be the "ultimate"

solution to ensure battery safety. The purpose of this

review is to summarize the existing safety issues of

lithium-ion batteries and to introduce the design of

relevant safety materials from three aspects: cathode,

anode and electrolyte, in order to improve the safety

of lithium-ion batteries and to promote the future

development and practical application of lithium-ion

battery material safety.

256

Dong, Y., Li, J. and Lu, Y.

Research Progress on the Safety of Lithium Ion Battery Materials.

DOI: 10.5220/0013910800004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 256-261

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

2 REASONS FOR SAFETY

PROBLEMS WITH LITHIUM-

ION BATTERIES

The organic liquid electrolyte in the lithium-ion

battery is inherently flammable, which also leads to

the easy loss of control of the battery under high heat

and pressure environment, which is one of the biggest

difficulties facing the safety of the lithium-ion battery

system. Therefore, fully understanding the causes and

processes of lithium-ion batteries in high

heat/pressure environment out of control, targeted

design of the functional materials of each part of the

battery, can better improve the safety and reliability

of lithium-ion batteries. For lithium-ion battery

thermal runaway inducement, can be roughly divided

into three categories: collision runaway, electrical

runaway, thermal runaway.

Collision runaway is due to the partial rupture of

the diaphragm caused by mechanical deformation of

the battery such as collision, extrusion, acupuncture,

etc. Electrical runaway is mainly due to the

penetration of the diaphragm during the battery

charging and discharging process, and thermal

runaway is due to the high-temperature environment

caused by overheating resulting in a large area

collapse of the diaphragm, and the result of the

destruction of the diaphragm caused by these three

inductions will eventually lead to an internal short

circuit inside the battery. A series of safety problems

caused by excessive local current. Usually different

incentives caused by the battery out of control, the

phenomenon will have a certain difference, but the

mechanism is similar.

3 ELECTROLYTE

The safety of lithium-ion batteries depends largely on

the characteristics of their electrolytes. The

electrolyte acts as a channel for the transport of

lithium ions within the battery and is usually

composed of organic solvents and lithium salts. The

safe and efficient operation of batteries often requires

electrolytes with high ionic conductivity, wide

electrochemical Windows, high safety and low cost.

However, the safety problem of electrolyte

flammability is a major difficulty faced by safety

performance.

At present, many researchers mainly use flame

retardant additives to reduce the problem of

electrolyte flammability. These additives are mainly

based on organophosphorus compounds or organic

halogenated compounds. However, most of these

additives have structural instability, low toxic

halogens in the ingredients may cause environmental

pollution and other problems, in order to avoid the

above problems, organophosphorus compounds

because of its efficient flame retardancy and

environmental friendliness and attention, become the

first choice of flame retardancy additives. The

mechanism of action of these phosphorous compound

flame retardants is usually to inhibit the transfer of

free radicals during the combustion process. At high

temperatures during combustion, phosphorous

compounds produce phosphorous free radicals due to

decomposition reactions, and such substances can

inhibit or even terminate the free radicals responsible

for continuous combustion generated during the

propagation of the chain reaction (Granzow, 1978).

However, phosphorus-containing flame retardants

can effectively reduce the flammability of the

electrolyte, but also have a certain impact on the

working performance of the battery. In view of the

adverse effects of such additives, some scientists have

proposed to modify the microscopic molecular

structure of phosphorous compounds as an idea and

successfully put into practice a variety of schemes:

fluorination of phosphoric acid compounds

containing alkyl with fluoride to obtain additives with

significantly improved stability and flame retardant

effect (Pires et al., 2015). Choose organic molecules

with excellent flame retardant properties and at the

same time have a protective shell (films), such as

dimethylallylphosphonate, where allyl polymerizes

on the graphite surface and forms a stable SEI film,

effectively preventing harmful side reactions (Jin et

al., 2013). The use of cyclic phosphazene instead of

organophosphorus additives (such as fluorinated

cyclophosphazene) enhances its electrochemical

compatibility (Xia et al., 2015). In addition,

researchers have proposed the preparation of a new

heat-triggered fiber protective diaphragm, flame

retardants can be polymerized as raw materials to

form a protective shell, and these shells are further

stacked to form a diaphragm through the polymer

processing process, so as to achieve the purpose of

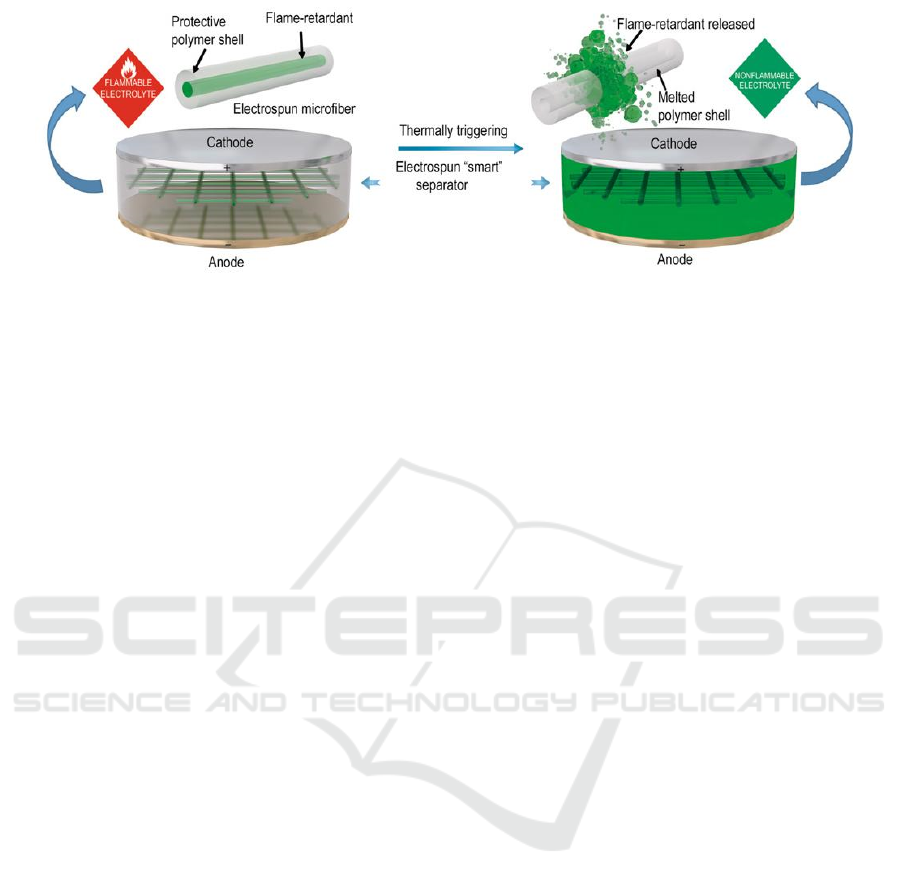

effective flame retardant (Figure 1).

4 CATHODE MATERIAL

Cathode materials are a key component of lithium-ion

batteries and require a number of properties to ensure

battery performance and safety. These characteristics

include high capacity, stable structure, stable voltage,

good cycling performance and easy preparation.

Research Progress on the Safety of Lithium Ion Battery Materials

257

Figure 1: Schematic diagram of the "smart" electrospinning diaphragm of a lithium-ion battery with heat-triggered flame

retardant properties (Liu et al., 2017).

The operation of cathode materials directly affects the

safety performance of the entire battery. There are

very many choices of lithium-ion battery cathode

materials in the current market, among which lithium

cobalt oxide is the first choice for very many

electronic products, while lithium nickel cobalt

manganese oxide is the leading emerging material,

and lithium nickel cobalt aluminate and lithium iron

phosphate are also materials that can't be ignored

(Zhang et al., 2024). Among them, lithium nickel

cobalt manganese oxide ternary cathode materials

(LiNixCoyMn1-x-yO2, abbreviated as NMC) have

become the research hotspot of mainstream cathode

materials for lithium-ion batteries due to their high

specific capacity.

NMC cathode materials may face the following

problems during the cycling process: (1) lithium-

nickel mixing affects the normal de-embedding of

lithium ions, resulting in capacity loss and lower

diffusion coefficients of lithium ions, which affects

the performance of the batteries; (2) the

polycrystalline secondary particles of NMC are

susceptible to cracking and fragmentation during the

cycling process, especially at high temperatures or

high pressures; and (3) the Surface side reactions may

lead to cell blistering or explosion.

In response to the above problems, some existing

commonly used NMC material modification methods

include: (1) preparation of small-particle single

crystals to avoid inter-crystalline cracks and

fragmentation, and to improve structural stability and

cycling performance. For example, by preparing

agglomerated and single-crystal

LiNi0.8Co0.1Mn0.1O2, the capacity of 0.1C is

216.3mAh/g and 213.7mAh/g at 3.0-4.3V,

respectively. The thermal decomposition temperature

of agglomerated ternary cathode materials in the

charging state of 4.3V is 208℃, while the single-

crystal type is 216℃ and the amount of heat release

is lower, so the thermal stability is better. By

changing the crystal morphology of the material, the

monocrystalline structure can enhance the structural

stability while ensuring the capacity, improve the

cycling performance and increase the thermal

decomposition temperature, thus enhancing the safety

of the battery (Zhao, 2020). (2) Elemental doping, the

introduction of metallic or non-metallic elements to

reduce cation mixing, enhance the structural stability

and lithium ion diffusion efficiency, such as Wang et

al. synthesized two-dimensional porous B, N co-

doped carbon/titanium nitride (BNC-TN) composites

by hydrogel and ionothermal methods (Wang, 2023),

which can be clearly seen that its elemental doping

has been improved. Using this method can effectively

improve the reduction of diffusion coefficient due to

lithium-nickel mixing, and ensure that its surface side

reactions are reduced to improve its safety. (3)

Surface coating, utilizing stable materials to isolate

cathode materials from electrolyte contact and

improve cycle stability and thermal safety. By

wrapping other highly stable materials, such as

phosphate, fluoride, solid oxide, etc., outside the

ternary cathode materials, the ternary cathode

materials are isolated from direct contact with the

electrolyte due to the good thermal and structural

stability of the wrapped materials (Tian et al., 2023).

From the experiments of Li et al. who used poly-3-

octylthiophene as a wrapping material for surface

modification of the cathode material, it is evident that

this approach has significantly improved its cycling

stability and thermal safety (Li, 2023).

In general, in order to solve the safety problems of

mixed rows, fragmentation and side reactions in

NMC cathode materials, small-particle single crystals

are generally used to avoid electrode fragmentation,

and elemental doping and surface coating methods

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

258

are used to reduce the generation of lithium-nickel ion

mixed rows and side reactions, so as to improve the

electrochemical performance and service life of the

overall battery, as well as safety and stability in

multiple cycles.

5 ANODE MATERIAL

Early lithium-ion batteries were made directly from

lithium metal, but dendrite lithium was often present

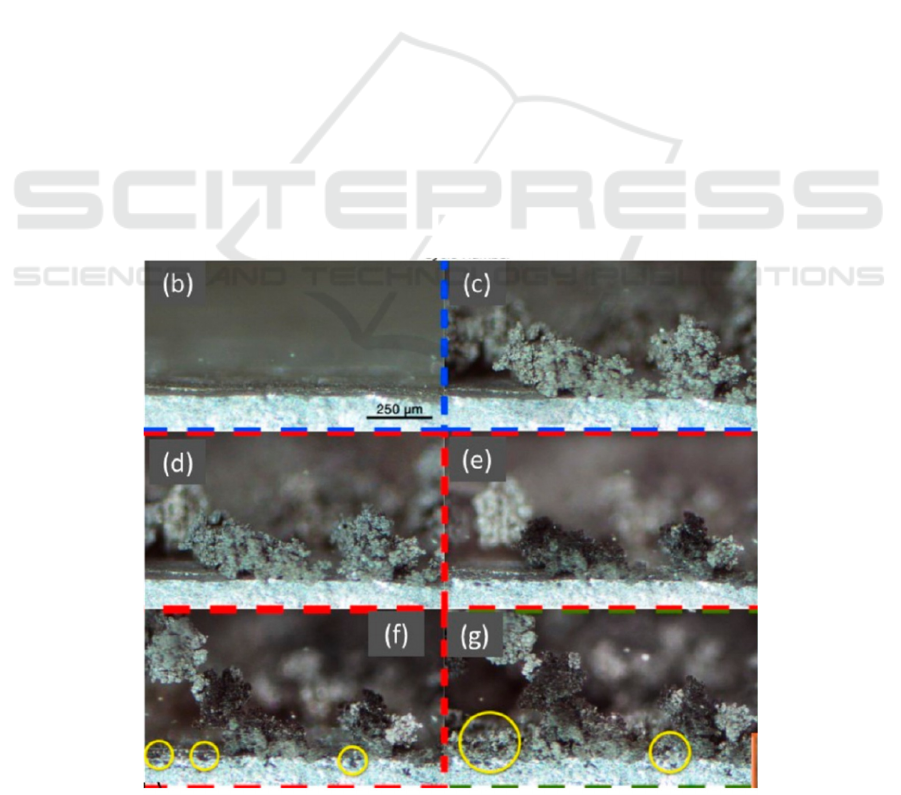

in the charge and discharge process (Figure 3),

causing extremely serious safety hazards. The advent

of rocking chair batteries solved this challenge by

successfully bypassing dendrite lithium, and I use a

layered approach here to solve the lithium-ion storage

problem (Wang et al., 2018). At the same time, when

the electrolyte comes into contact with the carbon

material, it becomes a very tight and connected layer,

called the passivation layer or the solid electrolyte

interface, which allows the lithium ions to move in a

certain space and prevents the movement of electrons

in this space. Although the formation of passivation

film will lead to irreversible loss of stored energy

during the first charge and discharge process, it is

caused by the improvement of battery charging

efficiency (Nitta et al., 2015). Therefore, layered

materials and passivation films become an important

part of battery anode safety. At the same time, adverse

reactions such as the formation of lithium dendrites

are the main safety hazards. In order to improve the

safety performance, the negative electrode material

needs to have the characteristics of high efficiency,

small volume effect, large reversible capacity, high

electrolyte sensitivity, low thermal stability and low

impurity content.

The crystallization of the anode material will lead

to an increase in the sensitivity to the electrolyte,

resulting in a significant decline in performance and

cycle stability, and a potential safety hazard. Our

purpose is obviously to improve the anode material,

so we should discuss the changes of lithium dendrites

and solid-liquid films.

The change of solid-liquid film (SEI) thickness is

closely related to the attenuation of battery capacity

and battery safety, and its decomposition is also one

of the important factors affecting battery safety. The

main reasons leading to the generation of lithium

dendrites are low temperature (Wang, 2017 &

Hossain et al., 2006), overcharge (Ohsaki et al., 2005;

Dietz et al., 2018 & Li et al., 2001) and high rate

charge (Marcicki et al., 2014 & Li et al., 2019). The

formation of lithium dendrites may also be caused by

an energy imbalance (Gallagher et al., 2015). For all

anode materials, high performance generally means

lower risk. For example, compared with graphite, the

soft carbon material formed by synthesis has better

Figure 2: Formation process of lithium ion dendrites (Dhanya et al., 2021).

Research Progress on the Safety of Lithium Ion Battery Materials

259

conductivity at low temperatures and amplification

performance under normal use (Broussely et al.,

2005). This is mainly due to the low degree of

graphitization of soft carbon, which is usually

composed of extremely small graphite nanocrystals,

thus shortening the diffusion path of lithium (Persson

et al., 2010). Under the same overcharge conditions,

it was found that less lithium metal was deposited on

the carbon surface than on the graphite surface. This

may be related to the complete disordered structure of

the carbon and the low efficiency of the first cycle of

carbon when only a small amount of graphite is

deposited. Therefore, mixing hard carbon with

graphite has been proposed by some scholars as a way

to slow down the formation of lithium ion dendrites.

However, this approach is often unsuccessful for

several reasons (Liu et al., 2017).

In general, since we want to solve some problems

of lithium-ion batteries and increase the safety of

lithium-ion batteries, the following methods can be

used. First of all, the layered structure of the rocking

chair battery can effectively prevent the generation of

lithium dendrites, but in practical applications, the

layered structure is difficult to achieve. It is also

possible to reduce the formation of lithium dendrites

by changing the anode material to prevent the

formation of lithium dendrites, thereby improving

safety.

6 CONCLUSION

Safety is the key criterion to evaluate the commercial

application of lithium-ion batteries, which directly

affects the future development and application range

of lithium-ion batteries. With the increasing demand

for battery energy density and rapid charge and

discharge, the design requirements for battery

materials are also more stringent. To date, researchers

have proposed a variety of modified material

strategies to solve the dilemma faced by battery

safety. This review summarizes the design of related

safety materials from the positive electrode, anode

and electrolyte. Through research efforts to reduce

the flammability of electrolytes, such as the use of

environmentally friendly phosphorus-containing

flame retardants or structural adjustments to improve

electrochemical performance; The cathode material

of the battery was improved by preparing small

particle single crystal, element doping and surface

coating to improve the safety performance and cycle

stability of the battery. By studying the layer structure

of rocking chair battery to store lithium ions to avoid

the safety problems caused by negative dendrite

lithium, improve the anode material, control the

change of solid-liquid film thickness and

decomposition to enhance the overall battery

performance.

AUTHORS CONTRIBUTION

All the authors contributed equally and their names

were listed in alphabetical order.

REFERENCES

Tarascon J M and Armand M 2001 Nature 414 359-67

Goodenough J and Kim Y 2010 Chem. Mater. 22 587-603

Armand M and Tarascon J M 2008 Nature 451 652-7

Balakrishnan P G, Ramesh R and Kumar T P 2006 J. Power

Sources 155 401-14

Wang Q, Ping P, Zhao X, Chu G, Sun J and Chen C 2012

J. Power Sources 208 210-24.

Wen J, Yu Y andn Chen C 2012 Mater. Express 2 197-212

Bandhauer T M, Garimella S and Fuller T F 2011 J.

Electrochem. Soc. 158 1-25

Doughty D H and Roth E P 2012 Electrochem. Soc.

Interface 21 37-44

Granzow A 1978 Acc. Chem. Res. 11 77-183

Pires J et al. 2015 J. Power Sources 296 413-25

Jin Z, Gao H, Kong C, Zhan H and Li Z 2013 ECS

Electrochem. Lett. 2 66-8

Xia L, Xia Y and Liu Z 2015 J. Power Sources 278 190–6

Liu K, Liu W, Qiu Y C, Kong B, Sun Y, Chen Z, Zhuo D,

Lin D and Cui Y 2017 Sci. Adv. 3

Zhang Z Y, Bao X J and Xie S Z 2024 J. Industrial

Minerals & Processing 1 16

Zhao M T 2020 J. Shandong Chemical Industry 49(22)

138-44

Wang C C 2023 (Wuhan: Wuhan Institute of Technology)

Tian G L, Li J and Wu Y K 2023 J. Battery Bimonthly 53(3)

347-51

Li T F 2023 (Changsha: Central South University)

Wang A, Kadam S and Li H 2018 NPJ. Comput Mater 4(1)

15

Nitta N, Wu F X, Lee J T and Yushin G 2015 Mater Today

18(5) 252-64

Wang T, Liu X, Zhao D and Jiang Z 2004 Chem. Lett. Phys.

389(4–6) 327-31

Wang K 2017 J. Open Access Library 4(11) 1-12

Hossain S, Kim Y, Saleh Y and Loutfy R 2006 J. Power

Sources 161(1) 640-7

Ohsaki T, Kishi T and Kuboki T et al 2005 J. Power

Sources 146(1–2) 97-100

Dietz R, Bare O and Li J 2018 J. Power Sources 385 148-

55

Li J, Murphy E, Winnick J and Kohl P A 2001 J. Power

Sources 102(1) 302-9

Marcicki J, Conlisk A T and Rizzoni G 2014 J. Power

Sources 251 157-69

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

260

Li H, Zhang W and Yang X 2019 Electrochim Acta 326

134966

Gallagher K, Trask S, Bauer C 2015 J. Electrochem Soc.

163(2) A138-49

Broussely M, Biensan P and Bonhomme F 2005 J. Power

Sources 146(1–2) 90-6

Persson K, Sethuraman V and Hardwick L 2010 J. Chem.

Lett. Phys. 1(8) 1176-80

Liu H, Liu X and Li W 2017 Adv. Energy Mater 7(24) 24

Dhanya P, Malik W and Satishchandra O 2021 Energy &

Fuels 35

Research Progress on the Safety of Lithium Ion Battery Materials

261