Research on Technical Characteristics and Development

Trend of P2G Technology

Lujia Xue

1,*

and Pengxiang Pei

2

1

University of Rochester/Department of Earth and Environmental Science,

500 Joseph C. Wilson Blvd., Rochester, NY, 14694, U.S.A.

2

North Carolina State University/Department of Exploratory Studies,

2710 Wolf Village Way 407, Mackenzie, Wolf Village Raleigh, NC, 27067, U.S.A.

Keywords: Power to Gas, Electrolysis, Methanation.

Abstract: The technical details, performance indicators, and developmental trends of Power-to-Gas (P2G) technology-

a crucial advancement for integrating renewable energy sources into the energy framework-are examined in

this study. As renewable energy usage grows, the inconsistent nature of sources like solar and wind introduces

challenges in maintaining grid stability and ensuring reliable energy supplies. P2G technology, which

transforms excess renewable electricity into hydrogen or methane, emerges as a viable solution to these issues.

It facilitates long-term energy storage, bolsters grid stability, and aids the decarbonization of the energy sector.

This study delves into various electrolysis methods-Alkaline (AEL), Polymer Electrolyte Membrane (PEM),

and Solid Oxide (SOEC)-essential to the P2G process, evaluating their efficiency, operational challenges, and

potential for scalability. Despite existing constraints such as high costs and low overall efficiency, the paper

highlights continuous improvements in electrolysis and methanation processes that are likely to mitigate these

issues. Additionally, it discusses the strategic importance of P2G in future energy systems, emphasizing its

role in enhancing energy security and sustainability through technical innovations and international

cooperation. This research not only highlights the technological promise of P2G but also delineates the steps

necessary for its broader implementation, which is vital for progressing towards a sustainable, low-carbon

energy future.

1 INTRODUCTION

The need to slow down climate change and lessen

dependency on fossil fuels is causing a major shift in

the world's energy system. Although renewable

energy sources, including wind and solar electricity,

are becoming more widely used, their intermittent

nature makes grid stability and the dependability of

the energy supply difficult. Due to the imperative to

diminish carbon emissions and the increase in the

capacity of renewable energy sources, researchers

were encouraged to exploit the production of

renewable energy sources to supply the energy

system (Mazza, Bompard and Chicco, 2018). Power

to gas (P2G), which produces gaseous chemical

energy carriers by using renewable or excess

electricity is a solution tackling the objective and

requirement (Wulf, Linßen and Zapp, 2018). This

study looks at the performance metrics,

*

Corresponding author

developmental trends, and technical specifications of

Power-to-Gas (P2G) technology, an important

development for incorporating renewable energy

sources into the energy framework (Mazza, Bompard

and Chicco, 2018). Ranging from small pilot projects

to large industrial installations, power to gas

technology has been demonstrated across various

scales. Electrolysis stands as a cornerstone

technology within the P2G system. AEL, PEM and

SOEC are the three distinct electrolysis technologies

that are relevant for power to gas process chains.

Solid oxide electrolysis technology is still in the

laboratory, while polymer electrolyte membrane

electrolysis (PEME) is a relatively recent technique

(Götz et al., 2016). In several countries, including

Germany, Japan, and the United States, considerable

emphasis has been placed on research, development,

and application of P2G technology. However, P2G

technology is currently facing several challenges. Its

114

Xue, L. and Pei, P.

Research on Technical Characteristics and Development Trend of P2G Technology.

DOI: 10.5220/0013849000004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 114-120

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

high costs, coupled with low efficiency during the

process, poses economic and technical burdens.

Scaling up from small-scale demonstrations is

difficult, and infrastructure modifications are

required. This paper will focus on discussing power

to gas’s major technology features, overall

performance, facing challenges, storage capabilities,

and outlook the future of this technology.

2 TECHNICAL PRINCIPLE OF

P2G

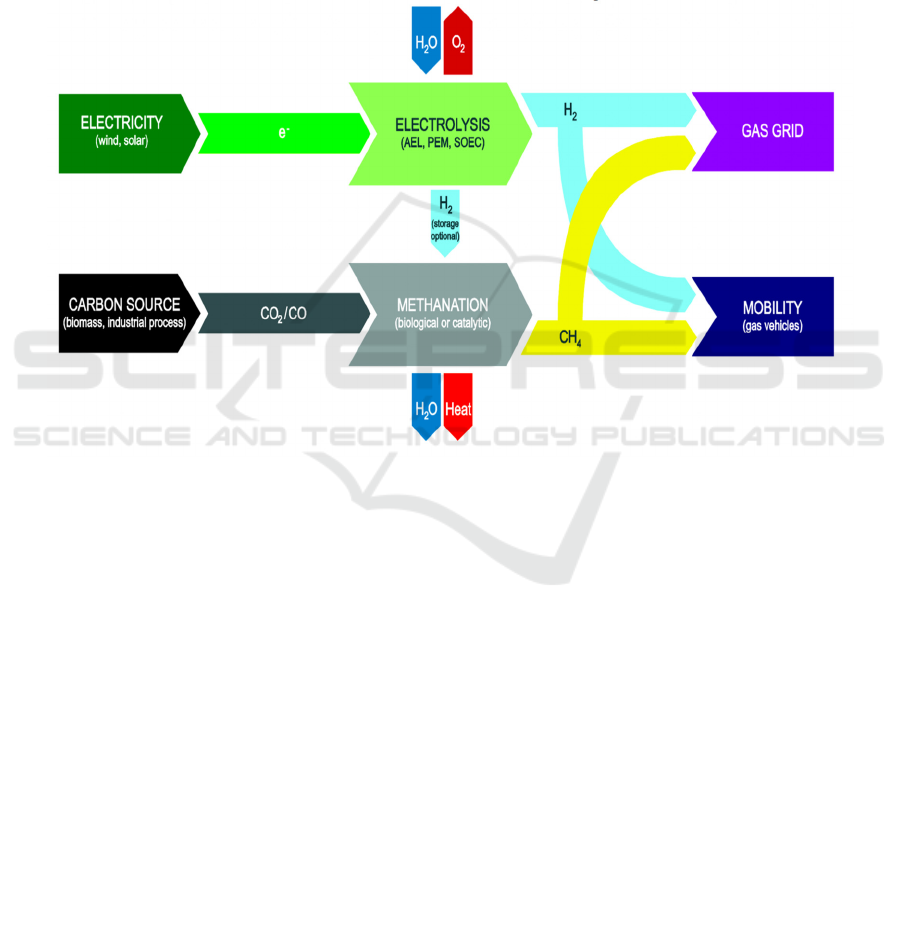

The conversion of electricity to gas is the

fundamental component of power to gas technology.

The two-step process of producing H

2

through water

electrolysis (electrolyze) and then converting the H

2

with an external CO or CO

2

sources to CH

4

(methanation) is how this conversion process

connects the power grid with the gas grid, as

illustrated in figure 1 (Götz et al., 2016).

Figure 1: Exemplary Power-to-Gas process chain

2.1 Electrolysis

By using an electric current, water can be electrolyzed

to produce hydrogen (H

+

) and hydroxide (OH

-

) ions.

Water electrolysis is one method of producing

hydrogen with surplus electrical energy. The P2G

technology relies on electricity derived from

renewable sources, including solar, wind, hydro, and

geothermal power, to supply the electrons required

for hydrogen generation. Three different electrolysis

methods are now being used by AEL, PEM, and

SOEC; these technologies are pertinent to P2G

process chains (Götz et al., 2016).

Alkaline electrolysis employs aqueous alkaline

solution (KOH or NaOH) as electrolyte, functioning

effectively under both atmospherically and elevated

pressure (Götz et al., 2016). AEL is the most

developed and understood technology that has been

for many years on the market and it can operate within

a flexible range of 20 to 100% of its design capacity,

and it can operate at up to 150% overload (Kreuter

and Hofmann, 1988). This operation versatility

makes alkaline electrolysis suitable for power to gas

system, which is coupled with fluctuating and

intermittent power sources. It is applicable for large-

scale plant demonstrations (Ursua, Gandia and

Sanchis, 2012). Moreover, the cost of alkaline

electrolysis is relatively low, and the operational

lifespan typically extends between 8 to 10 years,

signifying durability. Nevertheless, the electrolytes

are highly corrosive, the current density tends to be

low, and the maintenance costs are considerable

(Götz et al., 2016).

PEM relies on solid polymer membranes. The

primary benefit of PEM technology offers several

advantages, including faster cold starts, higher

flexibility, improved integration with dynamic and

intermittent systems, and higher purity of the

produced hydrogen (Götz et al., 2016). Therefore, it

demonstrates a better transient operation than alkaline

Research on Technical Characteristics and Development Trend of P2G Technology

115

electrolysis (AEL) and boasts better dynamic

adjustment capabilities (Gahleitner, 2013). However,

the current drawback of this technology is a higher

cost relative to AEL systems, which is attributed to

expenses related to the membrane and the utilization

of noble metal catalysts (Götz et al., 2016). Moreover,

PEM technology is characterized by a limited

lifespan, compared to the alkaline electrolysis (Ursua,

Gandia and Sanchis, 2012).

SOEC uses zirconium oxide doped with 8%

Yttrium oxide as the electrolyte. This technology

represents the most recent advancement in

electrolysis and is currently in the laboratory

development phase (Carmo et al., 2013). The

electrolyte has strong thermal and chemical stability

and is highly conductive for oxygen ions at high

temperatures. This technology shows high electrical

efficiencies, with the potential possibility to achieve

electrical efficiencies exceeding 100% (Brisse,

Schefold and Zahid, 2008). It also presents a low

electricity demand. However, challenges arise due to

rapid material degradation and limited long-term

stability, which require further attention (Götz et al.,

2016).

2.2 Methanation

Methanation is the hydrogen conversion with an

external carbon monoxide or carbon dioxide to

methane through hydrogenation, and it can be

realized through two distinct reactor types: biological

and catalytic reactors (Götz et al., 2016).

Reactors for biological methanation are normally

run between 20 ° C and 70 ° C with pressures

ranging from 1 to 10 bar (Götz et al., 2016). In these

systems, microbial communities catalyze the

conversion process, typically within anaerobic

environments. These reactors offer advantages such

as ambient operation conditions and the potential for

utilizing waste biomass as feedstock. In contrast,

catalytic methanation reactors operate within a

broader temperature and pressure spectrum. Metals

like nickel (Ni), ruthenium (Ru), rhodium (Rh), and

cobalt (Co) to drive the conversion reaction serve as

catalysts for promoting efficient chemical kinetics

and facilitating the methanation reaction (Götz et al.,

2016). Both biological and catalytic methanation

reactor types play crucial roles in real-life

applications like renewable energy storage. While

biological methanation offers environmentally

friendly and sustainable solutions, catalytic

methanation provides high efficiency and scalability.

3 PERFORMANCE ANALYSIS OF

P2G

3.1 Efficiency of P2G

In contemporary times, PEM electrolysis and alkaline

electrolysis are the two most popular technological

methods. Currently, alkaline electrolyzers lead the

market in maturity and affordability, yet PEM

electrolyzers, though early in their commercial

journey, possess significant prospects for

enhancements in cost savings, longevity, and

operational efficiency moving forward. Recently, the

rate at which hydrogen is produced for each stack and

the durability of the cells stand as significant

constraints for PEM electrolyzers. Ohmic losses,

concentration polarization, and activation

polarization are the main reasons for the losses of

Alkaline (Maroufmashat and Fowler, 2017).

Methanation is a method that can turn hydrogen

into synthetic natural gas. There are two kinds of

methanation reactors that can produce synthetic

natural gas (SNG): catalytic and biological. The

limitations imposed by the Sabatier reaction cap the

efficiency of each methanation method at 80% (Table

1) (Maroufmashat and Fowler, 2017).

Table 1: Technical, operational, and economic information for Alkaline and PEM electrolyzers (Maroufmashat and Fowler,

2017)

Current Alkaline

Electrol

y

ze

r

Improved Alkaline

Electrol

y

ze

r

Current PEM

Electrol

y

ze

r

Improved

PEM

System Efficiency (%HHV) 62-82 67-87 74-87 82-93

S

y

stem Efficienc

y

(

kWh/Nm³

)

4.5-7.0 4.3-5.7 4.5-7.5 4.1-4.8

Cell Area (m²) 4 - <1.5 -

H₂ Production per Stack

(Nm³

/

h) | <760-1000

<760-1,000 >1,500 <30 <250

S

y

stem Lifetime

(y

ears

)

20-30 30 10-20 20-30

Hydrogen Purit

y

99.90% - >99.90% -

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

116

3.2 Sustainability-Related Performance

P2G technology offers a solution to convert excess

renewable energy into hydrogen or synthetic natural

gas (SNG), reducing reliance on fossil fuels. It

leverages fluctuating renewable sources like wind and

solar energy to effectively decrease carbon emissions.

Indeed, emission charges are relevant for

renewable methane since the carbon it contains is

derived from fossil sources. Failing to allocate

emission costs to the generation of electricity with

renewable methane would lead to the discharge of

fossil carbon into the atmosphere. Nonetheless, this

release of carbon is delayed because it was initially

captured during the generation of electricity from

natural gas and is later emitted upon the burning of

renewable methane. Consequently, PtG should be

viewed as a carbon recycling strategy that ultimately

lessens the dependence on fossil fuels (Vandewalle,

Bruninx and haeseleer, 2015).

4 ISSUES NEED TO BE SOLVED

4.1 Efficiency Improvement

To assess the performance of the P2G conversion

process, the system under consideration incorporates

existing electrolysis methods such as AEL and PEM

that produce hydrogen at 25 bars with a 70%

electrical efficiency. The methanation reactor

operates at 20 bars and reaches an efficiency of 78%,

which is the maximum chemical efficiency

achievable. To preserve this efficiency, CO

2

is pre-

compressed to 20 bars, which helps prevent a 2%

efficiency loss in the methanation reaction (Götz et

al., 2016).

Efficiency enhancement efforts in P2G

technologies face numerous technical difficulties.

The primary challenge lies in the energy loss inherent

to the electrolysis process, where the efficiency of

electrolyzers is constrained by thermodynamic limits,

material performance, and operational specifics.

Additionally, achieving high catalytic efficiency and

longevity for both electrolysis and methanation poses

a significant obstacle. The task of selecting and fine-

tuning catalysts, which are vital for the reactions'

speed and energy efficiency, demands significant

ongoing research and development. Additionally, the

challenge of integrating P2G systems with

inconsistent renewable energy supplies complicates

the achievement of consistent operational efficiency

amid fluctuating input scenarios (Götz et al., 2016).

4.2 Cost of P2G Technology

Costs linked to P2G technology fundamentally fall

into three categories: upfront investments, ongoing

operational and maintenance expenses, and costs

related to energy use. Upfront investments encompass

expenditures for establishing the necessary

infrastructure, such as electrolyzers, catalysts, and

storage units. These costs are subject to variation

based on technology selection, project scale, and

geographical location. Operational and maintenance

expenses pertain to daily operational outlays as well

as equipment replacement and repair essential for

ensuring sustained system functionality. Lastly, the

expenses for energy consumption are tied to the

electricity needed for the electrolysis and

methanation processes, which are largely determined

by the cost and efficiency of the electricity supply

(Schiebahn et al., 2015).

4.3 Access to Key Materials

P2G technologies require a range of essential

materials for their functioning, notably in the

hydrogen generation electrolysis process and the

methanation catalytic process. This involves using

precious metals such as platinum and iridium in the

electrolyzers, as well as nickel-based catalysts for the

methanation reaction. The effectiveness, operational

efficiency, and longevity of P2G systems heavily rely

on these essential materials. However, the

procurement of these materials is fraught with

challenges, such as a limited availability, the

localized nature of resources, fluctuations in prices,

and the ecological and societal consequences

associated with their extraction.

4.4 Safety of P2G Technology

P2G technologies come with various safety hazards

throughout their conversion, storage, and distribution

stages. A significant risk is hydrogen's flammability,

a key output of P2G systems. Under specific

circumstances, hydrogen can create explosive blends

with air, demanding rigorous safety standards in

operating conditions. Moreover, the adoption of high-

pressure storage solutions poses potential dangers of

explosions and leakage, thus necessitating meticulous

engineering and comprehensive safety protocols to

reduce such threats (Gahleitner, 2013).

Research on Technical Characteristics and Development Trend of P2G Technology

117

5 ENERGY STORAGE

5.1 Technical Principle of Energy

Storage

Ensuring the availability of hydrogen and methane,

produced through P2G technology, relies

significantly on effective storage methods. Storage

methods are crucial for maintaining a steady supply

of these valuable energy sources. There are various

storage methods to store hydrogen and methane.

Hydrogen can be stored in compressed gas form,

where it is pressurized and stored in gas tanks and gas

grids. These high-pressure gas cylinders are

engineered to withstand significant pressures,

typically reaching up to 20 MPa (200 bar). Hydrogen

can be stored in liquefied form in cryogenic tanks at

21.2 K and ambient pressure (Züttel, 2004). On the

other hand, methane can be stored like compressed

natural gas storage, within natural gas pipelines

(Makal et al., 2012). Methane is compressed at

elevated pressures to facilitate its storage and

subsequent utilization.

Fuel cells, gas turbines, combined heat, and power

(CHP) plants, and synthetic fuels production are the

common methods available to convert stored

hydrogen or methane back into electricity. Fuel cells

offer a direct electrochemical process to generate

electricity from hydrogen (Gahleitner, 2013). It is a

highly efficient method with minimal emissions since

the only byproducts are water and heat. Methane or

hydrogen can be burned in gas turbines to produce

mechanical energy, which is then converted into

electricity via a generator. Combined heat and power

plants provide an avenue, where heat is generated

during electricity production captured for heating or

industrial processes, enhancing efficiency. This

approach is applicable to both hydrogen and methane.

Hydrogen or methane can also serve as feedstock for

industrial processes to produce synthetic fuels, which

can then be utilized in conventional power plants for

electricity generation. All of these approaches

provide diverse avenues for the conversion of stored

hydrogen or methane back into usable electricity,

addressing different applications and operational

needs.

5.2 Real Applications

P2G storage has applications across different sectors,

offering solutions in difficulties in renewable energy

integration and decarbonization. In regions where

renewable energy sources, such as wind and solar

energy, are prevalent but intermittent, P2G serves as

a practicable and pivotal solution for grid stability and

helps to balance the grid by storing excess energy

during periods of low demand and releasing it when

needed. Moreover, P2G plays an essential role in

reducing carbon emissions across different sectors

like transportation industrial production, replacing

fossil fuels with a clean alternative.

For example, in the European Union, considerable

emphasis is placed on research and development

initiatives to enhance renewable energy technologies

and promote sustainable energy practices.

International collaboration efforts facilitate

knowledge exchange and cooperation among nations,

fostering collective progress towards achieving

renewable energy targets and mitigating climate

change impacts.

The Energiewende, a project launched by the

German government, is to facilitate the switch from a

carbon-based to a low-carbon energy system (Mazza,

Bompard and Chicco, 2018). WindGas Falkenhagen,

which is a famous P2G project operated by E. ON, is

in Falkenhagen, Germany. The groundbreaking Wind

Gas Falkenhagen project achieved a significant

milestone of 1 MW of wind power into the local grid.

This P2G project was pivotal in establishing a

standardized process chain for WindGas product,

including the identification and engagement for new

suppliers (Patel, 2020). These efforts underscore the

commitment to spearhead the transition towards a

more sustainable and resilient energy future on a

global scale.

5.3 Existing Problems

Despite its great potential on providing solutions to

problems involved in renewable energy integration

and reducing carbon emissions, P2G storage is

currently facing several challengers. One primary

concern is the efficiencies. The fact that P2G

processes involve multiple energy conversion steps

inevitably cause energy losses, and lead to low

efficiency.

The cost of electrolyzers is also high, with an

investment of approximately 1088 dollars/kW for

Alkaline Electrolyzers. This figure may vary slightly

depending on specific conditions such as pressure and

size, which is significantly important in determining

the exact cost. The investment of Polymer Electrolyte

Membrane Electrolyzes is a minimum of 2177

dollars/kW, but the cost shows decrease trend in

which it reached a cost of less than 1088 dollars/kW

in 2018. Solid Oxide Electrolyzes have an investment

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

118

cost of about 2406 dollars/kW which is also set to

decrease to a cost of less than 1088 dollars/kW in the

year 2030. The cost for both biological methanation

and chemical CO

2

-Methanation is projected to fall to

900 dollars/kW and 642 dollars/kW accordingly.

Renewable electricity cost depends on location, time

of day, and availability of incentives or subsidies

(Götz et al., 2016).

Moreover, the availability of renewable energy

source for P2G operations is subject to intermittency

and seasonality. This will largely affect the reliability

and utilization of P2G facilities. Thereby, the

intermittent characteristic of renewable energy source

is a facing challenge, and it is essential to ensure a

stable and cost-effective renewable energy supply in

order to maximize the utilization of P2G assets.

There is a risk for potential hazards to occur is also

highly probably as hydrogen is highly flammable and

requires careful handling and storage to mitigate

safety risks. Another downside of the storage system

is the significant amount of water requires throughout

the whole system. It may lead to water scarcity and

raise environmental and social concerns. Also, the

infrastructure for storage, transport, and distribution

is underdeveloped. This poses challenges for scaling

up the P2G power plant’s capacity, and the

constructions of the infrastructure will lead to a heavy

financial burden.

6 FURTHER TREND

As the worldwide shift towards renewable energy

accelerates, P2G technology emerges as a pivotal

solution. It presents a long-term storage option with

its capability to convert renewable electrical energy

into gaseous chemical energy carriers. This not only

increases the flexibility of the electrical system but

also facilitates integration across different energy

systems (Götz et al., 2016). A lot of emphasis will be

placed on research and development to develop new

technologies that are more efficient and cost less.

Regarding storage, there are diverse methods to store

hydrogen and methane, including compression and

liquefaction, for efficient utilization and

transportation. The pathways for converting the

stored gas back to electricity include fuel cells, gas

turbines, combined heat and power (CHP) plants, and

synthetic fuels production. Research and

development are emphasized to offer varied options

for re-converting stored hydrogen or methane back to

usable electricity to meet different applications and

operational needs (Götz et al., 2016).

On the development and implementation front,

manufacturers are actively working on developing

electrolysis technologies to improve efficiency and

reduce costs. The United States, being one of the

largest gas power generating countries, promotes the

advancement of renewable energy technologies

through federal funding and tax incentives. The

European Union emphasizes research and

development initiatives, with international

collaboration efforts aimed at knowledge exchange

and cooperation towards achieving renewable energy

goals and mitigating climate change impacts.

In terms of technology feasibility, P2G plays a

crucial role in enhancing the overall efficiency of

energy systems, energy density, and the duration of

energy storage. Actions are being take to solve the

facing challenges related to energy loss during

storage and the speed of electricity generation. Cost

considerations include expenses for electrolyzes,

methanation, renewable electricity, and operation and

maintenance.

Overall, despite the challenges associated with

energy losses and significant capital costs, P2G

technology provides an effective solution for

integrating intermittent renewable energy sources,

enhancing grid stability and reliability, and achieving

sustainability through the production of zero or low-

carbon fuels. Moving forward, through technological

innovation and optimization of operational processes

to improve energy efficiency and density, and reduce

system costs, P2G technology is expected to realize

its greater potential in a renewable energy-dominated

future (Götz et al., 2016).

7 CONCLUSION

P2G technology emerges as a promising solution for

the renewable energy sector, including the

intermittent nature of renewable sources and the need

for long-term energy storage. P2G technology

converts excess renewable electricity into hydrogen

or methane, serving as an effective energy storage

solution. Additionally, it significantly contributes to

lowering carbon emissions within the energy system

and improving grid stability. Despite its potential,

P2G technology currently grapples with challenges

such as low efficiency in energy conversion

processes, high costs of electrolyzers and

methanation technologies, and the necessity for

significant infrastructure developments. Furthermore,

the sporadic availability of renewable energy sources

and the necessity for a stable supply underscore the

importance of ongoing research, development, and

Research on Technical Characteristics and Development Trend of P2G Technology

119

scaling up of P2G technologies. Future trends in P2G

point towards a focus on overcoming these challenges

through technological innovations aimed at

improving efficiency and reducing costs. The

ongoing advancements in electrolysis and

methanation processes, coupled with the

development of more efficient storage and conversion

methods, promise to enhance the viability and

effectiveness of P2G systems. Moreover,

international cooperation along with support from

governments and industries is crucial in promoting

the adoption of P2G technologies and aiding the shift

toward a more sustainable and renewable-focused

energy system. Ultimately, successfully integrating

P2G technology into the energy landscape demands a

multidisciplinary approach that merges

advancements in engineering, economics, and

environmental science. By continuing to address the

current challenges and leveraging the opportunities

for improvement, P2G technology can significantly

contribute to achieving a sustainable, reliable, and

low-carbon energy future.

AUTHORS CONTRIBUTION

All the authors contributed equally, and their names

were listed in alphabetical order.

REFERENCES

Mazza, A., Bompard, E., & Chicco, G. 2018 Applications

of P2G technologies in emerging electrical systems

Renewable and Sustainable Energy Reviews 92 794–

806.

Wulf, C., Linßen, J., & Zapp, P. 2018 Review of Power-to-

Gas Projects in Europe. Energy Procedia 155 367-378.

Götz, M., Lefebvre, J., Mörs, F., McDaniel Koch, A., Graf,

F., Bajohr, S., Reimert, R., & Kolb, T. 2016 Renewable

Power-to-Gas: A technological and economic review.

Renewable Energy 85 1371-1390.

Kreuter, W., & Hofmann, H. 1998 Electrolysis: The

important energy transformer in a world of sustainable

energy International Journal of Hydrogen Energy 23

661-666.

Ursua, A., Gandia, L. M., & Sanchis, P. 2012 Hydrogen

Production From Water Electrolysis: Current Status

and Future Trends Proceedings of the IEEE 100 410-

426.

Gahleitner, G. 2013 Hydrogen from renewable electricity:

An international review of power-to-gas pilot plants for

stationary applications International Journal of

Hydrogen Energy 38 2039-2061.

Carmo, M., Fritz, D. L., Mergel, J., & Stolten, D. 2013 A

comprehensive review on PEM water electrolysis

International Journal of Hydrogen Energy 38 4901–

4934.

Brisse, A., Schefold, J., & Zahid, M. 2008 High

temperature water electrolysis in solid oxide cells

International Journal of Hydrogen Energy 33 5375-

5382 https://doi.org/10.1016/j.ijhydene.2008.07.120.

Maroufmashat, A., & Fowler, M. 2017 Transition of future

energy system infrastructure; through power-to-gas

pathways Energies 10 1089.

Vandewalle, J., Bruninx, K., & D’haeseleer, W. 2015

Effects of large-scale power to gas conversion on the

power, gas and carbon sectors and their interactions

Energy Conversion and Management 94 28-39.

Schiebahn, S., Grube, T., Robinius, M., Tietze, V., Kumar,

B., & Stolten, D. 2015 Power to gas: Technological

overview, systems analysis and economic assessment

for a case study in Germany International journal of

hydrogen energy 40 4285-4294.

Züttel, A. 2004 Hydrogen storage methods

Naturwissenschaften 91 157-172.

A. Makal, T., Li, J.-R., Lu, W., & Zhou, H.-C. 2012

Methane storage in advanced porous materials.

Chemical Society Reviews, 41 7761-7779

Patel, S. 2020 WindGas Falkenhagen: Pioneering Green

Gas Production. POWER Retrieved on April 15 2024

Retrieved from https://www.powermag.com/windgas-

falkenhagen-pioneering-green-gas-production/

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

120