AI Control Based Matrix Converter Fed Induction Motor Drives in

Cement Industries

Akshay Sharma

a

and Vinod Kumar

b

Department of Electrical Engineering, College of Technology & Engineering, MPUAT, Udaipur, India

Keywords: Artificial Intelligence, Induction Motor Drive, Cement Industries, Fuzzy Logic, Matrix Converter.

Abstract: The cement industry plays a crucial role in infrastructure development and construction activities. There is a

need to enhance the efficiency and performance of cement industries to meet the growing demand for cement

while reducing energy consumption and environmental impact. One potential solution for enhancing

efficiency and performance in cement industries is the use of matrix converter-fed induction motor drives

with fuzzy logic control. By implementing this technology, the cement industry can benefit from improved

energy conversion, utilization, higher motor efficiency, reduced power losses and enhanced control

capabilities. This can result in significant energy savings, reduced operating costs, and a more sustainable

cement manufacturing process. The use of matrix converter-fed induction motor drives with fuzzy logic

control allows for better control of motor speed and torque, ensuring optimal performance and productivity

in cement production. The application of fuzzy logic control enables the system to adapt to changing operating

conditions and variations in load demand, leading to more precise and efficient motor operation. Overall, the

integration of matrix converter-fed induction motor drives with fuzzy logic control holds great potential for

enhancing efficiency and performance in cement industries. This paper provides a comprehensive review of

the matrix converter fed induction motor drive in cement industries.

1 INTRODUCTION

In today's rapidly evolving industrial landscape, the

quest to enhance the cement industry's efficiency and

performance has become more pressing than ever. As

the demand for cement continues to rise alongside the

need for sustainable and environmentally conscious

production processes, it is evident that implementing

advanced technologies is imperative for the sector's

growth and success. Among these technologies,

matrix converter-fed induction motor drives with

fuzzy logic control have emerged as a promising

solution with the potential to revolutionise the

efficiency and productivity of cement manufacturing

(Bento et al., 2021).

This review aims to interpret the groundbreaking

potential of matrix converter-fed induction motor

drives with fuzzy logic control in revolutionizing the

cement industry (Swami et al., 2022). By exploration

into the complexity of this innovative technology and

its implications for the industry. Through this

a

https://orcid.org/0009-0000-2896-9495

b

https://orcid.org/0000-0001-9953-8967

exploration, to reveal the integration of these

advanced systems can lead to substantial

improvements in energy efficiency, cost savings, and

overall sustainability within the cement

manufacturing sector (Ninduwezuor-Ehiobu et al.,

2023).

1.1 Overview of Cement Industries and

Drive Systems

The cement industry serves as a cornerstone of

infrastructure and construction, supplying the

essential building material for various developmental

projects. With the global demand for cement on the

rise, cement manufacturing processes have

increasingly come under scrutiny for their energy

consumption and environmental impact

(Ninduwezuor-Ehiobu et al., 2023). As a response to

these challenges, the integration of advanced drive

systems in cement manufacturing has garnered

significant attention.

140

Sharma, A. and Kumar, V.

AI Control Based Matrix Converter Fed Induction Motor Drives in Cement Industries.

DOI: 10.5220/0013652200004639

In Proceedings of the 2nd International Conference on Intelligent and Sustainable Power and Energy Systems (ISPES 2024), pages 140-149

ISBN: 978-989-758-756-6

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

Drive systems in the cement industry play a vital

role in the operation of machinery and equipment

involved in the production process, such as crushers,

mills, and kilns. These systems are tasked with

providing the necessary power, control, and

efficiency for the smooth functioning of the

equipment. Traditional drive systems often encounter

limitations in energy conversion and control, leading

to in efficiencies and higher operating costs (Peng et

al., 2021). This has prompted the exploration of

innovative solutions to enhance drive system

performance, thereby optimizing energy usage and

overall productivity in cement manufacturing.

1.2 Overview of Cement Industries and

Drive Systems

Efficiency and performance are critical factors in

cement manufacturing, influencing both the

operational costs and the environmental footprint of

the industry. By improving efficiency and

performance, cement manufacturers can reduce

energy consumption, minimize emissions, and

enhance overall sustainability (Vaghela & Bhesaniya,

2024). It increased efficiency and performance

directly impact the bottom line by reducing operating

costs and increasing production output.

The efficiency and performance in cement

manufacturing aligns with the broader global efforts

to promote sustainable industrial practices. It is

imperative for the cement industry to embrace

technologies and methodologies that prioritize

resource efficiency and environmental responsibility,

ensuring its long-term viability and contribution to

sustainable development (Vaghela & Bhesaniya,

2024).

1.3 Introduction to Matrix Converter-

Fed Induction Motor Drives

Matrix converter-fed induction motor drives

represent a technological advancement in the fields of

motor drives for industrial applications (Barbhuiya et

al., 2024). Unlike conventional drives, which depend

on intermediate energy conversion stages, matrix

converters facilitate direct energy conversion from

the supply to the motor, eliminating the need for

bulky and inefficient conversion components.

This direct energy conversion capability diffuse

matrix converter-fed induction motor drives with

superior energy efficiency, reduced power losses, and

enhanced control precision. Such attributes make

them particularly well-suited for the demanding

operational requirements of the cement industry,

where consistent and precise motor control is

essential for optimizing performance and efficiency.

1.4 Role of Fuzzy Logic Control in

Enhancing Drive Performance

Fuzzy logic control has emerged as for enhancing the

performance of drive systems within industrial

settings. Its adaptive and robust control capabilities

allow for the effective regulation of motor speed,

torque, and operational parameters in response to

varying load conditions and process dynamics.

Within the context of cement manufacturing, the

integration of fuzzy logic control in matrix converter-

fed induction motor drives holds the potential to fine-

tune motor operation, ensuring optimal efficiency and

performance in the face of dynamic and unpredictable

operating conditions.

The collective combination of matrix converter-

fed induction motor drives with fuzzy logic control

represents a fundamental change in drive system

optimization, promising to revolutionize the

efficiency and performance of the cement industry.

Through their collaborative impact, these

technologies offer the means to achieve unusual

levels of energy efficiency, operational flexibility,

and performance reliability in the production of

cement (Abunike et al., 2023).

2 MATRIX CONVERTER

TECHNOLOGY

The implementation of matrix converter technology

in various industrial applications, including cement

manufacturing, has collected significant attention due

to its potential to revolutionize energy efficiency,

control precision, and overall system performance

(Omrany et al., 2023).

2.1 Principles of Matrix Converters

Matrix converters represent a novel approach to

power conversion, enabling direct energy conversion

from the input to the output without the need for

intermediate energy storage or conversion stages.

Unlike traditional converters that rely on components

such as rectifiers and inverters. Matrix converters

facilitate seamless energy transfer thereby

minimizing power losses and enhancing overall

efficiency. The principle of matrix converters

involves the use of semiconductor switches to

dynamically control the energy flow between the

AI Control Based Matrix Converter Fed Induction Motor Drives in Cement Industries

141

input and output, allowing for precise and efficient

operation within industrial motor drive systems

(Gerami et al., 2021).

In the specific context of the cement industry, the

principles of matrix converters are particularly

compelling due to their ability to provide direct and

efficient energy conversion, ultimately contributing

to enhanced motor performance and energy

efficiency in critical cement manufacturing

processes.

Matrix converters are single-stage alternating

current (AC/AC) power converters mainly based on

power transistors with minimal passive component

requirements (Alammari et al., 2019). Even though

the industrial applications of matrix converters have

been limited by constraints such as efficiency and

semiconductor drive requirements, recent

developments in semiconductor technologies

combined with more affordable and powerful

computation devices, such as system-on-chip

technologies that combine both Field Programmable

Gate Array (FPGA) and microprocessors inside the

same chip enabling the use of more complex control

schemes, a promising future for matrix converters in

a variety of applications. Fuzzy logic-based matrix

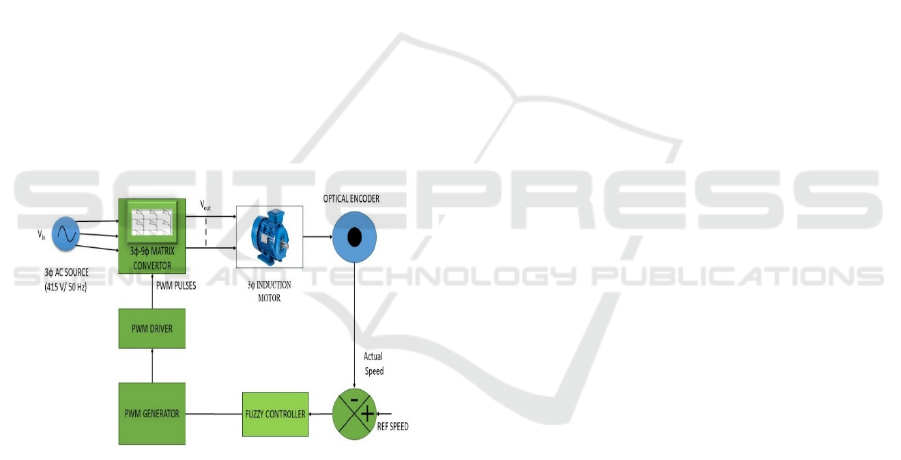

converter for IM shown in figure 1.

Figure 1: Fuzzy Logic Based Matrix Converter Fed IM

Matrix converters are bidirectional power

topologies that allow AC/AC power conversion,

without intermediate energy storage, revealing one of

the most important advantages of matrix converters

when compared to traditional back-to-back (B2B)

voltage source converters (VSCs) (Alammari et al.,

2019). The reduced filtering requirements makes the

matrix converter a topology mainly dependent on

power semiconductors and as a direct consequence

the matrix converter is able to achieve unparalleled

power densities. Matrix converters can be divided

into two different families of converters, single stage

or direct matrix converters (DMCs) and dual-stage or

indirect matrix converters (IMC) (Khanday, 2022).

2.2 Advantages in Industrial

Applications

The integration of matrix converter technology in

industrial applications, such as cement

manufacturing, offers a many of advantages that have

the potential to significantly impact operational

efficiency and sustainability (Mahmud & Gao, 2024).

Firstly, matrix converters enable direct and seamless

energy transfer, resulting in reduced power losses and

enhanced energy efficiency (Chen et al., 2024). This

translates to lower operating costs and minimized

environmental impact, aligning with the cement

industry's growing emphasis on sustainable and

resource-efficient practices (Khanday, 2022).

The precise control capabilities of matrix

converters, particularly in conjunction with induction

motor drives contribute to improved dynamic

response and operational flexibility. This is crucial

for cement manufacturing processes that often

encounter varying load demands and operational

conditions, enhance the practical utility of matrix

converters in optimizing motor performance and

productivity in the industry (Chen et al., 2024).

Another, advantage of matrix converters is their

compact and lightweight design, which minimizes

physical space requirements and installation

complexities (Kaleybar et al., 2024). This is

especially relevant in the context of cement

manufacturing facilities, where space optimization

and streamlined installation processes are essential

for maintaining efficient and cost-effective

operations (Evangeline et al., 2024).

2.3 Challenges and Limitations

While matrix converter technology holds insist for

industrial applications, including the cement industry.

One of the primary challenges associated with matrix

converters is the complexity of their control

algorithms and modulation strategies. Achieving

optimal performance and stability requires intricate

control methodologies, which may pose challenges in

terms of system design, implementation, and

maintenance, particularly in industrial environments

with exacting operational requirements and

regulatory standards (Molina, 2017).

The reliability and fault tolerance of matrix

converters under various operating conditions present

another critical consideration.

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

142

The robustness and resilience of these systems in

the face of voltage fluctuations, transient overloads,

and other operational disturbances is essential for

their successful integration into the demanding

operational environment of cement manufacturing

facilities.

The initial capital investment for implementing

matrix converter technology, although offset by long-

term energy savings and operational efficiencies, may

present a barrier to widespread adoption within the

cement industry, especially for smaller-scale

producers.

Despite these challenges, advancements in control

algorithms, fault tolerance mechanisms, and cost-

effective manufacturing processes are continuously

addressing the limitations associated with matrix

converter technology, improving for its broader

integration and sustained benefits in the realm of

cement manufacturing.

3 INDUCTION MOTOR DRIVES

IN CEMENT INDUSTRIES

3.1 Characteristics of Induction

Motors in Cement Manufacturing

In the context of cement manufacturing, induction

motors play a crucial role due to their robustness,

reliability, and ability to operate under varying load

conditions. These motors are often subjected to high

starting torque requirements and fluctuating loads,

making them indispensable for driving equipment

such as crushers, conveyors, and fans in cement

plants. Their simple and rugged construction makes

them well-suited for the harsh operational

environment of cement manufacturing, where dust,

high temperatures, and vibration are common

challenges. The ability of induction motors to operate

efficiently across a wide range of speeds further

enhances their suitability for diverse applications in

the cement industry.

3.2 Traditional Drive Systems and

Their Limitations

Induction motor drives in cement industries have

relied on fixed-speed drive systems, resulting in

suboptimal energy efficiency and limited control over

motor operation. Such traditional drive systems often

suffer from inherent limitations in adapting to

fluctuating load demands and optimizing energy

usage, leading to inefficiencies and increased

operational costs (Kim et al., 2024). The lack of

advanced control features and the inability to

dynamically adjust motor speed and torque according

to process requirements further restrict the overall

performance and flexibility of these drive systems in

cement manufacturing (Swami et al., 2016).

3.3 Need for Advanced Drive Solutions

The cement industry's demand for advanced drive

solutions is motivated by the need to improve energy

efficiency, productivity and sustainability, while also

addressing operational difficulties. Advanced drive

solutions incorporating modern control technologies,

such as variable frequency drives and advanced

control algorithms, can address the shortcomings of

traditional drive systems and unlock substantial

performance improvements (Xie et al., 2021). By

enabling precise control over motor speed and torque

these advanced drive solutions can optimize energy

usage. To minimize mechanical stress on equipment

and support the adoption of sustainable operational

practices within cement manufacturing facilities.

Moreover, the integration of advanced drive solutions

can contribute to reducing maintenance requirements

and extending the operational lifespan of critical

equipment, aligning with the industry's pursuit of

enhanced reliability and cost-effective operations

(Swami et al., 2016).

4 MATRIX CONVERTER-FED

INDUCTION MOTOR DRIVES

Industrial applications, particularly in the province of

cement manufacturing, have seen a growing

integration of matrix converter technology due to its

significant advantages and potential to optimize

operational efficiency and sustainability (Vinil Dani

& Jobin Christ, 2024).

4.1 Integration of Matrix Converter

Technology in Industrial Drives

The integration of matrix converter technology in

industrial drives presents a transformative approach

to power conversion and motor control (Rissman et

al., 2020). By directly converting AC power from the

grid into variable-frequency AC output for the

induction motors, matrix converters eliminate the

need for intermediate DC-link components resulting

AI Control Based Matrix Converter Fed Induction Motor Drives in Cement Industries

143

in a seamless energy transfer with reduced power

losses (Gong et al., 2024). This not only enhances

energy efficiency but also enables precise control

over motor speed and torque, addressing the variable

load demands inherent in cement manufacturing

processes.

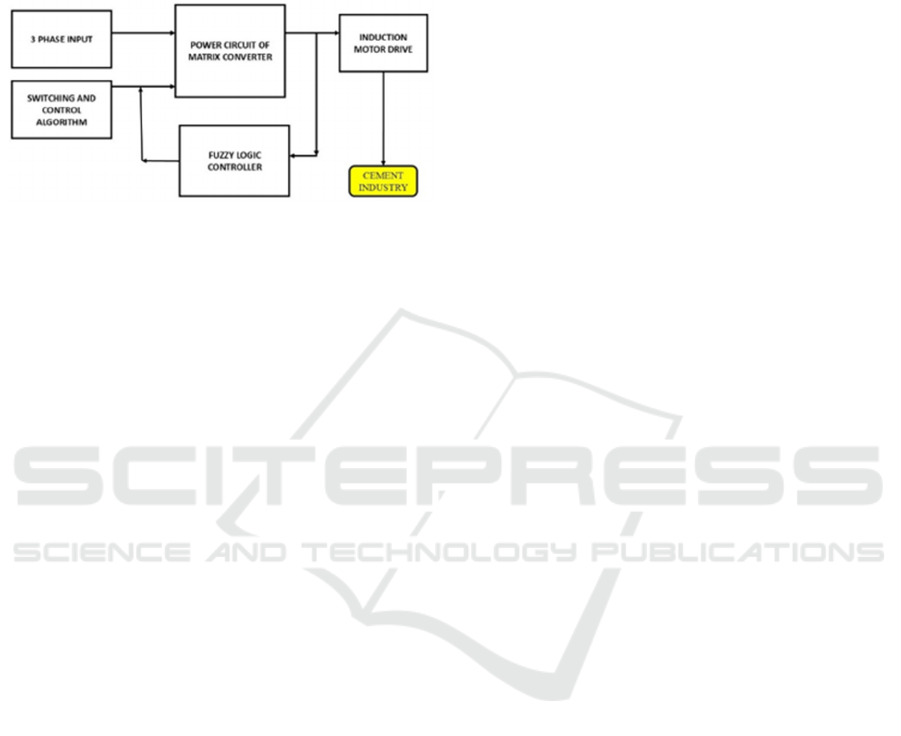

Figure 2: Proposed AI-based Matrix Converter Fed

Induction Motor Drive

The compact and lightweight design of matrix

converters also makes them well-suited for the space-

constrained environments of cement manufacturing

facilities, where efficient space utilization is crucial

for operational productivity. The proposed model of

AI based Matrix Converter Fed Induction Motor

Drive is shown in figure 2.

4.2 Technical Considerations and

Challenges in Implementation

Despite the substantial advantages offered by matrix

converter technology. Its implementation in industrial

drives, particularly in cement industries poses several

technical considerations and challenges. The

complexity of control algorithms and modulation

strategies, essential for achieving optimal

performance and stability, requires meticulous

system design, implementation and maintenance to

ensure seamless integration into the demanding

operational environment of cement manufacturing

facilities.

Moreover, ensuring the reliability and fault

tolerance of matrix converters under various

operating conditions, especially in the face of voltage

fluctuations and transient overload common in

industrial settings, is critical for the sustained

performance of these systems (Javaid et al., 2021)

(Swami & Kumar, 2020).

Additionally, while the long-term energy savings

and operational efficiency achieved through matrix

converter technology justify the initial capital

investment. The cost implications may pose a barrier

to widespread adoption, particularly for smaller-scale

cement producers.

In navigating these challenges, ongoing

advancements in control algorithms, fault tolerance

mechanisms, and cost-effective manufacturing

processes are crucial in addressing the limitations

associated with matrix converter technology, thereby

fostering its broader integration within the cement

industry and unlocking its full potential for driving

sustainable improvements in energy usage and motor

performance.

5 FUZZY LOGIC CONTROL IN

DRIVE SYSTEMS

Fuzzy logic control is a powerful and intuitive control

system that operates on the principles of fuzzy logic,

allowing for the representation of imprecise and non-

linear relationships between inputs and outputs.

Unlike traditional binary logic, where inputs are

either true or false, fuzzy logic allows for degrees of

truth, enabling a more nuanced and flexible control

approach (Vinil Dani & Jobin Christ, 2024).

FLC utilizes linguistic variables and fuzzy rules to

process input data and generate output control

signals, making it particularly well-suited for

complex and uncertain systems such as motor drives

in the cement industry.

Novel fuzzy logic-based controller development

of AI based Matrix converter fed Induction motor

drive model will be developed by using

MATLAB/SIMULINK environment. After that the

effectiveness of purposed fuzzy logic-based

controller will be tested under different operating

conditions (Swami et al., 2022).

Also, ensure the reliable and stable operation of

the cement industries. The application of fuzzy logic

control in motor drives within the cement industry

offers several advantages. FLC be excellent in

handling the non-linear and uncertain load

characteristics of cement manufacturing equipment

(Zhang et al., 2018).

It can adaptively adjust motor speed and torque

based on imprecise or fluctuating process

requirements, thereby enhancing the overall

operational efficiency and performance of the drive

systems.

Additionally, the ability of FLC to handle

imprecise input data, such as varying material

properties in crushers or fluctuations in conveyor

loads, enables precise and responsive control,

contributing to improved equipment reliability and

process stability.

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

144

5.1 Advantages of Fuzzy Logic Control

in Cement Industry Applications

The cement industry can benefit significantly from

the implementation of FLC in drive systems. Fuzzy

logic control enables adaptive and intelligent control

over motor drives, allowing for seamless adaptation

to changing operating conditions and load demands

(Utvic et al., 2023).

This adaptability not only enhances energy

efficiency by optimizing motor operation based on

real-time requirements but also contributes to the

continuity of drive system components by

minimizing stress (Diaz et al., 2020).

The inherent ability of FLC to handle imprecise

and uncertain data empowers drive systems to operate

reliably amidst the challenging environmental

conditions of cement manufacturing, ultimately

supporting sustainable and cost-effective operations.

The advantages of FLC enable cement plants to

achieve greater process stability, energy savings, and

overall operational reliability, aligning with the

industry's goals of efficiency and sustainability.

6 PERFORMANCE EVALUATION

AND CASE STUDIES

6.1 Methods for Evaluating Drive

Performance

Evaluating the performance of drive systems,

particularly those integrated with matrix converter

technology, requires the assessment of various

standard. Key parameters such as energy efficiency,

dynamic response, and torque control precision serve

as fundamental indicators of drive performance.

Energy efficiency can be quantified through

measurements of power losses and energy

consumption, while dynamic response reflects the

drive system's ability to adjust rapidly to load

changes.

Additionally, torque control precision assesses the

accuracy of the motor's response to varying torque

demands, crucial for meeting the operational

requirements of cement manufacturing processes.

Simulation and testing methodologies play an

integral role in evaluating drive performance.

Utilizing advanced simulation software allows for

virtual analysis of system dynamics and control

strategies under diverse operating conditions,

providing insights into energy utilization and system

response.

Complementing simulations with controlled

testing in real-world environments further validates

the performance of matrix converter-fed induction

motor drives, enabling the verification of energy

efficiency improvements and dynamic response

capabilities in actual operational scenarios.

6.2 Comparative Analysis with

Traditional Drive Systems

Conducting a comparative analysis between matrix

converter-fed induction motor drives and traditional

drive systems reveals the significant improvements in

energy efficiency and operational costs achievable

with the former (Swami et al., 2022). By eliminating

the need for intermediate DC-link components and

offering seamless energy transfer, matrix converters

exhibit superior energy efficiency conversion

capabilities, resulting in reduced power losses and

enhanced overall efficiency. This comparative

analysis serves to underscore the economic benefits

and long-term operational cost advantages associated

with the adoption of matrix converter technology in

cement industries.

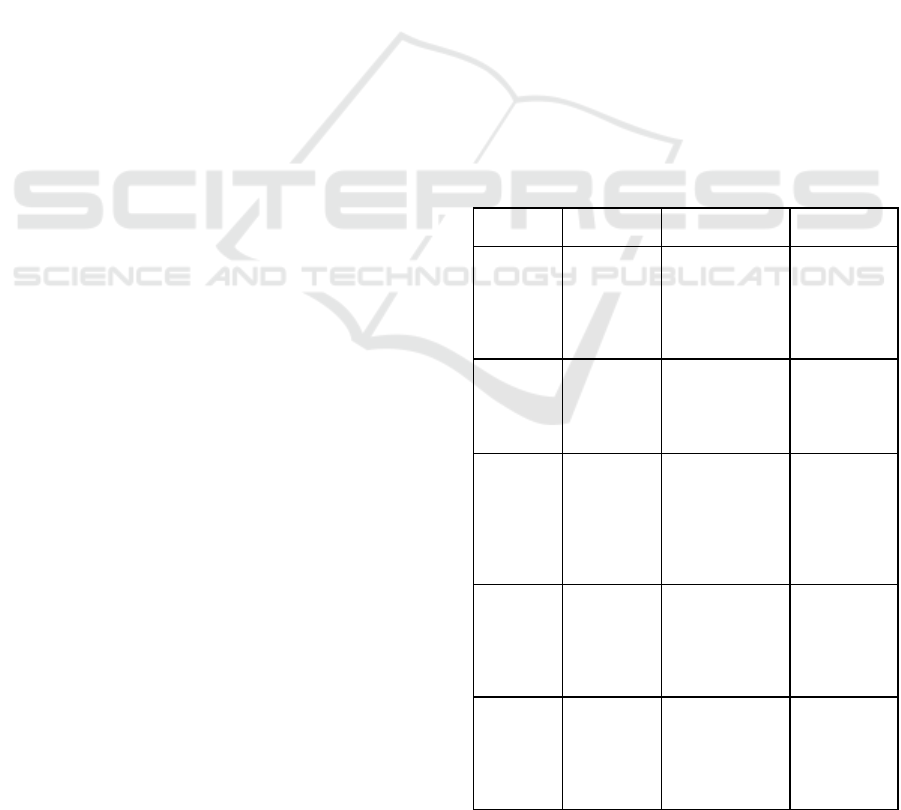

Table 1: Performance comparison of control strategies used

in matrix converter fed induction motor drive

Control

Strategy

Principle Description Advantages

Direct

Torque

Control

(DTC)

(Peng et al.,

2021)

Controls

torque and

flux directly.

Directly controls

motor torque and

flux using

hysteresis

controllers

High dynamic

performance,

no need for

modulation

indexes

Field-

Oriented

Control

(FOC) (Bi

et al., 2021)

Decouples

torque and

flux control.

Decouples torque

and flux control

using coordinate

transformations

Precise

control, good

dynamic

response

Scalar

Control

(V/f

Control)

(Swami &

Kumar,

2020)

Maintains

constant

voltage-to-

frequency

ratio.

Controls motor

speed by

maintaining a

constant voltage-

to-frequency ratio

Simple

implementatio

n, cost-

effective

Fuzzy

Logic

Control

(FLC)(Bajp

ai et al.,

2024)

Uses

heuristic

rules for

control.

Uses fuzzy logic

rules to handle

non-linearities and

uncertainties in the

control system.

Robust to

parameter

variations,

good for non-

linear systems

Model

Predictive

Control

(MPC)(Pen

g et al.,

2021)

Predicts and

optimizes

future control

actions.

Predicts future

behaviour of the

motor to optimize

control inputs

High

performance,

handles

constraints

explicitly

AI Control Based Matrix Converter Fed Induction Motor Drives in Cement Industries

145

Space

Vector

Modulation

(SVM)(Baj

pai et al.,

2024)

Optimizes

switching

sequences.

Uses space vector

theory to generate

optimized PWM

signals for the

matrix converter

High

efficiency, low

harmonic

distortion

Neural

Network

Control

(NNC)(Del

ille et al.,

2012)

Learns and

adapts to

system

dynamics.

Employs neural

networks to learn

and control motor

behaviour

dynamically

Adaptive,

handles

complex non-

linearities

Sliding

Mode

Control

(SMC)(Nah

in et al.,

2023)

Uses a

discontinuou

s control

signal.

Uses a sliding

surface to drive

system states to

desired values

Robust to

disturbances

and parameter

variations

Hybrid

Control

Strategies(

Swami &

Kumar,

2020)

Combines

multiple

control

methods.

Combines two or

more control

strategies to

leverage their

strengths and

mitigate their

weaknesses.

Balances

robustness and

precision.

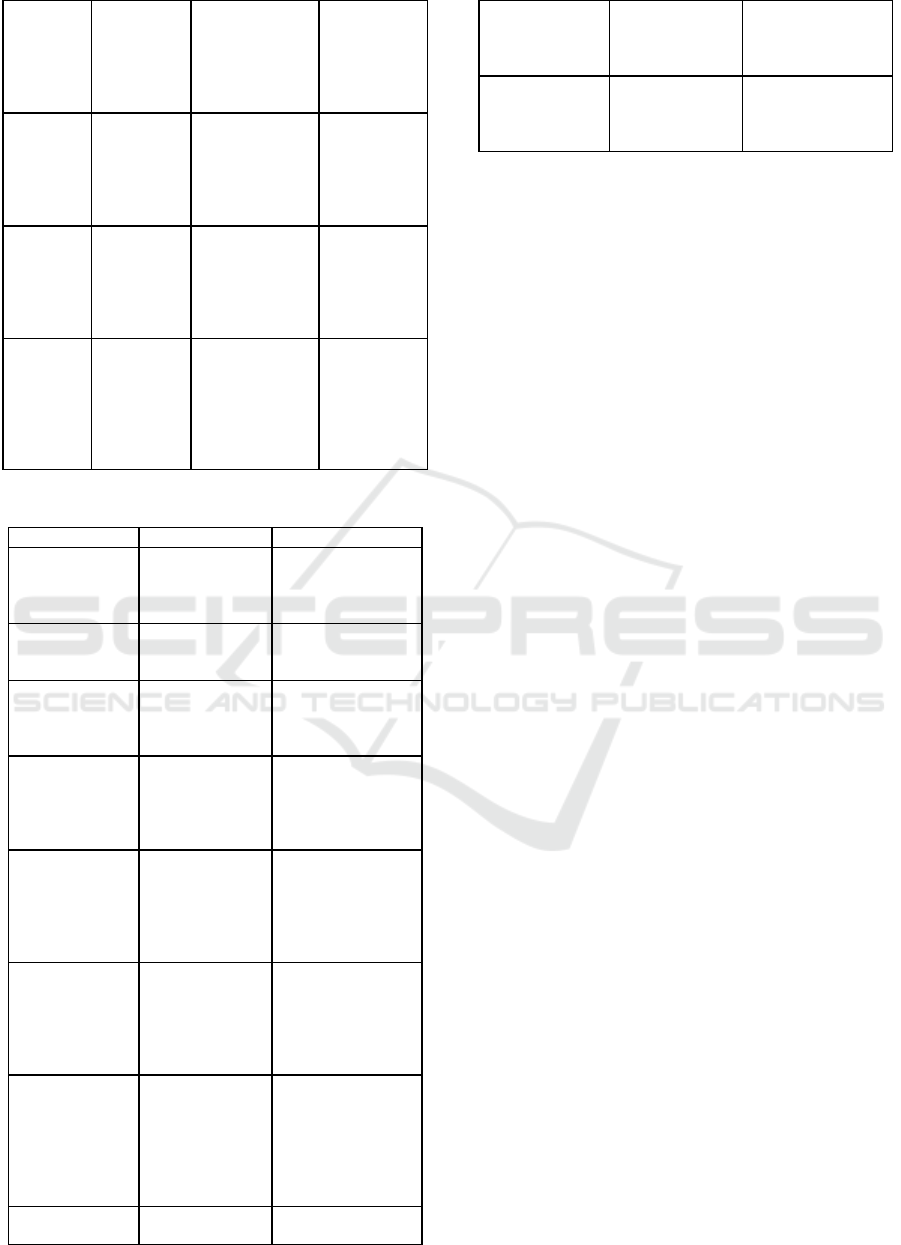

Table 2: Continuation of Table 1

Disadvantages Applications Remark

Torque ripple,

complex

implementation

Industrial drives

needing fast

response

DTC offers very high

dynamic response but

at the cost of higher

torque ripple.

Requires accurate

motor parameters,

complex

High-performance

applications.

FOC offers precise

control, good dynamic

response

Poor dynamic

performance,

limited to steady-

state

Fans, pumps, low-

cost drives.

Easy to implement but

lacks dynamic

performance and

robustness.

Complex design,

computationally

intensive

Systems requiring

robust control.

FLC balances ease of

understanding and

robustness but

requires careful rule

tuning.

High

computational

burden, complex to

design

Advanced systems

requiring precision.

MPC provides top-

notch performance

across the board but

demands high

computational power

and complexity.

Complex

implementation,

requires precise

calculation

High-performance,

low distortion

needs.

SVM offers very low

harmonic distortion

and excellent

performance but

involves complex

implementation.

Requires extensive

training, high

computational

effort

Adaptive control

systems.

NNC is adaptive and

handles complex

dynamics well but

requires extensive

computational

resources and training

data.

Chattering effect,

requires high-

Systems with large

uncertainties.

SMC is highly robust

and performs well

frequency

switching

dynamically, but can

be complex and

potentially introduces

chattering

Complex design

and integration.

Applications

needing versatile

control.

Specific needs but

involve managing the

complexities of

multiple methods.

7.1 Parameter Optimization Using

Fuzzy Logic Control

Fuzzy logic control enables the optimization of

parameters, such as motor speed, torque, and energy

consumption, based on real-time requirements. By

employing FLC, the drive systems can dynamically

adapt to fluctuating conditions, leading to improved

equipment reliability, enhanced energy efficiency,

and minimised stress and wear on the drive system.

7.2 Strategies for Improving Efficiency

and Performance

In addition to FLC, there are various strategies for

improving efficiency and performance in drive

systems. These may include the use of advanced

sensor technologies for accurate data acquisition,

predictive maintenance techniques to predict

potential issues, and the integration of machine

learning algorithms for continuous performance

optimization (Phoon et al., 2022). These strategies

enable the drive systems to operate at peak efficiency,

contributing to overall process stability and cost-

effectiveness.

7.3 Real-Time Adaptation and

Optimization Methods

In addition Real-time adaptation and optimization

methods involve the integration of advanced control

algorithms and predictive analytics to continuously

monitor and adjust the motor drives based on real-

time data. By using real-time data and advanced

optimization algorithms, the drive systems can adapt

to changing conditions, ensuring optimal

performance and energy efficiency (Phoon et al.,

2022). These methods provide the cement industry

with the ability to achieve sustainable and reliable

operations while also supporting the industry's goals

of efficiency and sustainability.

As the cement industry continues to pursue

advancements in optimization techniques, the

integration of real-time adaptation and optimization

methods, in conjunction with FLC, presents an

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

146

approach to drive system optimization, ultimately

driving continual improvements in motor

performance and operational excellence. Various

types of the control strategies used in matrix

converter fed induction motor drive are shown in

Table 1 and Table 2.

8 FUTURE DIRECTIONS AND

EMERGING TRENDS

The future of matrix converter technology holds

significant promise for advancing the energy

efficiency, operational flexibility, and reliability of

drive systems, particularly in the context of cement

industries. As technological advancements continue

to unfold, the potential advances in matrix converter

technology are poised to revolutionize the landscape

of motor drives and power conversion within

industrial settings.

8.1 Potential Advances in Matrix

Converter Technology

The ongoing research and development in matrix

converter technology are expected to lead to

increased power density, enhanced fault tolerance,

and expanded compatibility with various motor types.

Advancements in semiconductor materials and

switching technologies are expected to contribute to

the further miniaturization and increased efficiency of

matrix converter topologies.

The integration of advanced control strategies and

fault-diagnostic algorithms is also anticipated to

enhance the fault tolerance and reliability of matrix

converter-fed induction motor drives in the cement

industry.

Moreover, the exploration of novel modulation

techniques and advanced thermal management

solutions is poised to address the challenges

associated with high-power density and heat

dissipation, thereby paving the way for the

deployment of matrix converters in higher-capacity

drive applications within cement manufacturing

facilities.

These potential advances hold the promise of

optimizing energy utilization, enabling seamless

integration with smart grid systems, and fostering the

evolution of robust and resilient motor drive solutions

tailored to the specific requirements of the cement

industry.

8.2 Potential Advances in Matrix

Converter Technology

In charting the future trajectory of matrix converter-

fed induction motor drives in cement industries, the

prospects for further research and development are

multifaceted and encompass diverse areas of

exploration. With a focus on enhancing grid

compatibility, mitigating harmonic distortion, and

advancing robust control methodologies, research

endeavors are poised to elevate the grid-interfacing

capabilities of matrix converter technology, fostering

harmonious integration with the existing grid

infrastructure and supporting the seamless exchange

of power with minimal electromagnetic interference.

Additionally, the pursuit of enhanced

cybersecurity measures, fault-tolerant design

frameworks, and interoperable communication

standards stands to underpin the development of

secure, resilient, and standardized matrix converter-

driven drive systems.

This proactive approach serves to fortify the

operational integrity and reliability of drive systems,

aligning with the imperatives of safety, continuity,

and adaptability within the dynamic industrial

landscapes of cement manufacturing.

9 CONCLUSIONS

The integration of advanced control strategies, fault-

diagnostic algorithms, and novel modulation

techniques is anticipated to enhance the reliability and

efficiency of matrix converter-fed induction motor

drives, thereby fostering the evolution of robust and

resilient motor drive solutions tailored to the specific

requirements of the cement industry.

The implications of integrating matrix converter

technology with cement industries extend to energy

optimization, smart grid systems integration, and the

establishment of responsive production processes.

Implementing fuzzy logic control can further enhance

the adaptability and robustness of motor drives,

facilitating smooth transition towards smart

manufacturing principles.

Additionally, the adoption of advanced

communication protocols such as Time-Sensitive

Networking and 5G connectivity is recommended to

bolster the interoperability and scalability of matrix

converter-driven drive systems within the broader

ecosystem of smart manufacturing infrastructure.

AI Control Based Matrix Converter Fed Induction Motor Drives in Cement Industries

147

REFERENCES

Abunike, C. E., Okoro, O. I., Far, A. J., & Aphale, S. S.

(2023). Advancements in Flux Switching Machine

Optimization: Applications and Future Prospects. IEEE

Access.

Alammari, R., Aleem, Z., Iqbal, A., & Winberg, S. (2019).

Matrix converters for electric power conversion:

Review of topologies and basic control techniques.

International Transactions on Electrical Energy

Systems, 29(10), e12063.

B, N. P., Nithyashri, V., Sathyanarayana, P. V, Vikkas, R.

B., & Sampathkumar, S. (2022). Smart Induction Motor

Drive using Soft Computing Techniques and Cloud

Platforms. 2022 4th International Conference on

Inventive Research in Computing Applications

(ICIRCA), Icirca, 1482–1488.

https://doi.org/10.1109/ICIRCA54612.2022.9985486

Bajpai, R. S., Srivastava, A., Singh, A., & Kumar, S.

(2024). Intelligent Control of DC Microgrid Involving

Multiple Renewables for Fast Charging Control of

Electric Vehicles. Electric Power Components and

Systems, 1–22.

Barbhuiya, S., Das, B. B., & Adak, D. (2024). Roadmap to

a net-zero carbon cement sector: Strategies, innovations

and policy imperatives. Journal of Environmental

Management, 359, 121052.

Bento, A., Paraíso, G., Costa, P., Zhang, L., Geury, T.,

Pinto, S. F., & Silva, J. F. (2021). On the potential

contributions of matrix converters for the future grid

operation, sustainable transportation and electrical

drives innovation. Applied Sciences, 11(10), 4597.

Bi, G., Zhang, G., Wang, G., Wang, Q., Hu, Y., & Xu, D.

(2021). Adaptive iterative learning control-based rotor

position harmonic error suppression method for

sensorless PMSM drives. IEEE Transactions on

Industrial Electronics, 69(11), 10870–10881.

Chen, L., Zhang, Y., Chen, Z., Dong, Y., Jiang, Y., Hua, J.,

Liu, Y., Osman, A. I., Farghali, M., & Huang, L.

(2024). Biomaterials technology and policies in the

building sector: a review. Environmental Chemistry

Letters, 1–36.

Delille, G., Francois, B., & Malarange, G. (2012). Dynamic

frequency control support by energy storage to reduce

the impact of wind and solar generation on isolated

power system’s inertia. IEEE Transactions on

Sustainable Energy, 3(4), 931–939.

Diaz, M., Cardenas, R., Ibaceta, E., Mora, A., Urrutia, M.,

Espinoza, M., Rojas, F., & Wheeler, P. (2020). An

overview of modelling techniques and control

strategies for modular multilevel matrix converters.

Energies, 13(18), 4678.

Evangeline, S. I., Darwin, S., & Raj, E. F. I. (2024). A deep

residual neural network model for synchronous motor

fault diagnostics. Applied Soft Computing, 111683.

Gerami, N., Ghasemi, A., Lotfi, A., Kaigutha, L. G., &

Marzband, M. (2021). Energy consumption modeling

of production process for industrial factories in a day

ahead scheduling with demand response. Sustainable

Energy, Grids and Networks, 25, 100420.

Gong, C., Li, Y. R., & Zargari, N. R. (2024). An Overview

of Advancements in Multimotor Drives: Structural

Diversity, Advanced Control, Specific Technical

Challenges, and Solutions. Proceedings of the IEEE.

Javaid, M., Haleem, A., Singh, R. P., & Suman, R. (2021).

Substantial capabilities of robotics in enhancing

industry 4.0 implementation. Cognitive Robotics, 1,

58–75.

Kaleybar, H. J., Hafezi, H., Brenna, M., & Faranda, R. S.

(2024). Smart AC-DC Coupled Hybrid Railway

Microgrids Integrated with Renewable Energy Sources:

Current and Next Generation Architectures. Energies,

17(5), 1179.

Khanday, S. A. (2022). Comparative Study of Three Phase

AC / AC In-direct Matrix Converters : A Review. 2022

International Conference for Advancement in

Technology (ICONAT), 1–6.

https://doi.org/10.1109/ICONAT53423.2022.9726119

Kim, J., Sovacool, B. K., Bazilian, M., Griffiths, S., &

Yang, M. (2024). Energy, material, and resource

efficiency for industrial decarbonization: A systematic

review of sociotechnical systems, technological

innovations, and policy options. Energy Research &

Social Science, 112, 103521.

Mahmud, T., & Gao, H. (2024). A Comprehensive Review

on Matrix-Integrated Single-Stage Isolated MF/HF

Converters. Electronics, 13(1), 237.

Mızrak, F. (2023). Analyzing Criteria Affecting Decision-

Making Processes of Human Resource Management in

the Aviation Sector-A Fuzzy Logic Approach. Journal

of Aviation, 7(3), 376–387.

Molina, M. G. (2017). Energy storage and power

electronics technologies: A strong combination to

empower the transformation to the smart grid.

Proceedings of the IEEE, 105(11), 2191–2219.

Nahin, N. I., Biswas, S. P., Mondal, S., Islam, M. R., &

Muyeen, S. M. (2023). A modified PWM strategy with

an improved ANN based MPPT algorithm for solar PV

fed NPC inverter driven induction motor drives. IEEE

Access.

Ninduwezuor-Ehiobu, N., Tula, O. A., Daraojimba, C.,

Ofonagoro, K. A., Ogunjobi, O. A., Gidiagba, J. O.,

Egbokhaebho, B. A., & Banso, A. A. (2023). Exploring

innovative material integration in modern

manufacturing for advancing us competitiveness in

sustainable global economy. Engineering Science &

Technology Journal, 4(3), 140–168.

Omrany, H., Al-Obaidi, K. M., Husain, A., &

Ghaffarianhoseini, A. (2023). Digital twins in the

construction industry: a comprehensive review of

current implementations, enabling technologies, and

future directions. Sustainability, 15(14), 10908.

Peng, X., Liu, Z., & Jiang, D. (2021). A review of

multiphase energy conversion in wind power

generation. Renewable and Sustainable Energy

Reviews, 147, 111172.

Phoon, K.-K., Cao, Z.-J., Ji, J., Leung, Y. F., Najjar, S.,

Shuku, T., Tang, C., Yin, Z.-Y., Ikumasa, Y., & Ching,

J. (2022). Geotechnical uncertainty, modeling, and

ISPES 2024 - International Conference on Intelligent and Sustainable Power and Energy Systems

148

decision making. Soils and Foundations, 62(5),

101189.

Rissman, J., Bataille, C., Masanet, E., Aden, N., Morrow

III, W. R., Zhou, N., Elliott, N., Dell, R., Heeren, N., &

Huckestein, B. (2020). Technologies and policies to

decarbonize global industry: Review and assessment of

mitigation drivers through 2070. Applied Energy, 266,

114848.

Swami, R. K., & Kumar, V. (2020). DTC of Matrix

Converter Fed Induction Machine Based on Fuzzy

Logic. In Recent Advances in Power Electronics and

Drives: Select Proceedings of EPREC 2020 (pp. 517–

524). Springer.

Swami, R. K., Kumar, V., & Joshi, R. R. (2022). FPGA-

based Implementation of Fuzzy Logic DTC for

Induction Motor Drive Fed by Matrix Converter. IETE

Journal of Research, 68(2), 1418–1426.

https://doi.org/10.1080/03772063.2019.1649212

Swami, R. K., Samuel, P., & Gupta, R. (2016). Power

control in grid-connected wind energy system using

diode-clamped multilevel inverter. IETE Journal of

Research, 62(4), 515–524.

Utvic, M., Bontemps, P., & Dujic, D. (2023). Direct Arm

Energy Control of the Modular Multilevel Matrix

Converter. IEEE Access, 11(December 2022), 1793–

1805. https://doi.org/10.1109/ACCESS.2023.3234013

Vaghela, D. J., & Bhesaniya, M. M. (2024). Circulating

current control of MMC-fed induction motor drive

under entire speed range operation. International

Journal of Electronics, 111(9), 1475–1494.

Vinil Dani, W., & Jobin Christ, M. C. (2024). Converters

for induction motors enhancing fault tolerance in

matrix: a hybrid EOO–RERNN approach. Electrical

Engineering, 1–13.

Xie, P., Guerrero, J. M., Tan, S., Bazmohammadi, N.,

Vasquez, J. C., Mehrzadi, M., & Al-Turki, Y. (2021).

Optimization-based power and energy management

system in shipboard microgrid: A review. IEEE

Systems Journal, 16(1), 578–590.

Zhang, J., Li, L., & Dorrell, D. G. (2018). Control and

applications of direct matrix converters: A review.

Chinese Journal of Electrical Engineering, 4(2), 18–27.

AI Control Based Matrix Converter Fed Induction Motor Drives in Cement Industries

149