The Principle, Status and Development of Compressed Air Energy

Storage Technology

Chengqi Ye

Anhui Jianzhu University, Hefei, Anhui Province, 230601, China

Keywords: Compressed Air Energy Storage, Environment, Issues and Solutions, Applications, Prospects.

Abstract: Compressed Air Energy Storage (CAES) is an emerging energy storage technology with significant potential

for addressing the intermittency and volatility of renewable energy sources. CAES systems work by storing

electricity when it's not in high demand, and using it to compress air. This compressed air is then kept

underground or in containers above ground. When there's a spike in demand for electricity, the stored

compressed air is released to power a generator, helping to balance out the supply and demand. CAES has

several advantages, including large storage capacity, low operational costs, and long lifespan, making it highly

suitable for energy balancing and peak shaving in large-scale power systems. Moreover, a good and efficient

way is that CAES systems, when they're hooked up with renewable energy sources, can stash extra energy

when there's a lot being made and then let it out when production slows down. This paper aims to provide a

comprehensive understanding of CAES by exploring its types, principles, and technologies. It will delve into

various CAES configurations, including traditional isothermal CAES and more advanced adiabatic CAES,

which improves efficiency by capturing and reusing the heat. The paper will also analyze the environmental

impacts of CAES, addressing concerns such as potential impacts on local ecosystems and the carbon footprint

associated with different CAES technologies. Furthermore, it will propose feasible solutions to mitigate these

impacts and enhance the sustainability of CAES systems. By offering an in-depth analysis and a forward-

looking perspective, this paper seeks to inform and engage readers on the future development and applications

of CAES, emphasizing its contribution to building a more resilient and sustainable energy infrastructure.

1 INTRODUCTION

CAES is an emerging energy storage technology with

significant potential to address the intermittency and

volatility of renewable energy sources. CAES systems

work by using electricity during periods of low

demand to compress air which is then stored and

released to drive a generator and produce electricity

during periods of high demand. Compared to

traditional battery storage, CAES offers advantages

such as large capacity, low cost, and long lifespan,

making it particularly suitable for energy balancing

and peak shaving in large-scale power systems (Budt

et al, 2016). Currently, several CAES projects

worldwide have been put into commercial operation

or are under construction and planning stages. For

instance, China's Jiangsu Jintan and Zhangbei

demonstration projects have successfully connected to

the grid, showcasing the feasibility and benefits of

CAES in practical applications. Additionally, the

development of new storage technologies, such as salt

cavern storage, artificial cavern storage, and

abandoned mine storage, provides more flexible and

efficient solutions for CAES. In the future, with

continuous technological advancements and growing

market demand, CAES is expected to play an

increasingly important role in the global energy

structure, providing a solid foundation for achieving

sustainable energy development goals. The aim of this

paper is to help people easily understand the types,

principles, and technologies of CAES. It aims to

analyze the environmental issues associated with

CAES, propose feasible solutions, and provide an

outlook on the equipment, technology, and application

scenarios of CAES.

2 OVERVIEW OF CAES

2.1 Development Process and

Classification

The history of CAES technology can be traced back

to the late 19th century, but it was not until the 1970s

Ye, C.

The Principle, Status and Development of Compressed Air Energy Storage Technology.

DOI: 10.5220/0013885600004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 229-234

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

229

that this technology began to be developed for

electrical energy storage applications. The first stage

of development occurred at the end of the 19th

century. At that time, compressed air was used as the

power source with the aim of driving mechanical

equipment. In the 1900s, some industrial applications

began using compressed air, for example, in mining

and railway systems. The second stage marked the

beginning of modern CAES systems. In the 1970s,

with the emergence of the energy crisis, people began

to seek various energy storage solutions. In 1978, the

world's first commercial CAES project commenced

operations in Huntorf, Germany. This facility utilized

surplus electricity during low demand periods to

compress air, and the compressed air was then

released during peak demand periods to generate

electricity through turbines. In the 1980s, the

McIntosh power plant in Alabama, USA, became the

second facility to implement CAES technology,

demonstrating its potential in electricity grid peak

shaving. The third stage involves technological

progress and changes. From the 1990s to the 2000s,

advancements in technology enabled more efficient

management of thermal energy and pressure in CAES

systems, enhancing system efficiency. Researchers

began exploring more efficient compressed air energy

storage technologies such as Advanced Adiabatic

Compressed Air Energy Storage (AA-CAES). From

the late 2000s to the present, with the rapid

development of renewable energy, CAES technology

has been recognized as an effective solution for

storing renewable energy, especially for intermittent

sources like wind and solar power (Chen et al, 2016).

The underground salt cavern systems in CAES

technology have incorporated many innovative

elements, abandoned mines, or natural gas fields as

storage sites, and developing systems that reduce or

eliminate dependence on burning natural gas. CAES

technology can be classified based on scale as shown

in figure 1.

Figure 1. Classification of CAES (Picture credit: Original)

2.2 Working Principles of CAES

The storage and release of energy are the two stages

of the working principle of CAES. The energy storage

stage is further divided into three steps. First step is

air compression when there is excess electricity in the

grid, this electrical energy is used to drive

compressors, compressing the air into a high-pressure

state. Second step is heating management. The

generated heat is released into the environment,

which is a result of the compression process in

traditional CAES systems. While in advanced CAES

systems, this heat is captured through efficient heat

exchangers and stored in specialized thermal energy

storage devices such as high-efficiency insulated

thermal storage systems, typically using solid or

liquid heat media. The third step is storing the

compressed high-pressure air underground, in storage

tanks, or other containers. When electricity is needed,

the high-pressure air in the storage devices is

released. In traditional systems, the compressed air

must be preheated by burning natural gas or other

fuels to ensure it has enough heat during expansion.

However, in advanced systems, the high-pressure air

is heated by stored heat through heat exchangers,

restoring its expansion energy. Then comes power

generation - electricity is produced by a generator

driven by an expander or turbine powered by the

preheated high-pressure air. Finally, after passing

through the turbine, the air's pressure and temperature

decrease and it is released into the atmosphere.

2.3 Pros and Cons of CAES

2.3.1 D-CAES

When air is compressed, the temperature rises

significantly, but this heat is usually not retained and

is directly released into the air. Before releasing the

compressed air, it is necessary to reheat it by burning

natural gas and other fuels. This makes sure that the

air has enough energy when it expands again. The

advantages of D-CAES include two points. First, it is

easy to install and control. Second, when the air

reservoir is empty, it can operate as a gas turbine (

Nojavan et al, 2018, Shafiee et al, 2016). The

disadvantages of D-CAES include two points. First,

during the charging process, energy is lost in the form

of heat, resulting in significant energy waste. Second,

during the discharging process, it preheats the air

before expansion by burning fossil fuels, leading to

considerable environmental issues.

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

230

2.3.2 I-CAES

In a perfect isentropic compression and expansion

process, the heat produced during compression gets

stored using a heat exchanger to cut down on energy

loss. When it comes to the ideal isentropic expansion

process, the previously stored heat is reclaimed and

used again for the expansion process, which boosts

the system's efficiency. I-CAES has its perks. First

off, it really maximizes heat transfer during

compression or expansion and keeps heat loss at bay

thanks to some nifty heat exchange (Ren et al, 2019).

Plus, when it comes to storing compressed air energy,

it brings together great economic performance and

high efficiency ( Olabi et al, 2021, Patil et al, 2020).

But there are downsides too. For one thing, in the

whole heat exchange dealer, its compression and

expansion take their sweet time to make sure

everything's just right. And when it comes to getting

that near-isothermal compression happening, its

compressors stick with tradition and have low heat

transfer characteristics (Patil et al, 2020).

2.3.3 A-CAES Without TES

The super squished high-pressure air gets shoved into

underground storage tanks or other high-pressure

containers. Meanwhile, the heat made during the

squishing process gets stored in a thermal energy

storage gadget. When it's time to let out some energy,

the high-pressure air is set free from its storage spot,

warmed up through a heat exchanger, and then used to

spin a turbine and make electricity. After passing

through the turbine, the air's pressure and temperature

are reduced, and the air is then released into the

atmosphere. The advantages of A-CAES include two

points. First, during its expansion process, the air no

longer needs reheating, reducing energy consumption.

Second, its overall application significantly reduces

thermal energy loss (Dooner & Wang, 2020). The

disadvantages of A-CAES include two points. First,

because of material challenges in air tanks, more

expensive storage vessels are needed to store high-

temperature compressed air (Dooner & Wang, 2020).

Second, due to compression technology challenges,

air cannot be compressed to high pressure without

cooling, reducing its energy storage potential (Dooner

& Wang, 2020).

2.3.4 AA-CAES with TES

During the compression process, the air temperature

significantly increases. The heat is stored in thermal

energy storage devices (such as high-efficiency

insulated thermal storage systems, typically using

solid or liquid heat media). The advantages of AA-

CAES include two points. First, it has eliminated the

need for fuel, making its application environmentally

friendly. Second, it achieves the same power

generation using a smaller tank, thereby increasing

roundtrip efficiency (Dooner & Wang, 2020). The

disadvantages of AA-CAES include two points. First,

during adiabatic compression, its power consumption

increases due to high temperature rise (Chen et al,

2020). Second, in some specific cases, it requires

support from high-temperature thermal energy

storage technology (Chen et al, 2020).

3 ENVIRONMENTAL ISSUES

AND SOLUTIONS OF CAES

3.1 Environmental Issues

CAES technology, while beneficial for regulating

power grids and storing energy, also poses several

environmental challenges. Firstly, traditional CAES

systems usually require the burning of natural gas to

heat the air during energy release, which emits carbon

dioxide and other greenhouse gases, impacting the

environment. Secondly, storing compressed air

underground can affect the stability of geological

structures, posing potential risks of ground

subsidence and potentially impacting the safety and

stability of groundwater systems. Additionally, the

compressors and turbines in CAES facilities can

generate significant noise pollution during operation,

disturbing the living environment of nearby residents.

3.2 Solutions

To address the environmental issues associated with

CAES technology, several improvements can be

implemented. Firstly, advanced energy storage

technologies should be adopted. For example, AA-

CAES technology stores the heat and reuses it. Thus,

it not only reduces dependence on external fuels but

also lowers associated greenhouse gas emissions.

This system enhances energy conversion efficiency

and environmental friendliness through improved

thermal management. Secondly, geological

assessments and site selection must be improved.

During the planning and construction stages of CAES

systems, comprehensive geological assessments

should be conducted to select sites with stable

geological structures and minimal impact on

groundwater. Additionally, advanced monitoring

technologies can be used to continuously monitor the

geodynamics of the underground storage areas,

The Principle, Status and Development of Compressed Air Energy Storage Technology

231

ensuring operational safety and environmental

stability. Thirdly, noise control measures should be

implemented. Modern soundproofing materials and

technologies, such as sound barriers and anti-seismic

foundations, should be used in the design and

construction of CAES facilities to reduce noise

generated during operation. Facilities should also be

located as far away as possible from residential and

sensitive areas to minimize disturbances to the

surrounding environment (Rabi et al, 2023).

Fourthly, environmentally friendly operational

strategies should be implemented. Environmental

management strategies should be developed and

implemented, including demand response, to optimize

equipment operating times and loads, reducing energy

waste. Furthermore, integrating with renewable

energy projects can enhance the sustainability and

overall energy efficiency of the system.

Through these measures, not only can the

environmental issues faced by CAES technology be

resolved, but its application efficiency and

sustainability in modern energy systems can also be

enhanced, making it a more environmentally friendly

and economically viable energy storage solution.

4 DEVELOPMENT STATUS AND

APPLICATIONS OF CAES

4.1 Development Status

Currently, the commercially operating CAES projects

include the Huntorf plant in Germany, the McIntosh

plant in the United States, and the Jiangsu Jintan

National Demonstration Project in China, with

installed capacities of 290MW×4h, 110MW×26h, and

60MW×5h, respectively. All these three projects

utilize salt cavern air storage. The Zhangbei

Demonstration Project of the Chinese Academy of

Sciences, with an installed capacity of 100MW×4h,

uses pipeline steel and artificial cavern air storage and

is currently in grid-connected power generation status.

The power stations under construction include the

Silver City project in Australia, the Bethel project in

the United States, and the Carrington project in the

United Kingdom, with capacities of 200 MW×8 h, 317

MW, and 50 MW×6 h, respectively. These projects

use advanced adiabatic technology with abandoned

mine air storage, advanced adiabatic technology with

salt cavern air storage, and liquid air technology with

liquid tank storage, respectively. Regarding CAES

projects in China, there are the following: The Three

Gorges Group Ulanqab Demonstration Project with a

capacity of 10MW×4h using pipeline steel air storage.

The State Power Investment Corporation Hunan

Hengyang Project with a capacity of 100MW×4h

using salt cavern air storage. The China Green

Development Investment Group Golmud Project with

a capacity of 60MW×10h using liquid tank air

storage.The China Energy Engineering Group Gansu

Jiuquan Project with a capacity of 300MW×6h using

artificial cavern air storage. Projects in the feasibility

study stage include: The Three Gorges Group Hubei

Macheng Project with a capacity of 100MW×4h using

artificial cavern air storage.The China Energy

Engineering Group Shandong Tai'an Project with a

capacity of 350MW×4h using salt cavern air

storage.The Three Gorges Group Qinghai Xitieshan

Project with a capacity of 50MW×4h using abandoned

mine air storage. The Sinopec Shengli Oilfield Project

with a capacity of 100MW×4h using oil and gas

reservoir air storage. The CAES Projects in China can

be seen in table 1 and figure 2.

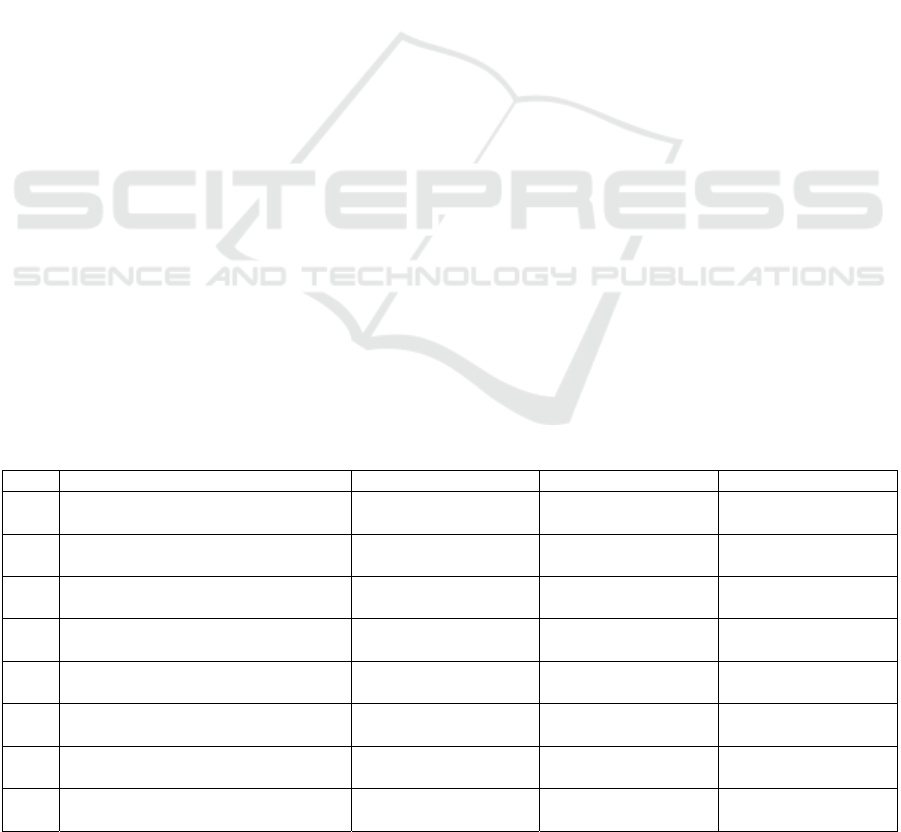

Table 1. Capacity, Storage Type, and Stage of CAES Projects in China

No. Project Capacity (MW×h) Storage Type Stage

1

Three Gorges Group Ulanqab

Demonstration Project

10MWx4h

Pipeline steel air

storage

Demonstration

2

State Power Investment Corporation

Hunan Hen

gy

an

g

Pro

j

ect

100MWx4h

Salt cavern air

stora

g

e

Operational

3

China Green Development

Investment Grou

p

Golmud Pro

j

ect

60MWx10h

Liquid tank air

stora

g

e

Operational

4

China Energy Engineering Group

Gansu Jiuquan Project

300MWx6h

Artificial cavern air

storage

Operational

5

Three Gorges Group Hubei Macheng

Pro

j

ect

100MWx4h

Artificial cavern air

stora

g

e

Planning

6

China Energy Engineering Group

Shandon

g

Tai'an Pro

j

ect

350MWx4h

Salt cavern air

stora

g

e

Planning

7

Three Gorges Group Qinghai

Xitieshan Project

50MWx4h

Abandoned mine air

storage

Planning

8 Sinopec Shengli Oilfield Project 100MWx4h

Oil and gas reservoir

air storage

Planning

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

232

Figure 2. CAES Projects in China (Picture credit: Original)

4.2 Application Scenarios

The CAES system has broad application prospects in

the future. First of all, CAES can really help balance

out the power supply and demand, do some peak

shaving and valley filling, and make the grid more

stable. Secondly, it can quickly respond to changes in

power demand, serving as a load balancing device

with a much faster start-up time compared to

traditional power plants. Additionally, in regions with

time-of-use pricing, CAES can help users reduce

electricity costs. It can also integrate with renewable

energy sources such as wind and solar power,

enhancing the utilization and reliability of renewable

energy (Wang et al, 2017). Finally, CAES systems

can serve as backup power sources, ensuring

continuous and stable power supply during

emergencies or equipment maintenance.

5 OUTLOOK FOR CAES

The installed capacity of CAES has shown a trend of

scaling up from kW to MW and even to hundreds of

MW, indicating its broad application prospects as an

energy storage technology. It is bound to provide

certain support to future power grids (Zuogang et al,

2020). Nevertheless, there is still potential for further

development, particularly evident in the following

areas.

Firstly, CAES plants experience frequent start-

ups and shutdowns and variable operating conditions,

requiring further optimization of compressors to

achieve high-load operation across a wide range of

conditions and to adjust pressure and exhaust

parameters under variable conditions. Turbine

expanders need to operate efficiently under wide-load

conditions to adapt to large pressure and flow

fluctuations, ensuring safe and efficient operation.

Heat exchangers need further optimization in terms of

materials, flow channel structure, and process

parameters to improve heat transfer efficiency.

The Principle, Status and Development of Compressed Air Energy Storage Technology

233

Secondly, experts should seek more

environmentally friendly external heat sources to

replace the fossil fuels traditionally used in

supplementary combustion CAES. Technicians need

to develop high-performance, low-cost heat transfer

media, such as low-melting-point mixed molten salts,

to raise the storage temperature of compressor heat

and enhance system heat transfer efficiency. As

CAES moves toward larger scales, increasing the size

of single units can effectively reduce investment costs

and improve system efficiency. Gas storage facilities

need to make full use of existing salt cavern resources

and strengthen research on artificial cavern gas

storage facilities to adapt to areas with scarce salt

cavern resources.

Finally, as a long-duration energy storage

technology, CAES has characteristics such as rapid

start-up and shutdown, long cycle life, and strong

load adaptability. It has broad applications in peak

shaving and valley filling, renewable energy

integration, frequency regulation, peak regulation,

reactive power regulation, spinning reserve,

emergency power supply, and black start.

Additionally, as a system capable of storing heat,

electricity, and gas, CAES features combined

cooling, heating, and power supply, making it well-

suited for integration with comprehensive energy

systems to leverage its advantages and achieve tri-

generation of cooling, heating, and power within

comprehensive energy systems.

6 CONCLUSION

The development of CAES technology has

progressed significantly, from its initial stages in the

late 19th century to its current applications in large-

scale energy storage projects. Various CAES projects

around the world and in China have demonstrated its

feasibility and benefits. Despite the environmental

challenges associated with traditional CAES systems,

such as greenhouse gas emissions and geological

impacts, advanced technologies and improved site

selection can mitigate these issues. CAES technology

is gonna be a big deal in the global energy game,

especially when it comes to bringing together

renewable energy sources and making sure we've got

a steady power supply. Future advancements in

CAES will focus on optimizing system components,

developing environmentally friendly heat sources,

and enhancing system efficiency, positioning CAES

as a key technology for sustainable energy

development.

REFERENCES

Budt, M., Wolf, D., Span, R., & Yan, J. 2016 A review on

compressed air energy storage: Basic principles, past

milestones and recent developments Applied energy

170 250-268

Chen, H., Peng, Y. H., Wang, Y. L., & Zhang, J. 2020

Thermodynamic analysis of an open type isothermal

compressed air energy storage system based on

hydraulic pump/turbine and spray cooling Energy

conversion and management 204 112293

Chen, L., Zheng, T., Mei, S., Xue, X., Liu, B., & Lu, Q.

2016 Review and prospect of compressed air energy

storage system Journal of Modern Power Systems and

Clean Energy 4 529-541

Dooner, M., & Wang, J. 2020 Compressed-air energy

storage In Future Energy 279-312

Nojavan, S., Najafi-Ghalelou, A., Majidi, M., & Zare, K.

2018 Optimal bidding and offering strategies of

merchant compressed air energy storage in deregulated

electricity market using robust optimization approach

Energy 142 250-257

Olabi, A. G., Wilberforce, T., Ramadan, M., Abdelkareem,

M. A., & Alami, A. H. 2021 Compressed air energy

storage systems: Components and operating

parameters-A review Journal of Energy Storage 34

102000.

Patil, V. C., Acharya, P., & Ro, P. I. 2020 Experimental

investigation of water spray injection in liquid piston

for near-isothermal compression Applied energy 259

114182.

Rabi, A. M., Radulovic, J., & Buick, J. M. 2023

Comprehensive review of compressed air energy

storage (CAES) technologies Thermo 3 104-126

Ren, T., Xu, W., Cai, M., Wang, X., & Li, M. 2019

Experiments on air compression with an isothermal

piston for energy storage Energies 12 3730

Shafiee, S., Zareipour, H., Knight,A. M., Amjady, N., &

Mohammadi-Ivatloo, B. 2016 Risk-constrained

bidding and offering strategy for a merchant

compressed air energy storage plant IEEE Transactions

on Power Systems 32 946-957

Wang, J., Lu, K., Ma, L., Wang, J., Dooner, M., Miao, S.,

... & Wang, D. 2017 Overview of compressed air

energy storage and technology development Energies

10 991

Zuogang, G. U. O., Xiyuan, M. A., Jinyong, L. E. I., &

Zhiyong, Y. U. A. N. 2020 Review on demonstration

progress and commercial application scenarios of

compressed air energy storage system Southern Energy

Construction 6 17-26

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

234