The Research on CO

2

Capture Technology and Its Practical

Feasibility

Yue Zhu

S

chool of Architecture, University of Liverpool, Liverpool, L69 7ZG, U.K.

Keywords: CCS, Carbon Dioxide Capture, Fossil Energy, Feasibility.

Abstract: At a time when greenhouse gases (GHG) are increasing rapidly, carbon dioxide is widely recognized as

attended as a significant influencing factor. CCS is an important method to achieve the net-zero carbon target,

which is effective in slowing down current global warming and mitigating climate changes, and works as a

buffer stage for future fully renewable energy sources' usage. This paper mainly focuses on three means of

carbon dioxide capture in Carbon Capture and Storage (CCS), pre-combustion, oxyfuel-combustion, and post-

combustion. Their features would be explored through comparative analysis to discuss their applicability in

the field of fossil energy. Generally, CO

2

Capture is considered to have great potential for practical application

in different power station types. Post-combustion can quickly adapt to existing thermal power plants and

effectively reduce high carbon emissions, while pre-combustion can suit new stations and synergize with the

development of clean energy, such as hydrogen. Oxyfuel combustion, which is still in the developing phase,

could possibly reduce current capture costs significantly along with new materials and technologies

developed. Although it is undeniable to develop renewable energy sources and promote the energy transition,

fossil fuels will still be widely used to guarantee energy security for decades to come, which makes carbon

capture technologies required to be emphasized since they can enable its low-carbon use of energy resources.

1 INTRODUCTION

Since sustainable development has become one of the

most critical issues in contemporary society,

environmental problems, such as global warming and

climate change, are receiving widespread attention. If

allowed to deteriorate uncontrollably, they would

break the balance of the earth's ecosystem and

jeopardize social development. Carbon dioxide is

considered to as a major factor in greenhouse gas

(GHG) that has been largely released into the

atmosphere and led to a worsening situation. Since

the natural sources remained relatively stable in the

pre-industrial era, the increase in CO2 concentration

detected is considered to be mainly of anthropogenic

origin, from 280 ppm to 390 ppm till 2010 in the last

two centuries (Garnier et al., 2011). It comes from

multiple sources, including the combustion of fossil

fuels, such as coal, natural gas, or petroleum, as well

as oil refineries, and industrial production, such as

cement and steel (Dantas et al., 2011). Currently,

CO2 is still being emitted at high rates, making

scientists estimate that its concentrations will rapidly

approach thresholds without appropriate mitigation

policies, reaching 500 ppm by 2050 (IPCC, 2005).

Therefore, the Intergovernmental Panel on Climate

Change (IPCC) strongly suggested increasing

emissions reductions and deploying technologies to

remove carbon emissions from the current

atmosphere, which are indispensable means to limit

future temperature increases within 1.5° set in the

Paris Climate Agreement.

Currently, in order to stabilize the atmospheric

concentration of CO2, various ways in different fields

are being developed and practically used, mainly

centering on energy conservation, emission reduction

efficiency enhancement, and carbon fixation increase.

Some key technologies include developing hydrogen

and solar energy in energy transitions, energy

recovery and waste reuse in transforming industrial

processes, and Carbon removal and carbon capture in

natural carbon sinks such as forests, oceans, and

wetlands (Zhang et al., 2021). Among them, Carbon

Capture and Storage (CCS) is an important method of

Carbon removal, since it is the only way to realize the

low carbon utilization of traditional fossil energy in

the transition towards net-zero development (Yao et

al., 2024). It is considered a process, mainly

172

Zhu, Y.

The Research on CO2 Capture Technology and Its Practical Feasibility.

DOI: 10.5220/0013853400004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 172-178

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

consisting of three steps: the separation of CO2 from

industrial and energy-related sources, transportation

to a storage location, and long-term isolation from the

atmosphere. This means is targeted at the

anthropogenic sources, especially the large stationary

point sources, and helps to reduce emissions by 80-

90% effectively (Holloway, 2007). According to the

Global CCS Institute report in 2022, its practical

usage is under a positive development trend.

Currently, there are 194 large-scale facilities located

in different regions of the world, of which 61 are new

projects added in 2022; while the CO2 capture

capacity increased to 244 million tons per year,

reaching a 44% year-on-year growth (Global CCS

Institute, 2022).

This research aims to explore different types of

CO2 capture technology in CCS and analyze its

feasibility relating to power stations. Generally, a

brief description will be given at first. Then, the three

capture methods will be detailly compared to analyze

their advantages and disadvantages. Finally, the

feasibility of each type will be discussed binding their

characteristic when applied in real projects of power

energy.

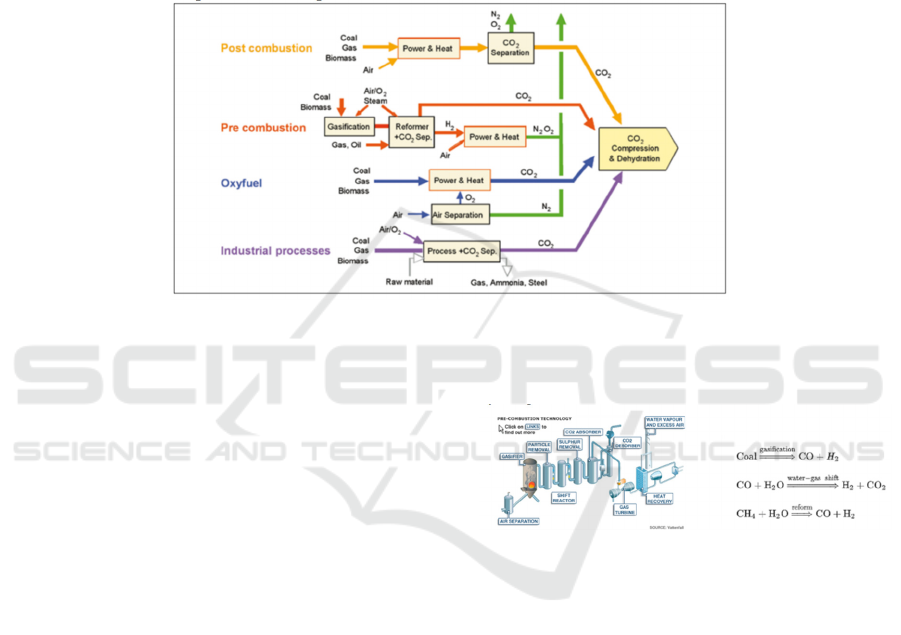

2 THE PRINCIPLE OF CCS

As mentioned above, CCS is generally made up of

three main steps: capture, transportation, and storage

(Figure 1), and the different components are currently

at varying levels of technological development and

application. The basic principles and features are

briefly described in this section.

Figure 1: Schematic Diagram of Possible Carbon Capture

and Storage Systems (IPCC, 2005).

2.1 Capture

As a first step, capture can remove CO2 emissions at

the source before its release, which makes the capture

efficiency directly affect the subsequent outcomes.

There are three main approaches to capture: pre-

combustion, oxyfuel-combustion, and post-

combustion. (Details are discussed in the below

sector.) Given the cost in practical use, purifying and

compression are two procedures required to conduct

after capture in order to obtain a high-pressure

concentrated liquid for easy transportation and

storage.

2.2 Transportation

Since storage methods must meet certain

requirements, the captured CO

2

usually needs

transportation to reach the selected special locations.

The approaches are various, often including pipeline,

ship, road, and rail transportation. Among them,

pipeline transportation on land is considered the most

mature technology in the current market, which has

high efficiency and economic advantages, especially

in large-scale and long-distance situations (IPCC,

2005). High pressure, typically 10-16 MPa, is needed

to avoid convection in the transport pipelines. The

IPCC report estimated the cost of a standard pipeline

for a distance of 250 km at 1-8 USD/tCO

2

(IPCC,

2005). However, the exact cost is also related to the

geographic and environmental characteristics of the

pathway.

2.3 Storage

Certain conditions of storage ways or places need to

be satisfied, which guarantees CO

2

can be sealed or

eliminated for long periods without leaking back into

the atmosphere. There are three main means:

injection into subsurface geological storage (depleted

oil, gas fields, and deep aquifers in porous rock

formations), oceanic storage, and solidification in

inorganic carbonates through industrial processes. In

practice, the suitable storage site is selected based on

a combination of factors, mainly including location,

geophysical properties, and relationship to densely

populated areas. For example, despite the large

amount of CO₂ released in the east part of China due

to the intensive energy consumption, oceanic storage

is a better option since the capacity of the land-based

storage is small and easily affected by the dense

population distribution (Zhang et al., 2023)

The Research on CO2 Capture Technology and Its Practical Feasibility

173

3 THREE MEANS OF THE

CARBON DIOXIDE CAPTURE

TECHNOLOGY

CO

2

Capture was initially applied in the refining and

chemical industries. Now, it is processed maturely in

production with relatively low costs and technical

difficulty since the emitted carbon dioxide is often in

high concentrations and pressures. However, the

application in power production requires further

exploration, which has much larger energy demands

and higher costs but is the largest single category in

all stationary CO

2

sources. In some studies, the power

station is the main industrial emission source,

accounting for more than two-thirds of global

emissions, up to nearly 65% (Gür, 2022). Therefore,

this section will focus on three capture methods that

are highly relevant to fossil fuels, pre-combustion,

oxyfuel-combustion, and post-combustion (Figure 2).

Figure 2: Overview of CO2 Capture Processes and Systems (IPCC, 2005).

3.1 Pre-Combustion Technology

This system aims to pre-treat fossil fuels before

combustion. It usually contains three steps:

1) processing the water steam and air into a

mixture of carbon monoxide and hydrogen

in a high-temperature reactor first,

2) conducting the second reaction of carbon

monoxide with the water steam to achieve

Hydrogen and carbon dioxide through a shift

reaction,

3) finally separating the carbon dioxide from the

gas mixture through physical or chemical

processes, such as cryogenic fractional

distillation and solution absorption.

This technology has been widely used in

industrial production but is still under development

for power plants. Because of the bad adaptability to

existing equipment, the Retrofitting investment is

often very high at the early stage (Yang, 2024). Thus,

this approach is mainly suitable for new plants

considering carbon capture, especially under linkage

with Integrated Gasification Combined Cycle (IGCC)

plants, which could improve efficiency (IPCC, 2005).

The main workflow in the factory is shown in the

following diagram (Figure 3), mainly containing

Gasification - Shift reaction - Carbon Capture –

Hydrogen Utilization.

Figure 3: Pre-combustion System (Arshad, 2009).

Greengen located in Tianjin (China) is a typical

project that adopts this capture system in practical

operation, which works with the IGCC system and the

annual capture capacity reaches 100,000 tons. The

purity of the recovered CO

2

reaches 98% and the

capture rate is up to 90%, while the energy

consumption for removal is less than 1.6GJ/t (Yang,

2024). The most outstanding advantage of this

technology is that hydrogen as a by-product can be

used as a carbon-free clean energy for power

generation. However, although its operating cost is

relatively low, the complexity of the paired IGCC

system is an important negative factor that cannot be

ignored as well as the large upfront construction cost

and capital investment. Some practical projects, such

as The Kemper County Energy Facility in

Mississippi, have been indeed shut down. Besides,

some experts pointed out low efficiency, theoretical

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

174

capture rates of which may be as low as 10% in some

projects (Li and Qiao, 2008).

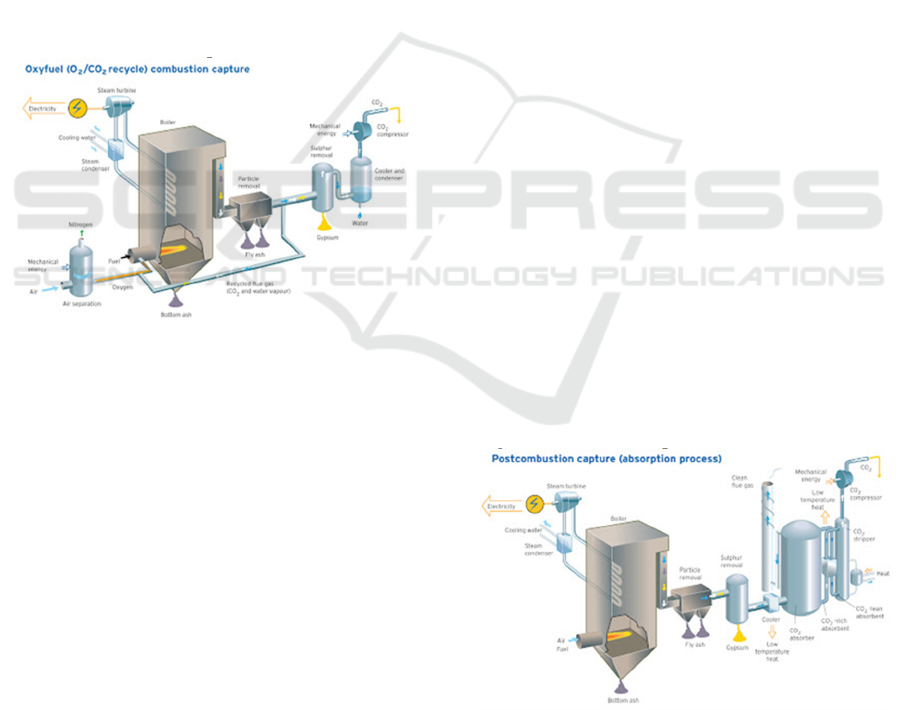

3.2 Oxyfuel-Combustion Technology

This system mainly focuses on the combustion

process, improving complete combustion efficiency.

It mainly has three steps:

1) using high-purity oxygen to replace air to make

reactions with fossil fuels under a pressurized

condition firstly,

2) then separates and collects CO

2

from the flue

gas, which is mainly a by-product of water

vapor, by means of low-temperature

condensation,

3) finally dry CO

2

collected from the condensate

water to prevent corrosion of the subsequent

transportation piping.

Figure 4 shows the main factory workflow below:

Oxygen Generation - Combustion - Cooling and

Water Removal - CO

2

Capture.

Figure 4: Oxyfuel-combustion System (Arshad, 2009).

Spremberg had operated a small pilot project

equipped with oxyfuel-combustion Technology,

Schwarze Pumpe Power Station in Germany (has

been shut down). It had an installed capacity of 30

MW and captured about 30,000 tons of CO

2

per year

(Kreutz et al., 2005). In China, a 35 MW industrial

demonstration plant is applied with this system as

well, which was built recently in Hubei by Huazhong

University of Science and Technology with China

Oriental Electric Corporation. (Yang, 2024). It uses a

compatible program that allows air and oxygen in

combustion reactions and achieves a capture rate of

up to 82.7%, which can be applied to new and existing

facilities. This technology can have several

advantages, including achieving high concentrations

of CO

2

directly, being easy to capture, and having the

potential to be applied in retrofitting existing power

plants. However, there are two main negative factors

for further development: the difficulty of temperature

control in oxyfuel combustion and the extra effort

required to develop materials and equipment with

high fire resistance, such as CO

2

compressors and ion

transport membranes (IPCC, 2005). In addition, there

is a view that the high cost of oxygen production

makes it less economically advantageous in practical

usage (Li and Qiao, 2008). However, according to

calculations by the IPCC, although the cost and

energy required for an oxyfuel-combustion system

may significantly increase the overall cost of power

generation, the costs can be offset by the technology's

potential to capture more than 90% of the emissions

(IPCC, 2005).

3.3 Post-Combustion Technology

This system usually captures CO

2

after the

combustion in the flue gas, which generally contains

two steps:

1) utilizing a liquid solvent to absorb CO

2

gas from

the combustion of fossil fuels or biomass,

2) separating CO

2

from the solvent and compressing

it for transportation or usage, while releasing the

purified flue gases back into the atmosphere.

This technology has several different separation

principles, including absorption, adsorption, and

membrane separation (Yang, 2024). Currently, the

process of monoethanolamine (MEA) is widely used

as a proven chemical adsorbent in factories (IPCC,

2005). Since it is highly compatible with current flue

gas systems, post-combustion technology is

particularly suitable to retrofit existing facilities, such

as modern pulverized coal (PC) power plants or

natural gas combined cycle (NGCC) power plants.

Atypical workflow is illustrated below (Figure 5),

consisting of Flue Gas Generation - Flue Gas

Treatment - CO

2

Capture - CO

2

Separation,

Regeneration, and Compression.

Figure 5: Post-combustion System (Arshad, 2009).

As one of the most mature technologies in CCS,

post-combustion capture has been applied in many

The Research on CO2 Capture Technology and Its Practical Feasibility

175

projects worldwide. Huaneng Beijing Thermal Power

Plant in Beijing (China) is a typical example, which

can achieve an average annual carbon capture scale of

3000 tons, and the capture rate is more than 85 with a

purity of 99.99%. Besides, the captured CO

2

achieves

source reutilization, which is produced as refined

food-grade carbon dioxide and supplied to the

carbonated beverage market (Wang, Zhang and

Kuang, 2010). The outstanding advantage of post-

combustion technology is its great flexibility in being

well adapted to various facilities, which allows direct

application in existing traditional power plants with

relatively low-cost investment. Besides, this

technology can especially be targeted at low

concentrations of CO

2

and applied to large,

centralized emission sources. However, high energy

consumption and equipment operation costs are also

inevitable results. Since the low CO

2

concentration in

the flue gas, generally accounting for 3-15%, small

airflow pressure, and large volume could result in a

high capture cost price. In addition, the corrosion

caused by liquid solvents can a decline in the service

life of the equipment, which is also considered a

negative factor in increasing the running cost (Yang,

2024).

Thus, the selection of a capture system requires

balancing all the positive and negative factors of each

technology and making the decision generally

according to different features of the practical project,

such as the CO

2

concentration in the gas stream, the

gas stream pressure, and the fuel type (solid or gas).

4 DISCUSSION

Based on the analysis above, this part will shortly

summarize the major negative factors that limit

carbon capture technology and emphasize its

importance first, followed by a discussion of the

practical feasibility and adaptability of the three

specific methods.

4.1 Technical Feasibility

Carbon capture technology is the first step of CCS,

the capture rate of which is the basis for the whole.

However, at this stage, several key reasons may

influence its wide application negatively. Firstly,

carbon capture technologies correlated with fossil

fuels still have not reached a mature market-oriented

stage. The optimization room does exist for varying

components, especially those linked to oxyfuel

combustion technology. Secondly, this technology

generally requires additional investments, especially

the capture technology that accounts for 70-80% of

the whole capital cost and should be responsible for

10-40% of extra energy consumption (Blomen,

Hendriks and Neele, 2009). Thirdly, it sometimes

raises questions among the public during practical

applications, especially environmentalists. The

Schwarze Pumpe power station is an example that has

been forced to shut down. Some viewpoints argue that

funds are fully invested in the development of clean

energy and resist the development of capture

technologies applied to traditional thermal power

stations. However, fossil fuels are an important

source of global energy supply, currently up to 80%

of the energy mix, and are also predicted to account

for more than 60% by 2050 (IEA, 2022). Since fossil

energy is indispensable to ensure energy security in

the coming decades, it is important to promote the

development of carbon capture technology, which

offers the possibility to continuously use it in a more

climate-friendly approach with a low-carbon

footprint. Besides, it can mitigate the high rates of

CO

2

emissions from the current stations and facilitate

the development of clean energy technologies such as

hydrogen. Furthermore, though capture is considered

to be energy-intensive, the net removal of CO

2

can be

reduced by 80-90% through this technology (IPCC,

2005).

4.2 Economic Feasibility

Currently, three carbon capture systems are

developed at various stages with distinct features that

can be applied to different types of fossil fuel stations.

In practical usage, existing technologies can

theoretically reach technical feasibility, while

economic viability becomes an important concern

due to the financing issue (Holloway, 2007). It mainly

includes the efficiency, the upfront investment in the

equipment, the cost of running the system, and the

energy loss. In pre-combustion technology, the

capture efficiency can be achieved by 85-92% with

81-88% CO

2

removal level of the emissions.

Correspondingly, energy demand would increase by

16-25%. However, in combination with an IGCC

system, the incremental costs can be reduced by about

20%, since the average energy demand and

equipment size are reduced due to the reduced

volume of gas being processed (IEA, 2022). For post-

combustion technology, the capture efficiency is

about 85-95% while the emissions reduction rate is

around 80-90%. It often requires an extra 24-42%

energy consumption, which is mainly used for solvent

regeneration and carbon dioxide compression.

Meanwhile, for oxyfuel-combustion technology,

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

176

there is a lack of data on the practical application.

Compared to the energy mainly spent on CO

2

separation in the last two adsorption-separation

approaches, the extra energy would be used in oxygen

purification.

4.3 Applicability

As the features of the three capture technologies

described above, they have their own unique

advantages for a typical scope of application. The pre-

combustion technology is characterized by low

operating costs, but has large upfront investment and

construction difficulty, which suits new plants,

especially for projects considering the development

of hydrogen energy; the oxyfuel-combustion has

received lots of attention in recent decades due to its

high decarbonization capacity, but is still in the

development stage and small-scale demonstration;

the post-combustion technology is currently the most

mature carbon capture technology with great

flexibility in applying to the existing equipment and

low upfront costs, while the daily operation of the

capture cost is relatively high and its optimization is

largely dependent on the research and development of

new materials

Generally, it is necessary to choose the

appropriate capture method according to the

characteristics of the combustion reactions and

equipment of the power plants for specific plants. In

addition, national law-making and related policy

framework-building can be positive enablers to

encourage its development under a long-term stable

financial incentive, such as carbon taxes and

subsidies (Coninck and Benson, 2014). Besides, the

establishment of a suitable testing system and

regulatory system is essential.

5 CONCLUSION

This paper mainly focuses on exploring the three

carbon capture technologies in CCS, pre-combustion,

oxyfuel-combustion, and post-combustion. The

features of the three systems are discussed through

comparative analysis for their feasibility and

applicability.

The research finds that carbon capture technology

types have different features that suit different types

of power stations, which generally gives it a high

potential for application in the field of fossil fuels. In

detail, as a mature technology with great flexibility

and many successful precedents, the post-combustion

system can focus on the present, quickly and

effectively changing the high carbon emission from

the existing traditional power plants. Meanwhile, pre-

combustion technology is more suitable for newly

built plants that are being prepared, especially the

ones that are synergizing with the development of

hydrogen energy. Besides, although oxyfuel

combustion is considered to have great potential to

reduce capture costs along with the development of

new materials and technologies, it is still under the

research and development stage in the laboratory, and

its actual potential for practical application requires

more data feedback. In general, this study considers

that CCS has great feasibility due to its broad usage

ranges in a wide range of sources. Thus, this paper

suggests the promotion of further development and

wide application of this technology in practical

projects, which can not only quickly change the

current high emissions condition but also help

achieve deep decarbonization of the entire economy

in the future.

In addition, further research could be carried out

by involving more annual reports about actual

production processes from different factories to gain

a broader perspective on the feasibility analysis.

REFERENCES

Garnier C, Finqueneisel G, Zimny T, Pokryszka, Z,

Lafortune S, Défossez P and Gaucher E 2011

International Journal of Coal Geology 78(2) pp 80-86

Dantas, T L P, Luna F M T, Silva I J. Torres A E B,

Azevedo D C 2011 Chemical Engineering Journal

172(2-3) pp 698-704

The Intergovernmental Panel on Climate Change (IPCC)

2005 IPCC Special Report on Carbon Dioxide Capture

and Storage (UK: Cambridge University Press)

Zhang X, Guo S, Kong H, Zhao W, Jia L, Liu J and Zhong

P 2021 Chinese Journal of Environmental Management

13(1) pp 65-70

Yao X, Wen X, Wu J, Zhu L, Liu Y, Huang Y and Sun S

2024 Energy Environmental Protection

Preprint https://doi.org/10.20078/j.eep.20240314 1-10

[2024-04-01].

Holloway S 2007 Phil. Trans. R. Soc. A 365(1853) pp 1095-

1107

Global CCS Institute 2022 Global Status of CCS 2022

https://status22.globalccsinstitute.com/ 2022-status-

report/introduction/ (Accessed: 01 May 2024)

Zhang X, Yang X, Lu X et al 2023 China Carbon Dioxide

Capture, Utilization and Storage (CCUS) Annual

Report (2023) The Administrative Center for China's

Agenda 21, Global Ccs Institute and Tsinghua

University

Gür, T 2022 Progress in Energy and Combustion Science

89 100965

Yang Y 2024 ACTA PETROLEI SINICA 45(1) pp 325-338

The Research on CO2 Capture Technology and Its Practical Feasibility

177

Arshad M 2009 CO

2

Capture Using Ionic Liquids

Li X and Qiao 2008 SINO-GLOBAL ENERGY 13(5) pp104-

107

Kreutz T, Williams R, Consonni S and Chiesa P 2005

HydrogenEnergy 30(7) pp 769-784

Wang Z, Zhang X and Kuang J 2010 Scientific and

Technological Management of Land and Resources 5 p

6

Blomen E, Hendriks C and Neele F 2009 Energy Procedia

1(1) pp 1505-1512

IEA 2022 World Energy Outlook 2022 IEA Paris

https://www.iea.org/reports/world-energy outlook-

2022 Licence: CC BY 4.0 (report) CC BY NC SA 4.0

(Annex A)

Coninck, H and Benson S 2014 Annual Review of

Environment and Resources 39 pp 243-270

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

178