Improvements in the Performance of Silicon-Based Anode Materials

for Lithium-Ion Batteries

Leirun Chen

College of Materials Science and Engineering, University of Jinan, Jinan, Shandong, 250000, China

Keywords: Lithium-Ion Batteries, Silicon Anode Materials, Structure Optimization, Composite Materials.

Abstract: Lithium-ion batteries (LIBs) have emerged as the preferred choice for electric vehicles (EVs) owing to their

lightness, prolonged lifespan, and superior energy density. Despite graphite's prevalent use as the anode

material in the commercial LIB, its limited specific capacity poses challenges in satisfying the escalating

energy storage requirements. As a result, high-energy anode materials for LIBs are prioritized. The silicon

anode materials have received widespread praise because of their high specific capacity. Still, the structural

alterations and growth in volume of silicon anode materials throughout both charging and discharging

processes severely restrict their practical uses. Through structural optimization and composite modification

of silicon anode materials, their electrochemical performance can be effectively enhanced, which is crucial

for the creation of high-energy LIBs. This paper systematically reviews the research progress of the silicon

anode and its composite materials in terms of structure optimization, composite modification, and energy

storage performance at this stage. It looks forward to the future development patterns of such materials.

1 INTRODUCTION

In the twenty-first century, the continuous growth of

global energy demand and the urgency of

environmental protection issues have driven the

energy transition to clean energy sources such as

electricity. In this transition, the rise of new energy

vehicles, especially electric vehicles (EVs), not only

offers a fresh approach to addressing the issues of

energy depletion and environmental pollution but

also promotes the rapid development of related

technologies. Compared with traditional fuel

vehicles, the environmental advantages of new

energy vehicles are particularly significant. Driven by

electricity, they significantly reduce CO

2

emissions,

helping to alleviate the pressure of global warming.

At the same time, new energy vehicles run more

quietly, significantly reducing urban noise pollution

and providing a more liveable environment for

residents. However, new energy vehicles are not

perfect. Although they have many advantages such as

environmental protection, energy saving, and high

efficiency, issues such as range and safety are still

challenges. To overcome these challenges,

innovations in battery technology have become

crucial. Because of its outstanding energy density and

prolonged cycle life, lithium-ion batteries (LIBs)

currently hold the top spot in the batteries used in

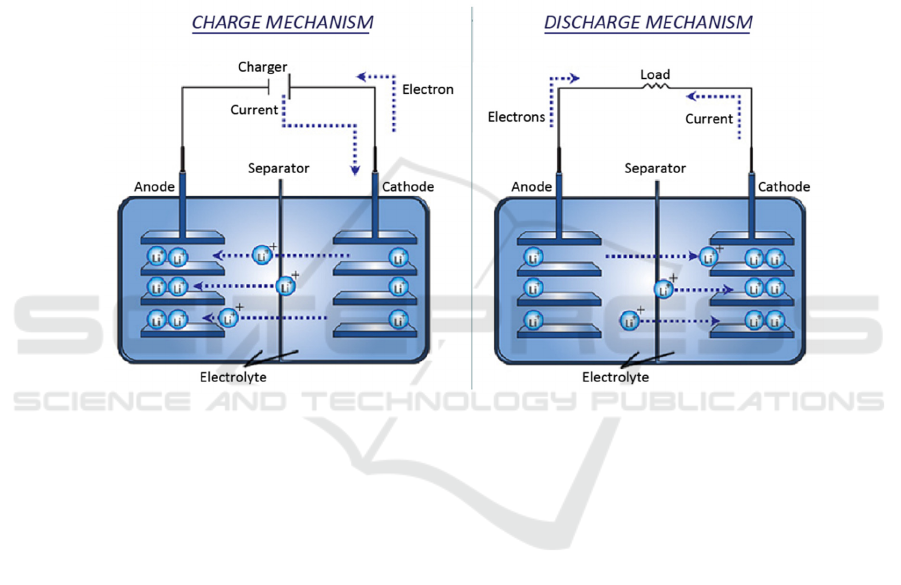

EVs. This kind of battery realizes the efficient

conversion of electrical energy and chemical energy

by shuttling Li

+

between the cathode and anode (as

shown in Figure 1), and its main structure includes the

cathode, anode, electrolyte, and diaphragm. Among

them, the anode material is a key factor affecting its

performance.

The traditional carbon anode material has better

stability, but its theoretical specific capacity is

limited, making it difficult to meet the demand for

high-capacity batteries in EVs. Since silicon anodes

can have a specific capacity of 3580 mAh/g, they are

highly respected. Additionally, silicon is thought to

be a viable anode material for LIB with a high energy

density because it is abundant in nature,

environmentally friendly, and has a good

electrochemical potential.

Nevertheless, there are several fatal drawbacks of

silicon material as anodes for LIBs. First, during

charging, the silicon anode undergoes an alloying

reaction with lithium, resulting in an expansion of the

electrode volume by about 300%. The silicon anode

is ground up and an unstable solid electrolyte

interface (SEI) is created as a result of this expansion,

leading to the active material and collector losing

their electrical connection, which makes it harder for

Li

+

to be embedded and eventually reduces capacity

218

Chen, L.

Improvements in the Performance of Silicon-Based Anode Materials for Lithium-Ion Batteries.

DOI: 10.5220/0013878500004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 218-223

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

and initial Coulombic efficiency. Furthermore, the

silicon anode's expansion increases the electrode

surface area, necessitating more Li

+

consumption to

form the SEI film, causing a decrease in battery

capacity. In addition, the diffusion coefficient of Li

+

in silicon is not high, ranging from 10

-14

to 10

-13

cm²/s,

a property that results in a large Li

+

concentration

gradient in silicon, which generates large internal

stresses during cyclic charging and discharging,

ultimately leading to fragmentation of silicon

particles. Meanwhile, the low conductivity of silicon

tends to electrically insulate the crushed silicon

particles, which in turn affects the capacity of the cell

and results in a significant loss of capacity.

To overcome these challenges, researchers are

actively exploring various modification methods.

They do so by designing rational silicon anode

structures, introducing buffer layers or composites,

and other techniques, to enhance the performance of

silicon anodes. Thus, this paper examines and

evaluates the research advancements of silicon anode

materials for LIBs, and anticipates future research on

silicon anode materials.

Figure 1: Schematic diagram of the operating principle of a LIB (Omar et al., 2012).

2 TYPES AND ADVANTAGES

AND DISADVANTAGES OF

LIBS ANODES

2.1 Nanosilicon Anode

The diffusion time of Li

+

in the electrode is jointly

influenced by the diffusion coefficient (D

Li

),

diffusion length (L) and the natural characteristics of

the material. Equation 1 shows that by drastically

lowering the particle dimension, the nanosizing

technology may greatly shorten the Li

+

diffusion

length, increasing power density and mechanical

strain tolerance. Therefore, in order to solve the

particle fragmentation problem of silicon anode due

to the large Li

+

concentration gradient, silicon

nanostructures such as nanotubes (NTs), nanowires

(NWs), and nanofibres (NFs) have been widely used

to optimise the electrode structure and electrical

properties, especially silicon nanowires (SiNWs) and

nanotubes (SiNTs), which have a significant

reversible capacity exceeding 200 mAh/g, and exhibit

excellent cycling stability.

t=

L

2

D

Li

ൗ

(1)

Among the preparation methods of nanosilicon,

hydrothermal method is favoured due to its low cost,

environmental friendliness, and applicability to large-

scale production. Scientists have successfully

prepared high-purity nanosilicon by selecting

different silicon sources, such as (2-

aminoethylamino) propyltriethoxysilane and

tetraethyl orthosilicate (TEOS), in combination with

hydrothermal methods. In addition, rice husk, as an

agricultural waste in people's daily life, has a SiO

2

content as high as 10% to 20%, which not only

reduces the cost but also is environmentally friendly

and feasible as a silicon source for the production of

Improvements in the Performance of Silicon-Based Anode Materials for Lithium-Ion Batteries

219

nanosilicon. Currently, Sudarman et al. (2024) have

successfully prepared high purity nanosilicon by

hydrothermal method using rice husk, and this

nanosilicon works well as a LIB anode, exhibiting a

capacity of 1,757 mAh/g and continuing to do so after

approximately 200 cycles. Its energy density and

cycling stability surpass those of commercial

batteries, graphite, and graphene.

Nonetheless, the nanosilicon anode still suffers

from poor electrical conductivity and high

manufacturing cost, which limits its large-scale

industrial application. Therefore, future research

needs to further explore how to reduce the

manufacturing cost of nanosilicon anodes while

improving energy density and cycling stability, in

order to promote their widespread application in the

field of LIBs.

2.2 Silicon Alloy Anode

In the pursuit of enhancing the electrochemical

performance of silicon anode, in addition to adjusting

the dimension of silicon particles, another effective

method is to combine silicon with suitable metals

(e.g., Ni, Cu, Sn, Pb, Li, etc.) to form an alloy phase.

This alloying strategy takes advantage of the ductile

properties of metals to give silicon alloy composites

the ability to slow down the volume expansion of

silicon.

Firstly, silicon and lithium can form a variety of

alloys, such as Li

12

Si

7

, Li

13

Si

4

, Li

7

Si

3

, Li

15

Si

4

, Li

22

Si

5

,

etc., which not only have high capacity, but also have

de-embedded lithium potentials lower than 0.5 V vs.

Li/Li

+

, with Li

22

Si

5

having a capacity of up to 4200

mAh/g.

In addition to Si-Li alloys, there are other silicon-

based alloy materials. Mukanova et al. (2017)

achieved a facet capacity of 80 mAh/cm² by forming

a three-dimensional composite anode with silicon

thin films on graphene-coated nickel foam by

chemical vapour deposition and magnetron

sputtering. Ding et al. (2020) prepared a binder-free

anode with bilayer graphene-coated silicon

nanoparticles (SiNPs) embedded in the porous nickel

current collector, and although a respectable face

capacity was achieved, the performance of the

interfacial layer still needs to be improved. In view of

this, Tzeng et al. (2023) proposed thick and porous

silicon-based anodes, and constructed porous anodes

with electrical conductivity on nickel foam by mixing

SiNPs, phenolic resin binder, and the conductive

agent Super P, which exhibited excellent cycling

performance and charge storage capacity.

Experiments shown that the 80 nm nickel foam

nanoporous silicon-based anode maintained excellent

performance after a total of 50 cycles, where the

current density was 4 mA/cm

2

, retaining a retained

area capacity of up to 6.5 mAh/cm², which provided

a charge storage capacity of 23.4 C for an anode area

of 1 cm² at a current rate of 4 mA.

In particular, the eutectic reaction takes place

throughout the melting procedure because the melting

points of Cu and Si are slightly different. This makes

it simpler for Si to create the Cu

3

Si alloying phase and

evenly disperse it on the Si matrix resulting in greater

suppression of the volume growth. Zhang et al.

(2021) first prepared Si-Cu

3

Si composite with a

capacity of 1000 mAh/g after 300 cycles, while Li et

al. (2023) prepared P-doped Si-Cu alloys by the

vacuum melting method, which improve the electrical

conductivity and lower the Li

+

diffusion barriers to

significantly enhance the electrochemical

performance, Among these, the P

0.5%

Si-Cu alloy had

a significantly lower R

ct

value than the undoped Si-

Cu alloys, with a capacity of 1048 mAh/g after 60

cycles.

In addition, Si-Sn alloy anode has sparked much

interest because of its unique lithium embedding

ability and buffering effect on volume change. Tian

et al. (2021) successfully prepared a novel anode

material consisting of tin nanowires (SnNWs)

embedded with SiNPs by solid-gas reaction method,

which exhibited a high and stable capacity at both

room and low temperatures.

Although silicon alloy structure has significant

effect in solving the swelling problem of silicon-

based anode, its preparation process is complicated

and costly, which limits its mass production

application. Therefore, researchers have turned to the

strategy of compositing nanosilicon and carbon

materials to seek performance enhancement and cost

reduction.

2.3 Silicon-Carbon Composite Anode

In the field of LIBs, carbon anodes are known for

their high cycle life, while silicon anodes exhibit

excellent specific capacity. Based on this, scientists

have proposed to dope carbon atoms into a silicon

anode to obtain a LIB anode with high specific

capacity and long service life Therefore, researchers

have proposed a silicon carbon anode and achieved

their goal with the help of nanotechnology. Wu et al.

(2024) have found through their study that the volume

variation of silicon was successfully inhibited when

the doping concentration of carbon atoms was in the

range of 1.56% to 15.6%. This suppression effect is

attributed to the high strength of the Si-C covalent

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

220

bond, which results in a denser structure of the

material and a consequent increase in bulk modulus.

In addition, the inhibition effect on the volume

expansion of silicon shows an enhanced trend as the

carbon concentration increases. Carbon compounds

come in a variety of forms, including graphite,

graphene (Gr), carbon nanotubes (CNTs), carbon

nanofibres (CNFs), graphene oxide (GO), reduced

graphene oxide (rGO), and so forth.

Graphene, renowned for its flexibility and

conductivity, mitigates silicon's volume changes,

enhances electron transfer, and isolates particles from

the electrolyte, suppressing excessive SEI formation.

Besides, its defects and edges provide additional sites

for lithium storage, accelerating Li

+

transport in the

anode and thus significantly improving the

multiplicity performance of the battery. However, it

is challenging to attain optimal dispersion via

straightforward mechanical mixing because of

graphene's neutral property. The introduction of GO

can effectively address the dispersion issue because

irregularly dispersed SiNPs are more likely to

undergo electrochemical sintering and agglomeration

throughout the charging and discharging process. So,

Ko et al.(2014) proposed the use of chemical vapor

deposition (CVD) technology to prepare porous GO

with silicon skeleton as an anode material for the LIB,

which significantly improved the cycle stability. The

material was tested to maintain an average capacity

of 1103 mAh/g after 1000 cycles with a Coulombic

efficiency of up to 92.5% on the first cycle. However,

CVD technology is expensive and not suitable for

large-scale industrialization.

Electrostatic spinning technology, on the other

hand, offers a simple and economical method of

preparing carbon fibres. As a result, silicon is often

embedded in carbon fibers as an anode material for

LIB. Gómez-cámer et al. (2011) utilized a SiO

x

layer

to strengthen the bonding of SiNPs to the CNFs

surface, which significantly enhanced the ion and

electron transport efficiency. However, this anode’s

capacity decayed from 2500 to 500 mAh/g after 500

cycles, due to excessive SEI formation and poor

stability. Ji et al. (2009), on the other hand, attempted

to convert the polyacrylonitrile/SiNPs solution into

SiNPs-embedded CNFs composites by

electrospinning, but the cycling stability dropped to

0.5 mAh/g, 51% of initial after 50 cycles, showing the

inadequacy of this method in suppressing the

generation of unstable SEI layers. Dirican et al.

(2015) went on to enhance the cycling stability by

depositing amorphous carbon on SiNPs-embedded

CNFs using the CVD method. However, the

aggregation of SiNPs and the problem of carbon fiber

fracture due to silicon swelling remain key challenges

to be addressed in this field.

Despite the high specific capacity and relatively

mature process of silicon-carbon composite

structures, their industrial production and cycling

performance still need to be further improved.

2.4 Yolk-Shell Structure Anode

While depositing SiNPs on the outer layer of carbon

materials can significantly improve the anode's

performance, the research on improving the LIB

anode's efficiency shows that each charge/discharge's

efficiency falls short of more than 99%. The reason

for this is that during the cycling process, a portion of

the silicon particles is near the fluid, causing the

particles to grow and shrink with each charge and

discharge. This prevents the SEI film from existing

steadily and causes it to be continually destroyed and

regrown. Therefore, the core-shell structure was born.

Despite the conventional core-shell design utilizing

silicon as the core with a carbon shell coating, it lacks

a buffer zone for silicon's volume expansion.

Consequently, researchers have innovated by

adopting a yolk-shell architecture, where silicon

serves as the yolk and carbon as the shell. This

approach introduces a gap between the carbon shell

and silicon particles, allowing for unconstrained

expansion and contraction of silicon while preventing

damage to the carbon shell due to volume variations

in the silicon particles. The anode designed by Liu et

al. (2012) is similar, which is shown in Figure 2. After

testing, yolk-shell anode demonstrated initial

capacity of 2800 mAh/g, retaining 74% (1500

mAh/g) after 1000 cycles, achieving 99.8%

Coulombic efficiency.

Figure 2: Structure of the yolk-shell type anode (Dirican et

al., 2015).

Liu et al. (2014) further optimized the previous

yolk-shell design in a follow-up study by adopting a

pomegranate-like layered architecture. This structure

featured SiNPs in a conducting carbon coating in a

yolk-shell-like configuration, and the entire structure

was encased in a thicker carbon shell at the micron

level. The strength of the SEI layer is increased by the

thicker carbon shell, which also has a significant

impact on the conductivity of electrons and Li

+

.

Durability testing revealed a capacity retention rate of

Improvements in the Performance of Silicon-Based Anode Materials for Lithium-Ion Batteries

221

97% and a Coulombic efficiency of 99.8% after 1000

cycles.

Yu et al. (2024), on the other hand, proposed a

Si@Void@FC (fiber carbon) composite structure.

This material simplifies the preparation process

through a one-step synthesis method and cleverly

combines a void yolk-shell structure with a

mesoporous carbon shell, which can exhibit excellent

cycling stability and outstanding rate performance,

and even after 500 cycles, the structure remained

intact without significant performance degradation.

This is so that excessive contact with the electrolyte

is avoided and the volume growth of silicon while

cycling is efficiently inhibited by the protective

coating that is the outside carbon shell. In addition,

the unique mesoporous structure significantly

improves the diffusion efficiency of Li

+

, which in turn

enhances the lithiation and de-lithiation ability of the

material.

In addition, Liu et al. (2024) pioneered the

concept of fluoride ion-modified yolk-shell-type

carbon-silicon anode materials. Through the

interfacial modification of fluoride ions, fluoride

components such as LiF were enriched in the SEI

membrane, which in turn significantly enhanced its

cycling stability. Experiments revealed that the F-

Si@Void@C anode can maintain a reversible

capacity of up to 1166 mAh/g after 900 cycles at a

current density of 0.5 A/g.

Although the yolk-shell structure is effective in

resolving the volume variation of Si anode throughout

charging and discharging, and it also enhances

Coulombic efficiency. However, the cost is still high,

and the preparation method can be subsequently

improved to achieve cost reduction.

3 OUTLOOK OF ANODE

MATERIALS FOR LIBS

In summary, the improvement technology of silicon-

based anode materials for LIBs has made rapid

development in the past few years, which effectively

solves the problem of volume variation of silicon-

based anodes when battery charging and discharging,

and improves the cycle life based on ensuring the

specific capacity. Therefore, with continuous

research, more and more novel improvement methods

of silicon-based anode will be discovered and

reported.

However, compared with other anode materials

for LIBs, Si-based anode has the problem of high

preparation cost. Therefore, designing more cost-

effective and environmentally friendly ways to

reduce costs while also enhancing the service life of

Si-based anode in accordance with the current

preparation process is unquestionably the direction of

key development for the future. Since silicon-based

anode materials are still in their infancy when

compared to graphite and other commercially

accessible anode materials, improving their cycle

stability, specific capacity, and cost reduction is

crucial for meeting the need for high-capacity LIBs in

the future.

4 CONCLUSION

In this paper, the modification methods of silicon

anode are summarized through a systematic review.

Firstly, in the nanosilicon anode, the diffusion time

was effectively reduced by shortening the diffusion

length, which significantly enhanced the power

density. Additionally, the small particle size particles

enhanced the mechanical strain adaptability and

successfully stopped the silicon volume expansion-

related mechanical failure. However, the capacity

degradation of silicon nanostructures remains to be

solved, mainly stemming from factors such as SEI

film formation, poor electrical contacts, and nano-

agglomeration. In order to address these challenges,

researchers have proposed combining silicon

nanostructures with other materials (carbon, metals)

to form anodes. Among them, silicon alloy anode can

slow down the volume expansion of silicon, but its

preparation process is complicated and costly.

Therefore, researchers have turned their attention to

compounding nanosilicon with carbon materials. The

carbon component of the silicon-carbon anode not

only acts as a barrier to stop the formation of unstable

SEI and as an effective transport channel for electrons

and Li

+

, but it also reduces silicon volume growth,

which is thought to be an exciting way to enhance the

performance of the silicon anode. On this basis,

researchers have proposed an improved method of

yolk-structured anode. In this anode, a carbon shell

layer acts as a barrier to form a void between the

silicon particles, allowing the silicon to expand and

contract freely without damaging the carbon shell.

Currently, there are still several issues to be

resolved. Firstly, the current cost of nanotechnology

is still high, and simple and economical preparation

methods are required to achieve nanoscale electrode

structures with excellent performance. Secondly, to

further explore theoretically how to enhance the

lithiation rate of silicon anodes in order to

manufacture LIB anode with improved performance,

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

222

an extensive comprehension of the kinetics of silicon

lithiation is required.

REFERENCES

Ding X, Wang Y 2020 2020 Electrochim. Acta 329 134975.

Dirican M, Yildiz O, Lu Y, Fang X, Jiang H, Kizil H, Zhang

X 2015 Electrochim. Acta 169 52-60.

Gómez-Cámer JL, Morales J, Sánchez L 2011 J. Mater.

Chem. 21 811-818.

Ji L, Zhang X 2009 Carbon 47 pp 3219-3226.

Ko M, Chae S, Jeong S, Oh P, Cho J 2014. ACS Nano 8

8591-8599.

Li Q, Yu M, Huang Y, Cai Z, Wang S, Ma Y, Song G, Yu

Z, Yang W, Wen C 2023 J. Electroanal. Chem. 944 p

117684.

Liu C, Wang Z, Wang Q, Bai J, Wang H, Liu X 2024 J.

Colloid Interf. Sci. 668 666-677.

Liu N, Lu Z, Zhao J, McDowell MT, Lee HW, Zhao W, Cui

Y 2014 Nat. Nanotechnol. 9 187-192.

Liu N, Wu H, McDowell MT, Yao Y, Wang C, Cui Y 2012

Nano Lett. 12 3315-3321.

Mukanova A, Nurpeissova A, Urazbayev A, Kim SS,

Myronov M, Bakenov Z 2017 Electrochim. Acta 258

800-806.

Omar N, Daowd M, Van Den Bossche P, Hegazy O,

Smekens J, Coosemans T, Van Mierlo J 2012 Energies

5 2952-2988.

Sudarman S, Taufik M 2024 Materials Science for Energy

Technologies 7 1-8.

Tian M, Ben L, Jin Z , Ji H, Yu H, Zhao W, Huang X 2021

Electrochim. Acta 396 139224.

Tzeng Y, Jhan CY, Chiu KM, Wu YC, Chen GY, Wang PS

2023 Mater. Today Chem. 30 101570.

Wu M, Cai G, Li Z, Ye L, Wang C 2024 Vacuum 225

113222.

Yu Y, Zhang Q, Teng N, Liu Y 2024 J. Alloy. Compd. 989

174423.

Zhang Y, Zhu C, Ma Z 2021 J. Alloy. Compd. 851 p

156854.

Improvements in the Performance of Silicon-Based Anode Materials for Lithium-Ion Batteries

223