Enhancing Catalyst Performance in Fuel Cells: Challenges and

Innovations

Nijie Fan

Inner Mongolia Normal University, Hohhot 010022, China

Keywords: Platinum-Based Catalysts, Proton Exchange Membrane Fuel Cells, Non-Metal Catalysts.

Abstract: The research of this study is to explore methods and innovations to improve the performance of fuel cell

catalysts. The oxygen reduction reaction (ORR) in the fuel cell is a critical step. Traditionally, platinum-based

catalysts were the best choice. However, their high cost limits the wide application. Therefore, this research

aims to find more cost-effective alternatives to improve the viability of fuel cells. This study divided

electrocatalytic materials into two parts which are platinum-based catalysts and non-noble catalysts for further

compare the different characteristics of various catalysts, including platinum-based catalysts, transition metals

oxides, transition metals nanomaterials, and single-atom catalysts. At the same time, the advantages and

disadvantages of electrocatalytic materials and non-metallic materials are compared, and the methods that

describe how to solve the research problems are proposed. This research also compares platinum-based

catalysts with transition metal catalysts and compares transition nanomaterials with traditional nanomaterials

which have different characteristics. In terms of environmental protection and sustainable development, non-

noble catalysts are more available and environmentally friendly than precious metal catalysts with complex

mining techniques. In the future, non-metal catalysts will have a wide range of commercial potential in various

applications and are expected to replace electrocatalytic materials.

1 INTRODUCTION

Proton Exchange Membrane Fuel Cells (PEMFCs)

are emission-free energy converters for various

applications, including stationary devices. They

convert chemical energy from hydrogen oxidation

and ORR into electrical power. These two reactions

also need the catalyst. However, hydrogen oxidation

and oxygen reduction need a catalyst, especially the

ORR which has naturally slow kinetics in PEMFCs

and requires electrocatalysts.

Platinum-based catalysts have been the preferred

choice owing to their superior efficiency in

facilitating ORR (Bai et al., 2022), with Pt-C catalysts

renowned for their exceptional electron and proton

mobility (Li et al., 2023). However, the exorbitant

cost associated with platinum has hindered its

widespread adoption, prompting a quest for more

cost-effective alternatives to enhance the feasibility

of PEMFCs

In response to this challenge, researchers have

turned their attention towards exploring alternatives

to platinum-group metals (PGMs) that offer stable

cell performance at a reduced cost (Snitkoff et al.,

2021). Among these alternatives, first-row transition

metals have emerged as promising candidates for

metal-based catalysts, primarily due to their

affordability relative to platinum.

In this study, we compare many styles of

catalysts and their characteristics (eg: platinum-based

catalyst, transition metals oxides catalyst, transition

metals nanomaterials, and Single atom catalyst.

Additionally, researchers have begun incorporating

heteroatoms into catalysts to enhance their

performance and transition from platinum to first-row

transition metals as cost-effective alternatives.

2 ELECTROCATALYTIC

MATERIAL

Due to the expensive cost of platinum-based

catalysts, the wide application of platinum-based

catalysts in fuel cells is limited, so many researchers

aim to find more cost-effective catalysts. Compare

the characteristics of platinum-based catalysts with

non-noble metals

The studies gradually add heteroatoms into the

electrocatalyst to improve the activities of the

Fan, N.

Enhancing Catalyst Performance in Fuel Cells: Challenges and Innovations.

DOI: 10.5220/0013906300004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 241-245

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

241

catalysts. At the same time, researchers switch the

catalysts from platinum-based catalysts to the less

costly catalysts transition metal catalysts.

2.1 Platinum-Based Catalyst

Recent studies revealed that Platinum-based catalysts

are becoming the most common catalyst in PEMFCs,

especially in oxygen reduction reactions. Based on

recent studies, Platinum-based catalysts have

different diameters. Platinum-based catalyst activity

became worse when the size of platinum

nanoparticles increased. When the diameter of the

platinum nanoparticles-based catalyst is 3nm, the

activity of the platinum nanoparticles-based catalyst

becomes maximum (Chen et al., 2022). The high

temperature also has a certain degree of influence on

the platinum-based catalyst. The interaction between

platinum and sulfur atoms doped in a carbon matrix

can inhibit the sintering of nanoparticles at 1000℃ so

that the average particle size of platinum-based

nanoparticles can be controlled within 5 nm at high

temperatures which can maintain the activity of

platinum-based catalyst (Han et al., 2022).

Firstly, silicon and lithium can form a variety of

alloys, such as Li

12

Si

7

, Li

13

Si

4

, Li

7

Si

3

, Li

15

Si

4

, Li

22

Si

5

,

etc., which not only have high capacity, but also have

de-embedded lithium potentials lower than 0.5 V vs.

Li/Li

+

, with Li

22

Si

5

having a capacity of up to 4200

mAh/g.

In addition to Si-Li alloys, there are other silicon-

based alloy materials. Mukanova et al. (2017)

achieved a facet capacity of 80 mAh/cm² by forming

a three-dimensional composite anode with silicon

thin films on graphene-coated nickel foam by

chemical vapour deposition and magnetron

sputtering. Ding et al. (2020) prepared a binder-free

anode with bilayer graphene-coated silicon

nanoparticles (SiNPs) embedded in the porous nickel

current collector, and although a respectable face

capacity was achieved, the performance of the

interfacial layer still needs to be improved. In view of

this, Tzeng et al. (2023) proposed thick and porous

silicon-based anodes, and constructed porous anodes

with electrical conductivity on nickel foam by mixing

SiNPs, phenolic resin binder, and the conductive

agent Super P, which exhibited excellent cycling

performance and charge storage capacity.

Experiments shown that the 80 nm nickel foam

nanoporous silicon-based anode maintained excellent

performance after a total of 50 cycles, where the

current density was 4 mA/cm

2

, retaining a retained

area capacity of up to 6.5 mAh/cm², which provided

a charge storage capacity of 23.4 C for an anode area

of 1 cm² at a current rate of 4 mA.

In particular, the eutectic reaction takes place

throughout the melting procedure because the melting

points of Cu and Si are slightly different. This makes

it simpler for Si to create the Cu

3

Si alloying phase and

evenly disperse it on the Si matrix resulting in greater

suppression of the volume growth. Zhang et al.

(2021) first prepared Si-Cu

3

Si composite with a

capacity of 1000 mAh/g after 300 cycles, while Li et

al. (2023) prepared P-doped Si-Cu alloys by the

vacuum melting method, which improve the electrical

conductivity and lower the Li

+

diffusion barriers to

significantly enhance the electrochemical

performance, Among these, the P

0.5%

Si-Cu alloy had

a significantly lower R

ct

value than the undoped Si-

Cu alloys, with a capacity of 1048 mAh/g after 60

cycles.

In addition, Si-Sn alloy anode has sparked much

interest because of its unique lithium embedding

ability and buffering effect on volume change. Tian

et al. (2021) successfully prepared a novel anode

material consisting of tin nanowires (SnNWs)

embedded with SiNPs by solid-gas reaction method,

which exhibited a high and stable capacity at both

room and low temperatures.

Although silicon alloy structure has significant

effect in solving the swelling problem of silicon-

based anode, its preparation process is complicated

and costly, which limits its mass production

application. Therefore, researchers have turned to the

strategy of compositing nanosilicon and carbon

materials to seek performance enhancement and cost

reduction.

2.2 Non-Noble Metal

Compared to platinum-based which belongs to

precious metals, non-noble metals are abundant on

Earth. These allow non-noble metal catalysts to have

a lower cost compared with platinum-based catalysts

wide appliance in the production process, which is

conducive to large-scale production and application.

In terms of environmental protection and sustainable

development, the process of precious metals may

cause pollution to the environment, while non-noble

metals are relatively environmentally friendly.

The activities of catalysts of non-noble metal

catalysts can be adjusted by changing their

composition and structure. This makes non-noble

metal catalysts have a wide range of applications and

prospects.

The researchers used the comparative study

method. The activities of catalysts of platinum-based

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

242

catalysts and transition metal catalysts were

compared. At the same time, transition metal

nanomaterials and traditional nanomaterials were

also compared. The studies divided the single-atom

catalyst into five categories based on the difference in

the supporting materials.

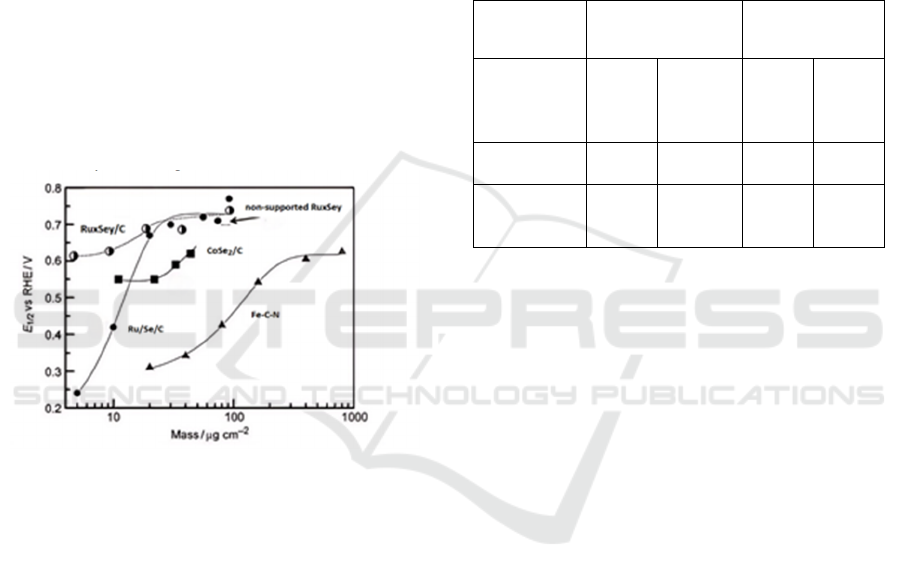

2.2.1 Transition Metals Oxides

Chevrel-phase-type compounds unveil Ruthenium-

centered catalysts as viable non-noble metal

alternatives for ORR in acidic environments (Vante,

2010). Ruthenium-based catalysts employed in these

reactions yield H

2

O

2

, a trend observed to decrease

with increasing electrocatalyst loading. Studies

indicate that metal center activities, at equivalent

loadings, follow the sequence Fe < Co < Ru < Pt, as

depicted in Figure 1. Further analysis, correlating

oxygen-binding energies with RRDE experiments

measuring H

2

O

2

, underscores the pivotal role of

electrocatalyst loading (Vante, 2010).

Figure 1: The curve of E1/2 with Mass. Chalcogenides:

non-supported RuxSey (1), RuxSey/C (2), and Ru/Se/C

(3); CoSe2/C (4); and Fe-C-N (5) (Vante, 2010).

In alkaline environments, corrosion-resistant non-

noble metals such as Fe, Co, and Mn exhibit notable

activity in oxygen reduction reactions. Graphene

oxide catalysts based on non-noble metals feature

stable spatial crystal structures and high corrosion

resistance, contributing to their favorable activity in

these reactions (Tao et al., 2024). The catalytic

activity of Mn oxide catalysts varies with different

valence states. Zhang et al. (2020) observed enhanced

catalyst activity during the high-potential or

hypervalent state of Mn.

In addition to the advantages of transition metal

oxides in acidic and alkaline media, there are these

three characteristics. The first characteristic is the

hydroxyl groups inserted on the surface of transition

metal oxides can be further functionalized. The

second is to maintain crystal structure and prevent

metal particles from agglomeration. The last

characteristic is Transition metal oxides have better

alkali corrosion resistance than carbon-based

materials in precious metals. For instance, Meng Sun

and co-workers found graphene/graphene oxide

supported single transition metal oxides show good

oxygen reduction reaction performance and long-

term durability. The reason is the rich functional

hydroxyl groups, stable spatial crystal structure, and

good alkali corrosion resistance (Sun et al, 2015).

Table1: Compares the Pt/C catalyst with Fe3/NG-800 in a

different electrolyte by onset and half-wave potential.

0.1M KOH 0.1M KClO4

Onset

potent

ial

Half-

wave

p

otential

Onset

potent

ial

Half-

wave

potent

ial

Pt/C (Yan et

al., 2023

)

1.02V 0.85V 0.95V 0.82V

Fe3/NG-800

(Xiong et

al., 2022) 1.03V 0.86V 0.92V 0.77V

2.2.2 Transition Metals Nanomaterial

Compared to conventional nanomaterials, the carbon

material Vulcan XC-72 stands out as one of the most

popular choices (Vante, 2010). It's well-known that

Pt/C catalysts exhibit low activity and carbon

instability, resulting in slow oxygen reduction rates.

To enhance activity, scientists have turned to

transition metal nanomaterials, which are cost-

effective and readily available. Through pyrolysis and

etching techniques, researchers synthesized Fe3/NG

nanoparticles. Notably, the catalyst Fe3/NG-800

displays heightened activity at 800°C compared to

other temperatures. Figure 2 illustrates the onset

potential and half-wave potential of Fe3/NG-800

versus Pt/C (Xiong er al., 2022).

2.2.3 Single-Atom Catalysts

Unlike traditional catalysts and nanomaterial-based

catalysts, where metal particle activity is typically

concentrated at corners or edges, single-atom

catalysts (SACs), as outlined by Zhang Tao’s team,

significantly reduce the energy barrier and exhibit

more than an order of magnitude greater activity (Su

et al., 2021).

Single-atom catalysts have witnessed rapid

development in recent years, with a myriad of styles

Enhancing Catalyst Performance in Fuel Cells: Challenges and Innovations

243

emerging over the past decade. Researchers have

categorized them into five distinct types based on the

support material: single metal atoms anchored on

metals, metal compounds, non-metallic carbon-based

supports, MOFs, and zeolites.

The activities of single-atom catalysis can be

changed with the enhancement of coordination. In

order to increase the activities of single-atom

catalysis, the operator should carefully select the

appropriate support while performing appropriate

metal-carrier interactions (Li et al., 2019). For

instance, Hutching and co-workers found that there

are different activities of vinyl chloride monomers in

Au single-atom catalysts. The reason is that the ratio

of Au(I): Au(III) is caused by the different Au-Cl

coordination (Malta et al., 2017).

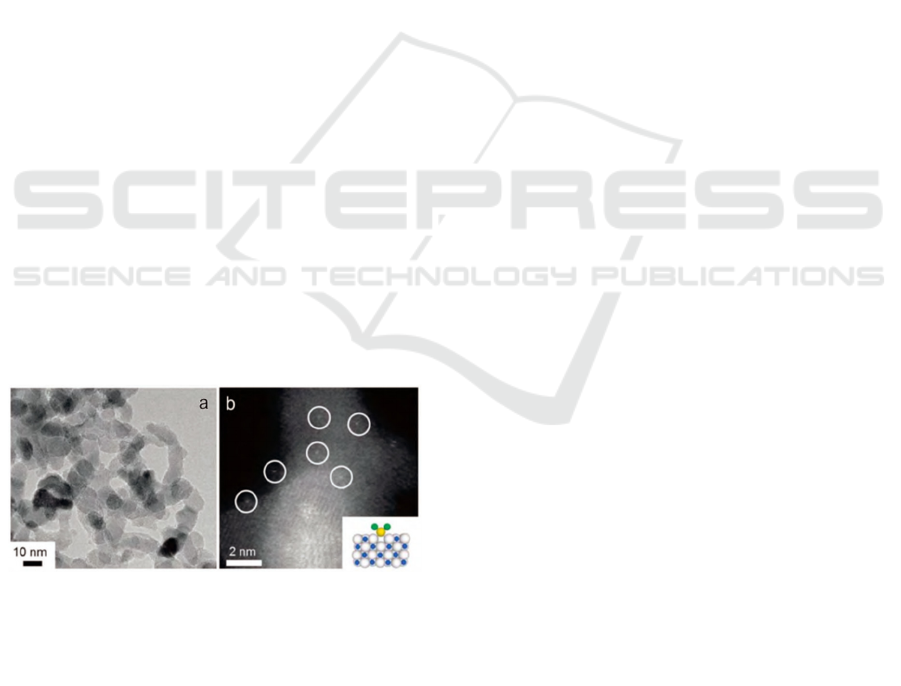

Recent studies have demonstrated that single-

atom catalysts can substantially enhance catalytic

activity by achieving maximal atomic utilization and

revealing ample active sites. Moreover, single-atom

catalysts exhibit high selectivity, as evidenced by the

comparison between desk current and ring current,

showcasing reduced desk current and increased ring

current. For instance, Yang and co-worker

successfully used a single platinum atom catalyst

which fixed on nanometer titanium nitride was

prepared by using chlorine ligands. According to

Figure 3. (a) which reveals high selectivity,

transmission electron microscopy images showed

that only TiN nanoparticles were present in 0.35wt%

of the platinum-TiN sample, and no platinum

nanoparticles were observed. However, Figure 3. (b)

is the HAPtDF-STEM image, where the white dots

are platinum nanoparticles.

Figure 2: (a) Transmission electron microscope image. (b)

HAPtDF-STEM image reveals 0.35 wt% Pt/TiN (Su et al.,

2021).

3 CONCLUSION

According to a comparison of electrocatalytic

material and non-metal material, they have different

advantages and disadvantages. As an electrocatalyst

material, platinum-based catalysts have high to be a

barrier to wide use.

In contrast, non-metal materials like Ru hold

promise for replacing Pt in oxygen reduction

reactions in fuel cells under acidic conditions.

Transition metal oxides exhibit high activity, ranking

second only to platinum-based catalysts. Notably, Mn

displays exceptional activity in alkaline environments

due to its unique structure and varying valence.

Transition metals nanomaterials, a subset of non-

metal materials, offer affordability and accessibility

compared to traditional electrocatalytic materials.

While traditional catalysts may lack sufficient

activity and durability in real-world applications,

single-atom catalysts show promise in overcoming

these limitations during oxygen reduction reactions.

However, their practical application remains limited.

Looking ahead, non-metal material catalysts hold

potential for widespread commercial use, potentially

replacing electrocatalytic materials in various

applications. Moreover, the incorporation of rare

earth elements into Proton Exchange Membrane Fuel

Cells can enhance their localized characteristics,

paving the way for further advancements in the field.

REFERENCES

Botao Qiao, Aiqin Wang, Xiaofeng Yang, Lawrence F.

Allard, Zheng Jiang, Yitiao Cui, Jingyue Liu, Jun Li

and Tao Zhang 2011 Nature Chemistry 17(2) 1441-49

Cui Chen, Liming Zhou, Ming Wen, Hao Cui, Manmen

Liu, Shaohong Liu 2022 Precious, Metals 43(4) 69-76

Grazia Malta, Simon A Kondrat, Simon J Freakley,

Catherine J Davies, Li Lu, Simon Dawson, Adam

Thetford, Emma K Gibson, David J Morgan, Wilm

Jones, Peter Wells, Peter Johnaton, C. Richard

A.Catlow, Christopher J. Kiely and Graham J.

Hutchings 2017 Science 355 1399

Hongliang Li, Mengling Wang, Laihao Luo and Jie Zeng

2019 Adv. Sci. 6 1801471

Jianan Su, Linzhou Zhuang, Shusheng Zhang, Qingju Liu,

Longzhou Zhang and Guangzhi Hu, 2021 Chin. Chem.

Lett. 32 2947-62

Jingsen Bai, Liting Yang, Zhao Jin, Junjie Ge and Wei Xing

2022 Chin. J. Catal. 43 6 1444-58

Liwei Xiong, Yukang Fu, Yongxin Luo, Youshan Wei, Ze

Zhang, Chaoguo Wu, Sicheng Luo, Gang Wang, David

Sawtell, Kefeng Xie, Tao Wu, Dong Ding and Liang

Huang 2022 J. Mater. Res. 37 2109–2123

Long Huang, Haichao XU, Bi Xing, Qiuxia Li, Wei Yi, and

Shigang Sun 2022 Electrochem, 28(1) 2108061

Meng Sun, Huijuan Liu, Yang Liu, Jiuhui Qu and Jinghong

Li 2015 Nanoscale 7(4) 1250-69

Min Li , Feng Liu , Supeng Pei , Zongshang Zhou , Kai Niu

, Jianbo Wu and Yongming Zhang, 2023

Nanomaterials 2023 13(3) 444

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

244

Nicolas Alonso-Vante 2010 CHEMPHYSCHEM 10.1002

Riflael Snitkoff ,Ariel Friedman ,Yan Yurko ,Piotr Zelenay

,Alan Bond and Lior Elbaz 2021, Reaearch Square

Rui Han, Qingchun Wang, Xiaona Zhou, Xiaolong Liang,

and Fenglong Zhang 2022, INDUSTRIAL CATALYSTS

10 9-15

Wei Yan, Xuan Wang, Mannan Liu, Kaiyue Ma, Liqi Wang,

Qicheng Liu, Caikang Wang, Xian Jiang, Hao Li,

Yawen Tang and Gentao Fu 2023 Adv. Funct. Mater.

34 2310487

Yong-Chao Zhang, Sana Ullah, Rongrong Zhang, Lun Pan,

Xiangwen Zhang and Ji-Jun Zou.2020 Appl. Catal., B

277 119247

Zeyu Tao, Hangcheng Liu, Jianfeng Liu and Zhengrong Shi

2024 BATTERY BIMONTHLY 54(1), 103-6

Enhancing Catalyst Performance in Fuel Cells: Challenges and Innovations

245