Analysis of the Preparation-Storage-Use of Hydrogen

Weisen Ma

Detroit Green Technology Institute, Hubei University of Technology, Wuhan Hubei, 430068, China

Keywords: Hydrogen, Electrolysis of Water, Hydrogen Energy Storage, Full Cells.

Abstract: In the past few decades, the production of electricity generated by chemical fuels has always dominated, but

the greenhouse gases produced by fossil fuels have become a major problem affecting the global climate.

Therefore, hydrogen energy, as the clean energy most used by mankind at present, has extremely high

exploration value. This article analyzes the use process of hydrogen energy in detail from three parts. First

part is the preparation of hydrogen, second part is the storage of hydrogen, and the last is how to use hydrogen.

Proton exchange membrane electrolyzer (PEMWE) technology is the main preparation technology of

hydrogen energy use process, which uses photovoltaic power generation as the main source of electricity. In

this article the principle of PEMWE’s hydrogen production technology and technical components and

functions of PEM electrolyzers, but also compare the more mature Proton exchange membrane (PEM)

technology with the Anion exchange membrane (AEM) electrolyzed water technology with great potential in

the future, and analyze the pros and cons of both. In terms of storage, this paper analyzes the advantages and

disadvantages of gas compressed storage, liquid storage, metal hydride storage and underground storage. In

terms of hydrogen energy treatment. Cogeneration technology, especially in hydrogen fuel cells, is the

primary method for converting hydrogen into electricity, and the remaining hydrogen will play a role in

different fields for different purposes.

1 INTRODUCTION

According to the "World Energy Statistical Yearbook

2023" report, primary energy consumption will

increase in most regions of the world in 2022 (except

Europe and the CIS). Despite rising prices for all three

fossil fuels, natural gas, oil and coal, only natural gas

has seen demand fall. Fossil fuels still account for 82%

of the world's total energy supply (Energy institute,

2023). This will lead to the production of greenhouse

gases, affecting climate change and global warming

(Baroutaji et al., 2023). The increase in the share of

renewable electricity generation has also become a

significant trend, with renewable electricity

(excluding hydropower) growing by 14% in 2022,

meeting 84% of the net increase in electricity demand.

In the 21st century, more and more people believe that

hydrogen is an important energy source that can

change the future energy system (Falcone, Hiete and

Sapio, 2021). Hydrogen fuel cells are the green energy

source most likely to make the "hydrogen economy" a

reality (Cheng et al., 2007). The development

potential of hydrogen energy is reflected in that it is a

green, clean and pollution-free energy source. This

article proposes a hydrogen energy usage process and

analysis of hydrogen production-storage-power

generation, with the purpose of using hydrogen energy

in an environmentally friendly and energy-saving

way. In the process of promoting the development of

hydrogen energy utilization, scientific and reasonable

measures should be taken to realize the dual benefits

of economy and environment.

2 PEM ELECTROLYSIS WATER

HYDROGEN PRODUCTION

TECHNOLOGY

2.1 Technical Principle of Hydrogen

Generation by PEM Electrolytic

Water

The main hydrogen generation technologies of PEM

are divided into two types as PEMFC and PEMWE.

Ma, W.

Analysis of the Preparation-Storage-Use of Hydrogen.

DOI: 10.5220/0013850700004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 133-139

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

133

PEMFC hydrogen generation technology produces

water as a byproduct of the chemical interaction

between hydrogen and oxygen, which transforms

chemical energy into electric energy (Baroutaji et al.,

2023). The chemical principle of the latter PEMWE

technology is as follows. The technical principle of

PEMWE is to inject deionized water into an

electrolytic cell, and the electrolytic cell consists of

two parts, and a is used to separate the two parts.

When an external power source is energized on the

cell, water (H

2

O) breaks down at the cathode and

anode. The reaction formula of cathode and anode is

shown below (Kya et al., 2020).

2𝐻

𝑂

→𝑂

4𝐻

4𝑒

𝐸

1.23𝑉

(1)

2𝐻

2𝑒

→𝐻

𝐸

0.00𝑉 (2)

Of the following two equations, formula (1) is

called oxygen evolution reaction (ORE) and formula

(2) is called hydrogen evolution reaction (HER). In an

acidic environment, the total reaction composed of

two half reactions is shown in formula (3). When a

DC power supply is connected to the electrode and

the applied voltage is higher than the thermodynamic

potential, water begins to be decomposed (Falcão and

Pinto, 2020).

Whole reaction:

𝐻

𝑂→𝐻

𝑂

(3)

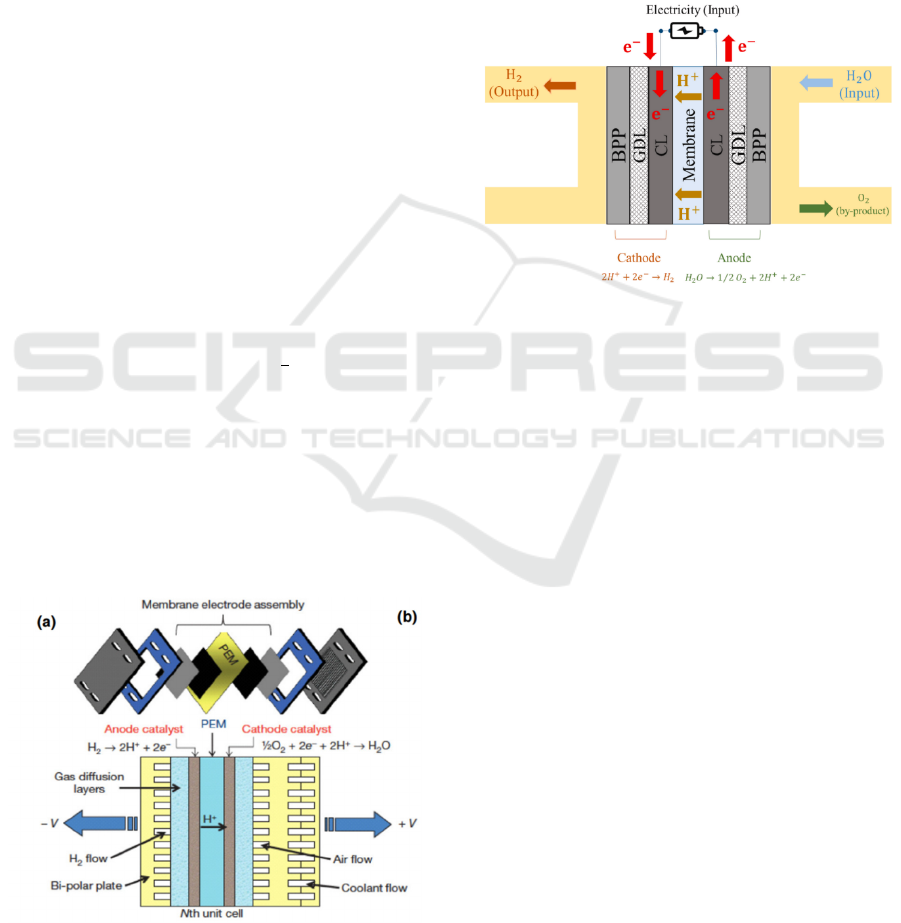

In summary, the technical principle of PEMWE

is that the cathode gains electrons to produce

hydrogen, and the anode loses electrons to produce

oxygen. The intermediate PEM (proton exchange

membrane) plays two roles, one is to allow hydrogen

ions to pass and block electrons, and the other is to

separate hydrogen and oxygen to prevent mixing.

And then end up with hydrogen and oxygen to collect

as shown in figure 1.

Figure 1: The structure of PEM fuel cell (Wang et al.,

2020)

2.2 PEM Electrolysis Water Hydrogen

Production Technology

Components

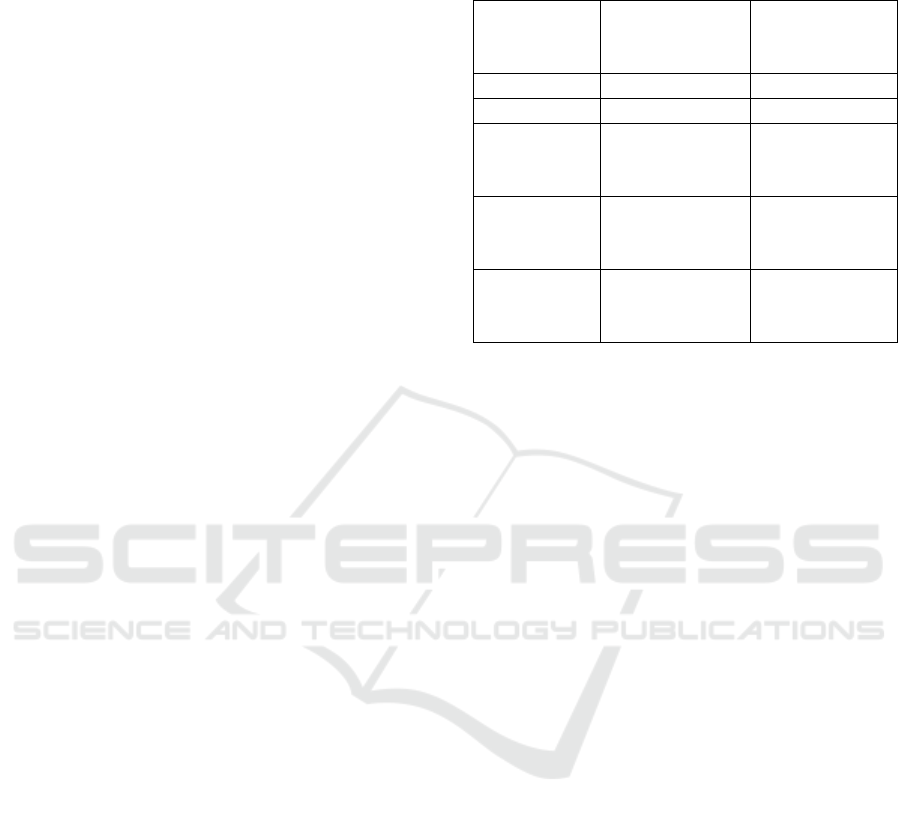

In addition to the DC power supply on the top, there

are four components in PEMWE electrolyzer device

including Bipolar Plates (BPP), Gas Diffusion Layer

(GDL), Catalyst Layer (CL) and Membrane, as

shown in figure 2.

Figure 2: Main components and working principles of

PEMWE (Baroutaji et al., 2023)

2.2.1 Bipolar Plate (BPP)

Also known as the collector plate, the main function

of bipolar plate is to provide two channels of air flow

and current conduction. The former serves to prevent

hydrogen and oxygen from combining in the fuel

electrolyzer, while the latter creates a channel for

electricity to flow between the cathode and anode

(Xiong et al., 2021). BPP is mainly divided into two

types, one is a metal bipolar plate, one is a graphite

bipolar plate. The main disadvantages of graphite

bipolar plates are that their strength is low and the

material is relatively fragile. The thickness of the

material needs to be increased to ensure the strength

of the material. However, increasing the thickness of

the material will lead to the increase of the quality of

the electrolyzer, which is not conducive to the

conditions of lightweight and convenient

transportation. In addition, the use condition of

graphite bipolar plates is high-temperature

graphitization treatment, which requires a long

production cycle. Hence, the aforementioned

shortcomings result in a subpar commercial impact of

graphite bipolar plate. The raw materials of metal

bipolar plates are usually corrosion-resistant metals,

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

134

such as titanium, aluminum, nickel alloys. Despite

challenges stemming from the acidic environment

and corrosion by reducing substances like hydrogen

and oxygen within the electrolytic cell, metal bipolar

plates offer significant advantages including high

strength, excellent conductivity, cost-effectiveness,

and easy scalability in production. Hence, metal

bipolar plates retain considerable application

potential and commercial viability (Wang et al.,

2020).

2.2.2 Gas Diffusion Layer (GDL)

Gas diffusion layer (GDL) is one component of PEM.

Ensuring that the gas can diffuse evenly into the

catalyst layer is the main goal of the gas diffusion

layer. Its porous construction makes it possible for the

gas to pass through and arrive at the intended

location. GDL also has a certain degree of

conductivity and thermal conductivity, which not

only helps to maintain the normal flow of current in

the electrolytic cell, but also helps to evenly distribute

and diffuse the heat inside the electrolytic cell,

thereby providing a suitable working temperature for

the electrolytic cell. The mechanical strength of GDL

provides support and protection for more fragile

membranes and catalyst layers. Its structure can also

drain the water by-product of the electrolyzer, and it

ensures that moisture does not accumulate inside the

electrode, thereby avoiding blocking the gas channel

and affecting performance (Ozden et al., 2019).

2.2.3 Catalyst Layer (CL)

The specific position of the catalytic layer is attached

to both ends of the proton exchange membrane, which

is divided into a cathode catalytic layer and an anode

catalytic layer. Currently, the cathode mainly uses

platinum carbon (Pt/c) catalyst to accelerate the

hydrogen evolution reaction (HER). The platinum-

carbon catalyst is composed of platinum

nanoparticles and carbon carrier, in which the

platinum nanoparticles are efficient hydrogen

precipitation catalysts, while the surface of the carbon

carrier has more pores, which increases the surface

area and stability of the catalyst. However, platinum-

based catalysts have a higher cost than what,

constituting approximately 35% of the total cost of

PEMWE (Baroutaji et al., 2023). Iridium oxide

(IrO

2

), which has good oxygen evolution reaction

(OER) activity and stability and can successfully

encourage oxygen precipitation, is the primary

material used in the anode. Reducing the activation

energy needed for water electrolysis is the catalytic

layer's purpose. As a result, the pace at which

hydrogen and oxygen evolve is accelerated.

Enhancing the electrolysis efficiency is possible by

increasing the electrode's current density through the

design and optimization of the catalytic layer. Lastly,

the catalytic layer's strong chemical stability

guarantees PEMWE's steady operation over the long

run (Sui, Zhu and Djilali, 2019).

2.3 Comparison of Technology of PEM

and AEM

In the field of producing hydrogen through water

electrolysis, PEM and AEM technologies currently

hold a dominant position. These two technologies

differ in their features and benefits. The solid

electrolyte utilized in PEM electrolysis cells ensures a

high energy density and efficiency, which is PEM's

advantage. As a result, PEM technology plays a big

role in the field of producing hydrogen by water

electrolysis. The benefit of AEM technology stems

from the utilization of non-precious metal catalysts,

which significantly reduces material costs and makes

the implementation of AEM technology for hydrogen

production via water electrolysis more economically

feasible (Pushkareva et al., 2020). However, the

current high cost has not affected the competitiveness

of PEM technology, because of the technical maturity

and wide application. The widespread application of

PEM fuel cells provides rich experience and technical

support for hydrogen production, further promoting

the development of PEM technology. Although AEM

technology has advantages in material cost, further

efforts are still needed in terms of technology maturity

and large-scale application (Santoro et al., 2022).

However, with the increasing focus on

environmental awareness and the rapid advancement

of renewable energy technologies, there is a growing

demand for electrolytic water hydrogen production.

This trend provides ample opportunities for the

development of AEM technology in this field (Li and

Baek, 2021). With its flexibility and low cost, AEM

technology is expected to emerge as a key technology

in future water electrolysis-based hydrogen

production (C

hina Energy News Network, 2024). In

summary, PEM and AEM have their own advantages

in hydrogen production technology through water

electrolysis. PEM technology is favored for its high

efficiency and maturity, while AEM technology

shows great potential for its economy and flexibility.

These two technologies will probably become

Analysis of the Preparation-Storage-Use of Hydrogen

135

increasingly significant in the field of hydrogen

production by electrolytic water in the future as

technology develops and application scenarios grow.

2.4 Source of Electricity for Hydrogen

Production

2.4.1 Generating Electricity from

Non-Renewable Sources

According to the report from the World Energy

Statistics Review, global energy demand will grow by

1% in 2022, with a record growth in renewable

energy. However, the dominant position of fossil fuels

has not changed, making up 82% of the world’s

energy supply. Natural gas contributes 27% to the

overall electricity generation from fossil fuel power

globally (Leonard, Michaelides and Michaelides,

2020). However, coal still ranks first in the total

power generation, accounting for approximately

35.4%.

2.4.2 Generating Electricity from

Renewable Sources

According to data from British Petroleum’s latest BP

World Energy Outlook, by the end of April 2023,

China had amassed a combined installed capacity of

820 GW from wind and solar power, constituting a

substantial portion of the nation's total power

generation capacity, which is 31% (Leonard,

Michaelides and Michaelides, 2020). Of this 31% of

total renewable energy capacity, wind power

accounted for 14 percent, while solar power

accounted for 17 %. Of the new installed capacity in

2023, wind added 14.2 GW and solar added 48 GW,

which accounted for 16.8% and 57.2% of the new

installed capacity, respectively. This data further

indicates that China's installed capacity of renewable

energy has increased by 11.5% year-on-year. By

2050, the share of wind and solar power in China's

total power generation will increase from less than

10% today to more than 50%, and may even increase

to more than 65%.

2.4.3 Cost Comparison

The cost of different method for hydrogen production

is summarized in table 1. The cost of electrolyzing

water is more than three times that of fossil fuels,

making it expensive. Additionally, the electricity cost

of electrolyzed water accounts for a significant

proportion of the total cost (>50%).

Table 1: Production costs from various energy

sources (China Energy Storage Network, 2024)

Traditional

method

Cost of raw

materials

(dollars/kg)

Cost of hydrogen

production

(dollars/m3)

Coal 8.68-18.33 1.36-1.90

Natural gas 0.23-0.28(m3) 1.36-1.89

Electrolysis of

water

Proportion of

electricity

consumption cost

Cost of hydrogen

production

(dollars/m

3

)

Proton

exchange

membrane

50.52 5.54

Alkaline

water

electrolysis

74.91 5.54

3 HYDROGEN ENERGY

STORAGE

3.1 Gaseous Compression Storage

Currently, among various hydrogen storage

technologies, room temperature compressed gas

hydrogen storage technology (CGH2) is the most

mature one. More than 80% of the 215 hydrogen

stations operating worldwide in 2010 used CGH2

technology. At present, the pressure of CGH2's on-

board storage tank is as high as 70MPa, which

changes the physical state of hydrogen and reduces

the distance between gas molecules, thereby

compressing and storing hydrogen into the hydrogen

storage tank. CGH2 technology requires low

equipment costs, high safety, and strong flexibility.

The storage of compressed gas at room temperature

is not limited by geographical location and climate

conditions, and can be stored and transported in

various environments. However, the bulk density of

hydrogen does not increase with the increase of

pressure, which makes it difficult to increase the

density of hydrogen (Yanxing et al., 2019), and if the

pressure is too large, it will also bring safety

problems.

3.2 Liquid Storage

The operational principle of liquid storage technology

(LH

2

) is to use a compressor to compress hydrogen

gas to extremely high pressure, thereby increasing gas

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

136

density, and then reducing the temperature of high-

pressure gas to -253 ℃ to achieve liquefaction.

Compared to gaseous compression technique, liquid

storage technology has a higher hydrogen density.

High energy density and long-term stability are

features of liquid storage technology. Because of its

higher liquid storage density and comparatively

stable physical characteristics, more hydrogen may be

held in each container. Nevertheless, the liquefaction

process is energy-intensive. It is inevitable that heat

will enter the container, causing a hydrogen loss of

2% -3%. Therefore, liquid storage technology is more

suitable for high-tech industries like the aerospace

industry (which consider performance more than

cost) (Yanxing et al., 2019).

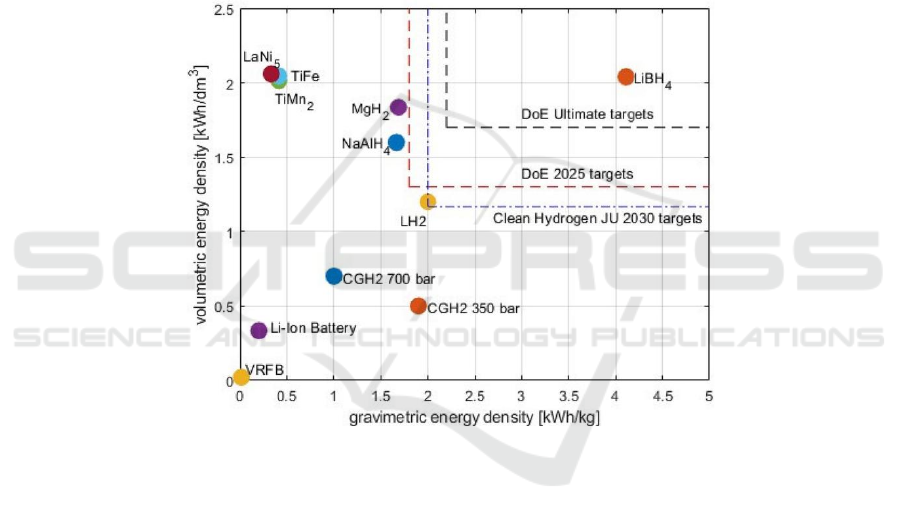

3.3 Metal Hydride Storage

Metal hydride storage is the use of metal or alloy with

hydrogen reaction to produce metal hydride, when

hydrogen and metal or alloy contact, hydrogen atoms

will enter the metal or alloy lattice, thus forming a

stable compound, the metal hydride. Heating the

compound until hydrogen is needed breaks the

chemical bond between the hydrogen atoms and the

metal, releasing hydrogen (Klopčič et al., 2023).

Metal hydrides have small space requirements and

strong ductility. Figure 3 lists the volume and weight

energy density of different metal hydride hydrogen

storage systems.

Figure 3. Volumetric and gravimetric energy densities of storage systems (Klopčič et al., 2023).

3.4 Ground Storage

In June 2019, underground storage was identified by

the International Energy Agency (IEA) as the optimal

storage mode for long-term and large-scale storage

(Elberry et al., 2021). It is a method to store hydrogen

by using the physical characteristics of underground

space. The injection of hydrogen gas into the ground

by drilling holes or pipelines into depleted oil and gas

reservoirs, aquifers, or cave storage (excavation or

dissolution of mined rock, such as salt coal, igneous

and metamorphic rocks). These underground media

have many pores and good permeability, and

hydrogen enters underground materials through

adsorption, dissolution, etc. A buffer gas such as N

2

or CH

4

is injected before hydrogen is injected. The

buffer gas is periodically expanded and compressed

to ensure the ground pressure and transportation rate

required for transportation (Zivar et al., 2021). The

underground hydrogen storage has a large capacity,

long storage time, and strong safety, because the

underground structure acts as a natural barrier,

separating hydrogen from the outside world and

greatly reducing risks. And this storage method does

not produce harmful substances, making it more

environmentally friendly.

Analysis of the Preparation-Storage-Use of Hydrogen

137

4 HYDROGEN PROCESSING

METHOD

4.1 Hydrogen Fuel Cell

Currently, hydrogen fuel cell technology primarily

finds application in the realm of new energy vehicles.

With zero emissions while using hydrogen and

oxygen as fuel, PEMFC technology's cleanliness and

environmental friendliness are its greatest advantages

(Cheng et al., 2007). Combination of heat and power

(CHP) is currently a mature technology suitable for

industrial applications and large-scale commercial

use for a high efficiency in power generation. Within

the entire energy production and supply system,

cogeneration utilizes the heat generated by fuel cells

to generate electricity, which is then converted into

low-grade thermal energy in power engineering,

resulting in higher efficiency in the utilization of

hydrogen energy. Therefore, the efficient and

environmentally friendly energy utilization method

combining the advantages of fuel cell and

cogeneration has broad application prospects

(Arsalis, 2019).

4.2 Analysis of Utilization Scenarios

Of the hydrogen production process, about 90% is

currently used for ammonia synthesis, methanol

production and refineries. This ratio will gradually

decline over the next few years, until hydrogen

production increases and this energy source is

gradually combined with other energy sectors, such

as for grid power generation (Tarhan and Çil, 2021).

In the metallurgical, fertilizer, and chemical

industries, as well as the processing and upgrading of

crude oil, hydrogen has a very high commercial

value. Additionally, it is important for fuel upgrading,

aviation and marine fuels, and other sectors (Okolie

et al., 2021).

5 CONCLUSION

PEMWE water electrolysis technology is now a very

mature technology, has been widely used and studied.

Further research on PEMWE is currently focused on

the modeling of electrolyzers and the cost efficiency

of electrocatalysts. In comparison with AEM

electrolysis water technology, PEMWE currently has

rich experience and market support. However, as the

demand for hydrogen energy continues to rise, AEM

electrolysis water technology that doesn't necessitate

valuable metals as materials has shown advantages

such as low cost and flexibility, and has greater

potential in future. As for hydrogen storage, the

selection of different storage technologies depends on

different regions, different economic conditions,

different technical differences and so on. This paper

analyzes the advantages and disadvantages of four

different storage technologies, namely gas

compressed storage, liquid storage, metal hydride

storage and underground storage, which should be

comprehensively considered according to the

requirements of specific application scenarios, safety,

cost, efficiency and other factors, and make decisions

based on the maturity and sustainability of the

technology. Regarding the utilization of hydrogen

energy, current hydrogen fuel cells are predominantly

employed in the new energy automotive sector. The

specific suggestion is to utilize the heat generated by

PEMFC when converting hydrogen energy into

electric energy and employing the CHP mode, the

efficiency of hydrogen fuel cell utilization is greatly

improved. The process of using renewable energy to

generate electricity, producing hydrogen through

PEMWE technology, and finally generating

electricity through hydrogen fuel cells through

cogeneration mode has the characteristics of

sustainability, environmental protection, and

efficiency, and has broad application prospects.

REFERENCES

Energy institute. Statistical Review of World Energy

(2023). Retrieved on April 15 2024, retrieved from

https://www.energyinst.org/__data/assets/pdf_file/000

7/1408075/5456af7ed79ea2b1943197dce2f0b019e78f

3ee2.pdf

Baroutaji, A., Arjunan, A., Robinson, J., Abdelkareem, M.

A., & Olabi, A. G. 2023 Additive manufacturing

for Proton Exchange Membrane (PEM) hydrogen

technologies: merits, challenges, and

prospects. International journal of hydrogen energy 52

561-584

Falcone, P. M., Hiete, M., & Sapio, A. 2021 Hydrogen

economy and sustainable development goals: Review

and policy insights Current opinion in green and

sustainable chemistry 31 100506

Cheng, X., Shi, Z., Glass, N., Zhang, L., Zhang, J., Song,

D., ... & Shen, J. 2007 A review of PEM hydrogen fuel

cell contamination: Impacts, mechanisms, and

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

138

mitigation Journal of Power Sources 165 739-756

Kaya, M. F., Demir, N., Rees, N. V., & El-Kharouf, A. 2020

Improving PEM water electrolyser’s performance by

magnetic field application Applied Energy 264 114721

Falcão, D. S., & Pinto, A. M. F. R. 2020 A review on PEM

electrolyzer modelling: Guidelines for beginners

Journal of cleaner production 261 121184

Wang, Y., Diaz, D. F. R., Chen, K. S., Wang, Z., & Adroher,

X. C. 2020 Materials, technological status, and

fundamentals of PEM fuel cells–a review Materials

today 32 178-203

Xiong, K., Wu, W., Wang, S., & Zhang, L. 2021 Modeling,

design, materials and fabrication of bipolar plates for

proton exchange membrane fuel cell: A review Applied

energy 301 117443

Ozden, A., Shahgaldi, S., Li, X., & Hamdullahpur, F. 2019

A review of gas diffusion layers for proton exchange

membrane fuel cells-With a focus on characteristics,

characterization techniques, materials and

designs Progress in Energy and Combustion Science 74

50-102

Baroutaji, A., Arjunan, A., Robinson, J., Abdelkareem, M.

A., & Olabi, A. G. 2023 Additive manufacturing for

Proton Exchange Membrane (PEM) hydrogen

technologies: merits, challenges, and prospects

International journal of hydrogen energy 52 561-584

Sui, P. C., Zhu, X., & Djilali, N. 2019 Modeling of PEM

fuel cell catalyst layers: status and outlook

Electrochemical Energy Reviews 2 428-466

Pushkareva, I. V., Pushkarev, A. S., Grigoriev, S. A.,

Modisha, P., & Bessarabov, D. G. 2020 Comparative

study of anion exchange membranes for low-cost water

electrolysis International Journal of Hydrogen Energy

45 26070-26079

Santoro, C., Lavacchi, A., Mustarelli, P., Di Noto, V., Elbaz,

L., Dekel, D. R., & Jaouen, F. 2022 What is next in

anion ‐ exchange membrane water electrolyzers?

Bottlenecks, benefits, and future ChemSusChem 15

e202200027

Li, C., & Baek, J. B. 2021 The promise of hydrogen

production from alkaline anion exchange membrane

electrolyzers Nano Energy 87 106162

China Energy News Network (cpnn),

https://cpnn.com.cn/news/baogao2023/202306/t20230

607_1607604.html, last accessed 2024/04/13

Leonard, M. D., Michaelides, E. E., & Michaelides, D. N.

(2020). Energy storage needs for the substitution of

fossil fuel power plants with renewables. Renewable

Energy, 145, 951-962.

China Energy Storage Network (ESCN),

https://www.escn.com.cn/2022-

11/01/c_1211743453.htm, last accessed 2024/04/13.

Yanxing, Z., Maoqiong, G., Yuan, Z., Xueqiang, D., & Jun,

S. 2019 Thermodynamics analysis of hydrogen storage

based on compressed gaseous hydrogen, liquid

hydrogen and cryo-compressed hydrogen International

Journal of Hydrogen Energy 44 16833-16840

Klopčič, N., Grimmer, I., Winkler, F., Sartory, M., &

Trattner, A. 2023 A review on metal hydride materials

for hydrogen storage Journal of Energy Storage 72

108456

Elberry, A. M., Thakur, J., Santasalo-Aarnio, A., & Larmi,

M. 2021 Large-scale compressed hydrogen storage as

part of renewable electricity storage

systems. International journal of hydrogen energy 46

15671-15690

Zivar, D., Kumar, S., & Foroozesh, J. 2021 Underground

hydrogen storage: A comprehensive review

International journal of hydrogen energy 46 23436-

23462

Cheng, X., Shi, Z., Glass, N., Zhang, L., Zhang, J., Song,

D., ... & Shen, J. 2007 A review of PEM hydrogen fuel

cell contamination: Impacts, mechanisms, and

mitigation Journal of Power Sources 165 739-756

Arsalis, A. 2019 A comprehensive review of fuel cell-based

micro-combined-heat-and-power systems Renewable

and Sustainable Energy Reviews 105 391-414

Tarhan, C., & Çil, M. A. 2021 A study on hydrogen, the

clean energy of the future: Hydrogen storage methods

Journal of Energy Storage 40 102676

Okolie, J. A., Patra, B. R., Mukherjee, A., Nanda, S., Dalai,

A. K., & Kozinski, J. A. 2021 Futuristic applications of

hydrogen in energy, biorefining, aerospace,

pharmaceuticals and metallurgy International journal of

hydrogen energy 46 8885-8905

Analysis of the Preparation-Storage-Use of Hydrogen

139