Smart Dam Automation Using Internet of Things, Image Processing

and Deep Learning

Maya Srinivas

a

, Akash R

b

, Barkha N

c

, Brunda P

d

and Ravikumar S

e

Department of Electronics and Communication Engineering, Dayananda Sagar College of Engineering, Bengaluru, India

Keyword: Dam Safety, Crack Detection, YOLOv5, IoT Automation, Structural Monitoring.

Abstract: The Integrated Dam Automation and Crack Detection System enhances dam safety and efficiency by

integrating advanced technologies. It achieves two key objectives. One is crack detection using the YOLOv5

deep learning model for high-precision structural defect identification and other is IoT-based monitoring and

control system for automating dam operations. YOLOv5, deployed using OpenCV with camera, detects

cracks in real-time, while IoT devices, managed by Arduino microcontrollers, monitor parameters like water

level, rainfall, and turbidity. Servo motors automate gate control based on real-time data from sensors thereby

ensuring efficient water management. A Telegram-based alert system provides real-time notifications about

critical issues, enabling timely interventions. Additionally, a dashboard offers visualized data for effective

monitoring and management. The developed system is having high accuracy in crack detection and effective

monitoring of various parameters of dam and significantly reducing human intervention.

1 INTRODUCTION

The Integrated Dam Automation and Crack Detection

System is an advanced solution designed to

modernize dam management using artificial

intelligence (AI), Internet of Things (IoT), and

automation technologies. Dams play a critical role in

water management, irrigation, hydroelectric power

generation, and flood control. However, aging

structures, environmental stresses, and the increasing

frequency of extreme weather events pose significant

challenges to their safety and operational efficiency

(Negi, 2023). Traditional methods of inspection and

management, relying on manual processes, are time-

consuming, labor-intensive, and prone to human error

(Adhikari, 2014). This increases the likelihood of

undetected cracks or delayed interventions, elevating

the risks of structural failures and associated

disasters. This system addresses these challenges

through two primary innovations.

a

https://orcid.org/0009-0008-6207-0625

b

https://orcid.org/0009-0009-1225-8205

c

https://orcid.org/0009-0005-1871-5308

d

https://orcid.org/0009-0009-9235-452X

e

https://orcid.org/0000-0002-4747-0283

First, it incorporates a crack detection mechanism

powered by the YOLOv5 deep learning model (Shi,

2024). Trained on a comprehensive dataset of dam

images, this model enables real-time crack detection

with high accuracy and minimal false positives.

Using a laptop camera and OpenCV, the system

ensures continuous monitoring of dam surfaces,

automating the detection process and reducing

dependency on manual inspections. Early

identification of structural defects allows for timely

maintenance and minimizes risks associated with

delays (Dais, 2021).

Second, the system integrates an IoT-based

automation framework to optimize dam operations

(Sathya, 2019). Arduino microcontrollers interface

with various sensors to monitor critical parameters

such as water level, rainfall, turbidity, temperature,

and flow rate. Real-time data from these sensors is

processed to automate the control of dam gates using

servo motors, ensuring precise regulation of water

164

Srinivas, M., R, A., N, B., P, B. and S, R.

Smart Dam Automation Using Internet of Things, Image Processing and Deep Learning.

DOI: 10.5220/0013652600004639

In Proceedings of the 2nd International Conference on Intelligent and Sustainable Power and Energy Systems (ISPES 2024), pages 164-170

ISBN: 978-989-758-756-6

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

discharge (Siddula, 2018). This automation improves

operational efficiency during both normal and

extreme conditions, such as heavy rainfall or high

water levels. Additionally, the system includes water

quality monitoring to ensure compliance with

environmental standards, while flow rate

measurements aid in effective discharge

management.

To enhance situational awareness and

communication, the system uses a Telegram bot to

send real-time alerts to authorities about critical

issues, such as high-water levels or detected structural

cracks (Krishnan, 2017). This feature facilitates rapid

decision-making and timely interventions during

emergencies. A dashboard visualizes sensor data for

efficient management, while a relay-controlled water

pump provides additional flood management

capabilities. Together, these features significantly

enhance dam safety and resilience, reducing human

intervention and response times during critical events

(Golding, 2022).

The results demonstrate the system's reliability

and effectiveness in improving dam management.

The YOLOv5 model achieves high precision in crack

detection, while the IoT-based automation system

ensures accurate environmental monitoring and

efficient gate control (Zhang, 2014). Automated

processes reduce human involvement while

maintaining operational safety, and the integration of

real-time alerts ensures comprehensive disaster

preparedness.

Looking ahead, the system offers opportunities

for further enhancement. Future developments may

include refining the YOLOv5 model to handle diverse

environmental conditions such as varying lighting or

surface textures (Kakad, 2021a). Additional sensors

for monitoring seismic activity and other structural

stresses could also be integrated. The system can be

scaled for deployment across multiple dams, with

centralized cloud-based analytics for improved

monitoring and management (Lan, 2020). By

combining innovative technologies with practical

applications, this project represents a transformative

step in modernizing dam infrastructure and

addressing critical challenges in water resource

management, public safety, and environmental

sustainability.

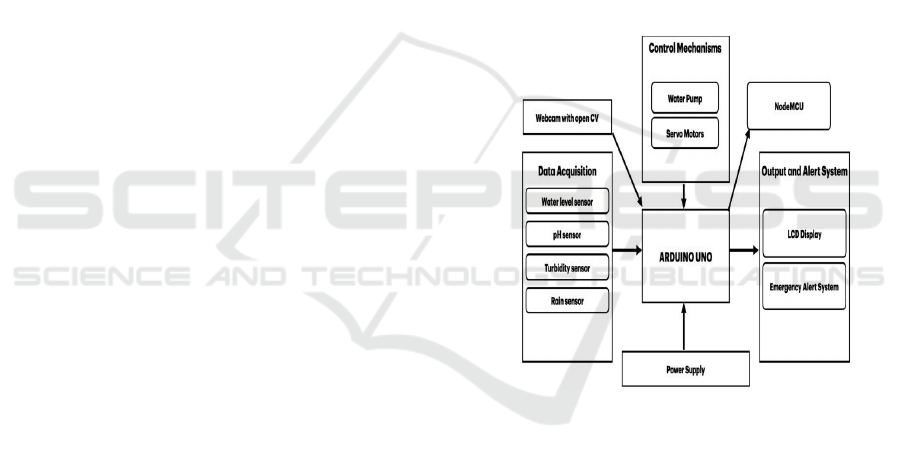

2 SYSTEM ARCHITECTURE

The proposed system integrates hardware and

software components which enhance dam safety and

automate operations (Kakad, 2021b). It includes a

Crack Detection system using YOLOv5 deep

learning for detecting structural defects in the dam

through real-time image analysis. Environmental

parameters such as water level, turbidity, pH, and

rainfall are monitored using IoT Sensors connected to

an ESP32 Microcontroller, which processes the data

and controls Servo Motors to manage dam gates

based on real-time requirements (Sathya, 2019). A

Telegram- based Alert System sends real-time

notifications to stakeholders in emergencies, ensuring

quick responses (Zou, 2012). The system also logs all

data, providing a comprehensive database for trend

analysis and future planning. A laptop running

OpenCV performs crack detection analysis, sending

results to the microcontroller, which then automates

gate control or triggers alerts. The system ensures

continuous operation with features like cloud

integration for remote access, real-time monitoring

through a web interface, and secure data storage.

Figure 1: Block Diagram.

Scalability is built into the design, allowing easy

expansion to other dams or additional sensors for

enhanced monitoring (Vijayakumar, 2017). Robust

security protocols, including encryption and secure

access controls, are implemented to protect data and

prevent unauthorized control of dam operations. This

integrated solution not only optimizes water

management but also helps in early detection of

structural issues and environmental changes,

significantly reducing disaster risks (Dhandre, 2015).

2.1 Arduino UNO

The Arduino UNO is a widely-used microcontroller

board that serves as the interface between sensors and

actuators in the system. It processes data from

Smart Dam Automation Using Internet of Things, Image Processing and Deep Learning

165

environmental sensors and controls outputs like servo

motors. With its 16 MHz clock speed and 14 digital

I/ O pins, it is capable of handling multiple sensor

inputs and actuator outputs simultaneously. The

Arduino UNO’s simplicity and flexibility make it

ideal for rapid prototyping and implementing real-

time applications in embedded systems. It also

features 6 analog inputs for reading sensor data,

making it essential for the system’s monitoring

function.

2.2 ESP32

The ESP32 is a powerful microcontroller with built-

in Wi-Fi and Bluetooth, allowing it to handle

communication and sensor data processing. It

connects the system to the internet, enabling real-time

data transmission to cloud services and the Telegram

bot for alerts. The ESP32 supports remote monitoring

and control, making it ideal for IoT applications like

this one. With a higher processing capacity compared

to Arduino, it ensures smooth operation of tasks

such as sending notifications, integrating with

dashboards, and performing complex data analysis.

Its versatility makes it an essential component in the

automation and remote control of the dam’s

operations.

2.3 YOLOv5

YOLOv5 is an advanced deep learning model for real-

time object detection, specifically used here for crack

detection in the dam structure. It processes images

captured by cameras placed around the dam, detecting

cracks and defects with high accuracy and low

latency. YOLOv5 is known for its ability to run

efficiently on embedded systems, making it suitable

for deployment in remote dam environments. It

continuously analyses the dam’s images, providing

timely feedback to the control system. Its ability to

detect even minor structural issues ensures that any

cracks are addressed before they escalate into major

problems.

2.4 Sensors Used

1. Water Level Sensor: This sensor is crucial for

measuring the water level in the dam reservoir. By

continuously monitoring the water height, it helps

prevent overflow by providing early warnings if water

levels approach critical thresholds.

2. Turbidity Sensor: The turbidity sensor detects the

clarity of the water, indicating the presence of

suspended particles or contaminants. It ensures that

the water quality remains within acceptable standards.

3. pH Sensor: The pH sensor measures the acidity or

alkalinity of the water, ensuring that the water quality

remains suitable for both human consumption and the

ecosystem.

4. Rain Sensor: This sensor detects rainfall intensity

and provides data used for predictive flood

management. By tracking rainfall patterns, it helps

forecast potential flooding and enables timely

response actions.

5. Water Flow Sensor (YF-S201): This sensor

measures the flow of water in the system, providing

data on the rate of water movement. It ensures that the

gates are adjusted correctly to maintain optimal water

flow and distribution, helping to prevent flooding or

underutilization of water resources.

2.5 Servo Motors

Servo motors are used to precisely control the

movement of the dam gates, adjusting their position

based on real-time data from sensors. They allow for

fine control of the water flow, ensuring that the dam's

gates open or close accurately to maintain the desired

water level. These motors are critical for the

automation aspect of the system, eliminating the need

for manual intervention and ensuring a quick, precise

response to changing conditions. The use of servo

motors enhances the system's ability to regulate water

flow, optimizing dam operations and preventing

potential disasters.

2.6 LCD Display

The LCD display provides real-time data

visualization for the system’s operations. It shows

important parameters like water level, pH, turbidity,

and flow rate, making it easy for operators to monitor

dam conditions on-site. The display also shows

system status, error messages, and alerts, providing

immediate feedback to users. This component is

useful for local monitoring and quick decision-

making, especially in situations where remote

communication is unavailable. The LCD ensures that

operators can access important information without

needing to interact with a computer or mobile device.

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

166

2.7 Web Camera

The web camera is used to capture images of the dam

structure for crack detection using the YOLOv5 deep

learning model. Positioned at strategic locations

around the dam, the camera continuously monitors the

structural integrity of the dam. It sends captured

images to a laptop or server running YOLOv5, which

processes the images for any cracks or damage. This

visual monitoring system enhances the overall safety

of the dam, allowing for early detection of structural

issues that could lead to catastrophic failures. The web

camera plays a crucial role in ensuring the dam's long-

term stability and safety.

2.8 Telegram Bot

The Telegram bot is a communication tool that sends

real- time notifications to stakeholders in case of

emergencies or critical conditions. By integrating

with the system, it delivers alerts about rising water

levels, crack detection, sensor malfunctions, or other

important events. The bot allows operators and

engineers to receive immediate updates on their

smartphones or computers, ensuring they can take

prompt action. This feature improves response times

during emergencies, making it easier for stakeholders

to stay informed and make decisions in real time. It is

an essential part of the system's communication

infrastructure.

3 WORKING PRINCIPLE

The system is designed for real-time monitoring,

control, and safety automation of dam operations,

integrating several key components (Shivappa,

2020). At its core is the ESP32 microcontroller,

responsible for data processing, decision- making,

and communication between sensors, actuators, and

the alert system. The data acquisition subsystem

includes sensors for monitoring water levels, pH,

turbidity, rainfall, and leakage, which provide crucial

environmental and structural data. A laptop equipped

with OpenCV and YOLOv5 deep learning model

processes real-time images from a camera to detect

cracks in the dam structure. Based on the data, control

mechanisms such as motor drivers, water pumps, and

gate control motors are activated to regulate dam

operations, including adjusting gate positions and

managing water levels (You, 2020). The output and

alert system includes an LCD display for real-time

monitoring, a buzzer for audible alerts, and an

emergency alert system that sends notifications via a

Telegram bot. The power supply ensures continuous

operation of all components, particularly during

critical times. The system works by collecting sensor

data, analyzing images for structural defects, making

decisions based on real-time conditions, and sending

alerts to operators through various communication

methods, ensuring efficient management of dam

operations and early intervention in emergencies.

Additionally, the system is designed to handle

multiple types of emergencies, such as high-water

levels, structural damage, or leakage, with predefined

actions based on the severity of the situation (Sathya,

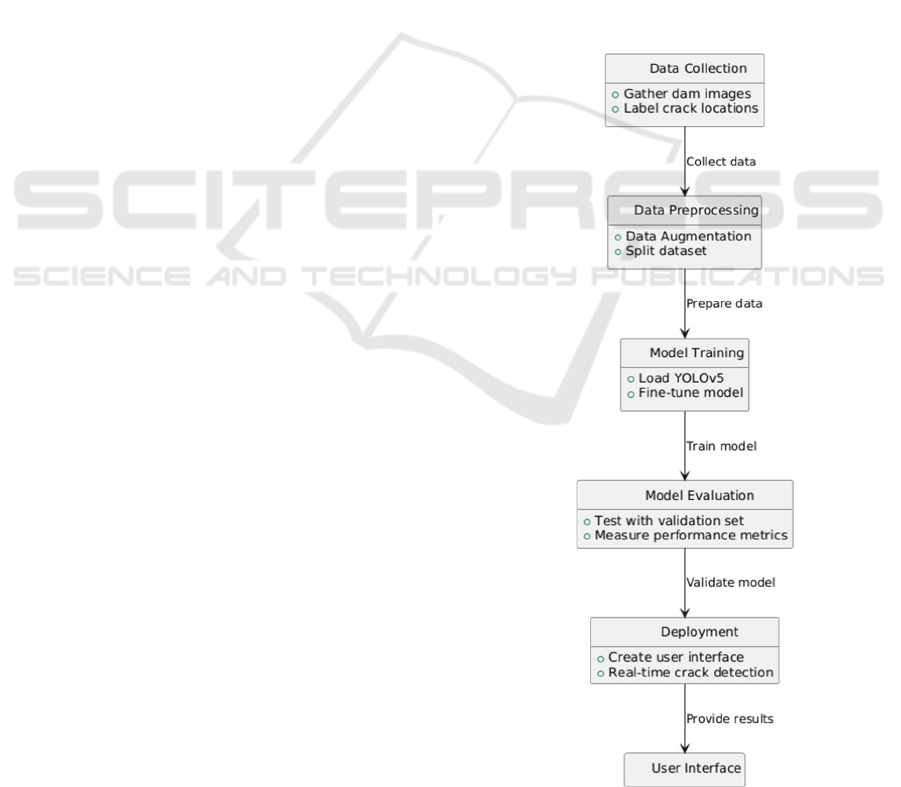

2019). Figure 2 outlines how to build and deploy a

crack detection system using YOLOv5 in a simple,

step-by-step process. First, data collection is done by

gathering images of dams and marking the locations

of cracks to create a dataset. Then, in the data

preprocessing stage, the images are enhanced (e.g.,

flipping

and

rotating

them)

to

make

the

model

more

Figure 2: Flowchart for crack detection.

Smart Dam Automation Using Internet of Things, Image Processing and Deep Learning

167

adaptable, and the data is split into training and testing

sets. During model training, the YOLOv5 model is

fine-tuned using this data, teaching it to identify

cracks accurately. After training, the model is tested

in the evaluation phase to check its performance and

accuracy. Once the model performs well, it is

deployed into a user-friendly interface for real-time

crack detection.

The user interface makes it easy to visualize

results and monitor the dam's condition. This system

helps reduce human effort by automating crack

detection, allowing for quicker responses to potential

problems. It also improves safety by providing timely

alerts for maintenance. By using data augmentation,

the model becomes more versatile, handling a variety

of real- world conditions.

In the end, the process creates a reliable, efficient,

and scalable solution for dam monitoring and

maintenance.

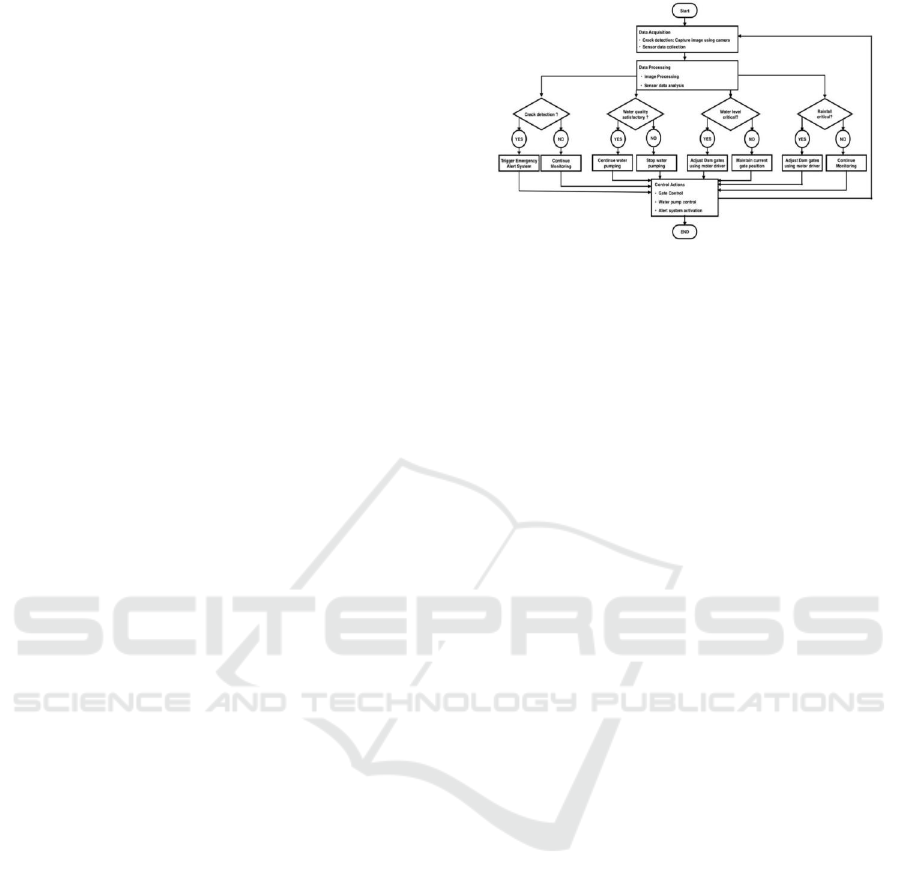

The flowchart in figure 3 explains an automated

system designed to monitor and manage dam

operations efficiently while prioritizing safety and

environmental protection. It begins by collecting data

using cameras to detect cracks and sensors to measure

water levels, water quality, and rainfall. This data is

then analyzed to identify any issues. Based on the

analysis, the system takes specific actions depending

on the situation. If cracks are detected in the dam, an

emergency alert is triggered to address the problem

immediately. If no cracks are found, the system

continues regular monitoring to ensure smooth

operations.For water quality, the system allows

pumping to continue only if the water is satisfactory,

ensuring no contamination occurs. If the water quality

is poor, pumping stops to protect the environment and

public health. Similarly, water levels are constantly

monitored, and if they become critical, the dam gates

are adjusted using motorized controls to prevent

flooding. If the levels are safe, the gates remain

unchanged. Rainfall is another important factor; in

case of heavy rainfall, the system adjusts the dam

gates to regulate water flow. When rainfall levels are

normal, the system simply keeps monitoring. All these

decisions lead to specific control actions, such as

adjusting dam gates, managing water pumps, or

triggering emergency alerts when needed. The

system’s real-time data collection and automated

responses ensure the dam operates efficiently while

protecting nearby areas.

Figure 3: Hardware Working Flowchart.

By reducing the need for human intervention and

improving response times, the system helps prevent

accidents caused by structural issues, poor water

quality, or flooding. This proactive and adaptive

approach ensures the dam remains safe, stable, and

environmentally sustainable in the long term.The

integration of cloud-based communication further

allows remote monitoring and control, enhancing the

flexibility and reach of the system. Regular calibration

and maintenance of the sensors ensure consistent data

accuracy, contributing to the system's reliability. The

automated nature of the system reduces human error

and ensures timely responses to potential hazards.

Overall, this comprehensive approach improves dam

safety, operational efficiency, and proactive disaster

management.

4 METHODOLOGY USED

The methodology adopted for the project "Smart Dam

Automation Using IoT, Image Processing, and Deep

Learning" integrates hardware and software

components to develop an automated and efficient

dam management system (Kakad, 2021b). The

system is designed using the ESP32 microcontroller,

which acts as the central unit, interfacing with

sensors, actuators, and communication modules.

Various sensors, including water level, rain, pH,

turbidity, and crack detection systems, are deployed

to collect real- time environmental and structural

data. Crack detection is achieved using the YOLOv5

deep learning model, which is trained on labeled

datasets and implemented using OpenCV for real-

time monitoring through a laptop camera (Zhang,

2014). Actuators such as servo motors and relay-

controlled water pumps are utilized for automated

gate control and water management based on sensor

inputs. IoT- based communication enables seamless

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

168

data transfer, with a dashboard visualizing sensor

output and a Telegram bot sending critical alerts to

designated authorities during emergencies. The

hardware implementation includes reliable power

supply mechanisms to ensure uninterrupted

operation, while the software system integrates

advanced deep learning and automation algorithms to

detect cracks, manage water levels, and optimize

safety protocols.

Figure 4: Hardware Model (Front View).

Figure 5: Hardware Model (Top View).

Extensive testing is conducted to validate the system’s

performance under diverse environmental conditions,

ensuring its scalability, cost-effectiveness, and

reliability for modern dam management.

Additionally, the system is designed with redundancy

in mind, incorporating backup power solutions and

fail-safe mechanisms to maintain continuous

operation during power outages or sensor

malfunctions. Regular calibration of sensors ensures

that the data collected is accurate and reliable,

contributing to precise decision- making. The

integration of cloud-based analytics allows for remote

monitoring and real-time decision- making,

enhancing the flexibility of the system. Furthermore,

the modular nature of the system ensures that it can

be easily scaled or adapted for different types of dams

or environmental conditions. The system's ability to

provide early warnings and automate critical tasks

enhances dam safety, reduces human intervention,

and improves operational efficiency.

5 RESULTS & OUTCOMES

The integrated dam monitoring and control system

enhances safety and efficiency by combining real-

time data collection from sensors (water level, pH,

turbidity, rainfall, and leakage) with automated

controls. YOLOv5-based image analysis detects

cracks and structural issues early, enabling proactive

risk management. The system can automatically

operate gates or pumps to regulate water levels and

prevent overflow. A Telegram alert system ensures

rapid communication during emergencies, while an

LCD display provides on-site real-time data

visualization. This integration improves disaster

response, optimizes water distribution, and reduces

structural failure risks, offering a reliable, automated

solution for dam safety and operations.

6 CONCLUSION

The proposed comprehensive solution for real-time

monitoring, control, and automation of dam

operations combines advanced sensors, image

analysis through YOLOv5, and automated control

mechanisms. The system ensures the structural

integrity of the dam, optimizes water management,

and enables rapid responses to potential emergencies.

The use of the ESP32 microcontroller for data

processing and communication allows seamless

coordination between various components, while the

inclusion of output systems like LCD displays,

buzzers, and Telegram alerts ensures that both on-site

and remote personnel are promptly informed. This

system enhances dam safety, improves operational

efficiency, and provides an effective means for early

detection of issues, ultimately mitigating the risks

associated with flooding and structural failures.

REFERENCES

Adhikari, R. S., Moselhi, O., & Bagchi, A. (2014). Image-

based retrieval of concrete crack properties for bridge

inspection. Automation in Construction, 39, 180–194.

https://doi.org/10.1016/j.autcon.2013.09.007

Al-hadhrami, Z. M. A., & Shaikh, A. K. (2017). A system

for remote monitoring and controlling of dams.

International Journal of Programming Languages and

Applications, 7(3), 1–18.

Dais, D., Bal, İ. E., Smyrou, E., & Sarhosis, V. (2021).

Automatic crack classification and segmentation on

masonry surfaces using convolutional neural networks

Smart Dam Automation Using Internet of Things, Image Processing and Deep Learning

169

and transfer learning. Automation in Construction, 125,

103606. https://doi.org/10.1016/j.autcon.2021.103606

Dhandre, N., & Jadhav, N. (2015). Dam data collection and

monitoring system. International Journal of Science

and Research (IJSR), 5(6), 80–85

Golding, V. P., Gharineiat, Z., Munawar, H. S., & Ullah, F.

(2022). Crack detection in concrete structures using

deep learning. Sustainability, 14(8117).

https://doi.org/10.3390/su14181117

Kakad, S., & Dhage, S. (2021). Cross domain-based

ontology construction via Jaccard semantic similarity

with hybrid optimization model. Expert Systems with

Applications,178,115046.https://doi.org/10.1016/j.esw

a.2021.115046

Kakad, S., & Dhage, S. (2021). Knowledge graph and

semantic web model for cross domain. Journal of

Theoretical and Applied Information Technology, 100,

123–130.

Krishnan, S., Sindhu, R., & Raghavi, S. (2017). Dam gate

level monitoring and control over IoT. SSRG

International Journal of Electrical and Electronics

Engineering, 4(2), 10–14.

Lan, Y., et al. (2020). Yulong dam maintenance

submersible for real-time inspection and safety

evaluation. In Proceedings of the Chinese Automation

Congress (CAC) (pp. 645–652). IEEE.

Negi, P., et al. (2023). Insight recommendations for

achieving sustainability in dam management using IoT.

InProceedings of the International Conference on

Sustainable Computing and Data Communication

Systems (ICSCDS) (pp. 312–318). IEEE.

Sathya, S., Arun, K., Mahajan, H., & Singh, A. K. (2019).

Automate the functioning of dams using IoT. In

Proceedings of the 3rd International Conference on

Computing Methodologies and Communication

(ICCMC) (pp. 245–250). IEEE.

Sathya, V., Arun, K., Mahajan, H., & Singh, A. K. (2019).

Automate the functioning of dams using IoT. In

Proceedings of the 3rd International Conference on

Computing Methodologies and Communication

(ICCMC) (pp. 245–250). IEEE. https://doi.org/10.xxxx

Shi, P., et al. (2024). Underwater dam crack detection using

instance segmentation and enhanced feature extraction

networks. IEEE Transactions on Instrumentation and

Measurement, 73, 1205.

Shivappa, N., Rao, A. S., Aishwarya, T., Athreya, J. S., &

Mandakini, H. (2020). Dam automation using IoT.

International Journal of Engineering Research &

Technology (IJERT), 9(5), 100–105.

Siddula, S. S., & Jai, P. C. (2018). Water level monitoring

and management of dams using IoT. In Proceedings of

the IEEE 8th International Advance Computing

Conference (IACC) (pp. 120–125). IEEE.

Vijayakumar, P., Kulkarni, M. S., & Joshy, M. (2017). IoT-

based water supply monitoring and controlling system.

International Journal of Innovative Research in

Science, Engineering, and Technology, 6(4), 50–56.

Zhang, Y. (2014). The design of glass crack detection

system based on image pre-processing technology. In

Proceedings of the Information Technology and

Artificial Intelligence Conference (pp. 10–15).

Zou, Q., Cao, Y., Li, Q., Mao, Q., & Wang, S. (2012). Crack

tree: Automatic crack detection from pavement images.

Pattern Recognition Letters, 33(3), 227–238.

https://doi.org/10.1016/j.patrec.2012.08.020

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

170