Research Advances on Electrocatalysts for Oxygen Reduction

Reaction in Fuel Cells

Wangjie Shangguan

School of Materials and Environmental Engineering, Hangzhou Dianzi University, Zhejiang, 310018, China

Keywords: Fuel Cell, ORR, Electrocatalyst.

Abstract: Nowadays, fuel cells have attracted much attention because they produce almost no carbon dioxide and air

pollutants, help reduce greenhouse gas emissions and air pollution, and mitigate climate change. Among them,

seeking electrocatalysts for the oxygen reduction reaction (ORR) is a top priority. This article aims to

introduce platinum group metals, transition metal compounds, and carbon-based non-noble metal

electrocatalysts with novel nanostructures. At the same time, it summarizes the research progress of various

electrocatalysts in recent years. The optimization strategies of catalytic processes are reviewed and their

development prospects are prospected. In addition, problems existing in the research on oxygen reduction

electrocatalysts are summarized. In the future, these contents can help researchers develop new catalysts and

electrolyte materials, optimize manufacturing processes, enhance system integration, study fuel cells for

portable and large-scale applications, explore hydrogen production and storage technologies, and integrate

fuel cells with smart grids and distributed Integrated energy systems.

1 INTRODUCTION

In today's society, energy consumption is increasing,

and concurrently, the issue of environmental

degradation is progressively intensifying.

Consequently, the advancement of alternative and

renewable energy sources has ascended to an

imperative priority status. A fuel cell typically

comprises three components: a cathode, an anode,

and an electrolyte. It uses hydrogen, methanol,

ethanol and other fuels to react with oxygen to

produce electrical energy and water. In a fuel cell, it

can be divided into ORR and Hydrogen Oxidation

Reaction (HOR) are direct reactions that occur at the

cathode and anode, respectively. ORR refers to a

sequence of reactions involving oxygen that transpire

within an electrochemical system, in which oxygen

accepts electrons and chemically reacts with water or

other substances. HOR refers to a series of reactions

that occur with water in an electrochemical system in

which water molecules lose electrons and form

hydroxides or other products with protons. In fuel

cells, the hydrogen oxidation reaction usually refers

to the reaction of hydrogen gas at the anode, in which

the hydrogen molecule loses electrons and combines

with protons to form water.

Compared with traditional internal combustion

engines, its advantages are more obvious. In practical

applications, the electrical energy conversion

efficiency of fuel cells is usually between 40% and

60%. However, traditional internal combustion

engines convert the thermal energy generated by fuel

combustion into mechanical energy, which is then

converted into mechanical energy through a

generator. Electric energy has low efficiency, only

20%~40%. More importantly, fuel cells have a lower

environmental impact. However, the slow kinetic

factor in the fuel cell results in a low oxygen reduction

reaction efficiency on the cathode, which in turn is

affected by the O=O bond energy (498 kJ/mol). Even

though platinum and its alloys have been validated as

the preeminent electrocatalysts for oxygen reduction,

their exorbitant cost and the complexities associated

with their preparation impede their large-scale

utilization. Hence, it is urgent to find a new cathode

electrocatalyst capable of supplanting the traditional

platinum-group metal-based counterparts, and non-

precious metal (NPM)-based oxygen reduction

electrocatalyst has emerged as an exceptional

alternative. The purpose of this paper is to introduce

platinum group metals, transition metal compounds

and carbon-based non-noble metal electrocatalysts

58

Shangguan, W.

Research Advances on Electrocatalysts for Oxygen Reduction Reaction in Fuel Cells.

DOI: 10.5220/0013845000004914

Paper published under CC license (CC BY-NC-ND 4.0)

In Proceedings of the 2nd International Conference on Renewable Energy and Ecosystem (ICREE 2024), pages 58-63

ISBN: 978-989-758-776-4

Proceedings Copyright © 2025 by SCITEPRESS – Science and Technology Publications, Lda.

with new nanostructures. Strategies for optimizing

the catalytic process are also reviewed, and finally

their development prospects are prospected. In

addition, the existing problems in the research of

oxygen reduction electrocatalysts are summarized.

2 ORR ELECTROCATALYTIC

MECHANISM

The mechanism of ORR mainly includes the

following steps. Firstly, O

2

molecules become

attached to the catalytic surface, engaging with the

active site on the surface to form adsorbed oxygen

(O

ads

). Adsorbed oxygen (O

ads

) accepts electrons and

is converted into peroxy intermediates (OOH

-

).

Secondly, the peroxy intermediate (OOH

-

) further

accepts electrons and protons and is reduced to water

(H

2

O).

The influence of catalysts on ORR is mainly

reflected in increasing the reaction rate and reducing

the activation energy. Excellent ORR catalysts should

have high active site density and catalytic activity,

and can reduce the energy loss of reaction. Current

challenges include issues such as catalyst stability,

cost and durability. In response to these challenges,

researchers are seeking to design more efficient and

stable catalysts and explore novel materials and

structural designs.

2.1 Dynamic Influencing Factors

The adsorption/desorption of oxygen-containing

intermediates, e.g. O

2

*

,

*

O,

*

OH,

*

OOH and HOOH

*

on the catalyst surface is a key factor affecting ORR

kinetics (Nørskov et al., 2004). O

2

→O

2

*

(The

adsorption process of O

2

) as the initial step of the

reaction determines the subsequent reaction process,

and the initial potential of the reaction is determined

by the adsorption/desorption of

*

OH (at high

potential), and the effective number of active centers

is determined by the adsorption amount of

*

OH. More

importantly, the adsorption of the catalyst to the

intermediate can directly affect the catalytic activity,

too weak adsorption strength will hinder the

proton/electron movement, too strong adsorption

strength will cause desorption.

2.2 Promotion Mechanism of Catalyst

Performance

By adjusting the diameter and shape of the catalyst

particles, the exposure degree of the active site of the

catalyst and oxidation reaction can be increased, so as

to increase the specific surface area of the catalyst, so

as to improve the performance of the ORR. The

synthesis of core-shell structured catalysts and the

choice of catalyst support possessing comparatively

expansive specific surface areas can markedly

enhance catalytic efficacy. Simultaneously,

modulating the electronic structure of Pt induces a

downward shift in the D-band center, thereby altering

the binding energy between the catalyst and aerobic

species. Appropriately tuning this binding energy can

thereby bolster catalyst activity at its fundamental

source.

2.3 Inhibition and Strategies for

Stability Enhancement

The decline in the activity stability of Pt catalyst can

be attributed to two primary factors: Initially, the

dissolution, aggregation, and dispersion of Pt

particles result in the depletion of active constituents.

Secondly, corrosion of the carbon carrier attenuates

the interaction between catalytic particles and the

carrier. The stability of catalyst activity can be

achieved through the fabrication of Pt-transition

metal alloys and intermetallic compounds.

Nevertheless, Pt electrode will generate PtO after a

long period of operation, thereby overlaying the

original active sites. Alternatively, the

oxidation/dissolution of other metals resulted in the

thickening of the Pt layer and subsequent reduction in

activity. Hence, when selecting various carriers to

enhance catalyst activity, the corrosion resistance of

the carrier stands as a pivotal consideration.

Based on the above, the search for a carrier with

high corrosion resistance is essentially to extend the

service life and reduce costs. Previous studies have

shown that the oxidation of Pt on the catalyst’s

surface will cause Pt to corrode and then chemically

dissolve. Therefore, in order to avoid that, it is an

effective means to cover the surface with a layer of

oxygen-bound substances. However, there is also the

possibility of electrochemical dissolution acting

directly on the unmasked Pt nanoparticles and thus

degrading the catalyst. Research in this area shows

that the quality of Pt does not change within the

working potential range of 0-0.8V vs. RHE. However,

in order to prevent Pt from being interfered by

oxidation factors, under highly acidic conditions and

the working potential is greater than 0-0.8V vs. RHE,

the quality of Pt was found to decrease significantly

(Liu et al., 2010 & Rinaldo et al., 2010). It can be seen

that if you want to enhance stability, you must

optimize the size and crystal structure of Pt, because

Research Advances on Electrocatalysts for Oxygen Reduction Reaction in Fuel Cells

59

the thermodynamic properties of tiny particles are

inherently unstable, and at the same time, the surface

energy is relatively high, making them easier to

aggregate. Not only that, the carbon corrosion

phenomenon caused by high potential is also not

conducive to maintaining the Pt/C system. Although

increasing the size has the potential to reduce ECSA

and catalyst activity because it results in a lower

surface-to-volume ratio, economic considerations

require sacrificing some activity to extend the

operational longevity of the catalyst. The following

related research is conducted based on the principle

of developing multi-dimensional Pt nanostructures.

Compared with conventional isotropic nanoparticles,

this complex structure remains more stable. Among

them, adding metals with higher oxidation potential

to improve the stability of Pt is one of the most

promising methods. For example, attaching Au

particles to the surface of Pt, after 30,000 potential

cycles, the catalyst still maintains good stability and

almost no decay (Zhang et al., 2007). In addition, you

can also consider using a protective coating, which

can effectively prevent the non-precious metals inside

from being corroded by the environment. However,

protective coatings, especially carbon coatings under

high-temperature conditions, will inhibit the

exchange process between reactants and active sites.

Although the size and structure of the catalyst are

optimized, its stability is still limited. Therefore, there

is an urgent need to find other methods to solve the

above problems, and alloying is one of them. The

alloy has stronger dissolution resistance and is

relatively cheap. Alloying can improve durability, but

it will still be accompanied by corrosion of the metal,

which will cause particles to overflow, leading to

redeposition and aggregation problems. This

phenomenon was found on the PtAu surface of the

PtAuCo catalyst, with only 25% loss after 100,000

potential cycles (Tan et al., 2015). Such excellent

stability is attributed to the self-healing mechanism of

Au to fine-tune the surface electronic structure.

Isolated Au with low surface energy can improve the

stability of the PtAu surface, thereby mitigating the

corrosion and dissolution process of Co (Sasaki et al.,

2012).

3 ELECTROCATALYSTS

Electrocatalysts are capable of diminishing the

activation energy associated with electrochemical

reactions, thereby augmenting the rate of these

reactions. In addition, it can improve the efficiency of

electrochemical reactions, resulting in higher product

output at the same voltage or current. Moreover, some

electrocatalysts can promote certain reaction

pathways, thereby improving product selectivity and

reducing the occurrence of side reactions.

3.1 Platinum Group Metals

The platinum group metals have the characteristics of

high melting point, high density, good corrosion

resistance, catalytic performance and oxidation

resistance, so they are excellent choices for use as

electrocatalysts. Platinum group metal

electrocatalysts mainly include platinum-based alloys

and core-shell structures. The former option has the

potential to diminish the utilization of the precious

metal platinum and concurrently mitigate the

likelihood of catalyst poisoning. The central layer of

the latter consists of base metals, while the outer layer

comprises platinum. Employed as an electrocatalyst,

it exhibits traits such as minimal Pt loading,

exceptional endurance, and commendable cost-

effectiveness.

3.1.1 Pt Alloy

While Pt exhibits highly efficacious catalytic activity

for ORR, its limited abundance and expensive nature

have emerged as primary obstacles impeding the

advancement of fuel cell technology. Therefore, the

use of platinum-based binary alloy or ternary alloy

electrocatalyst constitutes an efficacious method to

improve both the activity and stability of ORR. Pt-

based alloys serve to curtail the consumption of Pt

elements while concurrently mitigating the likelihood

of catalyst poisoning occurrences, and improving the

catalytic efficiency of ORR. Employing the soft

template method, Yang et al. successfully engineered

Pt-Co nanowire networks that serve as

electrocatalysts for ORR (Yang et al., 2016). Tang et

al. synthesized ultrafine Pt nanoparticles, doped with

minute amounts of Co and modified them on carbon

black carrier via modified ethylene glycol reduction

and chemical etching techniques (Tang et al., 2019).

The uniform distribution of Pt-Co nanoparticles was

successfully achieved without the addition of extra

surfactants, leading to enhanced catalytic efficacy and

stability of the Pt-Co nanoparticles.

3.1.2 Pt-Based Core-Shell Structure

While the fabrication of alloy-type catalysts helps to

minimize the financial expenditure of catalysts, the

potential loss of metal atoms through dissolution

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

60

during continuous operation may diminish the

catalytic activity of the catalyst. Core-shell Pt-based

catalysts exhibit attributes such as low Pt loading,

cost-effectiveness, and high durability, thus

showcasing broad prospects for application. Core-

shell Pt-based catalysts typically consist of two

components: the core layer is mainly composed of

non-precious metals, while the shell primarily

comprises precious metals. The non-precious metal

core layer is wrapped by a Pt layer of precious metal.

By establishing a thin Pt shell encapsulating the core,

the exposed surface area of platinum particles can be

effectively augmented, thereby significantly

improving the utilization rate of platinum. Owing to

the electronic interaction between the core and shell,

the existence of different metal clusters accelerates

the oxidation of Pt, thus alleviating the dissolution

and loss of Pt particles at high electric potential.

G.M.Leteba et al. synthesized binary Pt-Ni

nanoparticles via a co-pyrolysis approach and

optimized the synthesis parameters, consequently

yielding a substantial enhancement in catalytic

performance (Leteba et al., 2020). F. Zhou et al.

successfully synthesized Pt/C catalyst possessing a

core-shell architecture via an one-step self-assembled

calcination process (Zhou et al., 2020). In this

procedure, commercial platinum carbon underwent

treatment with isopropyl alcohol and Nafion. The

commercial platinum carbon underwent combustion

and decomposition in a nitrogen atmosphere,

resulting in the formation of a porous coating devoid

of sulfonate. The results show that there is a thin

porous layer between Pt particles and Nafion, which

effectively improves the performance of the catalyst

without affecting the electrical conductivity and

oxygen conduction rate.

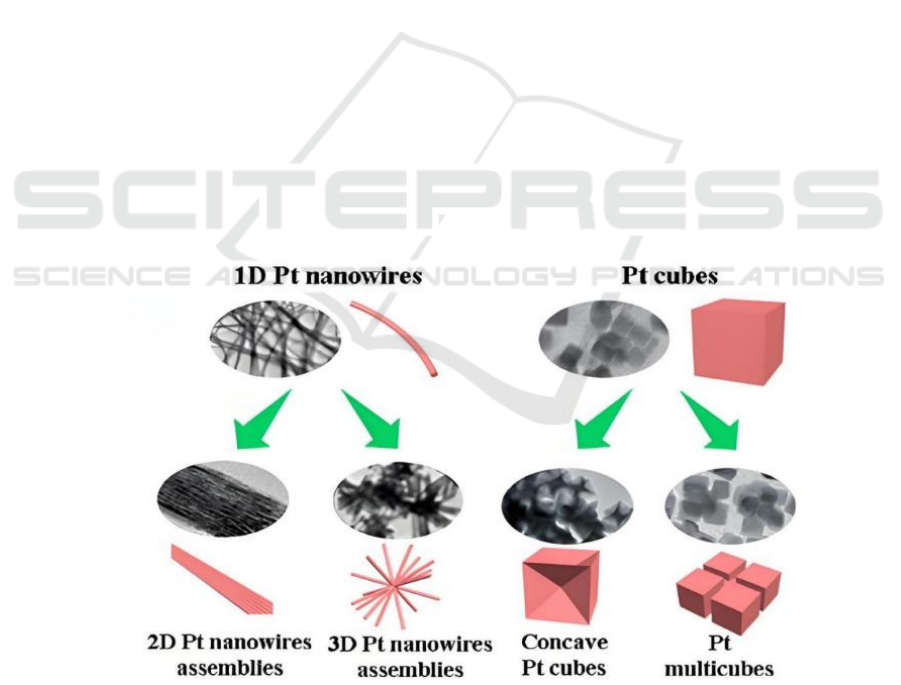

3.1.3 Pt-Based Nano-Structure

In recent years, researchers have devoted themselves

to designing and preparing different Pt

nanostructures, including 1D nanowires, 2D

nanoplates, and 3D nanoframes. The above-

mentioned nanostructures serve to effectively

augment the utilization rate of Pt, thereby improving

catalytic performance, accelerating electron transfer,

and exposing more active sites, shown as Figure 1. It

is worth noting that such nanostructures are

anisotropic and have stronger crystallinity, allowing

the catalyst to remain active for a longer period of

time. Ultra-long and ultra-thin platinum nanowires

not only facilitate the unimpeded conveyance of

electrons, but can also serve as the basic material for

forming 2D nanoplates and 3D nanoframes because

these nanowires are malleable. Moreover, this will

have a more stable structure and larger space, which

will help the stable transfer of electrons.

Figure 1: Structure control of Pt catalysts (Huang et al., 2021)

3.2 Transition Metal Electrocatalysts

Nowadays, Pt-based electrocatalysts have been

commonly used in ORR, with pronounced

initialization and robust half-wave potential.

However, it confronts challenges such as elevated

Research Advances on Electrocatalysts for Oxygen Reduction Reaction in Fuel Cells

61

costs and limited stability. Consequently, there is an

imperative necessity to identify cost-effective non-

noble metal catalysts (NPMC) to replace them.

Transition metal catalysts are cheap, have high

catalytic activity, and have better controllability,

thereby achieving precise control of the reaction.

More importantly, it has better stability and can

maintain its catalytic activity for a long time under

reaction conditions, extending the service life of the

catalyst.

3.2.1 Carbides

To find a catalyst at a lower cost, metal carbide

materials such as tungsten carbide (WC) were

initially evaluated. Tungsten carbide possesses

surface electronic properties akin to those of metal Pt

and is naturally occurring in various formations.

At present, the vast majority of research focuses

on its application as an anode electrocatalyst, and has

demonstrated exceptional catalytic performance.

However, the stability of WC is affected when it

encounters acids and high concentrations of oxygen.

Therefore, it seems difficult to realize the pristine WC

material as an ORR electrocatalyst and utilize it in

fuel cell cathodes without changing its composition

and structure.

Recently, Yu and his team conducted unbiased

structure searches and first-principles calculations for

the 2D TiC

2

, VC

2

, NbC

2

, TaC

2

and MoC

2

to

comprehensively investigate the electrocatalytic

properties (Yu, Zhou and Sun, 2020). Owing to their

excellent conductivity, these materials can facilitate

rapid charge transfer kinetics in catalytic reactions.

3.2.2 Oxides

Oxides have better stability in acidic, alkaline and

oxidising environments than transition metal

carbides. As well as demonstrating certain ORR

activity in alkaline solutions, however, enhancing

their ORR performance remains a formidable

challenge. Due to the altered atomic coordination

environment and electronic structure of the metal

oxides, a certain strain is generated on the catalyst

surface, which leads to a significant increase in its

adsorption capacity with ORR intermediates. Of

these, manganese oxide has garnered considerable

interest on account of its cost-effectiveness,

environmental protection, polyvalent states and

diverse crystal structures. Previous studies have

shown that MnO

x

activity follows a trend as Mn

5

O

8

<Mn

3

O

4

<Mn

2

O

3

. This shows that the MnO

x

catalyst

performance changes with its different crystalline

morphology (Chu et al., 2014). Thus, Zhang et al.

adopted the method of calcination of manganese

glycolate to synthesize Mn

3

O

4

with manganese

defects. In Mn

3

O

4

, the change in electronic structure

makes it a better conductor. Moreover, Wang and his

team prepared a new 3D oriented monolithic

integrated electrode. The electrode consists of Fe

3

O

4

cores and N-doped C shell composite nanostructure

(Wang et al., 2020). Owing to its judicious pore

architecture and N-Fe synergy, as well as the

optimized combination of metal species modification

of the N species catalytic site, the material exhibits

considerable ORR activity in acidic solutions.

3.3 Carbon-Based Electrocatalysts

A carbon-based electrocatalyst is a catalyst composed

of carbon-based materials that is used to promote

electrochemical reactions. The carbon nanotubes,

graphene, carbon black, and porous carbon have good

electrical conductivity, chemical stability and

structural tunability. Compared with transition metal

electrocatalysts, carbon-based electrocatalysts have

lower raw material costs; they do not contain heavy

metal elements and are environmentally friendly.

3.3.1 Metal-Organic Framework Carbon

Materials (MOFs)

MOFs represent a novel class of microporous

materials, constructed from the assembly of metallic

ions and organic linker molecules. The intrinsic

porosity of MOFs endows the resulting carbonaceous

materials with a wealth of pores and elevated specific

surface areas, facilitating enhanced mass transport

capabilities and, consequently, manifesting superior

electrocatalytic properties (Kalaj et al., 2020). Qiao

and colleagues employed a method of dissolve-

induced heteronucleation to create layered ordered

porous carbon on a polystyrene sphere (PS) template,

which was subsequently carbonized to yield a

material doped with atomically dispersed FeN

4

(FeN

4

/HOPC). Following this, they developed Fe-

doped ordered macroporous/microporous ZIF-8

(referred to as OMSFe-ZIF-8) (Xu et al., 2020).

In comparison to monometallic MOFs, bimetallic

MOFs exhibit enhanced catalytic performance due to

synergistic effects between the incorporated metallic

species, thereby demonstrating superior activity. Han

et al. successfully prepared a new type of binary Co-

Ni sites by pyrolysis of MOFs containing dopamine

(DPA) coating. These sites are atomically dispersedly

embedded into N-doped hollow carbon nanotubes,

showing a highly reactive single-atom dispersed state.

At the same time, the synergistic catalytic effect of the

bimetallic Co-Ni sites reduces the energy barrier of

the reaction and accelerates the reaction. the reaction

ICREE 2024 - International Conference on Renewable Energy and Ecosystem

62

kinetics. Consequently, it exhibits exceptional ORR

performance similar to Pt/C (Han et al., 2019).

4 CONCLUSION AND OUTLOOK

This article comprehensively reviews the research

progress of Pt noble metal, transition metal and

carbon-based material ORR electrocatalysts and

reviews strategies to optimize the catalytic process.

Although the ORR mechanism of some materials has

been extensively studied, for most emerging

materials, the mechanism of ORR remains

incompletely elucidated. Therefore, it’s urgent to

have an in-depth comprehension of the mechanism.

Although the overall scientific research strength is

increasing, the physical characterization methods are

becoming more and more perfect. Some ideal

catalysts can be prepared and constructed accurately

by in-situ characterization techniques, but there are

still some limitations in the study of these catalysts in

the field of theoretical calculation. Therefore, in the

future, it is necessary to further improve the research

capabilities by combining theoretical calculations and

experiments on Pt-based catalysts, and explore the

ability to operate within a wider pH range. Efficiently

working ORR electrocatalyst. All things considered,

designing a robust, efficient and eco-friendly

electrocatalyst is the current challenge that needs to

be solved.

REFERENCES

Nørskov J K, Rossmeisl J, Logadottir A, Lindqvist L,

Kitchin J R, Bligaard T and Jonsson H 2004 J. Phys.

Chem. B 108 17886-92

Liu X, Chen J, Liu G, Zhang L, Zhang H and Yi B 2010 J.

Power Sources 195 4098-103

Rinaldo S G, Stumper J r and Eikerling M 2010 J. Phys.

Chem. C 114 5773-85

Zhang J, Sasaki K, Sutter E and Adzic R 2007 Science 315

220-2

Tan X, Prabhudev S, Kohandehghan A, Karpuzov D,

Botton G A and Mitlin D 2015 ACS Catal. 5 1513-

24

Sasaki K, Naohara H, Choi Y, Cai Y, Chen W-F, Liu P and

Adzic R R 2012 Nat. Commun. 3 1115

Yang D, Yan Z, Li B, Higgins D C, Wang J, Lv H, Chen Z

and Zhang C 2016 Int. J. Hydrogen Energy 41

18592-601

Tang X, Fang D, Qu L, Xu D, Qin X, Qin B, Song W, Shao

Z and Yi B 2019 Chin. J. Catal. 40 504-14

Leteba G M, Mitchell D R, Levecque P B, Van Steen E and

Lang C I 2020 RSC Adv. 10 29268-77

Zhou F, Yan Y, Guan S, Guo W, Sun M and Pan M 2020 Int.

J. Energy Res. 44 10155-67

Huang L, Zaman S, Tian X, Wang Z, Fang W and Xia B Y

2021 Acc. Chem. Res. 54 311-22

Yu Y, Zhou J and Sun Z 2020 Adv. Funct. Mater. 30

2000570

Chu W, Higgins D, Chen Z and Cai R 2014 Non‐Noble

Metal Fuel Cell Catalysts (New York: Wiley) pp 357-

88

Wang Y, Wu M, Wang K, Chen J, Yu T and Song S 2020

Adv. Sci. 7 2000407

Kalaj M, Bentz K C, Ayala Jr S, Palomba J M, Barcus K S,

Katayama Y and Cohen S M 2020 Chem. Rev.

120 8267-302

Xu X, Yang T, Zhang Q, Xia W, Ding Z, Eid K, Abdullah A

M, Hossain M S A, Zhang S and Tang J 2020 Chem.

Eng. J. 390 124493

Han X, Ling X, Yu D, Xie D, Li L, Peng S, Zhong C, Zhao

N, Deng Y and Hu W 2019 Adv. Mater. 31 1905622

Research Advances on Electrocatalysts for Oxygen Reduction Reaction in Fuel Cells

63