Preparation and Application Research of Carbon Nanotubes

Mohan Zhang

1,*

and Siyu Zhang

2

1

Sino-European School of Technology, Shanghai University, Shanghai, 200444, China

2

College of Chemistry and Chemical Engineering, Central South University, Changsha, 410083, China

*

Keywords: Carbon Nanotubes, Chemical Vapor Deposition (CVD) Method, Laser Ablation Method, Arc Discharge

Method, Lithium Batteries.

Abstract: In recent years, carbon nanotubes have shown broad application prospects and become the research frontier

and hotspot in the international new materials field. This paper mainly discusses the classification,

mechanical, and electrical properties of carbon nanotubes and their preparation methods, and analyzes their

application examples in fields such as lithium batteries. The results show that the mechanical properties of

carbon nanotubes are far superior to traditional materials and they also have excellent electrical properties.

Regarding the preparation methods of carbon nanotubes, the arc discharge method is simple, fast, and high-

yield, the laser ablation method has relatively higher costs, while the equipment used in chemical vapor

deposition (CVD) method is simple and capable of large-scale production. In practical applications, carbon

nanotubes have achieved results in areas such as cathode materials in lithium batteries, solid-phase extraction

adsorbents, and catalytic materials. This study holds significant practical significance in exploring low-cost,

large-scale production of carbon nanotubes and provides a scientific basis for their future applications in other

fields.

1 INTRODUCTION

In 1991, Professor Iijima, an electron microscopy

expert from a Japanese electronics company,

discovered for the first time under a high-resolution

transmission electron microscope some needle like

structures composed of 2-50 concentric tubes, while

preparing C60 using an arc method μm. This is carbon

nanotubes.

Carbon nanotubes are a type of material with a

radial size in nanometers and an axial size in

micrometers, which has a structure different from

other materials. The hexagonal carbon atoms form the

carbon nanotubes, which curl along certain axes to

form coaxial circular tubes. The distance between

carbon atomic layers is about 0.34 nm, with most

diameters ranging from 2-20 nm. It is precisely

because its many properties, such as mechanical

properties, are better than other materials that it has

been widely used and has attracted the attention of

scientists in many fields.

This article analysed and studied the preparation

and application of carbon nanotubes. Firstly, the

*

Corresponding author

classification of carbon nanotubes and their

mechanical and electrical properties were explained.

Then, the preparation of carbon nanotubes was

introduced from three methods: arc discharge

method, laser burning method, and chemical vapor

deposition method. Finally, the application examples

of carbon nanotubes in lithium batteries, fuel cells,

and other fields were elaborated.

2 CLASSIFICATION OF CARBON

NANOTUBES

2.1 Single Walled Carbon Nanotubes

The incredible strength and flexibility of single-

walled carbon nanotubes (SWCNTs) make them a

fascinating material for researchers and engineers.

These nanotubes are entirely composed of carbon

atoms. Their shapes are mainly divided into

armchairs, serrations, and chirality, each with its own

unique electronic properties.

Zhang, M. and Zhang, S.

Preparation and Application Research of Carbon Nanotubes.

DOI: 10.5220/0013847500004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 103-108

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

103

When it comes to mechanical properties, carbon

atoms in SWCNTs are bonded through extremely

strong C-C covalent bonds, indicating flexibility. In

addition, these nanotubes exhibit incredible high axial

strength, approximately 100 times that of steel. Their

elastic strain can reach up to 5%, with a maximum of

12%.

SWCNTs have received much attention for their

superior properties and applications in composites.

SWCNTs can give composites extraordinary

mechanical properties, significantly improving their

strength, toughness, elasticity and fatigue resistance.

SWCNTs also possess properties including

anisotropy and diamagnetism. SWCNTs have

extremely strong capillary action and wetting

features. They are the materials with the largest

hydrogen storage capacity that are expected to

promote the development of hydrogen fuel cells

compared to other traditional hydrogen storage

materials.

2.2 Multi Walled Carbon Nanotubes

Carbon nanotubes are connected by stable C=C

covalent bonds and thus have excellent mechanical

properties. Theoretical calculations indicate that

carbon nanotubes have extremely high strength and

toughness. The theoretical value estimates that the

Young's modulus can reach 5 TPa, with a strength

about 100 times that of steel, while the weight density

is only 1/6 of steel. Treacy et al. used Transmission

Electron Microscope (TEM) for the first time to

measure the mean square amplitude of multi walled

carbon nanotubes in the temperature range from room

temperature to 800 degrees.

3 PERFORMANCE OF CARBON

NANOTUBES

Carbon nanotubes are a type of nanomaterial with

excellent performance and broad application

prospects, and their unique structural characteristics

determine their potential for application in multiple

fields. Carbon nanotubes, as an important

nanomaterial, have many unique properties,

including structural characteristics, mechanical

properties, electrical properties, and thermal

properties. Studying its performance will help

promote the application of nanomaterials in various

fields.

3.1 Mechanical Properties

The mechanical properties of carbon nanotubes refer

to their mechanical response and performance under

external forces. When studying the mechanical

properties of carbon nanotubes, indicators such as

elastic modulus, yield strength, fracture strength, and

tensile properties are usually considered.

Carbon nanotubes have excellent elastic modulus,

usually above 1 TPa, and even up to hundreds of TPa.

This makes carbon nanotubes have important

application potential in fields such as nanomaterial

reinforcement and nanocomposites. The introduction

of carbon nanotubes (CNTs) into NC will reduce the

percolation threshold and resistivity of composite

materials, and improve the tensile strength of

composite materials (Zhang et al., 2024).

Due to the nanoscale characteristics of carbon

nanotubes, their yield strength is usually much higher

than traditional materials, reaching tens of GPa or

even higher. This makes carbon nanotubes have

important application prospects in fields such as

nanodevices and nanosensors. Meanwhile,

due to the influence of structural defects, external

environment, and other factors on the yield behaviour

of carbon nanotubes, researchers are also committed

to exploring the yield behaviour laws and influencing

factors of carbon nanotubes, in order to better apply

them in engineering practice.

3.2 Electrical Performance

Carbon nanotubes have good electrical properties due

to their helical tubular structure. Research has shown

that the current carrying capacity of single-walled

carbon nanotubes is 1000 times that of copper,

approximately 109A/cm2.The conductivity of single-

walled carbon nanotubes also changes with the

change of their diameter and helical mode. CNTs

dispersed in polymer matrices are more likely to form

conductive networks, and composite materials

prepared with CNTs as conductive fillers have a

percolation threshold of less than 5%, or even less

than 1% (Qiu et al., 2020).

3.3 Thermal Conductivity

Like conductivity, carbon nanotubes are also

excellent thermal conductors, with an axial thermal

conductivity of approximately 6600 W/m·K or

higher, far greater than diamond and graphite. Their

application in composite materials more extensive,

and the study of their properties and applications has

important theoretical and practical significance

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

104

(Zheng et al., 2024). It can become a thermal

conductive agent for the heat sink of Central

Processing Unit (CPU) chips in computer central

processing units. The carbon nanotube CPU heat sink

produced by OCZ Company, as shown in Fig. 1, is a

physical image of the central processing unit and an

example of the CPU. Its thermal conductivity

efficiency is 5 times that of ordinary copper materials.

In addition, single-walled carbon nanotubes can also

be used in high thermal conductivity composite

materials, with good application prospects.

Figure 1: Physical image of central processing unit (Chen

et al., 2024).

4 CARBON NANOTUBE

PREPARATION METHODS

4.1 Arc Discharge Method

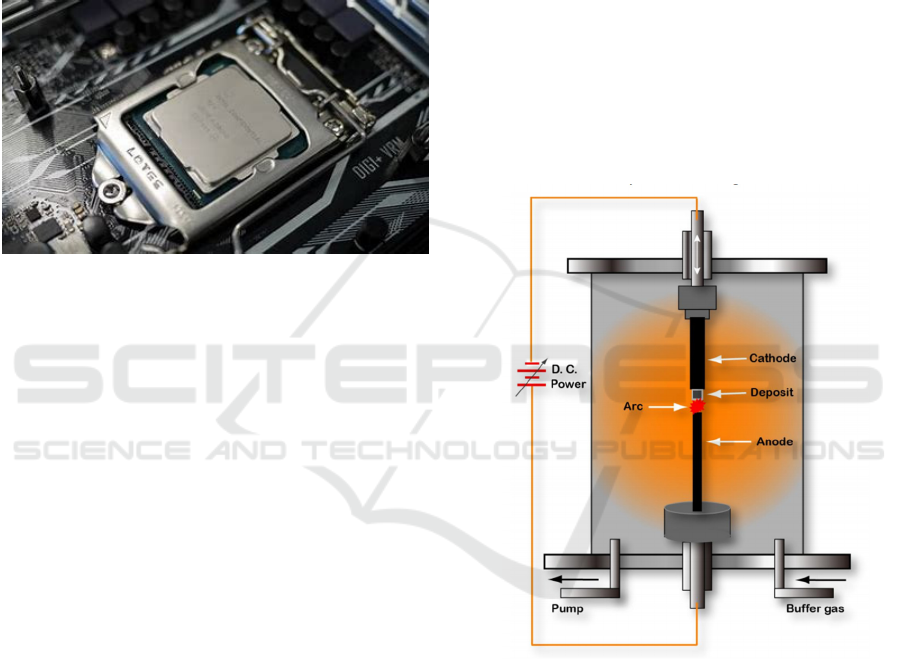

The main principle of the arc discharge method is to

place an anode and a cathode in a vacuum-sealed

container, fill it with an inert gas such as argon, and

apply a high voltage between the two poles to

generate an arc, creating high temperature and high

pressure conditions. In the high temperature

environment, carbon arc discharge generates high

energy, causing some atoms on the surface of the

conductive material to evaporate and ionize to form

high-energy ions. At the same time, the polarity of the

carbon source determines the type of product.

Ultimately, carbon atoms transfer in a free state at

high temperature and high energy under the action of

electrons and ions, condense, and deposit on the

cathode surface, forming carbon nanotubes. The

earliest carbon nanotubes were accidentally obtained

during the conventional arc discharge process used

for preparing fullerenes. In 1991, Iijima obtained

carbon nanotubes through arc discharge technology

in an argon environment (Iijima, 1991). In 1992,

Ebbesen et al. (1992) significantly increased the yield

of carbon nanotubes by increasing the helium gas

pressure in the arc chamber, reaching a level of

kilograms, making arc discharge one of the primary

methods for mass-producing carbon nanotubes. In

1993, Iijima and Ichihashi introduced a small amount

of transition metal iron into the graphite anode and

synthesized single-walled carbon nanotubes through

arc discharge in a methane and argon atmosphere

(Iijima, 1993).

The advantages of the arc discharge method are its

simplicity, speed, high yield, and high degree of

graphitization. Moreover, the carbon nanotubes

produced by this method exhibit excellent properties.

However, the arc discharge in this method is often

very intense, making it difficult to control the process.

Additionally, carbon nanotubes in the deposition on

the cathode during arc discharge are prone to sintering,

resulting in the presence of numerous carbon

nanograins. Fig. 2 shows the device for preparing

carbon nanotubes by arc discharge method.

Figure 2: Arc discharge apparatus for preparing CNTs

(Zhao, 2014).

4.2 Laser Ablation Method

This method was first discovered by Smalley et al.

(Guo et al., 1995), involves using high-energy lasers

as a heat source in an inert gas environment to

vaporize solid graphite for the synthesis of carbon

nanotubes. Initially, the graphite target is placed in a

tube furnace and heated to 1200 ℃ . The laser

vaporizes the graphite target, which is then carried by

a carrier gas to a copper collector equipped with a

wate cooling device, where carbon vapor condenses

Preparation and Application Research of Carbon Nanotubes

105

and grows on the cooled surface, forming carbon

nanotubes. Laser ablation method allows for the

control of carbon nanotube diameter by adjusting the

reactor temperature. However, the use of high-energy

lasers increases its cost compared to the arc discharge

method and chemical vapor deposition method. Fig.

3 illustrates a schematic representation of the

equipment used in the laser ablation method for

synthesizing carbon nanotubes.

Figure 3: Schematic representation of a laser vaporization

apparatus for preparing CNTs (Zhao, 2014).

4.3 CVD Method

Chemical vapor deposition is a process that utilizes

gaseous substances to undergo chemical reactions on

a solid surface, leading to the deposition of gaseous

products. In the context of carbon nanotube synthesis,

CVD involves the catalytic cracking and deposition

of carbon-containing gases on catalyst particles at

temperatures ranging from 700 ℃ to 1000 ℃

within a high-temperature tube furnace filled with a

carbon source and carrier gas.

Common carbon sources used in CVD include

ethylene, acetylene, ethanol, among others, while

commonly used carrier gases are mixtures of

hydrogen and argon. The Smalley research group, for

example, employed CO as the carbon source and

ferrocene as the catalyst, conducting continuous

synthesis of high-purity single-walled carbon

nanotubes with a diameter of 0.7 nm at temperatures

ranging from 1073 to 1473K and pressures from one

to ten atmospheres (Nilolave et al., 1999).

The equipment used in the CVD method is known

for its simplicity, easy controllability of conditions,

scalability for large-scale production, and the ability

to directly grow carbon nanotubes on suitable

substrates. Fig. 4 is a CVD apparatus for growing

CNTs.

Figure 4: Schematic representation of a CVD apparatus for

growing CNTs (Zhao, 2014).

5 APPLICATIONS OF CARBON

NANOTUBES IN PRACTICE

Carbon nanotubes possess unique electrical

conductivity, mechanical properties, and

physicochemical properties, which have attracted

widespread attention since their inception, and in

recent years, they have been widely applied in

numerous scientific research fields.

5.1 Applications in Lithium Batteries

Lithium-ion battery performance indicators such as

capacity and voltage largely depend on the

performance of the cathode material. However,

common cathode materials like lithium iron

phosphate and lithium cobalt oxide suffer from low

electrical conductivity, poor rate capability, and

cycling stability issues (Shi and Ding, 2012). These

problems mainly stem from structural changes

occurring within the material during the repetitive

lithium-ion intercalation and deintercalation

processes. Simultaneously, there is a decrease in

electron transport capability, ultimately leading to

cathode material pulverization and increased internal

resistance (Lu, 2022).

Carbon nanotubes exhibit excellent electron

conductivity and mechanical properties. They not

only provide good electron transport pathways for

cathode materials but also further enhance the

electrode's mechanical performance. Consequently,

carbon nanotubes are widely used in cathode

materials. Due to their superior electrical conductivity

and ion diffusion capabilities compared to traditional

materials like carbon black, carbon nanotubes are

commonly used as conductive additives in cathode

materials. Additionally, high-strength carbon

nanotubes can also enhance the mechanical

performance of electrodes.

Yang et al. prepared a LiFePO4@CNT composite

material with core and shell structure. By reducing the

radius of LiFePO4, the process can greatly reduce the

transmission path of lithium ions. At the same time,

the introduction of CNT can improve the conductivity

of the electrode material. The electrode material is

recycled at a large doubling rate of 50 C, and the

specific discharge capacity can still reach 65 mAh/g.

5.2 Applications of Solid Phase

Extraction Adsorbents

Carbon nanotubes have a large specific surface area

and strong adsorption capacity, making them

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

106

promising materials for solid-phase extraction.

Literature reports indicate that carbon nanotubes

exhibit high enrichment capabilities for organic

compounds (Liang et al., 2004), metal ions (Muñoz et

al., 2005), organic metal compounds (Cai et al., 2003),

and other environmental pollutants. Cai et al.

employed multi-walled carbon nanotubes to enrich

organic pollutants from environmental water samples,

such as bisphenol A, 4-nonylphenol and 4-

octylphenol. The results showed that multi-walled

carbon nanotubes had high enrichment efficiency,

surpassing or equaling that of solid-phase extraction

adsorbents like C18-bonded silica gel, XAD-2 resin,

and C60 fullerene (Liang et al., 2004; Cai et al., 2003

& Cai et al., 2005).

The development of novel adsorption devices

based on carbon nanotubes is becoming a research

hotspot in this field. Yuan Dongxing et al. (2004)

tested the performance of multi-walled carbon

nanotubes for enriching volatile organic pollutants

and compared them with common adsorbents

Carbopack B and VOCARB 3000, demonstrating the

superior enrichment performance of carbon

nanotubes. Saridara et al. (2005) used ethylene and

carbon monoxide as carbon sources to generate

carbon nanotube films on the inner surface of

stainless steel using chemical vapor deposition and

fabricated them into microtrap devices for volatile

organic compound detection. Experimental results

showed that carbon nanotubes synthesized from

ethylene had higher density and larger adsorption

capacity, exhibiting strong adsorption capabilities for

volatile organic small molecules.

5.3 Applications in Catalyst Materials

Due to recent advancements in the functionalization

of carbon nanotube walls, coupled with their

excellent electron conductivity, unique adsorption

and desorption properties towards reactants and

reaction products, special spatial stereoselectivity in

pore structure, strong metal-carbon interactions in

carbon-metal catalysts, as well as the specific

catalytic and photocatalytic properties induced by

quantum effects in carbon nanotubes, along with their

strong oxidizing and reducing capabilities, there has

been considerable interest in the application of carbon

nanotubes in catalytic chemistry. Currently, there are

not many examples of direct utilization of carbon

nanotubes as catalysts. Lou et al. reported the direct

application of carbon nanotubes with a surface area

of 180 m2/g in the catalytic reduction of NOx,

achieving 8% conversion of NO at 573K, which

increased to 100% at 873K. This represents a

successful application of nanomaterial quantum

effects in catalytic chemistry. Carbon nanotubes are

mainly used as carriers in catalytic processes due to

their unique electronic properties, pore structure and

adsorption capacity. Planeix was among the first to

utilize carbon nanotubes as catalyst supports. They

found that catalysts with multi-wall carbon nanotubes

loaded with Ru exhibited up to 90% selectivity and

an 80% conversion rate in the hydrogenation

synthesis of cinnamaldehyde to cinnamyl alcohol.

6 CONCLUSION

Carbon nanotubes possess unique electrical

conductivity, mechanical properties, and physical and

chemical properties, making them widely applied in

various scientific research fields in recent years.

Carbon nanotubes mainly include single-walled

carbon nanotubes and multi-walled carbon nanotubes.

The mechanical properties of carbon nanotubes far

exceed those of traditional materials, reaching tens of

GPa, while also exhibiting excellent electrical

conductivity, making them excellent thermal

conductors.

Among the methods for preparing carbon

nanotubes, the arc discharge method offers the

advantages of simplicity, speed, and high yield, while

the laser ablation method incurs relatively higher

costs. On the other hand, the equipment used in CVD

method is simple and capable of large-scale

production. Currently, carbon nanotubes are widely

used as cathode materials in lithium batteries,

showcasing broader application ranges and higher

mechanical performance. Additionally, their

application as solid-phase extraction adsorbents

presents promising prospects. However, there are

relatively few examples of direct application of

carbon nanotubes in catalytic materials.

In the future, researchers should focus on

improving the existing shortcomings of carbon

nanotubes and developing more diverse applications

to achieve their large-scale utilization. This study

holds significant practical significance in exploring

low-cost, large-scale production of carbon nanotubes

and provides a scientific basis for their future

applications in other fields.

AUTHORS CONTRIBUTION

All the authors contributed equally and their names

were listed in alphabetical order.

Preparation and Application Research of Carbon Nanotubes

107

REFERENCES

H.J. Zhang, Q.F. Wang, H.R. Wei, et al. Engineer. Plas.

Appl., 52, 7 (2024)

J. Qiu, Z.W. Jiang, H.P. Xing, et al. Chinese J. Appl.

Chem., 37, 8 (2020)

M. Zheng, J. Liu, K. Shi, et al., Molec. Cat., 554113737

(2024)

G. Chen, Y.Z. Hu, N. Chen, et al., Mater. Chem and Phys.,

314128842 (2024)

S. Iijima, Nature, 354, 56-58 (1991)

T.W. Ebbesen, P.M. Ajayan, Nature, 358, 220-222 (1992)

S. Iijima, T. Ichihashi, Nature, 363, 603-605 (1993)

T. Zhao, Shanghai Jiao Tong University (2014)

T. Guo, P. Nikolaev, A. Thess, et al., Chem Phys Lett, 243,

49-54 (1995)

P. Nilolave, M.J. Bromikowski, P.K. Bradley, Chem. Phys.

Lett., 313, 91-94 (1999)

J.Y. Shi, Y.S. Ding, Anhui Chemical Industry, 38, 37-39

(2012)

X.T. Lu, Close Ag. appl. mater., 51, 121-123 (2022)

P. Liang, Y. Liu, L. Guo, et al., J. Anal. At. Spectrom, 19,

1489–1492 (2004)

J. Muñoz, M. Gallego, M. Valcárcel, Anal. Chem., 77,

5389–5395 (2005)

Y.Q. Cai, G.B. Jiang, J.F. Liu, et al. Anal. Chem., 75, 2517–

2521 (2003)

Y.Q. Cai, G.B. Jiang, J.F. Liu, et al.l, Anal. Chim. Acta.,

494, 149–156 (2003)

Y.Q. Cai, Y.E. Cai, S.F. Mou, et al., J. Chrom. A., 1081,

245–247 (2005)

Q. Li, D. Yuan, Q. Lin, et al., J. Chrom. A., 1026, 283–288

(2004)

C. Saridara, R. Brukh, Z. Ipbal, et al., Anal. Chem., 77,

1183–1187 (2005)

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

108