Analysis of Technical Specifications and Application of

Pumped-Storage Hydro Power

Juncheng Qian

College of Environmental Engineering, China University of Petroleum, Beijing, 100100, China

Keywords: Pumped Storage Hydropower, Hydro Power, Sustainable Development, Environment Protection.

Abstract: As an important form of hydroelectric energy storage, pumped storage plays a crucial role in

balancing grid demand and promoting renewable energy integration. Its energy density and

efficiency are significant indicators for measuring project effectiveness, yet these values are often

lower than theoretical expectations due to various influencing factors. Nonetheless, through

optimized management and technological upgrades, the energy utilization rate and lifespan of

pumped storage power stations can be significantly improved. The application practices in China

and the United States in the field of pumped storage indicate that this technology possesses long-

term stability and high efficiency, which is of great significance for the sustainable development

of power systems. The construction of pumped storage power stations requires thorough

consideration of geographical elevation differences and reservoir capacity to achieve optimal

energy storage performance. At the same time, the lifespan management and maintenance of

facilities are equally important, especially in the inspection and replacement of critical components

such as turbine rotor blades. Through regular maintenance and interventions, the service life of

power stations can be extended, enhancing their economic benefits and performance. In the future,

with technological advancements and experience accumulation, the energy density, efficiency, and

lifespan of pumped storage power stations are expected to be further improved. Simultaneously, it

is necessary to strengthen research and assessment of their environmental impacts to ensure they

play a greater role in sustainable development. In conclusion, pumped storage is an efficient,

reliable, and environmentally friendly energy storage technology, deserving wider application and

in-depth research in power systems.

1 INTRODUCTION

Pumped Storage Hydroelectricity (PSH) or Pumped

Storage Hydroelectric Power Stations (PHES) is a

crucial form of hydroelectric energy storage for

balancing grid demand (Rehman et al, 2015). As the

largest-scale energy storage technology currently

available, PSH holds a pivotal position in power

systems due to its clean and pollution-free nature. It

not only excels in peak shaving, frequency and phase

modulation, and spinning reserve, but also plays a key

role in optimizing the utilization efficiency of new

energy in power systems, thereby enhancing the

overall benefits of power generation. PHES, as a

special type of hydropower station, stores energy by

pumping water from a lower to a higher elevation

using pumps, and releases this energy to generate

electricity during peak power demand. When the grid

load is low, it converts excess electric energy into

water potential energy for storage; during peak load

periods, this potential energy is converted back into

electric energy to supply the grid, effectively storing

and redistributing electricity over time. This process

effectively regulates the dynamic balance between

energy production, supply, and consumption, making

it the most mature, reliable, economical, largest-

capacity, and longest-lifespan energy storage solution

in current power systems.

As the largest and most widely distributed energy

storage method, PSH plays a crucial role in enhancing

grid reliability, improving energy security, and

promoting the integration of renewable energy. Its

ability to efficiently store and regenerate energy

makes it a crucial component in the transition to a

190

Qian, J.

Analysis of Technical Specifications and Application of Pumped-Storage Hydro Power.

DOI: 10.5220/0013873300004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 190-196

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

more sustainable energy mix, helping to mitigate

volatility and ensure the stability of grids heavily

dependent on intermittent renewable energy sources

such as wind and solar (Erixno et al, 2022).

The history of PSH development dates back to the

late 19th century, when the world's first PSH was

built in Switzerland. In the 1960s to 1980s, with the

growth of energy demand and the development of the

power industry, PSH construction entered a golden

period of booming development, especially in

developed countries and regions such as the United

States, Western Europe, and Japan. However, after

entering the 21st century, with the slowdown in

economic growth and the rise of new energy sources,

the development of PSH stations has slowed down

somewhat. In recent years, however, with the

adjustment of global energy structures and the

demand for clean and low-carbon transitions, PSH

stations have regained attention due to their unique

flexible regulation characteristics, becoming an

important means to ensure the stability of new energy

generation and ushering in new development

opportunities.

This paper investigates several technical

indicators of PSH and identifies a lack of effective

recording of energy density in PSH projects. It

proposes suggestions to improve the construction cost

and efficiency of PSH facilities, demonstrating the

superiority of PSH as a well-tested energy storage

method. Through quantitative analysis of PSH

technology indicators (energy density, energy

efficiency, equipment service life), analysis of

practical cases in China and the United States, and

comparison of actual data with theoretically

calculated data, this paper conducts research on PSH

technology.

2 THE OPERATING PRINCIPLE

AND TECHNICAL

INDICATORS OF PUMPED

STORAGE

2.1 The Operating Principle and

Components of Pumped Storage

The pumped storage system consists of two

reservoirs at different elevations. When water

flows from one reservoir to an

other (water

discharge), it passes through turbines to generate

electricity, converting its stored gravitational

potential energy into electrical energy to meet

corresponding power demands (Emmanouil et al,

2021). During periods of high electricity demand,

when both electricity prices and demand are high, the

stored water is released and converted into electricity

through turbines (Hossain et al, 2020, Kucukali,

2014, Zhang et al, 2022)This process allows for a

rapid response to fluctuations in energy demand and

supply, making it a valuable tool for managing grid

stability.

A typical pumped storage system includes the

following components: upstream and downstream

reservoirs (some projects may choose multi-level

reservoirs), an upper reservoir which is usually a

reservoir at a higher elevation or an artificially

constructed water storage tank used to store pumped

water during low grid load periods for power

generation during peak load periods; and a lower

reservoir, typically a river, lake, or sea area at a lower

elevation, serving as a source of water for power

generation and also meeting the need for water during

pumping. The system also includes pump units for

pumping water from the downstream reservoir to the

upstream reservoir, large generator sets for power

generation at the upstream reservoir, and turbine units

for converting gravitational potential energy into

mechanical energy. The mechanical energy is then

converted into electrical energy through hydraulic

turbines pushing generator blades. Additionally, the

system may include structures such as flood gates and

gratings to ensure safe and stable operation.

2.2 Types of Pumped Storage

Hydroelectric (PSH) Systems

Research on the distribution characteristics of MPs

usually covers several dimensions such as polymer

type, size, abundance, and color. Most studies show

that MPs in mangrove ecosystem sediments are

mainly polyethylene (PE) and polypropylene (PP). In

the mangroves of Sanya, Hainan, the main polymers

are PP (42.10%) and PET (37.14%). In Colombia, PS

is the main polymer, while in Guangdong, China and

Singapore, PE and PP are the predominant polymers.

The primary reason for the differences in polymer

types is the variation in plastic elements . In Sanya,

Hainan, the extensive use of textile fiber for fishing

has resulted to a high local PET content. Regarding

size, more than half of the MPs in Sanya, Hainan are

large-sized MPs (1–5 mm), while more than 90% of

the MPs in Singapore’s mangroves are less than

1mm9. The main reasons for this difference are

differences in seawater flow and ocean current

patterns in Sanya, as well as the substantial amount of

plastic debris from local tourism that has not been

Analysis of Technical Specifications and Application of Pumped-Storage Hydro Power

191

degraded in time. In terms of abundance, the

abundance of MPs in Sanya, Hainan is 67–228

items/kg, higher than 12.0–62.7 items/kg in

Singapore. The interception effect of artificial forests

is superior than that of natural forests, which is one of

the reasons for the higher abundance in Sanya. In

terms of color, white (transparent) MPs accounts for

the largest proportion in global mangrove research,

and in Sanya, Hainan, this proportion is as high as

89.04%. This is related to the large use of white

plastic products and the fading of MPs during the

diffusion process.

2.3 Technical Indicators and

Calculation Formulas

2.3.1 Energy Density

Energy density refers to the amount of energy

stored

within a given volume or mass of a substance,

commonly used to measure the energy contained in a

unit volume or unit mass of a material. In the context

of pumped storage hydropower, energy density,

under an ideal model that neglects frictional

resistance and various energy losses associated with

Bernoulli's equation, can be simply understood as the

total gravitational potential energy possessed by the

upper reservoir divided by its total volume. However,

in practical engineering applications, due to

inevitable losses, the actual energy density will be

significantly lower than the theoretically calculated

value.

To calculate the energy density of a pumped

storage hydropower plant, this study first needs to

determine the hydropower potential P(W) and the

corresponding reservoir volume V. Based on the

given formulas and tabular data, the following

calculations can be performed.

Firstly, this study assumes that H1 and H2 are

transformed into a low-head pumped storage

hydropower system (LCHES), where H1 represents

the upper reservoir and H2 represents the lower

reservoir. This study will utilize the data from H1 to

calculate the energy density, as it possesses regulating

capacity and a larger reservoir volume (Zhang et al,

2022).From Table1, the paper acquires the following

data: Forebay water level range: [691 m, 745 m]

Regulating reservoir Volume: V = 20.37 × 108 m³

Installed capacity: 1040 MW

To simplify the calculations, this study selects an

average flow rate Q, which is typically determined

based on actual flow data or design flow. In this

instance, a h

ypothetical value of Q = 10000 m³/s is

used, as it closely approximates the average flow rate

of a large hydropower station in the western region of

China.

Subsequently, this paper employs Equation (1) to

calculate P(W):

P(W) = Q × H × g × η × ρ (1)

Here , g = 9.81 m/s² , η = 0.8 ( 80%

efficiency),ρ = 1000 kg/m³,Q represents

the average runoff, and H denotes the head

difference between the upper and lower

reservoirs, which is simplified as their height

difference.

P(W) = 10000 m³/s × 54 m × 9.81 m/s² × 0.8 ×

1000 kg/m³

P(W) = 42,391,20000 W = 4239.12 MW

Now, this paper utilizes Equation (2) to

calculate the energy density P:

V

WP

P

)(

=

(2)

P = 0.0208 W/m³

It should be noted that this is a simplified

calculation based on the average flow rate Q and

known data. In practical applications, the flow

rate Q typically needs to be determined based on

actual measurements or design data.

Additionally, this calculation assumes that all

energy can be effectively stored and converted,

but in reality, due to various losses such as

friction and leakage, the actual efficiency will be

lower than the theoretical value.

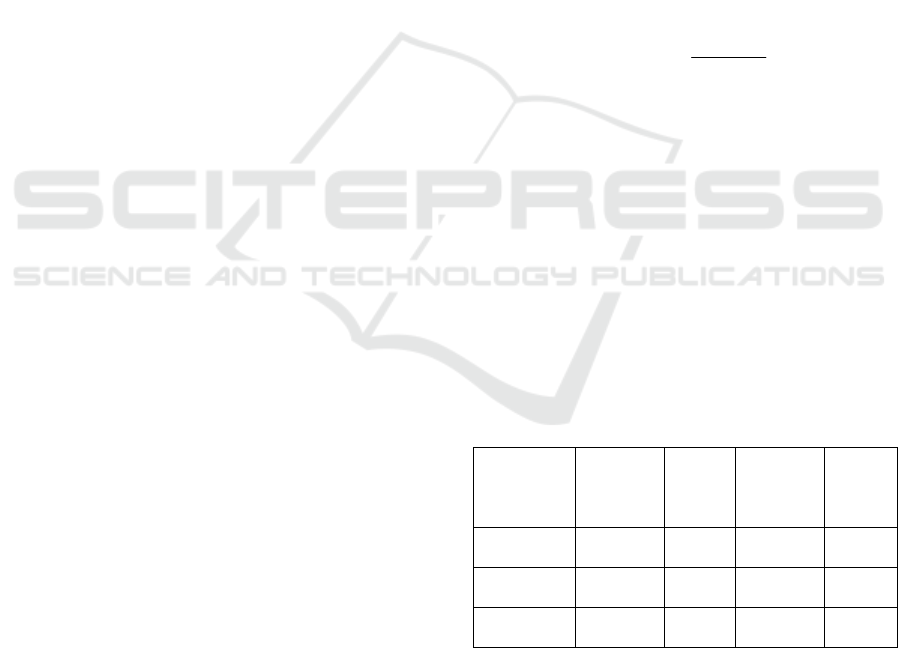

Table 1. Basic characteristics of the cascade hydropower

stations.

Hydropower

Station

Regulation

ability

Forebay

water

level

range

Regulating

reservoir

Volume

Installed

capacity

H1 Multi-year [691 m,

745 m]

20.37 × 10

8

m

3

1040

MW

H2 Daily [580 m,

585 m]

0.31 × 10

8

m

3

558 MW

H3 Daily [483 m,

490 m]

1.44 × 10

8

m

3

880 MW

2.3.2 Energy Efficiency

During the pumping phase, the sequence of energy

conversion is from electrical energy to mechanical

energy and then to gravitational potential energy. In

the generation phase, the sequence is reversed, with

gravitational potential energy converted into

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

192

mechanical energy and ultimately into electrical

energy. During this stage, water from the upper

reservoir passes through the pump-turbine to generate

mechanical energy, driving the generator to produce

power that is supplied to the grid. Conversely, during

the pumping phase, electrical power from the grid

drives an electric motor, converting it back to

mechanical energy, which is used to pump water from

the lower reservoir back to the upper reservoir for

storage, via various systems.

Generally, the overall efficiency of the power

station and the combined efficiency of the unit

can be calculated using Equations (3) and (4),

respectively:

Overall efficiency:

A

= %100

energy grid-Off

energy grid-On

× (3)

Comprehensive efficiency:

B=

%100

waterpumpingUnit

capacityUnit

× (4)

Taking an energy storage power station in China

as an example, the actual electricity that the unit

should generate is 1304.37 million kWh, and the

electricity that the power station should deliver to the

grid is 1,292.47 million kWh (Liu et al, 2023).

Therefore, the actual combined efficiency of the unit

(ηg) is 83.60%, and the actual overall efficiency of

the power station (ηS) is 82.1%. As a result, when the

conversion efficiency is only 75%-80%, the energy

can typically be increased to over 80%.

2.3.3 Estimated Durability

During quantitative analysis, factors highly correlated

with human intervention should be disregarded.

Based on this principle, the service life of a typical

pumped storage hydropower station (PSHs) primarily

depends on two factors: the service life of the

hydraulic turbine and the durability of the generator

set. Since this project is also based on a hydraulic

turbine, the calculation of the expected life of the

turbine is equivalent to the service life of the pumped

storage hydropower station. Considering a turbine

rotor blade with an angular crack, the crack

propagates along the interface between the blade and

the crown, originating from the outlet edge of the

blade's pressure side. Table 2 provides relevant

technical parameters of the turbine rotor, and Table 3

presents the initial data for this evaluation.

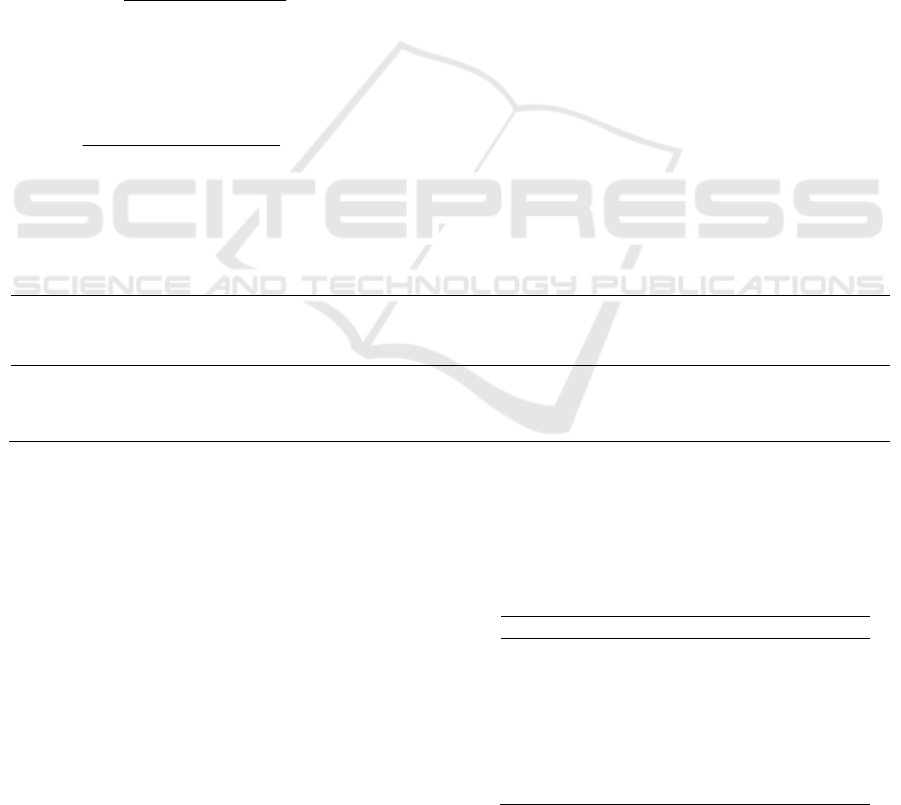

Table 2. Related factors of the turbine

Paramet

er

Output,

MW

Flow

rate,

m

3

/s

Net

head, m

Rotation

al speed,

rpm

Runner

diamete

r, m

Z

b,

pcs Z

g,

pcs Fr, hz f

Rst

, hz

R1 240 254 96 125 5.5 14 24 2.08 50

R2 255 285 100 125 5.58 15 24 2.08 50

R3 245 315 86 125 5.5 16 20 2.08 41.7

Under the influence of high-frequency loads, the

point at which the crack begins to propagate rapidly

corresponds to a crack length of 44.4 mm. The critical

crack length, indicating imminent failure of the rotor

blade, is 87.3 mm.

In this example, the allowable increase in crack

length from the onset of rapid crack growth to the

point of blade failure is approximately 42.9 mm. This

equates to approximately 9.33 × 108 loading cycles at

the RSI frequency, or approximately 6230 hours

(roughly one year) of operational time. In contrast,

under the influence of low-frequency loads, it takes

approximately 71,000 hours (about ten years) for the

crack to grow from its initial defect size of 3 mm to

44.4 mm. Notably, until the crack reaches a length of

44.4 mm, its growth is gradual, allowing for detection

and repair during scheduled maintenance intervals

(Georgievskaia, 2019). In summary, the lifespan of a

PSH system without any maintenance should be at

least 10 years.

Table 3. Initial data for the assessment

Parameter Value

Kth, MPa·

√m

2

KC, MPa·

√

m 80

Static stress value at design point

without crack, MPa

150

Amplitude of dynamic stress intensi

ty at design point

without crack, MPa

9.1

Residual stress, MPa 100

Analysis of Technical Specifications and Application of Pumped-Storage Hydro Power

193

3 ACTUAL APPLICATION IN

CHINA AND US

3.1 Actual Application in China

Based on its energy storage principle, the energy

storage capacity of pumped storage hydropower

(PSH) is primarily proportional to the height

difference and reservoir capacity between the two

reservoirs. Due to the relatively minimal losses from

water evaporation or infiltration, PSH systems exhibit

a wide range of energy storage periods, ranging from

a few hours to several years. Considering additional

mechanical and transmission losses, the round-trip

efficiency of PSH systems lies between 70% and

80%, and the expected service life is approximately

40 to 60 years, depending on the scale and design of

each PSH plant (Qiang et al, 2023).

When comparing comprehensive nationwide

statistical data with theoretical calculations, it was

found that energy density varies among reservoirs and

is often unrecorded in most projects. However, in

terms of energy efficiency, the theoretical

calculations closely align with actual conditions,

demonstrating the simplicity yet effectiveness of the

formula. In China, the actual expected lifespan of

PSH systems exceeds 40 years. As mentioned in the

previous chapter, this formula overlooks all human

intervention factors. The ideal calculation represents

only the minimum lifespan of a PSH system.

This implies that while the formula provides a

basic, theoretical estimate of lifespan, the actual

lifespan may be longer due to positive impacts from

factors such as human intervention and maintenance.

Therefore, in practical applications, regular

maintenance and inspections can further extend the

service life of PSH systems.

3.2 Actual Application in the US

The Taum Sauk Pumped Storage Hydropower

Station, located in Missouri, USA, is a high-head

pumped storage power plant constructed in 1963 with

a capacity of 350 MW. In 1995, the station underwent

an upgrade and retrofit to enhance its performance

and efficiency. The objective of the retrofit was to

significantly improve the plant's operational

efficiency and reduce the time required from cold

start to full load operation (Du, 2004).

To achieve these objectives, the design team

enhanced the capabilities of the turbines and pumps

without replacing the generators. During the retrofit,

the team evaluated various rotor designs and

ultimately selected a solution that effectively

addressed leakage issues. Additionally, updates to the

rotor's blade and structural design significantly

improved the turbine's hydraulic performance and

extended the expected service life. These

improvements not only increased the plant's output by

90 MW, but also achieved a cost significantly lower

than installing new gas-fired generators. Post-retrofit,

the plant experienced significant improvements in

operational frequency and efficiency, maintaining a

high availability and successful start-up rate for

several years (Du, 2004).

Concurrently, the retrofit of the Taum Sauk

Pumped Storage Hydropower Station underscores the

importance of technological upgrades and retrofits for

PSH (pumped storage hydropower) systems. By

updating equipment and technology, PSH systems

can extend their service life, improve energy

efficiency, and increase energy density, thereby

enhancing their economic benefits and application

potential in the renewable energy sector. Although

US projects may lag behind in efficiency compared to

Chinese PSH projects, the retrofit case of Taum Sauk

provides valuable experience and insights for the

development of PSH systems.

The retrofit case of the Taum Sauk Pumped

Storage Hydropower Station exemplifies the crucial

role of technological upgrades and retrofits in

enhancing the performance and energy efficiency of

PSH systems. By improving equipment and

technology, the station has achieved efficient and

reliable operation, providing valuable reference for

the development of PSH systems. While PSH systems

may have lower energy density compared to other

energy storage methods, continuous technological

innovation and optimization will ensure that PSH

systems continue to play a significant role in the

renewable energy sector.

4 SUGGESTIONS FOR THE

FUTURE DEVELOPMENT OF

PUMPED STORAGE

HYDROELECTRICITY

During the research process, the author believes that

pumped storage hydropower primarily faces issues

such as low energy density, relatively large energy

losses during conversion, slow conversion speed, and

sluggish response. The proposed solutions are as

follows:

(1) In future engineering applications, pumped

storage hydropower can select geographical locations

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

194

with a greater relative elevation difference for

planning. In regions with abundant water resources

but difficult to construct, such as karst landscapes, it

is possible to explore the utilization of naturally

existing water bodies to build open-type pumped

storage hydropower systems. The parallel connection

of more generator sets can significantly enhance

energy storage density.

(2) Pumped storage hydropower can be integrated

with a wide range of renewable energy systems to

build a comprehensive green energy system. Green

energy sources such as hydropower, wind power, and

solar power all exhibit significant diurnal and annual

fluctuations. As a well-tested energy storage

technology, pumped storage hydropower can store

excess energy produced during high-production

seasons of these technologies. As an essential energy

storage facility in the power system, pumped storage

hydropower plants play a crucial role in peak shaving,

valley filling, and optimizing resource allocation.

Improving their energy conversion efficiency is

crucial, as it directly affects the economic and

environmental performance of the power stations. To

address this issue, the introduction of more efficient

turbines and generator sets is the most significant

solution, while more rational hydraulic design can

also contribute to reducing energy losses to a certain

extent.

(3) Additionally, pumped storage hydropower

plants require higher flexibility and response speed.

To achieve this, the introduction of intelligent

monitoring and automated control systems becomes

essential. These systems can monitor the real-time

operating status of the power plants and automatically

adjust operating strategies based on grid demand,

ensuring the stability and reliability of power supply.

5 CONCLUSION

This study analyzes and calculates the theoretical

calculation model of technical indicators related to

pumped storage hydropower (PSH) technology and

its practical applications in China and the United

States. The typical energy conversion efficiency of

PSH technology is approximately 80%, with an

energy density mostly less than 1W/m³. The service

life of its facilities is around 40 years, and with proper

maintenance and upgrades, they can have an even

longer lifespan. PSH technology is widely used due

to its long facility lifespan, reliable operation, and

relatively simple maintenance. However, its energy

density and energy conversion efficiency are

relatively low. Among the existing facilities in China

and the United States, Chinese PSH facilities tend to

have higher energy conversion efficiency due to their

newer construction and the adoption of more efficient

turbine units and generators. In terms of service life,

many PSH units built in the early stages in the United

States have reached their design life, but after mid-

life extension and upgrades, they can continue to

operate.

For the future application of PSH technology, it is

necessary to select more suitable locations, which can

be combined with the development of land

consolidation technology in recent years. Building

PSH facilities in regions such as karst landforms,

where construction was difficult in the past but have

significant topographic drops and abundant

hydropower resources, can significantly increase

energy density. At the same time, selectively

replacing older turbine units and generators for some

older PSH facilities and systemizing their

maintenance work can result in higher facility

lifespan and energy conversion efficiency.

This study fills the gap in the comparison of

quantitative indicator data between related projects in

China and the United States in PSH research,

providing a reference for subsequent cross-country

comparisons of similar energy storage technologies.

This research will be beneficial for researchers in new

energy and energy storage technologies who require

quantitative calculation formulas and specific data for

studying PSH. But this study focuses on providing

relatively simple quantitative calculations, thus

ignoring the influence of some hydraulic

characteristics on turbine units, resulting in larger

errors in the calculated energy density under small

runoff or some extreme conditions. In subsequent

research, more variables will be introduced to provide

a more accurate calculation method or relevant

correction coefficients.

REFERENCES

Du Q 2004 Int. J. Electr. Power Energy Syst. 06 32

Emmanouil S, Nikolopoulos E I, François B, Brown C, and

Anagnostou E N 2021 Energy 226 120354

Erixno O, Rahim N A, Ramadhani F and Adzman N N 2022

J. Sustain. Energy Techn. 51 101944

Georgievskaia E 2019 J. Eng. Fail Anal. 105 1296–1305

Hossain E, Faruque H M R, Sunny M S H, Mohammad N,

and Nawar N 2020 Energies 13 3651

Kucukali S 2014 J.Rser. 5 52

Liu F, Che Y, Tian X, Xu D, Zhou H, and Li Z 2023 J.

Shanghai Jiaotong U. 57 757–768

Qiang S, Weiqiang Z, Jishi G, Jianjun H, Yuliang Z, Chao

L, and Yuxiang L 2023 Int. J. Coal Geol. 51 18

Analysis of Technical Specifications and Application of Pumped-Storage Hydro Power

195

Rehman S, Al-Hadhrami L M and Alam M 2015 J. Rser. 44

586–598

Zhang J, Cheng C, Shen Y, Shen J, Wu X and Su H 2022

J.Energy 260 125163–125165.

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

196