Method to Reduce the Cost of Proton Exchange Membrane Water

Electrolysis

Yongqi Hu

Water Supply and Drainage, East China Jiaotong University, Luoshi South Road, Hongshan District, Wuhan City, Hubei

Province, 430070, China

Keywords: PEM Water Electrolysis, Low Iridium Catalyst, Water Electrolysis, Stainless Steel Bipolar Plate, Hydrogen

Production Efficiency.

Abstract: Hydrogen energy is a kind of clean, pollution-free, long-term storage of secondary energy. It plays a pivotal

role in an energy system dominated by renewable energy sources to relealize emissions peaking and carbon

neutrality goals. The production of green hydrogen is a prerequisite for decarbonization. Proton exchange

membrane (PEM) hydroelectrolysis technology is an important way to produce green hydrogen using green

electricity. However, the high cost restricts the popularization of PEM electrolysis technology. To reduce the

cost of hydrogen fuel, it is necessary to strengthen the research on hydrogen production technology. The study

found that the cost of electrolysis is mainly composed of two parts: equipment cost and energy cost, replacing

expensive materials with low-cost materials to make electrolytic equipment and catalysts, and changing the

current density and temperature can reduce the cost of pem electrolytic water. However, how to make the

electrolytic equipment made of cheap materials meet or exceed the requirements of electrolysis still needs

further research, but how to make the electrolytic equipment made of cheap materials meet or exceed the

requirements of electrolysis still needs further research. This paper summarizes and analyzes the cost structure

of PEM electrolysis and the ways to reduce the cost and looks forward to the improvement direction of PEM

electrolysis system from two aspects of equipment cost and energy cost.

1 INTRODUCTION

Nowadays, the water electrolysis of hydrogen

production process mainly includes alkaline water

electrolysis (ALK), proton exchange membrane

water electrolysis (PEM), anion exchange membrane

water electrolysis (AEM) and solid oxide water

electrolysis (SOEC). Among them, the proton

exchange membrane water electrolysis hydrogen

production technology has developed rapidly in

recent years and is considered as one of the most

promising water electrolysis technologies to produce

hydrogen at this stage. PEM has compact structure,

high current density, small floor area, fast response

speed, electrolytic hydrogen production efficiency

can reach more than 85%, wide power regulation

range, good adaptation with fluctuating wind power

and photovoltaic, high integration degree, can

achieve long-term stable operation, and simple

opening and closing operation (Ge et al., 2024).

However, because the PEM electrolytic cell is

working in an acidic environment, platinum and

iridium need to be used as catalysts, the bipolar plate

and diffusion layer use titanium-based material (Sun

et al., 2024), the device cost is about 3~5 times of the

alkaline electrolytic cell, and the proton exchange

membrane mainly depends on import, and the service

life is short. This research looks for ways to lower the

cost of PEM water electrolysis and advance the

technology to produce more green hydrogen using

PEM water lysis.

2 PROTON EXCHANGE

MEMBRANE PRINCIPLE

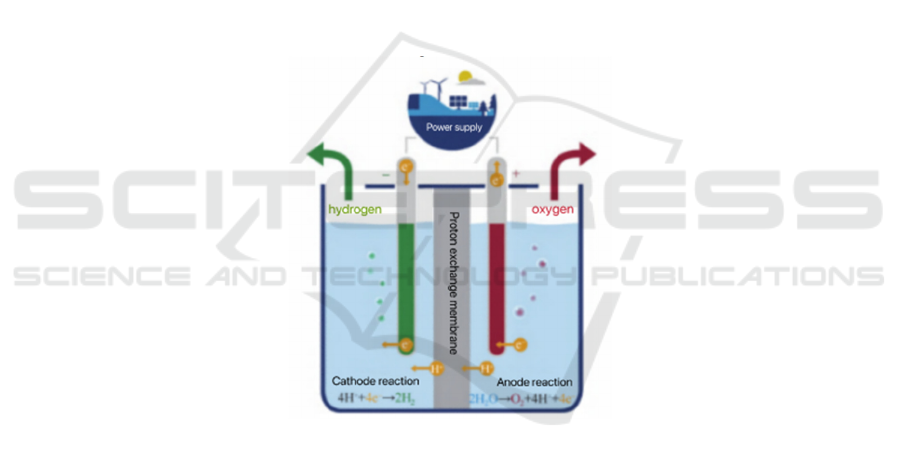

PEM electrolysis of water for hydrogen production is

an efficient electrolysis technology based on ion

exchange technology. Membrane electrode assembly

(MEA), which comprises of anode and cathode

Hu, Y.

Method to Reduce the Cost of Proton Exchange Membrane Water Electrolysis.

DOI: 10.5220/0013850300004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 127-132

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

127

diffusion layer, anode and cathode catalytic layer, and

proton exchange membrane, is the essential

component of PEM electrolytic hydrogen production.

Schematic of PEM electrolysis cell can be seen in

figure 1. Proton exchange membrane is a kind of

polymer material, mostly using Nafion membrane

(Song et al., 2024), which plays an important role in

isolating the cathode and anode. The membrane used

in electrolysis has selective permeability, which can

conduct protons, but blocks the transmission of

electrons and gases. The catalytic layer is where

electrochemical reactions take place, and precious

metals are usually used as catalysts. The diffusion

layer is the intermediate layer between the collecting

plate and the catalytic layer, which transmits water,

gas and current. The electrochemical reaction occurs

at the three-phase interface (Wen et al., 2023), at the

junction of the proton exchange membrane, catalyst

and water.

Water is decomposed with electricity, generating

O2 and H+ on the anode side. The reaction occurring

in the PEM electrolytic cell is performed as in

equation (1) to equation (3).

Anode: 2H

2

O → 4H

+

+ O

2

+ 4e

-

(1)

Cathode: 4H

+

+ 4e

-

→ 2H

2

(2)

Whole reaction: 2H

2

O → 2H

2

+ O

2

(3)

Specifically, in the proton exchange membrane

electrolytic cell engineering, under the action of input

power and catalyst, water molecules in the anode is

decomposed into oxygen, H

+

and electron e

-

, H

+

and

water molecules into hydration ion H

3

O

+

, through the

membrane to the cathode under the electric field,

while the electron through the external circuit to leave

the electrolytic cell to the cathode, hydration ion

H

3

O

+

and electron e-in the cathode and solution

interface reduction reaction to produce hydrogen.

Figure 1: Schematic of PEM electrolysis cell (Song et al., 2024)

3 INFLUENCING FACTOR FOR

PEM PERFORMANCE

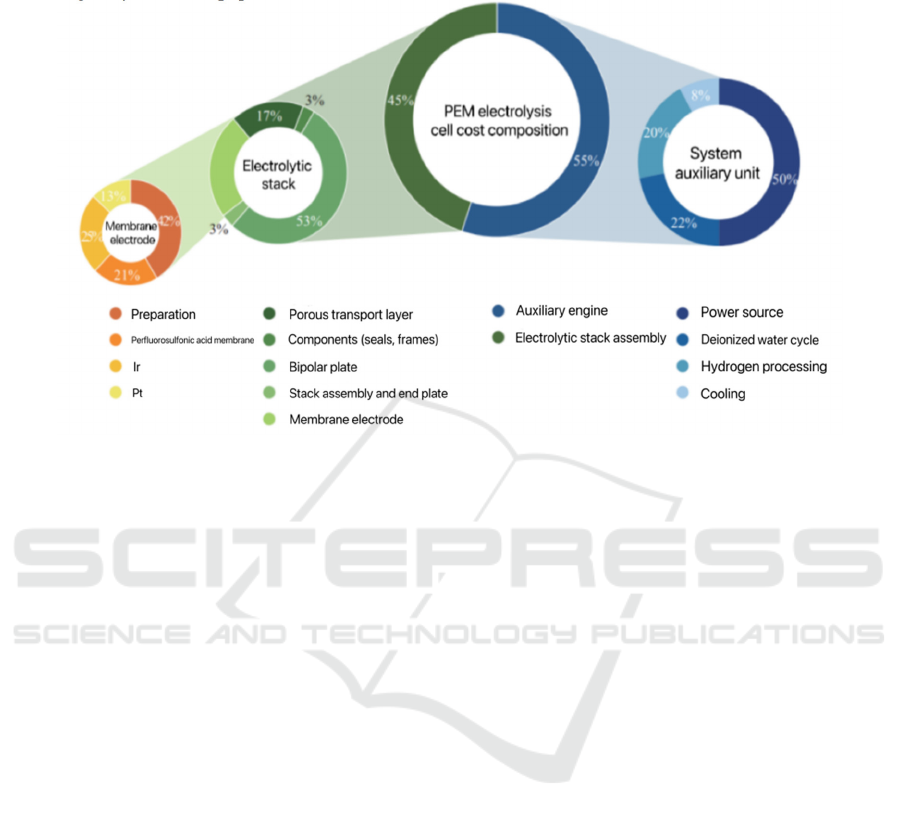

The cost of hydrogen production consists of four

parts: equipment cost, energy cost, other operating

cost and raw material cost (Zhao et al., 2021). Among

them, the energy cost, namely the electricity cost,

accounts for the largest proportion, generally

40%~60% (Guo et al., 2020; H, 2021 & Zhang et al.,

2021), or even up to 80% (The China Hydrogen

Energy Alliance, 2020), which is mainly affected by

the efficiency factor of electrolytic hydrogen

production. As a result, one crucial metric to capture

the economics of hydrogen production is its

efficiency of production. In order to lower the cost of

producing hydrogen from PEM water, it is crucial to

optimize the system's operating parameters and boost

production efficiency. The price of essential parts like

bipolar plates largely determines the equipment cost.

Because bipolar plates typically need to be coated

with Au or Pt, their cost makes up roughly 53% of the

total. The innovation of material technology to ensure

the performance of bipolar plates is of great

significance in terms of equipment cost reduction.

Less affordable alternative materials are currently

being studied. The rare metal Ir is indispensable for

making membrane electrodes. Although the cost of

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

128

anode catalyst is not large in the total cost of the

electrolytic cell is large, the demand for iridium will

increase greatly with the popularization of iridium

technologies, such as PEM hydro electrolysis for

hydrogen production (Figure 2).

Figure 2: Cost break down for 1MW PEM electrolyser (International Renewable Energy Agency, 2020)

4 RESOLVENT FOR PEM

PERFORMANCE

ENHANCEMENT

4.1 Reduce the Equipment Cost

4.1.1 Change the Material of the Bipolar

Plate

The bipolar plate functions to provide mechanical

support to separate the membrane electrodes in the

stack, conduct heat and current in the stack, and

disperse water inside the PEM stack to deliver the

generated gas to the outlet. Generally, with gold-

plated or platinum-coated titanium plate as a bipolar

plate. The oxide film on the surface of the titanium

plate is low, and the oxide film on the surface must be

removed before coating. In addition, electroplating

needs to be punched on the surface, which will reduce

the corrosion resistance, and the coating thickness

needs to be increased to reduce the impact of the

pinhole. The thick coating and the complex

manufacturing process make the manufacturing cost

of the bipolar plate high, accounting for 18%~21% of

the total cost of the electrolytic cell (GAOAS et al.,

2026). In recent years, researchers have tried to use

non-precious metal material as the main material of

bipolar plate and modify its surface. Rojas et al.

(2021) used CrN/TiN, Ti/TiN, Ti and TiN as coatings,

and different models of stainless steel SS321,

SS316L, and SS904L as substrates. They were made

by PVD method. After testing the performance of the

electrolytic cell, they found that the performance of

CrN/TiN combination was comparable to that of

titanium-based bipolar plates coated with platinum.

4.1.2 Low-Cost HER Catalysts

Cathodic catalyst catalyzes the hydrogen evolution

reaction (HER) in the process of water electrolysis,

generally using platinum-based precious metal. The

platinum-catalyzed hydrogen evolution is three

orders of magnitude faster than the order of anode

(Hong, Gu and Zhen, 2024). Although the amount of

cathodic platinum is much lower than that of anodal

iridium, the amount of Pt still will increase

significantly with the large-scale application of PEM

hydroelectrolysis. Therefore, the development of low

Pt catalysts such as single atom catalyst, Pt alloy

catalyst and non-PT catalyst can effectively reduce

the cost of HER catalyst. Recently, it was found that

materials such as phosphide (CoP), sulfide (MoS2)

and nitride may replace Pt in the manufacture of

cathode catalysts, which have higher activity, better

stability and lower cost, although their performance

is still inferior to that of Pt (Ma et al., 2022).

Method to Reduce the Cost of Proton Exchange Membrane Water Electrolysis

129

4.1.3 The OER Catalyst for the Low Ir

Compared with the cathode hydrogen evolution

reaction, the reaction dynamics is slower and the

working potential is higher (> 1.23V) (Hong, Gu and

Zhen, 2024). The catalyst material needs to withstand

the high potential, strong oxidation and strong acidic

environment of the anode, which only some precious

metals can meet.

The anode catalyst of PEM electrolytic cell

commonly used in industry is mainly IrBlack and its

oxide IrO

2

. Considering the small Ir reserves and high

price, the anode catalyst becomes one of the main

obstacles to reduce the cost of PEM electrolytic cells.

Research and development of high activity, high

stability of PEM low iridium catalyst, is the key to

realize the commercial application of PEM

electrolytic cell. In recent years, doping or loading Ir

and oxides become the mainstream research

direction, usually known as low Ir catalyst, through

suitable preparation process, screening and

preparation performance of excellent anode catalyst,

effectively reduce the amount of precious metal Ir.

Doping other metallic elements with Iridium to

Form binary or ternary composite is a method to

directly reduce the Ir content in the catalyst. Its form

can be abbreviated as IrxMyNzOa, where M and N

are other precious metals or non-precious metals. The

addition of non-precious metals can effectively

expand the surface area of the catalyst and further

reduce the amount of precious metals without

reducing the activity. Commonly used non-precious

metals include Sn, Ta, Mo, Gd, Ce and other (Wang

et al., 2020 & Wang et al., 2021).

In addition to direct bonding, the doped

components can also adjust the electronic structure of

Ir by introducing oxygen vacancies, such as doped Fe,

Co, Ni, Zn, etc., which can produce large amounts of

oxygen vacancies. The crystal phase changes caused

by the introduction of other elements into the iridium-

based catalyst can also effectively enhance the OER

activity of the catalyst, such as the preparation of

perovskite-type and pyrochlorite-type iridium-based

catalyst (Hong, Gu and Zhen, 2024).

Loading the precious metal on the carrier is

another effective way to improve the dispersion and

reduce the dosage. It can also improve the utilization

rate of Ir through the carrier and the carrier to improve

the intrinsic activity of the precious metal. Due to the

harsh OER reaction conditions, the electrode catalyst

carrier needs to have both oxidation resistance,

corrosion resistance and high electrical conductivity

properties. However, common electrochemical

carriers cannot meet the above requirements at the

same time, such as cheap metals Ni, Fe, Co have good

electrical conductivity but poor corrosion resistance;

SnO

2

, TiO

2

, SiO

2

and others have acid resistance but

are all semiconductors or insulators with poor

electrical conductivity. Despite their corrosion

resistance and high conductivity, carbon carriers can

easily oxidize at high potentials. Therefore, materials

such as doped metal oxides, metal carbide and metal

nitrides have become the focus of supported iridium

catalyst carriers in recent years (Hong, Gu and Zen,

2024).

4.1.4 Change the Proton Exchange

Membrane Material

As a key component of PEM cell, the proton

exchange membrane is one of the determinants of the

cost and performance of PEM cell, and it acts as a

barrier to the conduction of protons and the resulting

gas produced. The key indicators of the proton

exchange membrane include electrical conductivity,

gas permeability, dimensional stability, and chemical

stability. Generally composed of polymer backbone

and negatively charged ion exchange groups,

additional additives and enhancers can be added to

improve membrane stability and reduce gas cross-

diffusion.

The most widely used in the PEM electrolytic cell

is the perfluoro sulfonic acid (PFSA) membrane, also

known as the Nafion membrane. The membrane

internal resistance is higher, the required electrolytic

voltage is higher, and the electrolytic efficiency of the

electrolytic cell is lower, but reducing the thickness

of the proton exchange membrane will lead to gas

penetration, reduce the purity of hydrogen

production, reduce the chemical and mechanical

stability of the membrane, and curtail the life of the

electrolytic cell. In addition, Nafion film also has

disadvantages such as high cost and fluorine pollution

(Beyraghi et al., 2020). Therefore, it is significant to

develop low-cost proton exchange membrane

materials with high conductivity.

Hydrocarbon based membrane not only low cost,

high conductivity, but also has high chemical stability

and dimensional stability, but also can reduce gas

penetration, is the first choice to replace Nafion

membrane.

The development of hydrocarbon-based

membrane and ionomer has great potential for cost

reduction, which is of great significance for the

construction of low-cost and high-performance PEM

electrolytic cell (Ma et al., 2022). Among them,

sulfonated polyaromatic ether is easy to synthesize

and modify and has excellent film formation, which

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

130

has wide applications in the preparation of proton

exchange membrane.

4.2 Improve the Efficiency of

Hydrogen Production

4.2.1 Relationship Between Current Density

and Hydrogen Production Rate

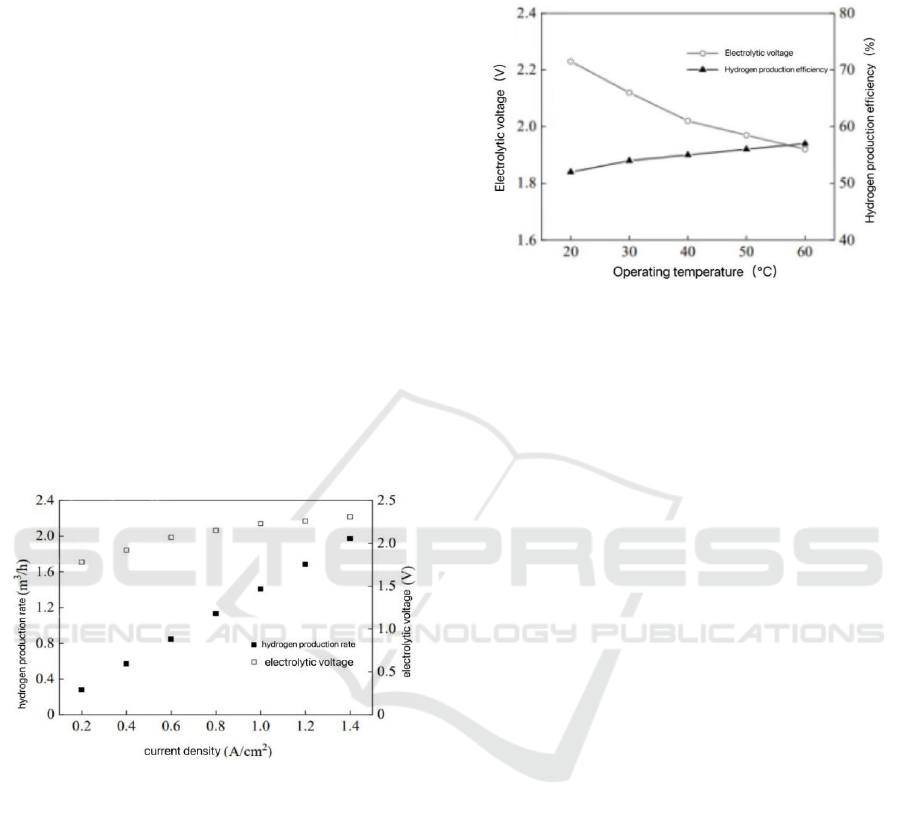

According to ZHU et al. (2020), when current density

rises, the electrolytic cell chamber's average

electrolytic voltage rises steadily and the rate at which

hydrogen is produced rises progressively as well.

Figure 3 illustrates that the rate of hydrogen

production is about 2.2 m3/h when the current density

is 1.4A / cm

2

. This is because the auxiliary equipment

gradually reaches the rated load operation state, and

the power utilization efficiency is gradually

improved.

In general, the PEM hydroelectrolysis hydrogen

production system has obvious technical economy

when the current density is high than when the current

density is low, which is consistent with the conclusion

that GRESPI et al (2023) PEM system running 60kW.

Figure 3: Relationship between current density and

hydrogen generation rate (Zhu et al., 2024)

4.2.2 Relationship Between Operating

Temperature and Hydrogen

Production Efficiency

The holding current density is 1.4A / cm

2

. The

electrolytic cell's average chamber voltage sharply

drops as the operating temperature rises, and the

system's efficiency in producing hydrogen is likewise

enhanced. Figure 4 illustrates that the efficiency of

hydrogen production is around 57% at an operating

temperature of 60 ℃ . This is because raising the

temperature lowers the active overpotential, quickens

the rate of the electrochemical reaction, and enhances

the electrolytic cell's performance. As a result, the

system uses less energy to produce hydrogen per unit.

OZDEMIR et al (2023) uses laboratory PEM

electrolytic cell at different temperatures, and the test

results are consistent with this test.

Figure 4: Cell voltage and hydrogen production efficiency

(Zhu et al., 2024)

5 CONCLUSION

This paper aims to reduce the cost of pem electrolysis

water, make hydrogen as a common fuel in the future,

and promote the application and development of

green hydrogen hydrogen production technology and

equipment. In terms of equipment costs, bipolar

plates, proton exchange membranes, and precious

metal catalysts make the equipment cost of pem water

electrolysis systems extremely high. Using stainless

steel as the main material and surface modification to

make bipolar plate, using cheap materials to make

proton exchange membrane, using low-cost, low

iridium catalyst play important roles in reducing the

equipment cost. In terms of energy cost, current

density and operating temperature are effective

control parameters for optimizing hydrogen

production efficiency. Hydrogen production

efficiency is influenced by both current density and

operating temperature. The peak working parameter

of hydrogen production efficiency appears at the

current density of 1.4A /cm2 to 1.7A/cm2, and the

best working temperature is about 60℃. Under these

conditions, the hydrogen production efficiency can

reach 50%-70%. Maintaining the optimal operating

temperature and current density, and making the low-

cost equipment achieve the same electrolytic effect as

the original expensive equipment is a problem that

needs to be overcome.

Method to Reduce the Cost of Proton Exchange Membrane Water Electrolysis

131

REFERENCES

Ge Shuqiang, Bai Jie, Ding Yongchun, et al. 2024

Development status and prospect of renewable energy

hydrogen production technology and its main

equipment Journal of Taiyuan University of

Technology 1-39

Sun Hao, Wu Weining, Chen Lijie, et al. 2024 Overview on

the development of new energy water hydrogen

production technology Journal of Power 1-18

Song Jie, Gao Jie, Liang Danxi, et al. 2024 Study of proton

exchange membrane Power Construction, 45 58-78

Wen Chang, Zhang Bohan, Wang Yaqin, et al. 2023

Research progress of high efficiency proton exchange

membrane water electrolysis technology Journal of

Huazhong University of Science and Technology

(Natural Science Edition) 51 111-122

Zhao Xueying, Li Gendi, Sun Xiaotong, et al. 2021 Key

technology and application progress of electrolytic

hydrogen production under the target of "double

carbon" The Global Energy Internet, 4 436-446

Guo Xiuying, Li Xianming, Xu Zhuang, et al. 2020 Cost

analysis of hydrogen production by electrolysis of

renewable energy. Energy Storage Science and

Technology, 9 688-695

Hu Daling. SIEMENS energy Power-to-X solution.2021

Renewable Energy Hydrogen Production Forum,

Shanghai

Zhang Xuan, Fan Xinye, Wu Zhenyu, et al. 2021 Hydrogen

supply chain cost analysis and suggestions Chemical

industry progress 41 2364

The China Hydrogen Energy Alliance. 2020 China

Hydrogen energy and fuel cell industry manual. Beijing

International Renewable Energy Agency. 2020 Green

hydrogen cost reduction: scaling up electrolysers to

meet the 1.5℃climate goal. AbuDhabi

Gagoas, Ansarsa, Saruhanb, et al. 2026 Protective coatings

on stainless steel bipolar plates for proton exchange

membrane ( PEM ) electrolysers. Journal of power

sources, 307 815-825

Rojasn, Sánchez-Molinam, Sevillag, et al. 2021 Coated

stainless steels evaluation for bipolar plates in PEM

water electrolysis conditions. International journal of

hydrogen energy, 46 25929-25943

Hong Siqi, Gu Fangwei, Zhen GJinyu. 2024 Development

status and prospect of low-iridium hydrogen catalyst

produced by PEM water electrolysis Chemical progress

1-15

Ma Xiaofeng, Zhang Shuhan, He Yong, et al. 2022

Research status and application prospect of PEM water

electrolysis for hydrogen production technology The

Journal of Solar Energy 43

420-427

Wang Yahui, Hao Shaoyun, Liu Xiangnan, et al. 2020 Ce-

dopedIrO(2)electrocatalysts with enhanced

performance for water oxidation in acidic media ACS

Applied Materials & Interfaces 12 37006-37012

Wang Yibo, Hou Shuai, Ma Rongpeng, etal. 2021

Modulating crystallinity and surface electronic

structure of IrO2 via gadolinium doping to promote

acidic oxygen evolution. ACS Sustainable Chemistry &

Engineering 9 10710-10716

Beyraghi F, Mirfarsi S H, Rowshanzamir S, et al. 2020

Optimal thermal treatment conditions for durability

improvement of highly sulfonated poly (ether ether

ketone) membrane for polymer electrolyte fuel cell

applications International journal of hydrogen energy

45 13441-13458

Zhu Ningwei, Zhao Jinghui, Xie Haiyang, et al. 2024 Effect

of current density and operating temperature on the

energy consumption of hydrogen production by PEM

water electrolysis New energy progress 1-5

Crespi E, Guandalini G, Mastropasqua L, et al. 2023

Experimental and theoretical evaluation of a 60 kW

PEM electrolysis system for flexible dynamic operation

Energy conversion and management 277 116622

Ozdemir S N, Taymaz I, Okumus E, et al. 2023

Experimental investigation on performance evaluation

of PEM electrolysis cell by using a Taguchi method

Fuel 344 128021

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

132