Adaptive Fuzzy Logic Control for Optimal Speed Regulation in Single

Phase Induction Motors

Sumukh M S

a

, Sumanth A R

b

, Shree Harsha M Kalyanshetti

c

, Shiva Prasad A

d

and

Suganthi N

e

Department of Electrical and Electronics Engineering, Dayananda Sagar College of Engineering,

Kumaraswamy Layout, Bangalore, Karnataka, India

Keywords: Fuzzy-Logic, Inverter, Error.

Abstract:: The present work addresses the design of an intelligent controller for single-phase induction motors to achieve

precise speed regulation. Due to their straightforward design and reliability, these motors are commonly used

in both industrial and domestic applications. Traditional control methods often face challenges with

nonlinearity and variations in load, which has led to the development of a fuzzy logic-based controller that

offers better real- time adaptability. The proposed fuzzy logic controller enhances the motor's responsiveness,

reduces overshoot, and minimizes steady-state errors, resulting in smoother and more efficient control.

Simulations conducted in MATLAB/Simulink show significant improvements in speed control, stability, and

efficiency, highlighting its potential for modern intelligent motor control applications.

1 INTRODUCTION

The necessity of the speed control of induction

motor has increased due to increasing application of

induction motor, hence finding efficient method to

control the motor has become the at most need of the

moment. In order to tackle this problem we have

designed a robust and efficient control system to

address precise speed regulation challenges in single-

phase induction motors, which are widely used in

both industrial and domestic settings due to their

simple design and reliability. Achieving effective

speed control however, is challenging because of

inherent nonlinearities and load sensitivity.

Traditional methods, such as basic PI controllers,

often fall short in delivering the required stability and

dynamic response. To overcome this, the project

integrates fuzzy logic controller, creating a hybrid

control system that can dynamically adjust

parameters in real time. This integration makes the

motor highly responsive to load changes while

a

https://orcid.org/0009-0004-2553-3345

b

https://orcid.org/0009-0009-0151-2909

c

https://orcid.org/0009-0003-4581-8332

d

https://orcid.org/0009-0009-9594-2976

e

https://orcid.org/0000-0003-2222-856X

minimizing issues like overshoot and steady-state

errors, leading to smoother, more accurate speed

control even under fluctuating loads.

Previous studies have primarily focused on

(Abdelwanis et al., 2023) fuzzy logic control using

the dspic controller here we are using Atmega and

esp32.

Fuzzy logic provides notable benefits compared to

traditional control methods, especially when dealing

with systems that involve uncertainty, complexity,

and imprecision. Unlike conventional control

techniques that depend on exact mathematical

models, fuzzy logic accommodates "degrees of

truth," allowing for more nuanced decision-making

based on partial truth values. This flexibility makes it

particularly effective in scenarios where human

reasoning and expert knowledge play a crucial role.

Moreover, fuzzy logic is resilient to noise and

disturbances, enabling it to manage input variability

without the need for complicated adjustments.

178

M S, S., A R, S., M Kalyanshetti, S. H., A, S. P. and N, S.

Adaptive Fuzzy Logic Control for Optimal Speed Regulation in Single Phase Induction Motors.

DOI: 10.5220/0013652800004639

In Proceedings of the 2nd International Conference on Intelligent and Sustainable Power and Energy Systems (ISPES 2024), pages 178-184

ISBN: 978-989-758-756-6

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

It also facilitates smooth, gradual transitions between

states, which is particularly useful in applications that

require fine-tuned control, such as regulating

temperature or speed. The straightforward design of

fuzzy systems and their wide-ranging applicability

from consumer electronics to automotive systems

further highlight their versatility. The adaptability,

robustness, and simplicity of fuzzy logic position it as

a strong alternative and complement to traditional

methods in various practical applications.

The system also utilizes IGBTs, providing efficient

and rapid switching from a DC source, which reduces

power losses and enhances overall system

performance. MATLAB/Simulink simulations

confirm improvements in speed control, stability, and

energy efficiency. By allowing real-time adjustments,

this fuzzy logic-based controller maintains stable

motor performance amid unpredictable load changes,

making it especially useful in industrial contexts. This

approach not only extends motor life and reduces

mechanical stress but also optimizes power

utilization, offering practical solutions for advancing

motor control. The design of fuzzy membership

functions, and rules were made by referring (Alwadie,

2018) and (El Ouanjli et al., 2019a), in the hardware

implementation of the controller the tachometer was

designed by referring (El Ouanjli et al., 2019b) and

lastly the single phase full bridge inverter, gate

driving SPWM circuitry were all designed by

referring to (Firdaus, 2019). The main reason we have

opted for fuzzy control is due to its abilities of

providing adaptive control over the speed drive under

non-linear conditions caused by sudden application or

removal of mechanical shaft loads, unlike the PI or

PID controller where one has to determine the

controller constants that are prone to vary for non-

linear loads. In this project, we have chosen to use

V/F as our speed control method, under open-loop

conditions this method is used to change the output

voltage and frequency of the inverter according to set

speed. This method is suitable for changing speed and

can obtain high speeds. Simply when speed

regulation with varying load regulations will not so

much of a concern. In closed loop V/F drives, the

torque is constant for a given constant V/F ratio,

however, the lower the speed is, the more difficult in

keeping the input impedance of the induction motor

with change in f. Therefore, to obtain a torque that is

constant from low speed to high speed it is necessary

to adjust V/F ratio at low speed in accordance to

characteristics of the motor. Emerging trends in fuzzy

logic-based speed control for single-phase induction

motors involve the incorporation of machine learning

algorithms to improve adaptability and performance

across various operating conditions. `

With the advent of IoT-enabled controllers, there will

be opportunities for real-time monitoring and remote

optimization of motor functionality. Improvements in

hardware, including high-speed processors and

affordable sensors, will support quicker and more

efficient fuzzy controller implementations.

Furthermore, investigating hybrid intelligent systems

that combine fuzzy logic with neural networks or

evolutionary algorithms could lead to greater

precision and resilience in motor control.

2 SYSTEM CONFIGURATION

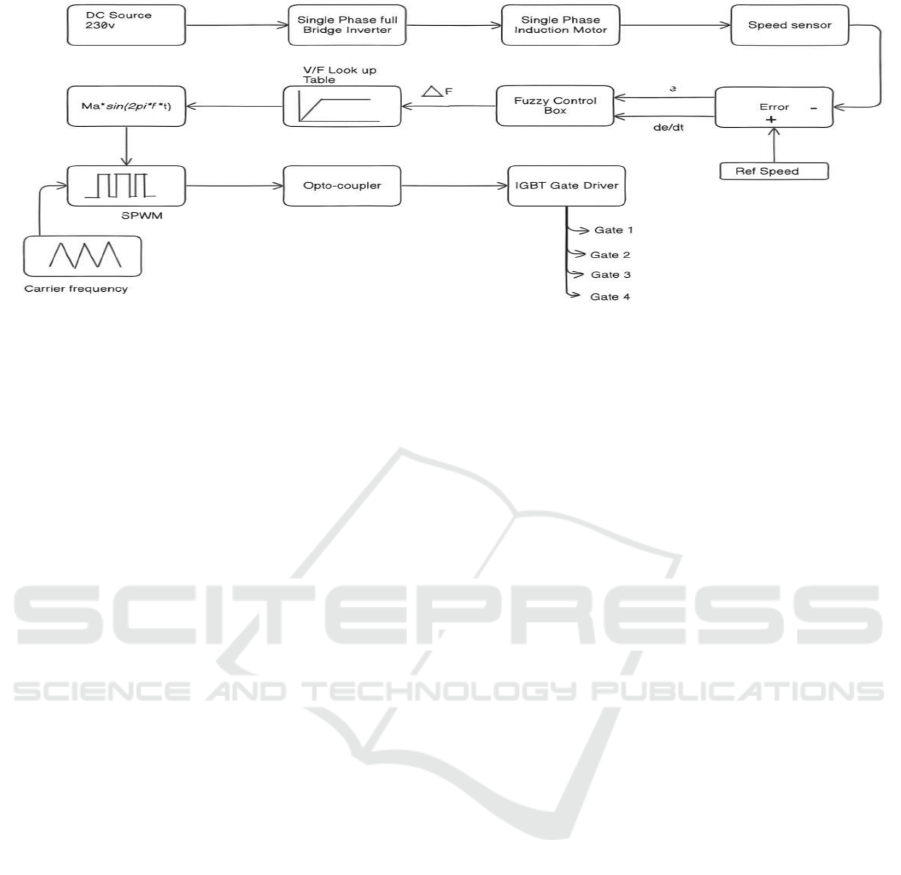

This block diagram represents a control system for a

single-phase induction motor using a fuzzy logic

controller. The fuzzy controller adjusts the motor's

frequency to control its speed based on the error

between reference speed and actual speed. The

system employs SPWM (Sinusoidal Pulse Width

Modulation) for driving the IGBT gates to control the

inverter's output.

2.1 Speed Control of Single-Phase

Induction Motors:

Single-phase induction motors (SPIMs) have been

widely known due to their simple structure,

robustness, and relatively low production costs.

However, the variation of parameters of SPIMs and

nonlinear behaviour pose big challenges to SPIM

control. Moreover, conventional control methods

cannot provide stable and efficient operation under

variations; thus, there is a great interest in advanced

techniques, like FLCs, to maximize the operation of

SPIM.

2.2 Fuzzy Logic Control in Motor

Drives

Fuzzy logic controllers are robust in handling the

nonlinear character of a motor drives, and that

property makes them extremely useful for an

application like SPIM even without a good

mathematical model. That further enhances dynamic

response and stability. The tools in

MATLAB/Simulink make them a preferred platform

for designing and simulating FLCs.

Adaptive Fuzzy Logic Control for Optimal Speed Regulation in Single Phase Induction Motors

179

Figure 2.1: Block Diagram.

2.3 Simulation of MATLAB Fuzzy

Logic Controllers

MATLAB is a very good tool for implementation of

fuzzy logic controller design. MATLAB Fuzzy Logic

Toolbox allows a direct way of creating the FIS with

predefined membership functions and rule base. Also,

upon there are ways to convert the FIS file into the

Arduino IDE compatible .ino file using online

converters. For SPIM-based speed control, FIS can

be defined using Mamdani or Sugeno methodologies,

while inputs are defined by examples similar to error

in speed affecting output signals like voltage. A rule

base is generated from expert knowledge in the form

of if-then rules for computing the outputs of the

controller.

2.4 Role of IGBTs in Motor Drives

IGBTs play a very important role in motor drives. Its

high switching time, high efficiency, and high power-

handling capabilities improve the use with low losses

during switching. Since the losses associated with

SPIMs' switching are greatly reduced, more detail can

be taken into the control of motor speed and torque.

In addition, the implementation of a fuzzy logic

controller with IGBTs improves efficiency and quick

response.

2.5 Optocoupler

An optocoupler isolates the control circuitry from the

high-power section and utilizes light to transmit

signals. It ensures safe and noiseless communication

between sinusoidal pulse width modulation generator

and gate driver.

2.6 Gate Driver

The gate driver boosts the low-power control signals

from the optocoupler to effectively drive the gates of

the IGBTs. It supplies the necessary power and timing

to switch the IGBTs in the inverter, ensuring proper

control of the motor. In practical implementation

either TLP250 or IR21101 can be used for the

building the gate driving circuit, TLP250 is an

optocoupler with high frequency operating

characteristics that can be controlled by a

microcontroller , or the IR21101 can also be used as

Mosfet/IGBT gate driver.

3 METHODOLOGY

Our speed control system is based on

v/f(voltage/frequency) control of the single-phase

induction motor. In v/f control, the applied voltage to

the motor is varied in proportion to the frequency of

the ac supply to maintain a constant flux in the motor.

This approach ensures that the motor operates

efficiently across different speeds. Since the system

assumes a constant load torque, the torque demand

remains steady, and the control focuses on

maintaining the appropriate balance between voltage

and frequency to achieve the target speed.

3.1 Fuzzy Logic Controller

Fuzzy logic control (FLC) provides a practical

method for managing the speed of induction motors,

particularly in situations characterized by nonlinear

dynamics, varying loads, and uncertain conditions.

In contrast to traditional control techniques that

depend on exact mathematical models, FLC mimics

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

180

human decision-making through linguistic rules,

allowing it to effectively manage the intricate

behaviour of motors. The process starts by gathering

inputs like the speed error (the difference between the

desired speed and the act. The linguistic variables are

explained as follows: “NL” is “Negative and Large”,

“NM” is “Negative and Medium”, “NS” is “Negative

and Small”, “ZZ” is “Zero”, “PS” is “Positive and

Small”, “PM” is “Positive and Medium” and “PL” is

“Positive and Large”. The membership range is

normalized to [-1, 1] by dividing the error of speed

before giving it to for the fuzzification, as illustrated

in Fig. 3.1.1.Fuzzy rules can be processed based on

knowledge about the control process, which is dealt

with linguistically in an "if-then" form. It eliminates

detailed knowledge of the mathematical model that

represents the control plant. Whose first three fuzzy

rules are represented as follows: If (speed error is

NL), and (speed error variation is NL), Then

(frequency change is NL) If (speed error is NM) and

(speed error variation is NL) Then (frequency

variation is NL) If (speed error is PM) and (speed

error variation is NL) Then (frequency variation is

NS) as shown in table 3.1.1

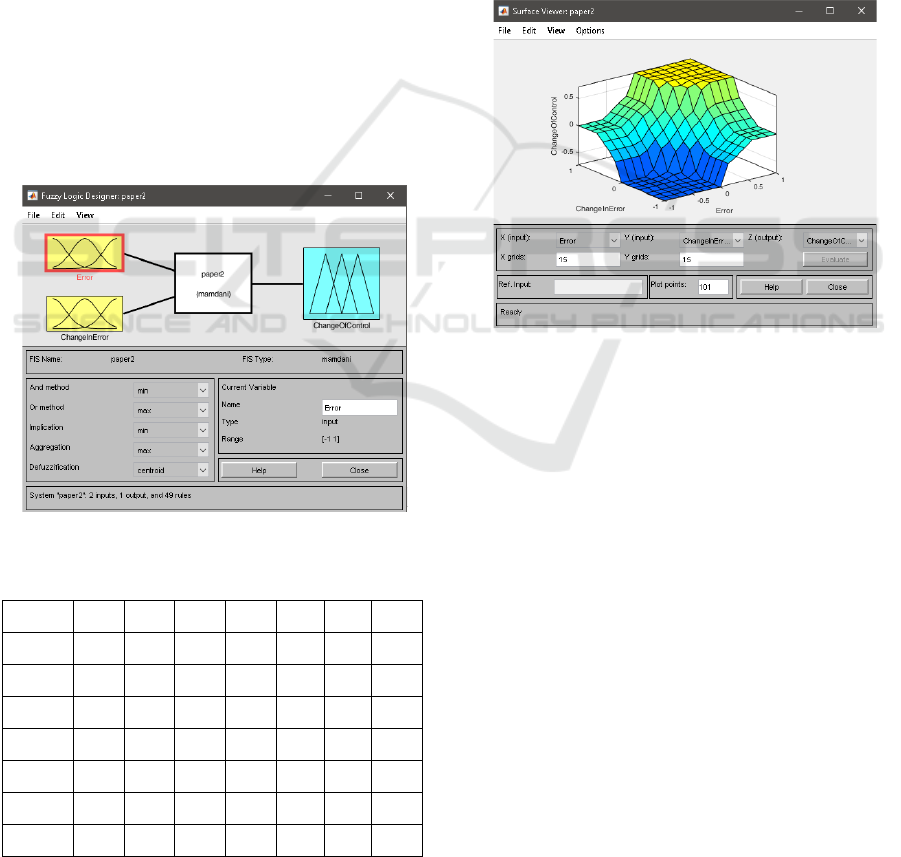

Figure 3.1.1 Fuzzy membership function.

Table 1: Membership Table.

e/de/dt NL NM NS ZE PL PM PS

NL NL NL NL NL ZE PS NM

NM NL NL NL NM PS ZE NS

NS NL NL NM NS PM PS ZE

ZE NL NM NS ZE PL PM PS

PL ZE PS PM PL PL PL PL

PM NS ZE PS PM PL PL PL

PS NM NS ZE PS PL PL PM

The surface plot's shape illustrates the fuzzy rules

used in the controller, demonstrating its response to

various combinations of error and change in error.

When both error and change in error are significant,

the controller enacts a stronger corrective action,

which is depicted by the peaks or dips in the plot. As

these values get closer to zero (the centre of the plot),

the output also approaches zero, signifying that the

system is nearing the desired state. The smooth

gradient across the surface showcases the fuzzy

controller's gradual response, preventing sudden

changes and ensuring a more fluid control action.

This visualization is helpful for fine-tuning the fuzzy

rules, enabling adjustments for either more aggressive

or more gradual responses to error, based on the

specific needs of the application.

Figure 3.1.2 Fuzzy logic surface plot.

3.2 Working

The 4 IGBTs in our circuit serve as the switches in a

full-bridge inverter, converting the DC input voltage

(230V) into single-phase AC voltage. This AC

voltage, with a frequency controlled by the PWM

signals, drives the motor at the desired speed based

on the V/f control strategy. In our circuit, the control

system is designed to compare the actual speed of the

motor with are reference speed. The reference speed

is the desired output speed that the motor should be

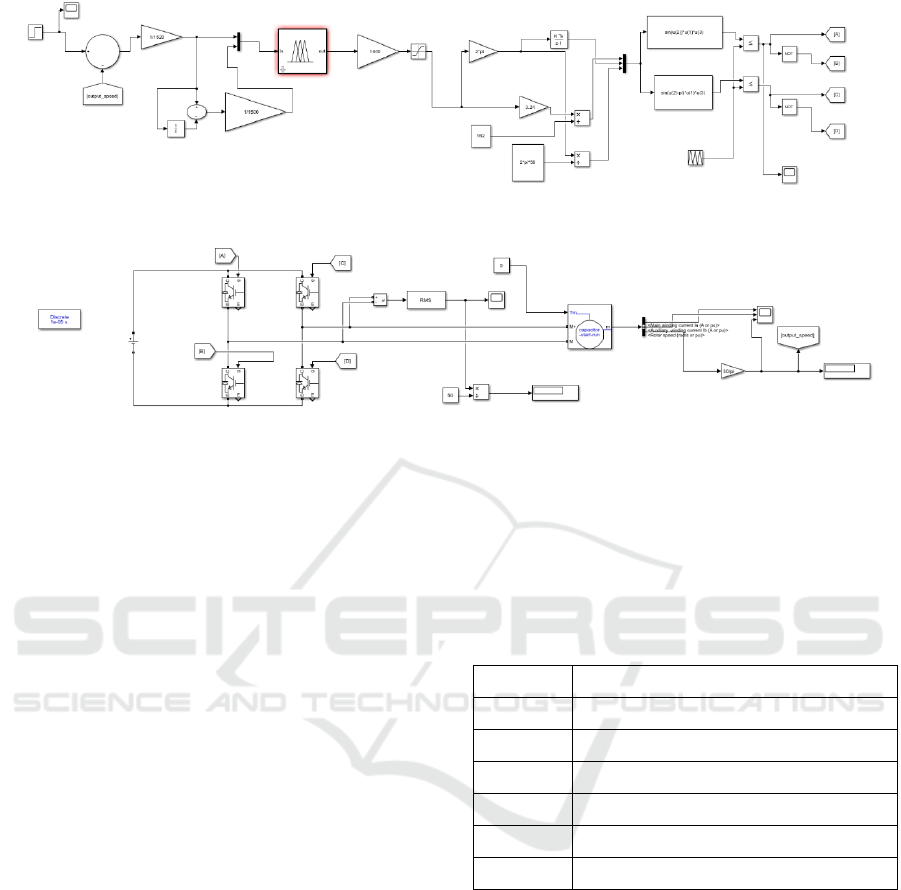

driven to. In the first diagram Fig.3.2.1, we notice the

control section of the system. The process of

controlling begins with an input reference signal

indicating the desired speed of the motor. This signal

is compared with the actual speed of the motor to

produce an error signal, which indicates a difference

in desired and the actual speeds. The error is

downscaled for easier processing, probably to get it

Adaptive Fuzzy Logic Control for Optimal Speed Regulation in Single Phase Induction Motors

181

Figure 3.2.1: Fuzzy logic control circuit.

Figure 3.2.2: Motor driving circuit.

within the range expected by the fuzzy logic

controller. The fuzzy logic controller uses this error,

and possibly the rate of change in error, to determine

the necessary adjustments to the control signals.

These controller elements, in turn, dynamically adjust

the frequency and voltage parameters according to the

error to ensure that the V/F ratio achieves the desired

motor speed. Signal processing blocks and

trigonometric functions further refine the signals to

give single phase AC outputs that have been correctly

shifted to make them suitable for their role of driving

the motor.

The second diagram Figure 3.2.2, illustrates the

power circuit and motor model. A full bridge inverter,

made up of switches like IGBTs, receives the adjusted

frequency and voltage signals from the control

section and converts them into a single phase AC

output to power the motor. The inverter is managed

by signals labelled [A], [B], [C], and [D], which

correspond to the switching states required to create a

rotating magnetic field. This single phase output is

then applied to the induction motor model, which

simulates real motor behaviour with parameters such

as resistance, inductance, and back-EMF, providing a

realistic depiction of motor dynamics under varying

load conditions. The system features a feedback loop

where the motor’s actual speed and current are

measured and sent back to the controller. RMS blocks

assess the motor output characteristics, which can be

used for monitoring and control purposes.

Additionally, capacitors and filters are likely included

to stabilize and smooth the motor voltage, ensuring

that the AC supply to the motor remains steady. The

feedback loop enables continuous adjustments based

on realtime motor performance, and the output speed

is displayed as [output speed], confirming that the

motor is operating at the intended speed. Matlab tools

specification table: Most of the tools used are the

built-in functions/blocks. The tools used in the

Matlab are listed as following:

Table 2: Matlab tools used.

Sl No Tools

1 Fuzzy Control Toolbox

2 Saturation limit box

3 Discrete time integrator

4 Repeating sequence block

5 Relation operator block

6 Asynchronous Single Phase machine

3.2.1 SPWM Working

The repetitive sequence block here generates a

triangular waveform, given certain time and output

values. These time values are [0 1 2] * (1/10000),

which set the timing for the triangular carrier

waveform. Now, by multiplying these values

by1/10000, you create a time interval of

0.1milliseconds corresponding to a frequency of

10kHz. The output values are [-1 1 -1], which means

that the triangular waveform has oscillations between

-1 and 1, and it generates a repeating triangular shape.

Basically, the logical operator blocks help in

comparing the carrier waveform with the time

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

182

varying sinusoidal signal generating the Sinusoidally

pulse width modulated signals for the gates of IGBT.

3.2.2 Logical Operator for SPWM

The sequence block here produces a triangular

waveform provided you have this set of time and

output values. These time values are [0 1 2]

*(1/10000), which determines the time on or off for

the triangular carrier waveform. By multiplying these

by 1/10000, you then get a time interval of

0.1milliseconds corresponding to a frequency of

10kHz. The output values are [-1 1 -1], which means

that the triangular waveform has the oscillations

between -1 and 1, and it generates a repeating

triangular shape.

4 RESULT

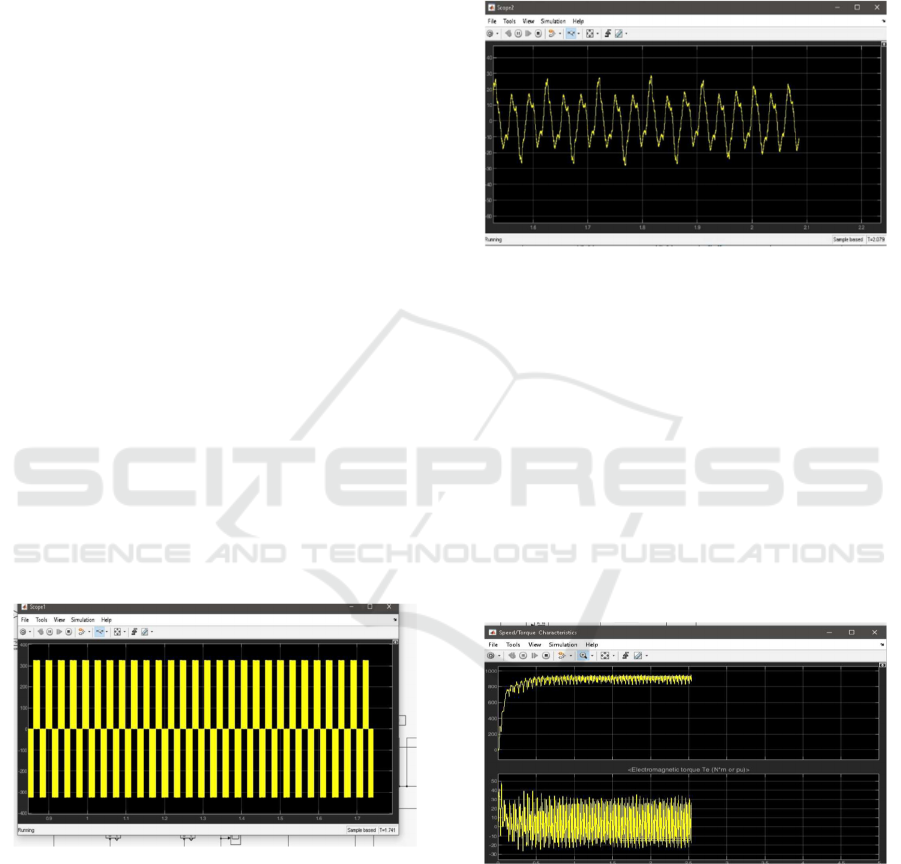

The image shows the speed and electromagnetic

torque characteristics of a single-phase induction

motor controlled using a fuzzy controller. The graph

represents Fig 4.1, the output voltage for controlling

the speed of a single-phase induction motor using

pulse-width modulation (PWM). The horizontal axis

represents time, ranging from approximately 0.9 to

1.7 seconds. The vertical axis represents voltage, with

values ranging from -325 to 325 units. The consistent

voltage pulses demonstrate how varying the duty

cycle controls the power delivered to the motor,

ensuring precise speed regulation.

Figure 4.1: Output Voltage Graph

The graph displays Fig 4.2, the output current for the

speed control of a single-phase induction motor. The

x-axis represents time, ranging from approximately

1.6 to 2.2 seconds, while the y-axis represents current,

with values from -20 to 40 units. The waveform is

oscillatory, indicating fluctuating current over time.

These fluctuations correspond to the motor's response

to speed control inputs, essential for maintaining

desired speed and ensuring efficient operation. Even

though the output voltage waveform appears to be in

the form of square wave in the simulation, in practical

implementation it will appear as sinusoidal in shape

which can further be filtered for harmonics using

capacitors and inductors.

Figure 4.2: Output current graph.

The speed response Figure 4.3 of the single-phase

induction motor starts at zero and quickly increases

within the first second. Once it reaches about 900units

in RPM, the speed levels off with minor oscillations.

This pattern shows that the controller successfully

brings the motor to its target speed, though there are

slight variations in the steady state as the system

works to maintain that speed. The torque varies

around an average value, indicating dynamic

adjustments to keep the desired speed efficiently.

These variations are crucial for ensuring stable and

effective motor operation.

Figure 4.3: Output speed and Torque.

The most important thing to note in this configuration

of speed control is that we have not included any kind

of inner control loop for controlling the current which

is often times a good practice to ensure the safety of

the motor’s windings, however the single Fuzzy logic

controller is enough to implement both the outer

speed and inner current loop

Adaptive Fuzzy Logic Control for Optimal Speed Regulation in Single Phase Induction Motors

183

REFERENCES

Abdelwanis, M. I., Fayez F. M. El-Sousy, & Ali, M. M.

(2023). A Fuzzy-Based Proportional–Integral–

Derivative with Space-Vector Control and Direct

Thrust Control for a Linear Induction Motor.

Electronics, 12(24), 4955–4955.

https://doi.org/10.3390/electronics12244955

Alwadie, A. (2018). A Concise Review of Control

Techniques for Reliable and Efficient Control of

Induction Motor. International Journal of Power

Electronics and Drive Systems (IJPEDS), 9(3), 1124.

https://doi.org/10.11591/ijpeds.v9.i3.pp1124-1139

El Ouanjli, N., Derouich, A., El Ghzizal, A., Motahhir, S.,

Chebabhi, A., El Mourabit, Y., & Taoussi, M. (2019).

Modern improvement techniques of direct torque

control for induction motor drives - a review.

Protection and Control of Modern Power Systems, 4(1).

https://doi.org/10.1186/s41601-019-0125-5

El Ouanjli, N., Derouich, A., El Ghzizal, A., Motahhir, S.,

Chebabhi, A., El Mourabit, Y., & Taoussi, M. (2019).

Modern improvement techniques of direct torque

control for induction motor drives - a review.

Protection and Control of Modern Power Systems, 4(1).

https://doi.org/10.1186/s41601-019-0125-5

Firdaus, A. Z. A. (2019). Design and Simulation of Fuzzy

Logic Controller for Variable Frequency Drive of Three

Phase AC Induction Motor. Journal of Advanced

Research in Dynamical and Control Systems, 11(12-

SPECIAL ISSUE), 834–842.

https://doi.org/10.5373/jardcs/v11sp12/20193283

Guiza, D., Djamel Ounnas, Youcef Soufi, & Naoual

Tidjani. (2023). Design and Real Hardware

Implementation of Fuzzy Logic Controller for DC-DC

Boost Converter. PRZEGLĄD

ELEKTROTECHNICZNY, 1(7).

https://doi.org/10.15199/48.2023.07.19

Hannan, M. A., Ali, J. A., Mohamed, A., & Hussain, A.

(2018). Optimization techniques to enhance the

performance of induction motor drives: A review.

Renewable and Sustainable Energy Reviews, 81, 1611–

1626. https://doi.org/10.1016/j.rser.2017.05.240

Hannan, M. A., Ali, J. A., Mohamed, A., & Hussain, A.

(2018). Optimization techniques to enhance the

performance of induction motor drives: A review.

Renewable and Sustainable Energy Reviews, 81, 1611–

1626. https://doi.org/10.1016/j.rser.2017.05.240

Maghfiroh, H., Saputro, J. S., Adriyanto, F., Sujono, A., &

Lambang, R. L. (2021). Performance Evaluation of

Fuzzy-PID in Speed Control of Three Phase Induction

Motor. IOP Conference Series: Materials Science and

Engineering, 1096(1), 012071.

https://doi.org/10.1088/1757-899x/1096/1/012071

Maghfiroh, H., Wahyunggoro, O., Cahyadi, A. I., Lian, K.

L., & Ke, B. R. (2016). Speed Control of a Single Taipei

Mass Rapid Transit System Train by Using a Single

Input Fuzzy Logic Controller. International Journal of

Electrical and Computer Engineering (IJECE), 6(2),

621. https://doi.org/10.11591/ijece.v6i2.8123

Overview of advanced control strategies for electric

machines. (2017). Chinese Journal of Electrical

Engineering, 3(2), 53–61.

https://doi.org/10.23919/cjee.2017.8048412

Plamena Dinolova, Vyara Ruseva, & Ognyan Dinolov.

(2023). Energy Efficiency of Induction Motor Drives:

State of the Art, Analysis and Recommendations.

Energies, 16(20), 7136–7136.

https://doi.org/10.3390/en16207136

Rekha Tidke, & Chowdhury, A. (2024). An experimental

analysis of fuzzy logic-sliding mode based IFOC

controlled induction motor drive. AIMS Electronics and

Electrical Engineering, 8(3), 340–359.

https://doi.org/10.3934/electreng.2024016

Sahoo, A. Ku., & Jena, R. Ku. (2022). Improved DTC

strategy with fuzzy logic controller for induction motor

driven electric vehicle. AIMS Electronics and Electrical

Engineering, 6(3), 296–316.

https://doi.org/10.3934/electreng.2022018

Shaikh, A. (2014). Speed Control of Induction Motor by

V/F Method Using Fuzzy Technique, IJSR, Call for

Papers, Online Journal. International Journal of

Science and Research (IJSR).

https://www.ijsr.net/getabstract.php?paperid=ART201

97800

Suwongsa, T., Areerak, K., Areerak, K., & Pakdeeto, J.

(2021). Energy Saving Approach for an Electric Pump

Using a Fuzzy Controller. Energies, 14(11), 3330.

https://doi.org/10.3390/en14113330

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

184