Analysis on the Status of Compressed Air Energy Storage (CAES) in

China and Future Development Trends

Wenchu Wang

*

Environmental Engineering, Dalian Maritime University, Dalian, Liaoning Province, 116000, China

*

Keywords: "Dual Carbon" Goals, Compressed Air Energy Storage, New Energy Storage Technologies.

Abstract: To achieve the ambitious goals of carbon peaking and carbon neutrality, China is vigorously developing

renewable energy sources to replace the combustion of fossil fuels. Concurrently, in recent years, China has

also been intensively developing new energy storage technologies to mitigate the fluctuations caused by the

integration of renewable energy into the grid. Among these new energy storage technologies, the development

of Compressed Air Energy Storage (CAES) technology stands out. Although relatively mature, CAES has not

yet been widely applied, presenting significant research potential. This article will start by comparing CAES

technology with traditional Pumped Hydro Energy Storage (PHES) to analyze the advantages of CAES. It

will then systematically examine various types of CAES technologies, predicting the future development

trends of this technology in China based on the status. The analysis concludes that CAES is the most promising

new energy storage technology in China. In the future, it is expected to achieve performance comparable to

pumped hydro storage, enabling large-scale applications across diverse scenarios.

1 INTRODUCTION

With the development of society, people's standard of

living is continuously improving, leading to an

increase in energy demand. Currently, the

combustion of fossil fuels remains the primary means

of energy acquisition in China, leading to a

continuous increase in atmospheric greenhouse gas

concentrations and carbon emissions. In 2020, China

officially proposed the "dual carbon" goals of peaking

carbon emissions by 2030 and achieving carbon

neutrality by 2060. This objective has significantly

accelerated the development of renewable energy. In

recent years, China has vigorously developed

renewable energy sources such as wind and

photovoltaic power. However, these energy sources

are characterized by volatility and randomness,

necessitating the integration of energy storage

technologies to mitigate issues arising from the

mismatch between power supply and demand (Wu et

al, 2001). Energy storage technologies enable the

large-scale and efficient utilization of renewable

energy, thereby promoting the transition to low-

carbon energy and sustainable development. In recent

years, China has been seeking low-cost, high-

*

Corresponding author

efficiency, and sustainable energy storage

technologies to support the future new power system.

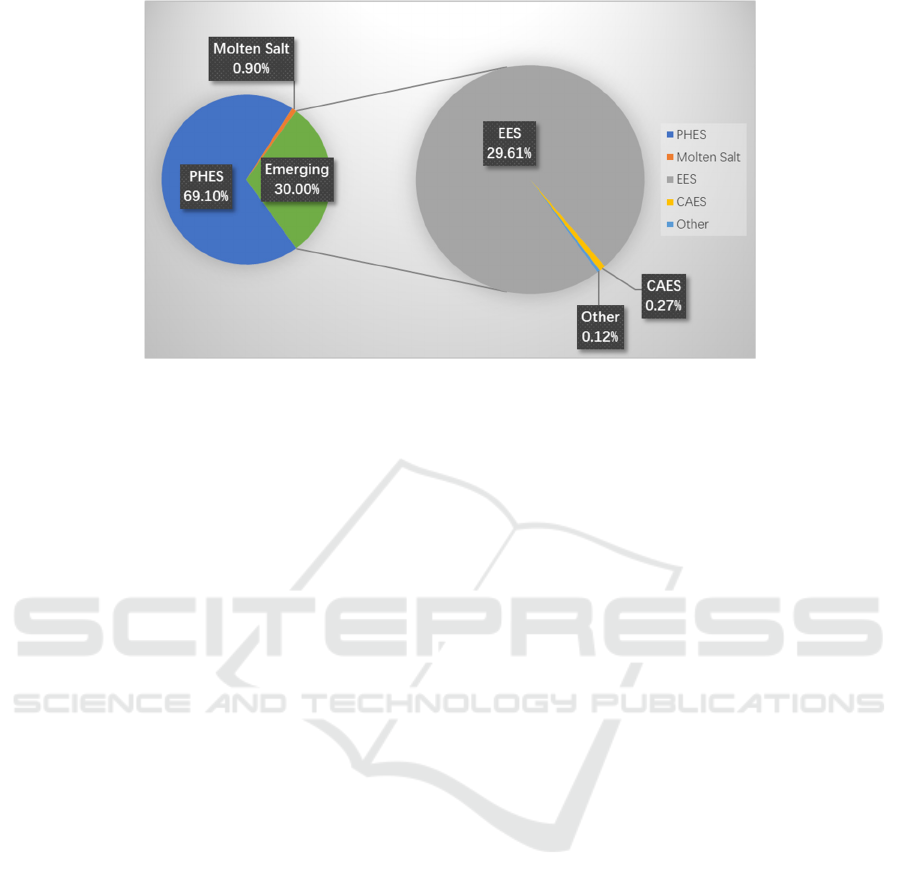

Energy storage systems can generally be divided

into two primary categories, traditional and novel.

Pumped Hydro Energy Storage (PHES), as an

efficient and widely used traditional energy storage

technology, holds the largest share of installed

capacity among energy storage technologies in China.

However, its construction and operation are

significantly influenced by terrain and water

conditions, and it has reached a bottleneck phase with

increasing development costs, indicating limited

future growth. In the realm of emerging energy

storage technologies, Electrochemical Energy

Storage (EES) currently holds the largest share.

Nonetheless, it remains immature and is constrained

by numerous factors such as the challenges of end-of-

life disposal and very high development costs,

making it far from ready for large-scale application.

CAES, the second most installed emerging

technology after electrochemical storage, has seen

rapid development in China in recent years and has

reached a relatively mature stage, as shown in figure

1. CAES boasts inherent advantages such as large

storage capacity, environmental friendliness, short

184

Wang, W.

Analysis on the Status of Compressed Air Energy Storage (CAES) in China and Future Development Trends.

DOI: 10.5220/0013872700004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 184-189

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

Figure 1: The cumulative installed capacity of operational energy storage projects in China (as of the end of June 2023)

construction periods, and long operational lifespan.

These attributes give it significant development

potential and the prospect of large-scale commercial

deployment in the future.

2 INTRODUCTION AND

COMPARISON OF RELEVANT

ENERGY STORAGE

TECHNOLOGIES

2.1 PHES

PHES is currently the most widely used and

technologically mature large-scale energy storage

technology in China. It has been established as a

traditional energy storage technology, with

significant utilization and development within the

country. The energy is converted in the form of

gravitational potential energy and electrical energy. A

pumped storage system mainly consists of two

reservoirs at different altitudes. During periods of low

electricity demand, excess electrical energy is used to

drive the pump motor units to transfer water from the

lower reservoir to the upper one. In this stage, energy

in the form of electricity is converted into the

potential energy of water. When the demand for

electricity rises, the stored water flows from a higher

elevation to a lower one, driving the generator to

produce electricity and converting potential energy

back into electrical energy. The earliest pumped

storage power plant in China was built in the 1960s.

As of 2021, the total capacity of PHES in China

reached 36.39 million kW (Li et al, 2023). According

to China's "Pumped Storage Medium and Long-term

Development Plan (2021-2035)," the total installed

capacity of pumped storage will exceed 62 million

kW by 2025 and reach 120 million kW by 2030 (Zhou

et al, 2023). The development of China's PHES

industry is expected to continue accelerating in the

future, with an average annual installed capacity

projected to exceed 6 million kW within the next

decade, tripling the current scale. In conclusion,

PHES is anticipated to remain the primary method of

energy storage in China in the future.

2.2 CAES

CAES, similar to pumped storage, falls under the

category of mechanical energy storage. However, it

represents a relatively mature form of new energy

storage technology. In China's array of new energy

storage technologies, its installed capacity ranks

second only to electrochemical energy storage, and it

has experienced rapid development in recent years.

The operational principle of CAES involves utilizing

surplus electrical energy to power compressors for air

compression, thereby converting it into the pressure

energy of compressed air. When there is a need for

electricity, the stored compressed air in tanks,

caverns, or other storage spaces is released to drive

turbines, generating electricity and thus transforming

the stored energy back into electrical energy. The

origin of CAES dates to the 1940s when German

engineer Stal Laval patented the concept of storing

electricity using air in underground storage chambers,

marking the advent of CAES technology. In China,

the development of CAES technology began

relatively late, only starting in the 21st century. The

10 MW compressed air energy storage power station

in Feicheng, Shandong Province, is the country's first

Analysis on the Status of Compressed Air Energy Storage (CAES) in China and Future Development Trends

185

grid-connected commercial CAES power station,

which successfully delivered power for the first time

on August 4, 2021. China possesses abundant natural

geological resources, such as salt caverns, which have

significant potential for utilization.

2.3 Comparison of PHES and CAES

PHES, as the earliest developed and most mature

technology, has numerous advantages including large

energy storage capacity, low operating costs, high

power output, and high efficiency. However, it also

has inherent disadvantages, such as a heavy reliance

on geographic conditions like significant elevation

differences. As the scale of construction expands, the

difficulty of development increases. Additionally,

pumped storage projects are expensive to build, have

long construction periods, and may cause

environmental pollution during construction. CAES,

in contrast, not only shares the advantages of large

storage capacity, high system efficiency, and long

storage duration, but also boasts lower construction

costs, shorter construction periods, and zero

pollution—advantages that pumped storage does not

have. However, both technologies share common

drawbacks, including slow start-up speeds and low

energy density, which are critical issues that need to

be addressed in the future. Table 1 shows the specific

data comparison between the two technologies.

Table 1: Comparison of CAES and PHES

Parameter PHES CAES

Energy Storage

Powe

r

(

MW

)

100-3000 50-500

Operational

Lifespan (a)

40-60 20-40

Efficiency (%) 70-85 40-55 (up to 70%

with heat recovery)

Cost ($/kWh) 0.05-0.15 0.10-0.20

Construction

Perio

d

(a)

4-10 2-5

Start-up Speed Minutes to

tens of

minutes

Minutes to tens of

minutes

Despite the advantages, pumped storage in China

has reached a period of bottleneck, making significant

breakthroughs difficult. In contrast, CAES is in a

rapid development phase, with the potential to

achieve cost parity with pumped storage and large-

scale commercialization in the future (Li et al, 2023).

To meet the “dual carbon” goal, China is expected

to implement a series of environmentally friendly

energy storage support policies, further promoting the

development of zero-pollution energy storage

technologies like CAES. CAES has enormous

potential for future development and is highly

valuable for research and development.

3 THE CLASSIFICATION OF

CAES

3.1 Classified by Storage Capacity

CAES can be classified based on storage capacity into

large-scale CAES systems, small-scale CAES

systems, and micro CAES systems (Zhang et al,

2023). Large-scale CAES systems typically operate

at the 100 MW level, offering the greatest peak

shaving capabilities and the largest scale. These

systems are usually integrated with sustainable

energy, for instance, photovoltaic power generation,

hydrogen, and wind power. Because of their reliance

on natural spaces like caverns and mines for air

storage, large-scale CAES systems are often

constrained by geographical location. Small-scale

and micro CAES systems, on the other hand, utilize

artificial high-pressure containers, such as high-

pressure storage tanks, for air storage. Small-scale

CAES systems, with power capacities around 10

MW, can couple with renewable energy sources like

wind energy, offering high flexibility without the

need for additional generators (Tan et al, 2019).

These systems are suitable for residential areas and

small grids. Micro CAES systems have power

capacities three orders of magnitude lower than

small-scale systems, with weaker power generation

capabilities and smaller air storage spaces. However,

they offer greater flexibility and ease of installation

and removal, making them ideal for home backup

energy or vehicle-mounted systems.

3.2 Classified by Idealized Change of

State

3.2.1

Diabatic Compressed Air Energy

Storage

(D-CAES)

D-CAES, also known as traditional compressed air

energy storage, improves compression efficiency

through inter-stage cooling during the gas

compression process. In the energy release process,

external heat sources or fossil fuel combustion are

used to heat the air, driving the expansion turbine.

The combustion heat increases the air temperature,

enhancing the enthalpy of the compressed air and its

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

186

work capacity, thereby improving cycle efficiency

(Zhang et al, 2023). Due to significant heat

dissipation to the environment, the cycle efficiency of

D-CAES typically reaches only about 40%.

3.2.2 Adiabatic Compressed Air Energy

Storage (A-CAES) & Advanced

Adiabatic Compressed Air Energy

Storage (AA-CAES)

A-CAES addresses the low efficiency of D-CAES to

some extent by storing the heat generated during air

compression in thermal storage devices, which is

subsequently utilized to raise the heat of the

compressed air in the energy discharge phase. This

technique does not require burning fossil fuels,

making it clean and environmentally friendly.

Although the construction costs are higher, the cycle

efficiency is significantly improved, reaching 55% to

75% (Wu et al, 2023). AA-CAES is a further

advancement of A-CAES, involving more advanced

technologies and system designs. As an "upgraded

version" of A-CAES, AA-CAES can achieve even

higher efficiency.

3.2.3 Isothermal Compressed Air Energy

Storage (I-CAES)

I-CAES is a new type of energy storage that maintains

the air temperature within a specific range during the

compression and expansion processes using

specialized temperature control methods (He & Sun,

2022). According to thermodynamic theory,

isothermal compression consumes the least

compression work, while isothermal expansion

produces the most expansion work (Dib et al, 2021).

I-CAES systems generally use liquids with high

specific heat capacity, such as water or oil, to provide

a nearly constant temperature environment. This

increases the contact time between the gas and the

liquid, ensuring that the gas approaches isothermal

conditions during compression, thereby minimizing

heat loss and improving the overall cycle efficiency

(Wu et al, 2023). Although the theoretical efficiency

can reach up to 90%, achieving this in practical

designs is challenging. The development costs are

high, and the technology is still at a low level of

maturity.

3.3 Other Emerging Technologies of

CAES

In recent years, to achieve green energy storage and

the dual carbon goals, China has innovated and

derived several new technologies in the CAES field.

The main advancements include Liquid Air Energy

Storage (LAES) and Supercritical Compressed Air

Energy Storage (SC-CAES).

3.3.1 LAES

LAES is a thermomechanical energy storage

technology that uses electrical or renewable energy to

compress purified air to high pressure. The

compressed air is then cooled and liquefied by

passing through a cryogenic storage unit, storing the

excess energy in the form of low-temperature liquid

air. During the energy release phase, the liquid air is

pressurized by a cryogenic pump and then re-gasified

by extracting cold from the storage unit. Driven by

heated high-pressure gas, the turbine functions and

produces electricity. Liquid gas possesses a higher

density compared to compressed gas, providing

LAES with higher energy storage density and

efficiency (Xu, 2023). Additionally, the high density

means that a large amount of storage space is saved,

indirectly reducing dependence on specific

geological conditions such as underground salt

caverns and mines.

3.3.2 SC-CAES

SC-CAES is a technology first proposed by Chinese

researchers. SC-CAES fully utilizes the properties of

supercritical fluids. This type of fluid has excellent

heat conversion capabilities and its molecules are

packed very tightly. At the same time, it also

possesses high solubility, as well as low viscosity,

high diffusion coefficient, and good permeability of

supercritical gases. The operating principle is as

follows: During the energy storage phase, the air,

after processing, is at a supercritical condition.

(temperature > 132K, pressure > 37.9 bar) (Xu,

2023). The heat of compression is transferred using a

thermal storage heat exchanger, cooling the air to

ambient temperature and subsequently liquefying it

through isobaric cooling, with the compression heat

being recovered and stored. The compressed air, now

in liquid form, is stored at atmospheric pressure in

low-temperature storage tanks. During the energy

releasese phase, liquefied air is pressurized to

supercritical levels using a low-temperature pump. It

then passes through a cold storage heat exchanger,

which recovers cold energy as well as releases heat,

warming the air to ambient temperature. Finally, the

air expands through an expander to perform work,

simultaneously absorbing the stored compression

heat from the energy storage phase. The SC-CAES

system removes the need for burning fossil fuels and

Analysis on the Status of Compressed Air Energy Storage (CAES) in China and Future Development Trends

187

extensive corresponding storage facilities. It achieves

an energy density of up to 3.4×105 kJ/m³ and a

round-trip efficiency of 67% (Zhang et al, 2023).

4 THE STATUS AND

CHALLENGES OF THE

DEVELOPMENT OF CAES

4.1 Current Development Status in

China

CAES has seen very rapid growth domestically over

the past decade, gradually moving towards large-

scale, mature, and systematic implementation. In

China, the performance of CAES equipment has

significantly improved, progressing from the 10MW

class to the current 300MW class. In 2022, the biggest

350MW salt cavern CAES demonstration project in

the world commenced in Tai'an, Shandong Province.

This project employs an innovative low-melting-

point molten salt high-temperature adiabatic

compression technology. Once completed, it will

achieve several "world firsts" in the field of CAES.

On April 9, 2024, the world's first 300MW CAES

power station successfully connected to the grid and

began generating electricity in Hubei Province,

China, setting three world records in single-unit

power, energy storage capacity, and conversion

efficiency. These achievements signify that China has

elevated CAES technology to a new milestone

4.2 Challenges Faced and Related

Development Directions

4.2.1 System Efficiency

With current technology, the theoretical system

efficiency of CAES can reach approximately 75%.

Although China has become a world leader in this

technology, there remains a gap between the actual

system efficiency and the theoretical value. In China,

the system efficiencies for 1MW, 10MW, and

100MW systems are approximately 52%, 60%, and

70%, respectively, which are still lower than the

efficiency of PHES, indicating room for improvement

(Xu, 2023). To enhance equipment performance, the

country should continue to increase research and

development efforts, undertake technological

breakthroughs, and address core technical challenges.

Additionally, the promotion and application of this

novel technology should be strengthened,

accelerating the industrialization, commercialization,

and large-scale deployment of CAES technology.

This will foster a virtuous economic cycle, promoting

the perfection and development of the technology.

4.2.2 Construction Costs

Compared to traditional energy storage technologies,

the development cost of CAES technology is

relatively high, resulting in a higher cost per kilowatt-

hour. The primary reason for the high costs is the

substantial investment required for constructing

artificial air storage facilities, compressors, and

expanders. These three key components correspond

to three crucial systems. For projects utilizing salt

caverns for air storage, the total investment in these

three stages accounts for nearly 45% (Zheng et al,

2023). For projects using artificial caverns for air

storage, the cost of the storage system alone exceeds

30% (Zheng et al, 2023). In terms of building the

compression and expansion systems, China should

strive to develop more advanced technologies to

control costs. Additionally, related entities should

seek ways to achieve large-scale production to reduce

costs. For the air storage system, the government

should encourage the development of natural storage

facilities such as underground salt caverns, which not

only have lower construction costs compared to

artificial storage facilities but also offer larger storage

capacities. Furthermore, for the research and

development of all related technologies, government

departments should provide financial subsidies and

policy incentives.

4.2.3 Air Storage Devices

At the current stage, for CAES, air storage devices in

China are commonly located underground, utilizing

natural formations or artificially excavated caverns.

The selection of storage sites introduces a challenge,

for instance, the uncontrollable variations in

geological conditions can lead to underground gas

leaks, affecting construction and increasing difficulty

and costs (Zheng et al, 2023). Additionally, ensuring

the airtightness of the storage device itself is a core

challenge. Poor airtightness can result in energy loss,

increased operational costs, and reduced energy

conversion efficiency. If impurity gases leak, it could

also pose an explosion risk. To address these issues,

relevant safety departments should first implement

rigorous monitoring, inspection, and maintenance to

prevent accidents. Factors affecting airtightness

mainly include the cap rock, lining, and materials of

the storage containers (Zhang et al, 2023). Future

improvement measures should focus on these three

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

188

aspects, seeking more suitable materials to enhance

the airtightness of the devices and fundamentally

resolve the problem.

4.3 Prospects Forecasts

CAES, with its advantages of site flexibility,

environmental friendliness, short construction period,

and low unit cost, is one of the most promising energy

storage technologies in China, offering significant

promotion value. Currently, China is in its 14th Five-

Year Plan period, which explicitly aims for the

transition of new energy storage technologies from

commercialization to large-scale development by

2025 (Liu, 2022). Moreover, under the backdrop of

the "dual carbon goals," new energy storage

technologies, exemplified by CAES, are undoubtedly

experiencing a golden development period. It can be

predicted that in the coming years, with continuous

technological advancements, improvements in

system efficiency, reduction in construction costs,

and national support, CAES technology is expected

to become one of the mainstream large-scale energy

storage technologies alongside PHES, helping to

alleviate the energy storage burden.

5 CONCLUSION

In comparison to PHES, CAES has the advantages of

shorter construction periods, better environmental

compatibility, and more flexible site selection. It is

currently the only large-scale, long-duration new

energy storage technology comparable to PHES, with

broad application prospects. At present, under the

vigorous promotion of new energy storage

technologies in China, CAES is at a critical stage of

large-scale commercial development, showing a

positive development trend. Although the energy

storage efficiency of CAES in China has not yet

reached the level of pumped hydro storage, with the

continuous maturation of technology and system

optimization, and the emergence of new technologies

such as LAES and SC-CAES, it can be predicted that

in the coming years, CAES will achieve large-scale

commercialization. It will be able to compete with

pumped hydro storage, becoming one of the key

technologies supporting China's achievement of its

"dual carbon" goals and promoting the quality of

energy storage infrastructure. This article provides a

comprehensive introduction to CAES technology and

its development status in China, offering a valuable

reference for researchers interested in further

studying this technology. It is hoped that future

analyses will take an international perspective to

evaluate the development of this technology, offering

recommendations and predictions.

REFERENCES

Wu Haowen, Wang Jun, Gong Yingli, et al. 2001 Analysis

of the Development Status and Application Prospects

of Energy Storage Technologies. Journal of Electric

Power 36 434-443

Zhou Xingbo, Zhou Jianping, Du Xiaohu. 2023 Reflections

on the High-Quality Development of Pumped Storage

Power Stations in the New Era [J]. Hydropower and

Pumped Storage 9 20-24+36

Li Ziyu, Lü Hong, Li Zuhui, et al. 2023 Development Status

and Application Prospects of Compressed Air Energy

Storage. Resource Conservation and Environmental

Protection 08 5-8

Zhang Wen, Wang Longxuan, Cong Xiaoming, et al. 2023

Novel Compressed Air Energy Storage and Its

Technological Development. Science and Technology

& Engineering 23 15335-15347

Tan Xin, Zhao Chen, Yu Qihui, et al. 2019 Overview of

Research on Small Wind-Compressed Air Energy

Storage Systems. Hydraulics and Pneumatics 01 47-58.

Wu Quan, Sun Chunliang, Guo Haitao, et al. 2023 Analysis

of the Economic Characteristics and Development

Directions of Compressed Gas Energy Storage

Technology. Oil & Gas and New Energy 35 90-98

He Qing, Wang Ke. 2022 Isothermal Compressed Air

Energy Storage Technology and Its Research Progress.

Thermal Power Generation 51 11-19

Dib G, Haberschill P, Rullière R, et al. 2021

Thermodynamic investigation of quasi-isothermal air

compression/expansion for energy storage. Energy

Conversion and Management 235 114027

Xu Jianxin. 2023 Discussion on the Development and

Application of Compressed Air Energy Storage

Technology in China. Hydropower and New Energy 37

36-39

Zhang Weiling, Gu Han, Zhang Chao, et al. 2023 Economic

Characteristics and Development Trends of

Compressed Air Energy Storage Technology. Energy

Storage Science and Technology 12 1295-1301

Liu Jian. 2022 "Progress and Trend Outlook of New Energy

Storage in the 14th Five-Year Plan Period" China

Electric Power Enterprise Management 10 59-60

Analysis on the Status of Compressed Air Energy Storage (CAES) in China and Future Development Trends

189