Effect of Cobalt-Platinum Nanoalloy Combination with Non-Metallic

Catalyst Fe-N-C on Anti-Poisoning Performance of Hydrogen Fuel

Cell Catalyst

Yue Feng

Zhejiang Wanli University, Ningbo, China

Keywords: Hydrogen Fuel Cell, Platinum Cobalt Nano Alloy Catalyst, Catalyst Poisoning, Catalyst Catalytic Effect.

Abstract: Due to the growing global demand for sustainable energy sources, the advent of hydrogen energy reduces

dependence on fossil fuels. Hydrogen possesses a high calorific value and emits non-polluting substances in

comparison to traditional fossil fuels. As a result, hydrogen energy exhibits significant potential for

development. Hydrogen fuel cells are a major technology for the realization of multi-directional hydrogen

energy applications. Changes in catalyst activity during battery use will affect battery life. Catalyst poisoning

is a major difficulty affecting battery life. Combining cobalt-platinum nanoprecious metals with non-metallic

catalysts Fe-N-C. This paper combined with a number of current research results explores the effect of

combining cobalt-platinum nanoprecious metals with non-metallic catalysts Fe-N-C on the catalyst's

antitoxicizing effect. The catalyst was investigated for battery performance studies. Cost of catalyst

manufacturing is evaluated into battery use. The feasibility of using batteries for manufacturing is analyzed.

Under a multi-faceted inspection, combining nanoprecious metals with non-precious metal catalysts plays an

important role in the anti-toxicity effect and performance enhancement of batteries. Under conditions of

catalyst poisoning, Exploiting the anomalous infrared absorption effect of cobalt-platinum on carbon

monoxide, Improved catalyst resistance to toxicity. Significantly extends battery life. For the distribution of

metals over spatial locations. The combination of precious metals and catalysts is particularly important. In

this paper, we mainly consider metal-nanometal bonding, graphene encapsulation and graphene tessellation.

Comparison of graphene mosaicing method for battery performance has a large improvement through the

study. The method also reduces the use of precious metal catalysts. In addition, compared with the

conventional nickel-cobalt alloy. The advantages of cobalt-platinum nano-alloys are not only reflected in their

antitoxicity effect. The performance of the catalyst is further enhanced.

1 INTRODUCTION

With utilization of fossil fuel increasingly

intensifying, the environment problem created behind

it cannot be ignored it becomes the centre of global

attention. The development of hydrogen fuel cells

meets the demand of non-pollution and zero-

emission. The advent of this technology favourale to

the continue advancement of global carbon emissions

and carbon neutrality. Nowadays, alkaline fuel cell

(AFC), acidic fuel cell (PAFC), proton exchange

membrane fuel cell (PEMFC) etc. are widely used.

Among the cells, PEMFC is the one most widely used

especially in the new energy electric vehicle with

good prospects for development (Xu, Zhu and Xu,

2023). The ability to convert chemical energy directly

into electrical energy with the advantage of no

pollution, and enables hydrogen fuel cells to generate

electricity with much greater efficiency than

generator (Xu, Zhu and Xu, 2023). Although the

hydrogen fuel cells have such superior performance,

the problem behind the battery is still non-negligible.

The issue arises from the trade-off between the

battery’s performance and construction cost. It is

not feasible to optimize both factors simultaneously.

The precious metal catalyst exhibits excellent

catalytic properties. However, its high price becomes

a limiting factor as demand for its application

increases and resources become increasingly scarce

(Zhang et al., 2023). Non-precious mental catalyst

has low price, but compared with precious one, the

catalytic properties are not outstanding. The other

problem is catalyst poisoning. Nowadays, the most

mature non-metallic catalyst is Fe-N-C, with the

increase in the temperature carbon contain in it.

Porous structures are characteristic of hydrogen

140

Feng, Y.

Effect of Cobalt-Platinum Nanoalloy Combination with Non-Metallic Catalyst Fe-N-C on Anti-Poisoning Performance of Hydrogen Fuel Cell Catalyst.

DOI: 10.5220/0013850900004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 140-144

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

energy fuel cells, where the oxidation of the carbon

reacts with oxygen, carbon monoxide will be

generated. The production of carbon monoxide by the

electrode, its attachment to the catalyst surface, and

occupation of the active site can lead to catalyst

poisoning, which is a primary factor in decreasing

battery life (Huang, Wang and Pei, 2023). Pt-Co-N-C

catalysts exhibit excellent stability and catalytic

effectiveness under both acidic and alkaline

conditions, thereby exerting a positive impact on

delaying the process of catalyst poisoning (Deng et

al., 2023).

By employing the co-reduction method to

produce nanopolyhedral-type metals of Pt and Co, the

catalyst reaction contact area is increased and its

stability is enhanced compared to using a single metal

(Cao et al., 2023). It exhibits superior catalytic

activity, particularly when using Pt and Co for

absorption compared to a single metal catalyst.

Additionally, the nickel-cobalt alloy shows an

anomalous infrared effect in the nanometer range.

The addition of cobalt strengthens the ability of

platinum to absorb carbon monoxide, in addition,

making use of co-reduction method increases the

degree of alloying of two metals. For the structural

performance, this method provides certain guarantee

for the stability of catalyst by reduction- deposition

method (Dey and Dhal, 2020 & Chen et al., 2023).

This method compared with other preparation method

simplifies the manufacturing process, furthermore,

applying this approach catalyst usually have high

catalystic activity within a relatively wide

temperature range. The proposal of such catalyst will

contribute to the mitigation of catalyst poisoning

resulting from carbon monoxide and improve battery

performance. The aim of this article is to investigate

the antitoxicity ability of catalysts in hydrogen energy

batteries, and discuss the impact of the use of the

catalyst on the performance of the battery and analyze

its feasibility.

2 PLATINUM-COBALT

INFRARED ANOMALOUS

ABSORPTION

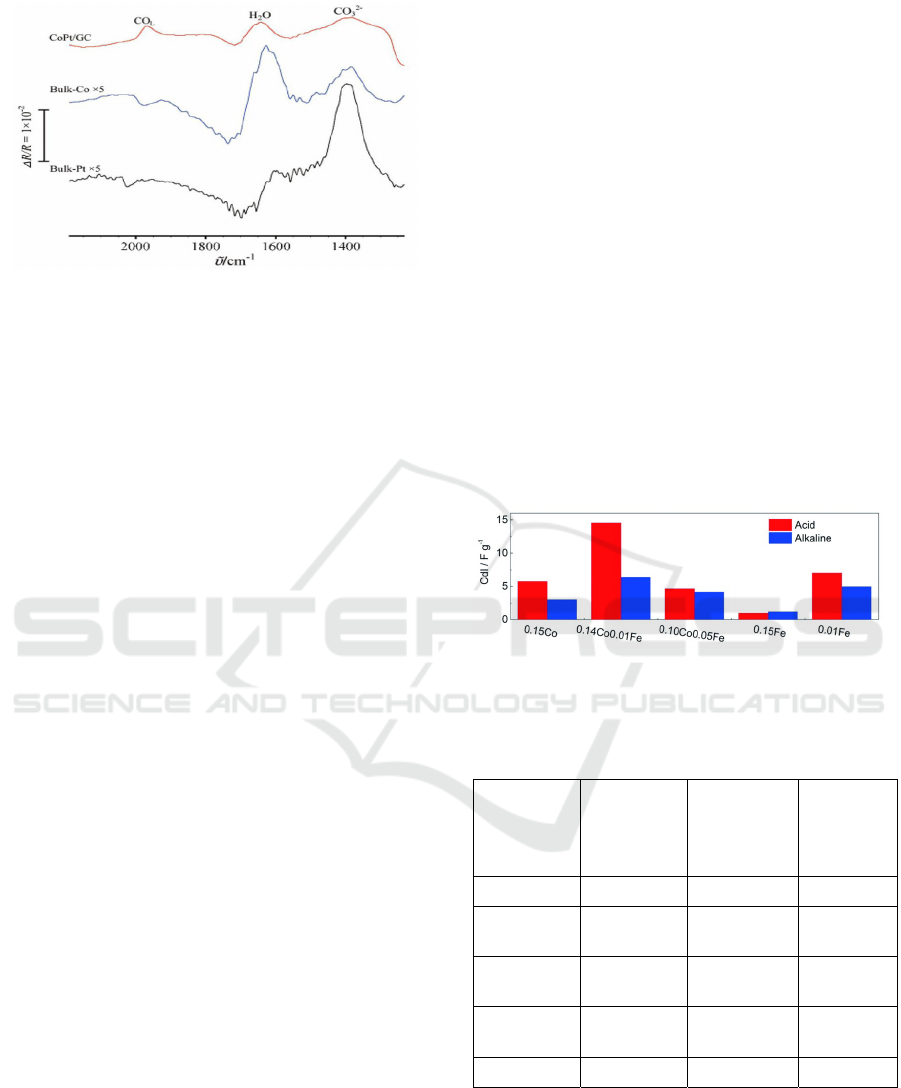

Electrochemical deposition to manufacture the

catalyst and primary potentiometric infrared

spectroscopy is used to detected abnormal infrared

absorption effect of cobalt platinum alloy,

quantification of infrared anomalous absorption

intensity using infrared absorption factors at different

wavelengths of light (according to the formula), as

shown in figure1. According to the figure, compared

with the native platinum and cobalt electrodes, the

infrared absorption of the nano-platinum and cobalt

film electrode is significantly enhanced. Even if the

infrared absorption intensity of platinum-cobalt

monometallics is increased by a factor of five, the

value is still lower than that of platinum-cobalt alloys

(Chen, Guo and Sun, 2014). In a researcher conducted

in University of California a graphene-nanosphere

encapsulated platinum-cobalt nanocatalyst was

developed. The catalyst has excellent durability after

endurance testing mass activity remains 78% (Zhao

et al., 2022). Besides, the team UCLA embeds tiny

crystals of platinum cobalt in rice-resistant bags made

of graphene. The catalyst maintains the advantages of

high efficiency and high toxicity resistance. Reduced

the use of platinum 40% (Zhao et al., 2022).

Generally, Infrared anomalous absorption effects

in platinum-cobalt nano-alloys provide the new idea

in the study of battery antitoxicity. In catalyst

manufacture, different process methods lead to

various effect of resistance to poisoning. Among

these manufacture methods, the catalyst made by the

team UCLC is most reliable. Although

electrochemical deposition has the shortest

preparation cycle among several methods and the

mild manufacture conditions, the compactness of its

internal structure greatly reduces the effective

utilisation of the catalyst. This technology is an

extension of the use of thin metal films, and provided

a theoretical basis for further research that followed.

The research team in Los Angeles and UCLA used

the more precise graphene wrapping and embedding

methods. The difference between the two lies in the

different spatial position relationship between cobalt

platinum alloy and graphene, which leads to the

difference in the consumption of nano alloys and

effective contact area during reaction. Using cobalt

platinum alloys of the same quality, graphene

embedding method has a larger effective reaction area

compared to encapsulation method, and the catalyst

prepared by embedding method requires less

platinum cobalt material. Achieved the goal of

reducing resource consumption. Compared to

graphene encapsulated catalysis, embedded catalysts

have weaker resistance to poisoning. But using multi-

layer graphene to increase surface area can solve this

problem.

Effect of Cobalt-Platinum Nanoalloy Combination with Non-Metallic Catalyst Fe-N-C on Anti-Poisoning Performance of Hydrogen Fuel

Cell Catalyst

141

Figure 1: MSFTIR spectra of saturated adsorption of CO

on C and Co, Pt electrodes (Chen, Guo and Sun, 2014)

3 EFFECT OF IRON AND

COBALT IN CATALYSTS ON

BATTERY PERFORMANCE

The greatest impact of PtCo-Fe-N-C catalyst on

battery performance is the interaction of cobalt and

iron. The catalytic mechanism of iron and cobalt is

the reaction of both with oxygen and form

coordination bonds. The addition of water reacts to

form Fe(OH)

2

and Co(OH)

2

, afterwards OH-

disengage the catalyst (Jiang et al., 2021). Use of

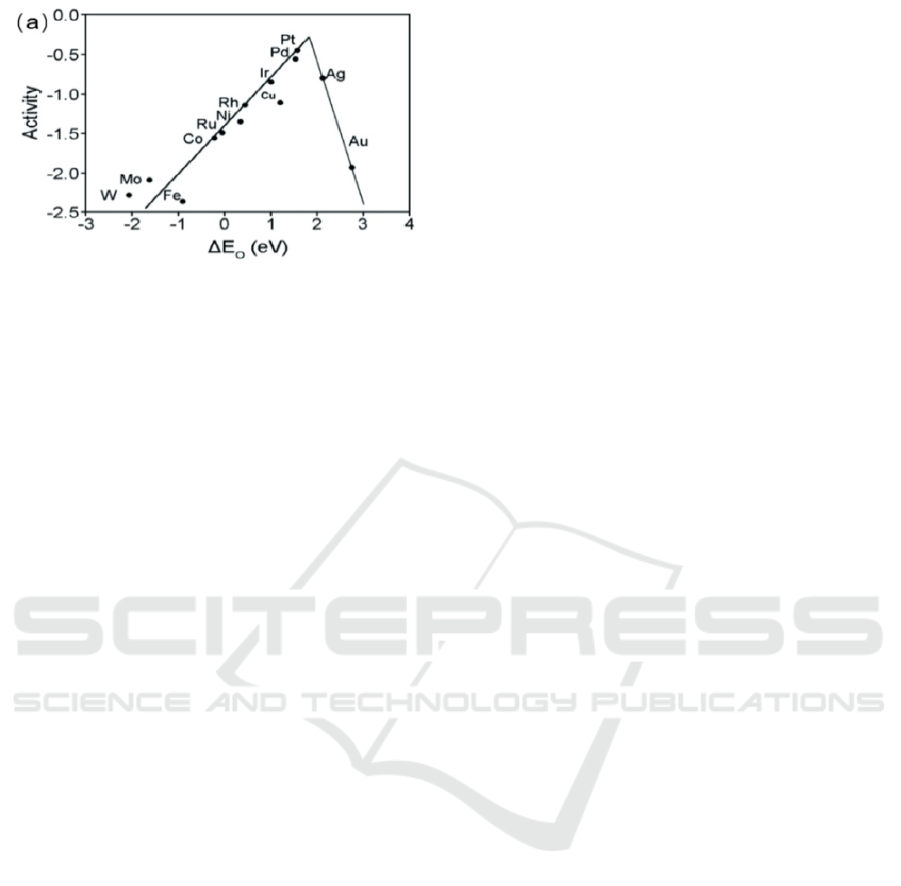

cobalt and iron to enhance battery performance

provides new ideas. Bimetallic interdoping is used in

manufacture of bimetallic catalysts. Later, EIS was

utilized to detect catalyst double layer capacitor.

Utilizing different ratios of cobalt to iron to

quantitative cell performance figure 2. The larger

capacitance represents that in ORR process, the

catalyst has a greater catalytic surface area. And when

the ratio of cobalt to iron reaches 14:1, catalyst has

higher catalytic performance relatively. And the

durability of the cell's catalytic have better

performance under acidic conditions compared to the

alkaline environment (Lei et al., 2023). Based on the

chart half-wave potential and limiting current are the

basis for judging the catalytic oxidizing ability of the

catalyst. Platinum has a better catalytic oxidizing

ability than nickel and catalytic effects of iron and

cobalt oxidation much lower than the catalytic effect

of iron, cobalt and nickel ternary metal catalysts (Li,

2023). This demonstrates the limitations of bimetallic

catalysts. However, it is affirmed that ternary metals

have a significant role in enhancing catalyst

performance. And a ternary metal catalyst for

platinum instead of nickel Provides some basis.

Previous scientists have used DFT calculation. Based

on the binding energy of ORR activity to free radicals

on metals. The table1 was plotted. In Table 1 the ORR

catalytic performance of Pt is much better than that of

Ni in the most suitable potential energy. Based on the

trend line on the way, platinum has higher catalytic

activity than nickel (Guo, 2024). This is better

illustrated by the catalytic activity of the different

metals in figure 3, where platinum has a higher upper

limit of catalytic performance compared to nickel.

In generally, the performance enhancement of

catalysts is closely related to the use of multiple

metals. Compared to a single metal, the anti-

poisoning ability and catalytic efficiency are greatly

enhanced. Although in terms of manufacturing costs,

with the addition of multiple metals, the

manufacturing cost of catalysts will also increase.

The prolonged service life of the catalyst and the

increased reaction efficiency cannot be ignored. In

the balance between catalyst performance and

manufacturing cost. The iron cobalt platinum ternary

nano alloy catalysts have the highest cost-

effectiveness.

Figure 2: The comparison of double layer capacitance

(Cdl) values (Li, 2023)

Table 1: Summary of ORR performance of catalysts and

pt/c at 0.1M KOH (Guo, 2024)

Catalyst

name

Half-wave

potential(

V)

Limiting

current(

mA/cm

2

)

Tafel

slope(

mV/dec

)

Ni@NDC 0.793 4.98 109

Fe-Co-

Ni@NDC

+0.109 +0.38 -39

Co-

Ni@NDC

+0.051 +0.36 -2

Fe-

Co@NDC

+0.053 -2.23 +16

Pt/C +0.040 +0.33 -20

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

142

Figure 3: Transition metals and precious metals ORR

oxygen active adsorption energy △E0

4 CONCLUSION

With collation of the literature reveals that even

though the catalyst has good catalytic properties as

well as resistance to toxification. The scope of use of

this technology is limited. The use of ternary metal

catalysts has a tremendous amount of voltage and

energy within them. Mismatched original materials

may cause structural damage inside the battery.

Accelerates battery aging and can even be potentially

dangerous. Even if this technology incorporates

precious metals into non-metallic catalysts enhance

the performance of non-metallic catalysts. But

compared to catalysts made directly from precious

metals there may still be some gaps. For battery

manufacturing costs, this catalyst uses two types of

precious metal ctalysts will undoubtedly lead to an

increase in battery manufacturing prices. In order to

pursue the good anti-poisoning properties of

catalysts. Using Platinum to replace metals such as

Nickel would lead further increase the manufacturing

cost of catalysts. In addition, the manufacturing of

nanometals compared to the direct use of large-

diameter particle metals. The technical costs

contained within it cannot be ignored in catalyst

process manufacturing. Fabrication techniques for

nanometers have process drawbacks. When battery

life runs out battery aftercare is unavoidable. Leakage

of cobalt from the catalyst in this battery can cause

some ecological damage. In future research on

hydrogen energy cells, multi-component nanometal

catalyst technology could provide new idea and solve

the catalyst poisoning in the field of hydrogen fuel

cells, and in subsequent studies, it is not limited to the

effect of carbon monoxide on battery catalysts. It is

possible to advance the study of the catalyst's

antitoxicity to other gases. In future studies,

compared to mitigating cell catalyst poisoning

tackling catalyst poisoning at its source is even more

important. In catalyst material selection, it is hoped

that a catalyst will be created that will be able to

absorb and convert carbon monoxide. Formation of a

new energy source through internal conversion of

carbon monoxide. Achieving the goal of sustainable

recycling of hydrogen energy cells. Researching high

performance and anti-toxicity catalysts while

pursuing simpler manufacturing processes. Striving

for a better balance between performance and

manufacturing costs. In the field of responding to

hydrogen energy fuel cell catalyst poisoning still has

a bright future.

REFERENCES

Xu Zhihong, Zhu Xiaowen, Xu Caini 2023 Structural

characteristics of hydrogen fuel cells and development

overview of hydrogen fuel cell vehicles. Times

Automotive 13 88-90

Zhang Yanhong, Zhou Qi, Wang Caikang, etc. 2023

Development status of non-precious metal catalysts

used for catalyzing CO

2

hydrogenation reaction to

generate carbon containing fuels. Energy Research and

Utilization 5 2-9

Huang Xuelian, Wang Jun, Pei Danni. 2023 Simultaneous

measurement of inorganic gases and total hydrocarbon

impurities in hydrogen gas for fuel cell vehicles using a

gas chromatograph with one injection. Metrology and

Testing Technology 50 21-24

Deng Han, Sun Xiaohui, Lu Lu, etc. 2023 Preparation and

Performance Study of PtCo-N/C Low Platinum

Catalyst. Journal of Dalian Jiaotong University 44 99-

103+113

Cao Yunzhong, Zheng Junning, Wu Hui, etc. 2023

Research progress on Pt based catalysts for catalytic

hydrolysis of ammonia borane to produce hydrogen.

Rare Metals 47 1122-1131

S. Dey, G.C. Dhal 2020 Property and structure of various

platinum catalysts for low-temperature carbon

monoxide oxidations. Materials Today Chemistry 16

2468

Xiaojie Chen, Wenqiong Gou, Jiaqi Xu, etc. 2023 Low-

loading and ultrasmall Ir nanoparticles coupled with

Ni/nitrogen-doped carbon nanofibers with Pt-like

hydrogen evolution performance in both acidic and

alkaline media. Chemical Engineering Journal 471

144481

Chen Qingsong, Guo Guocong, Sun Shigang 2014 Cyclic

voltammetric electrodeposition of cobalt platinum alloy

thin films and their anomalous infrared properties.

Electrochemistry 20 410-415

Zhao Zipeng, Xue Wang, Liu Zeyan, etc. 2022 Graphene-

nanopocket-encaged PtCo nanocatalysts for highly

durable fuel cell operation under demanding ultralow-

Pt-loading conditions. Nat. Nanotechnol 17 968-975

Effect of Cobalt-Platinum Nanoalloy Combination with Non-Metallic Catalyst Fe-N-C on Anti-Poisoning Performance of Hydrogen Fuel

Cell Catalyst

143

Min Jiang, Fei Wang, Fan Yang, etc. 2021 Rationalization

on High-Loading Iron and Cobalt Dual Metal Single

Atoms and Mechanistic Insight into the Oxygen

Reduction Reaction. Nano Energy 93 106793

Ran Lei, Wang Luyuan, Zhang Xingyu, etc 2023 Research

progress on non-precious metal Fe-N-C catalysts for

proton exchange membrane fuel cells. Chemical

Bulletin 86 1426-1433

Li Ziyao 2023 Nanostructure design and ORR-OER

electrocatalytic performance study of iron cobalt based

electrocatalysts. Anhui University of Science and

Technology.

Guo Jiangnan 2024 Preparation and electrocatalytic

properties of PtM (M=Co, Ni) nanocomposites. Central

South University

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

144