Orthogonal Test Study on Hybrid Fiber Concrete

Maojun Peng

1a

, Qihang Zhang

2,* b

, Heng Cao

1c

, Xixiao Shi

1d

, Chunlin Deng

2e

and Fang Yu

2f

1

The Fourth Engineering Company of CCCC Fourth Harbor Engineering Co.,Ltd., Chengdu 610000, China

2

CCCC Forth Harbor Engineering Institute Co., Ltd., Key Laboratory of Harbor & Marine Structure Durablity

Technology, Ministry of Transport of PRC, Key Laboratory of Construction Material of CCCC, Guangzhou 510230, China

*

Keywords: Impact and Wear-Resistant Concrete, Orthogonal Experiment, Variance Analysis, Fiber, Mechanical

Property, Value Engineering.

Abstract: In order to improve the performance of hydraulic structure flow surface against high-speed sand-containing

water flow impact and wear, an orthogonal test was designed to study the effects of three fiber dosage levels

of polyvinyl alcohol fiber, polypropylene fiber and steel fiber on the compressive properties, splitting

properties and impact and wear resistance of C35 impact and wear resistant concrete. Based on the concept

of value engineering, the optimal fiber dosage was determined within the test range. The results show that

adding the above three kinds of fibers to concrete will slightly reduce the compressive strength of concrete,

but can significantly improve the splitting strength and impact and wear resistance of concrete. Among them,

the PVA fiber dosage level has a significant effect on the splitting strength of concrete, and the PVA fiber

and PP fiber dosage levels have a significant effect on the impact and wear resistance of concrete.

Considering the performance and cost of concrete comprehensively, the impact and wear resistant concrete

mix ratio of 1kg/m

3

PVA fiber and 1kg/m

3

PP fiber can achieve the best production efficiency.

a

https://orcid.org/0009-0002-8889-0791

b

https://orcid.org/0009-0005-9134-5614

c

https://orcid.org/0009-0009-3457-9739

d

https://orcid.org/0009-0009-3110-4025

e

https://orcid.org/0009-0003-5307-4011

f

https://orcid.org/0009-0009-1906-1974

1 INTRODUCTION

Since the 1970s, scholars have begun to conduct

research on the abrasion resistance of hydraulic

concrete

(Deng and Wang, 2005; Deng et al., 2017).

Some scholars have focused on the construction

quality aspect, believing that strictly controlling the

outlet temperature, placement temperature, and

flatness of the abrasion-resistant concrete, along

with subsequent temperature-reducing maintenance

work, and minimizing the appearance defects of the

concrete, are beneficial to flood discharge and

energy dissipation of hydraulic structures

(Wang et

al., 2013).

In addition, incorporating suitable substances

into the concrete can also effectively enhance its

abrasion resistance (Wu et al., 2019), including fiber

with high tensile properties such as steel fiber and

polypropylene fiber, as well as admixtures such as

silicon powder, abrasion-resistant agents, and HF fly

ash, which can improve the strength or abrasive

resistance of the concrete (Zu, 2010; Toiu Tanji et

al., 1998; Parviz and Siavash, 1998). When studying

the abrasion resistance of concrete, most scholars

adopt the underwater steel ball method specified in

the Test Code for Hydraulic Concrete (DL/T 5150-

2017) . This method can well simulate the abrasion

effect of bed load on the concrete surface. However,

in many engineering research and development

cases, experimental studies are often only conducted

based on the influence of a single material on

concrete performance

(Dong et al., 2022; Huang et

al., 2014). Few scholars have studied the influence

Peng, M., Zhang, Q., Cao, H., Shi, X., Deng, C., Yu and F.

Orthogonal Test Study on Hybr id Fiber Concrete.

DOI: 10.5220/0013632000004671

In Proceedings of the 7th International Conference on Environmental Science and Civil Engineering (ICESCE 2024), pages 241-247

ISBN: 978-989-758-764-1; ISSN: 3051-701X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

241

law of mixing multiple substances on various

concrete properties.

This paper selects steel fiber, polypropylene(PP)

fiber, and polyvinyl alcohol (PVA) fiber as the

research objects. By designing orthogonal tests, it

studies the influence of hybrid fiber on the

performance of abrasion-resistant concrete and

further analyzes the significance between single

substances and concrete strength indicators, aiming

to find a mix proportion scheme that balances

strength performance and economic benefits.

2 PROJECT OVERVIEW

The Fengdongzi Shipping Project on the Qujiang

River is the "last link" in illuminating the

development channel of the Qujiang River. The

project mainly includes the construction of a new

Class III navigation lock with effective dimensions

of 200m×23m×4.2m; a new hydropower station with

an installed capacity of 75 MW; and new water

retaining and discharging structures, including 20

flood discharging and sand flushing gates, non-

overflow dams, and joint dams on the left and right

banks. Among them, the water conveyance corridors

of the navigation lock, the floors of the flood

discharging and sand flushing gates, gate piers,

stilling basins, stilling piers, and power generation

plants all require a 0.5m-thick layer of C35 abrasion-

resistant concrete on the exposed structural surfaces

to resist the damage caused by turbulent high-speed

flows carrying sediment. High-quality abrasion-

resistant layers can ensure the durability of the

structures, extend their normal service life, and

reduce the time and economic costs associated with

subsequent damage inspection, repair, and

reinforcement.

3 OVERVIEW OF TESTING

3.1 Test Materials

3.1.1 Cement

42.5 low-heat Portland cement produced by

Chongqing Xinjianan Building Materials Co., Ltd.

was selected. Quality inspection was conducted on

the Xinjianan cement, and the results of various

performance tests are shown in Table 1. The test

report indicates that the physical and mechanical

parameters of this cement meet the technical

requirements for P·LH 42.5 cement specified

in Low-heat and Medium-heat Portland

Cement (GB/T 200-2017).

3.1.2 Admixture

Class F, LevelII fly ash produced by Guodian

Sheneng Huayingshan Power Generation Co., Ltd.

was selected. Quality inspection was conducted on

the Class II fly ash produced by this company. The

test report indicates that the performance indicators

of this fly ash meet the technical requirements for

Class F II fly ash specified in Fly Ash for Use in

Cement and Concrete (GB/T 1596-2017).

3.1.3 Fine

Aggregate Limestone machine-made sand produced

by Huaxin Cement (Quxian) Co., Ltd. was selected..

The test results indicate that the technical indicators

of the aggregate meet the requirements specified

in Specification for Construction of Hydraulic

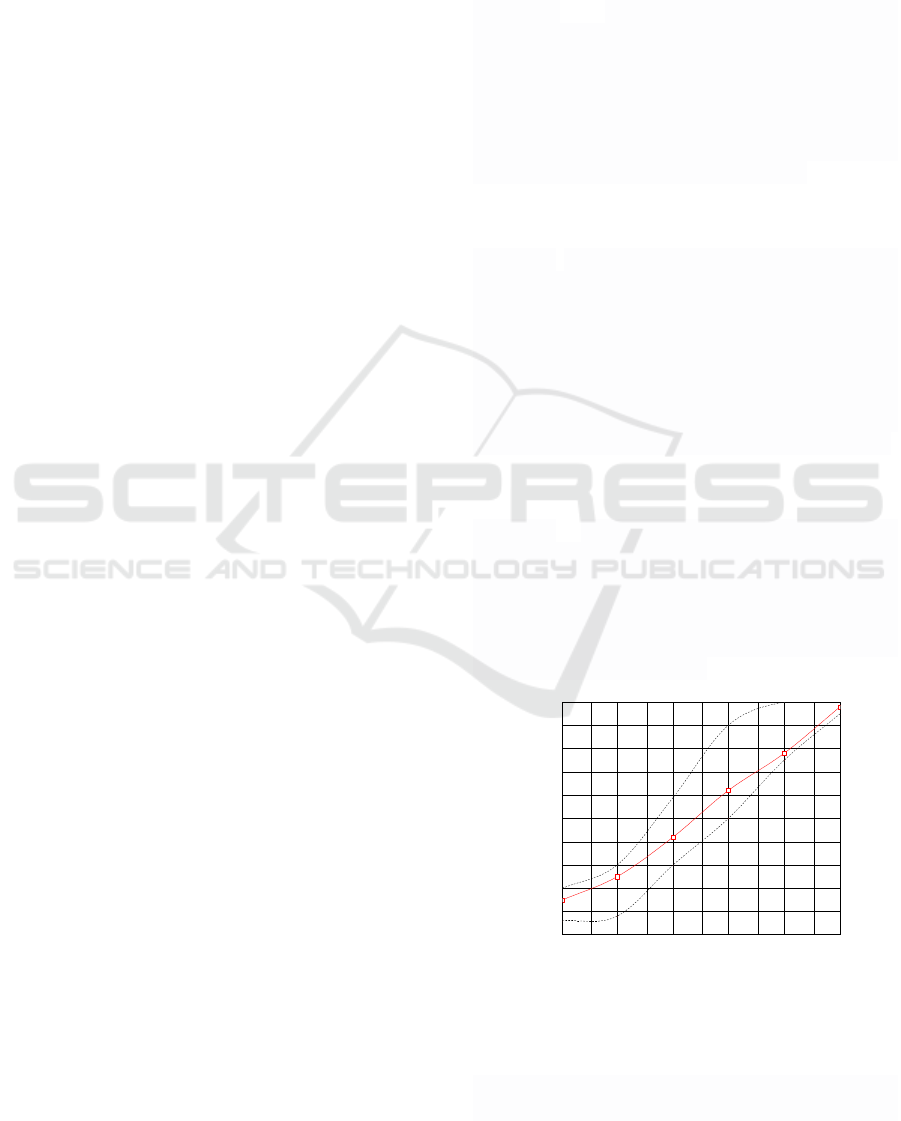

Concrete (DL/T 5144-2015). The gradation meets

the quality requirements for sand in Zone II

specified in Sand for Construction (GB/T 14684-

2022), and the gradation curve is shown in Figure 1.

3.1.4 Coarse

Aggregate Limestone graded crushed stone

(5~20mm:16~31.5mm=6:4) produced by Hengyuan

Mining Co., Ltd. in Dazhu County was selected. The

technical indicators of the aggregate meet the

requirements specified in the Specification for

Concrete Construction of Water Transport

Engineering (JTS 202-2011).

0.16 0.315 0.63 1.25 2.5 5

100

90

80

70

60

50

40

30

20

10

0

Mesh size/mm

The cumulative sieve residue/%

Figure 1: Gradation Curve of Machine-Made Sand.

3.1.5 Fiber

Three types of fiber were selected: PVA fiber, PP

fiber, and steel fiber. Among them, PVA fiber and

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

242

PP fiber are monofilament, while steel fiber is shear-

type. The specific physical properties are shown in

Table 1.

Table 1: Physical Performance Test Results of Fiber.

Fiber variety Length/mm

Fiber diameter

/μm

Tensile

strength/MPa

Elastic

modulus/GPa

Elongation at

b

reak/%

Bending

performance

Execution

standards

PVA fiber 12 10~15 ≥1450 35 4~8 -

GB/T 21120-

2018

Fiber variety 12 20~45 ≥450 3.5 <30 -

GB/T 21120-

2018

PVA fiber 32 0.7±0.2 ≥600 - - ≥3

JG/T

472-2015

3.1.6 Admixtures

Two types of admixtures were selected: impact-

resistant and abrasion-resistant agent, and high-

performance polycarboxylate superplasticizer. The

water-reducing rate of the superplasticizer is 30.8%,

with a pH value of 6.3.

3.2 Design Method for the Experiment

Intuitive analysis and analysis of variance play an

important role in data analysis and statistics. When

there are many independent variables, using this

analysis method can greatly reduce the amount of

experiments. This experiment uses visual analysis as

a prerequisite for variance analysis. Through visual

analysis, the impact of each factor on the indicator

results is preliminarily judged, and further combined

with variance analysis, the significance of the

factor's impact on the results is determined,

providing reference for the values of each factor.

3.3 Concrete Mix Proportion

To systematically analyze the effects of different

fiber types and dosages on the compressive strength,

splitting tensile strength, and abrasion resistance of

impact-resistant concrete, an L9(3

4

) orthogonal

experiment was designed using an orthogonal

experimental design method with a four-factor,

three-level table. The optimal fiber type and dosage

level were determined through visual analysis and

variance analysis. The experimental factors A, B, C,

and D correspond to PVA fiber, PP fiber, steel fiber,

and a control group, respectively. The three levels of

factors A and B correspond to dosages of 0 kg/m

3

,

0.5 kg/m

3

, and 1 kg/m

3

, respectively, while the three

levels of factor C correspond to dosages of 0 kg/m

3

,

5 kg/m

3

, and 10 kg/m

3

. For example, A2B1C3

represents a concrete mixture with 0.5 kg/m

3

of PVA

fiber, 0 kg/m

3

of PP fiber, and 10 kg/m

3

of steel fiber.

The specific mix proportions and mixture properties

are shown in Table 2.

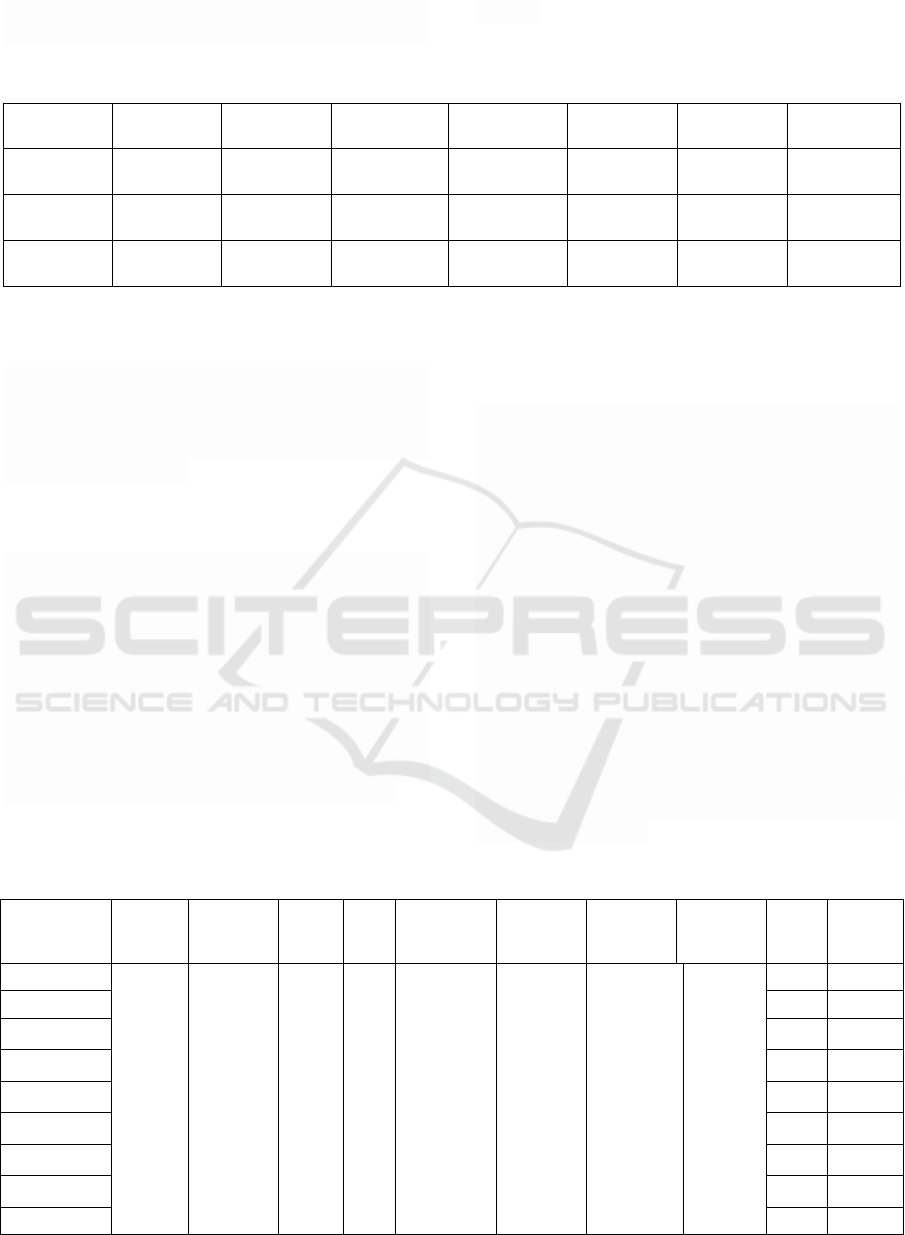

Table 2: Mix Proportion and Mix Performance of Concrete L9 (34) Orthogonal Test.

Type of fiber

Cement/kg/

m

3

Fly ash/

kg/m

3

Water

cement

sand

ratio

/%

Fine aggregate

/kg/m

3

Coarse

aggregate

/kg/m

3

Water

reducing

agent/kg/m

3

Anti impact

agent

/kg/m

3

Slump

/mm

air content

/%

A1B1C1D1

340

60

0.40

40

732

1099

4.8

12

165 3.1

A1B2C2D2 145 3.3

A1B3C3D3 135 3.4

A2B1C3D2 140 3.3

A2B2C3D1 135 3.3

A2B3C1D2 130 3.4

A3B1C3D2 135 3.4

A3B2C1D3 130 3.4

A3B3C2D1 120 3.5

Orthogonal Test Study on Hybrid Fiber Concrete

243

The results showed that adding fiber would

reduce the slump of the mixture, while the air

content showed an increasing trend. This is because

fiber have a thickening effect and cannot be mixed

evenly in concrete mixtures, especially fine PP fiber

and PVA fiber, which tend to aggregate into clumps.

Therefore, the fluidity of concrete will decrease, and

fiber may be wrapped in air during the mixing

process. As the fluidity of concrete decreases,

internal air becomes more difficult to discharge,

leading to an increase in the air content of concrete.

4 TEST RESULTS AND ANALYSIS

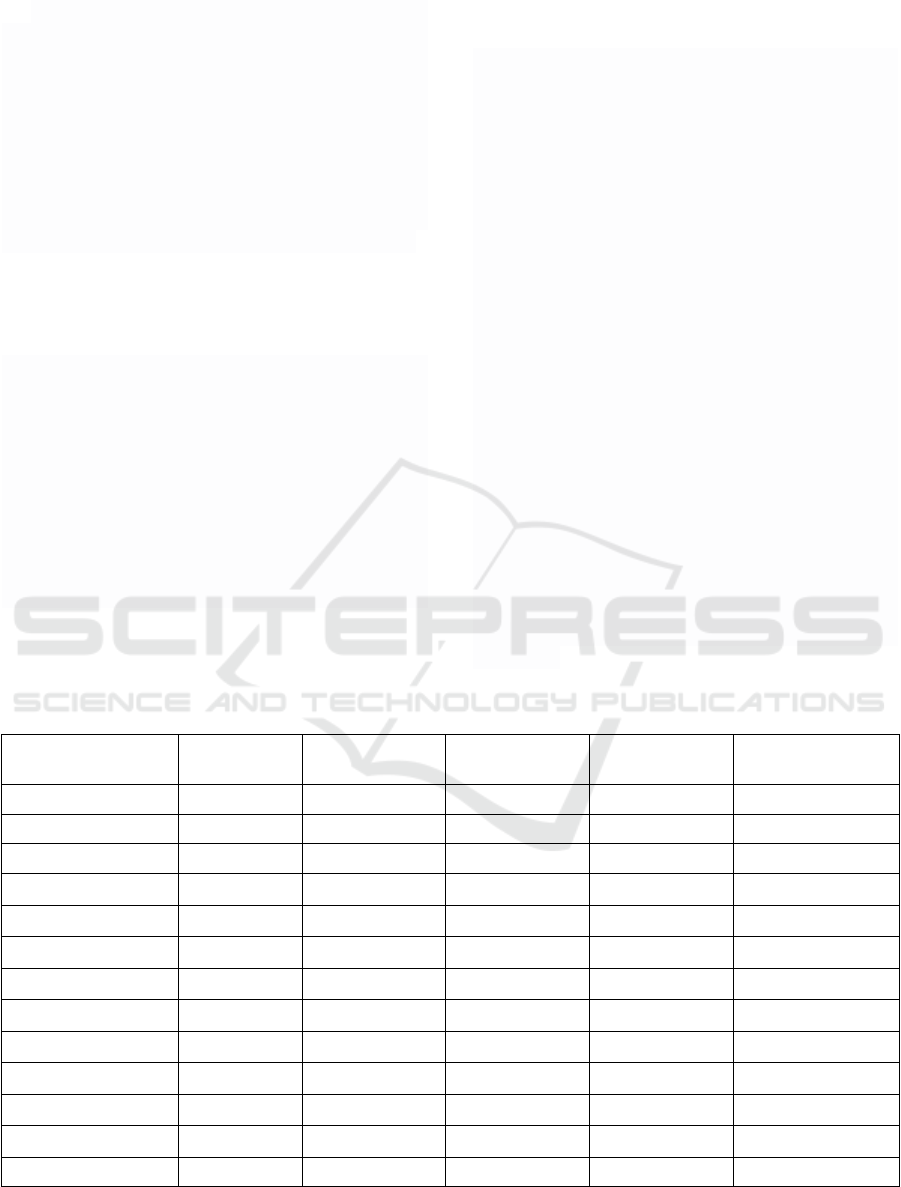

The compressive strength test and splitting tensile

strength test were conducted according to the

"Standard for Test Methods of Physical and

Mechanical Properties of Concrete" (GB/T 50081-

2019); the abrasion resistance test was carried out

using the underwater steel ball method specified in

the "Specification for Testing of Hydraulic

Concrete" (DL/T 5150-2017). The results of the 28-

day compressive strength, 28-day splitting tensile

strength, and abrasion resistance of the concrete

specimens are shown in Figure 2 (where 28d CS is

compressive strength on the 28 day , 28d STS is

splitting tensile strength on the 28 day, IARS is impact

and abrasion resistance strength on the 28 day).

4.1 Compressive Strength

As seen in Figure 2, the addition of hybrid fiber may

reduce the compressive strength of concrete, but the

splitting tensile strength and abrasion resistance can

be enhanced to a certain degree. To refine the impact

of PVA fiber, PP fiber, and steel fiber on various

performance indicator. From Table 3, it can be seen

that, a visual analysis of the compressive strength

results shows that the level corresponding to the

maximum values of k1, k2, and k3 is A1B1C3. The

range term R indicates: A > B > D (error) > C,

suggesting that steel fiber have a minimal impact on

the compressive strength of concrete. The

compressive strength of fiber-reinforced abrasion-

resistant concrete is primarily determined by the

dosage levels of PVA fiber and PP fiber. Higher

dosages of these two types of fiber result in lower

compressive strength. This is because filamentous

materials such as PVA and PP fiber cannot provide

compressive capacity to concrete themselves. fiber

distributed chaotically in the slurry can reduce the

integrity of the specimens, and their external

contours can become weak interfaces when the

specimens are subjected to significant compressive

loads, leading to damage first. Since the independent

variables and dependent variables in this test are

negatively correlated, further variance analysis is not

conducted.

Table 3: Visual Analysis of Orthogonal Test Results for Compressive Strength.

Type of fiber/

Type of

k

A B C D

Compressive

strength/MPa

A1B1C1D1 1

a

11145.2

A1B2C2D2 1 2 2 2 44.2

A1B3C3D3 1 3 3 3 43.1

A2B1C3D2 2 1 2 3 43.7

A2B2C3D1 2 2 3 1 43.4

A2B3C1D2 2 3 1 2 41.2

A3B1C3D2 3 1 3 2 42.4

A3B2C1D3 3 2 1 3 41.3

A3B3C2D1 3 3 2 1 40.9

k1

a

44.2 43.8 42.6 43.2 -

k2 42.8 43.0 42.9 42.6 -

k3 41.5 41.7 43.0 42.7 -

R 2.6 2.0 0.4 0.6 -

a

The number 1, 2, and 3 in the table represent dosage levels, and the rest number represent strengths in MPa.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

244

0

10

20

30

40

50

28d

CS

28d

STS

28d

IARS

2.5

I

mpact and abrasion resistance strength/h/(kg/m

2

Intensity value/MPa

A1B1C1D1

A1B2C2D2

A1B3C3D3

A2B1C3D2

A2B2C3D1

A2B3C1D2

A3B1C3D2

A3B2C1D3

A3B3C2D1

Figure 2: Concrete Strength Properties.

4.2 Splitting Tensile Strength

The results are presented in Table 4. The levels

corresponding to the maximum values of k1, k2, and

k3 are A3B3C3. The range term R indicates that the

primary factors influencing the splitting tensile

strength of concrete are PVA fibers, steel fibers, and

PP fibers, in the order of A > C > B > D (error). In

the experiment, the range of the error series

objectively exists. To accurately determine whether

there is a significant correlation between various

factors and the splitting tensile strength of concrete,

it is necessary to further conduct variance analysis

based on the results of this intuitive analysis. This

will clarify the relationship between the treatment

effect and the random error. If the treatment effect

dominates, then the level of that treatment effect

should be adopted.

The variance analysis of the splitting tensile

strength data is shown in Table 5. it is found that the

sum of squares of deviations for factors A, B, and C

is greater than the error term D, so the error term

does not need to be combined. In this F-distribution,

the P-value for factor A is less than 0.05, while the

P-values for factors B and C are both greater than

0.05, indicating that factor A has a significant

correlation with the splitting tensile strength of

concrete, while factors B and C are relatively

insensitive. This phenomenon can be explained by

the advantages of PVA fiber over steel fiber in terms

of quantity and specific surface area when

comparing the same mass. Literature records show

that uniformly distributing 0.9 kg/m³ of

monofilament fiber in concrete results in over 20

fiber per cm³ of concrete (Xiang et al., 2010). These

fiber can bond fully with the concrete slurry,

forming a uniform and chaotic support system that

effectively helps concrete resist external tensile

stresses.

Table 4: Visual Analysis of Orthogonal Test for Splitting Tensile Strength.

Type of fiber/

Type of k

A B C D

Splitting Tensile

strength/MPa

A1B1C1D1

1 1 1 1 2.43

A1B2C2D2

1 2 2 2 2.62

A1B3C3D3

1 3 3 3 2.74

A2B1C3D2

2 1 2 3 2.69

A2B2C3D1

2 2 3 1 2.76

A2B3C1D2

2 3 1 2 2.66

A3B1C3D2

3 1 3 2 2.79

A3B2C1D3

3 2 1 3 2.73

A3B3C2D1

3 3 2 1 2.85

k1

2.60 2.64 2.61 2.68 -

k2

2.70 2.70 2.72 2.69 -

k3

2.79

2.75

2.76

2.72 -

R

0.19 0.11 0.16 0.04 -

Orthogonal Test Study on Hybrid Fiber Concrete

245

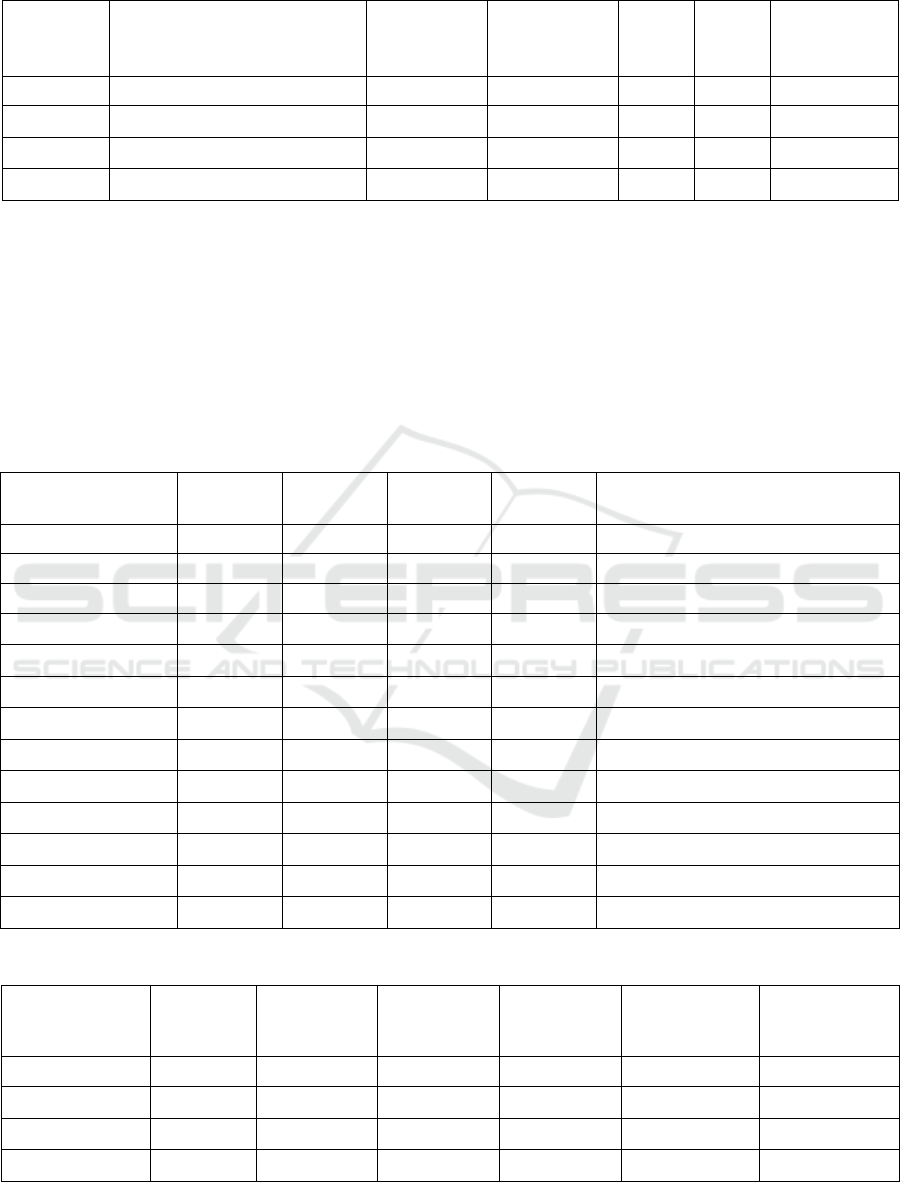

Table 5: Variance Analysis of Orthogonal Test for Splitting Tensile Strength (α=0.05).

Variance

source

Sum of squared deviations Free degree Mean square F value P value Significance

A 0.056 2 0.028 21.641 0.044

√

B 0.019 2 0.010 7.45 0.118 ×

C 0.039 2 0.020 15.10 0.062 ×

D 0.003 2 0.001

- - -

4.3 Impact and Abrasion Resistance

Strength

A visual analysis was conducted on the results of the

abrasion resistance and impact strength, and the

findings are presented in Table 6. The levels

corresponding to the maximum values of k1, k2, and

k3 are A3B3C3. The range R indicates: A > B > C >

D (blank error). The primary factors influencing the

splitting tensile strength of concrete are PVA fibers,

PP fibers, and steel fibers, respectively. The ranges

of these factor columns are all greater than the error

term D. The results are shown in Table 7.

Table 6: Visual Analysis of Orthogonal Test for Impact and Wear Resistance Strength.

Type of fiber/

Type of k

A B C D

Impact and Abrasion Resistance

Strength/(h/(kg/m

2

))

A1B1C1D1

1 1 1 1 12.20

A1B2C2D2

1 2 2 2 13.09

A1B3C3D3

1 3 3 3 13.50

A2B1C3D2

2 1 2 3 13.66

A2B2C3D1

2 2 3 1 14.07

A2B3C1D2

2 3 1 2 13.83

A3B1C3D2

3 1 3 2 14.07

A3B2C1D3

3 2 1 3 14.23

A3B3C2D1

3 3 2 1 14.72

k1

12.93 13.31 13.42 13.66 -

k2

13.85 13.80 13.83 13.66 -

k3

14.34

14.02

13.88

13.80 -

R

1.41 0.70 0.46 0.14 -

Table 7: Variance Analysis of Orthogonal Test for Impact and Wear Resistance Strength (α=0.05).

Variance

source

Sum of

squared

deviations

Free degree Mean square F value P value Significance

A 3.075 2 1.538 83.6800 0.012

√

B 0.782 2 0.391 21.2800 0.045 √

C 0.381 2 0.190 10.3600 0.088 ×

D 0.037 2 0.018 - - -

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

246

The P-values for factors A and B are less than

0.05, indicating a significant correlation with the

abrasion resistance and impact strength of concrete,

while factor C shows insensitivity. Randomly

distributed fibers can serve as bridging elements

within the concrete matrix, aiding in effectively

bearing and dispersing the abrasive energy from

high-speed bedload, thereby hindering the

propagation of abrasive cracks. Even when part of

the matrix experiences minor damage, the fibers can

restrain the fragments and reduce the deterioration

rate. Therefore, consider reducing the level of factor

C based on the A3B3C3 mix ratio.

The market prices of polyvinyl alcohol (PVA)

fibers, polypropylene (PP) fibers, and steel fibers are

approximately 12 yuan/kg, 7 yuan/kg, and 4 yuan/kg,

respectively. Further tests on the relevant properties

of A3B1C1 and A3B3C1 were conducted: their

abrasion resistance and impact strengths are 13.78

h/(kg/m²) and 14.42 h/(kg/m²), respectively, and

their splitting tensile strengths are 2.71 MPa and

2.77 MPa, respectively. Based on the value

engineering concept, V = F/C (where V is value, F is

function, and C is cost), when replacing A3B3C2

with A3B1C1 and A3B3C1, the abrasion resistance

and impact functions of the materials decrease by

approximately 6.4% and 2.0%, respectively, while

the costs decrease by approximately 9.4% and 8.0%.

This results in an increase in engineering value by

approximately 2.2% and 6.5%, respectively. The

splitting tensile strength of the materials decrease by

approximately 4.9% and 2.8%, respectively, leading

to an increase in engineering value by approximately

5.0% and 5.7%, respectively. Therefore, consider

eliminating steel fibers while retaining a PP fiber

dosage of 1.0 kg/m³ and incorporating 1.0 kg/m³ of

PVA fibers.

5 CONCLUSION

Through the above experimental analysis and

demonstration, the following conclusions can be

drawn:

(1) Fiber have a thickening effect and are easily

aggregated into clusters when added to concrete

mixtures, reducing the fluidity of the mixture. fiber

are prone to carry air into the mixture during the

mixing process, increasing the air content of the

mixture.

(2) Weak filamentous substances such as PVA

fiber and PP fiber cannot provide compressive

strength for the interior of concrete, and are prone to

forming weak interfaces during the compression

process, which deteriorates the compressive

performance of concrete. PVA fiber, PP fiber, and

steel fiber can effectively enhance the splitting

tensile strength and impact and wear resistance of

concrete.There is a significant correlation between

the PVA fiber content level and the impact and wear

resistance, as well as the splitting tensile

performance, with the most obvious gain effect.

(3) Adding 1kg/m

3

PVA fiber and 1kg/m

3

PP

fiber to the C35 impact resistant and wear-resistant

concrete results in relatively high functional and

economic advantages, making it a preferred mix

ratio.

REFERENCES

Deng, W. D., Wang, Y. M. 2005. Resistances of impact

and abrasion for polypropylene fiber concrete.

Concrete, 2005(01): 43-45.

Deng, Z. Z., Yang, H. Q., Xiao, K. T. 2017. Performance

test of abrasion-resistant concrete with fiber. Concrete,

2017(04): 8-10+14.

Wang, F., Zhao, X. P., Chen, W. M. 2013 Construction

technology of anti impact and wear-resistant concrete

for spillway tunnel of Xiluodu Hydropower Station.

Water Resources and Hydropower Engineering,

44(04): 29-32.

Wu, X. F., Li, J. M., Song, W. J. 2019. Research on

impact wear resistance of fiber concrete. China Water

Power & Electrification, 2019(11): 47-51+25+26.

Zu, F. X. 2010. Study on the Property and Its Application

of Resisting Impact Abrasion Concrete of Shiplock.

Master' s Thesis. Chengdu: Southwest Jiaotong

University. p43.

Toiu Tanji, H., Mcneil, S., Bayasiz. 1998. Chloride

permeability and impact resistance of polypropylence-

fiber-silica fume concrete. Cement and Concrete

Research, 28(7): 961-968.

Parviz, S., Siavash, R. 1998. Control of plastic shrinkage

caracking with specialty cellulose fibers. ACI

Materials, 1998(7): 429-435.

Dong, Z. C., Li, S. X., Meng, Y. Y. 2022. Experimental

Study on the Anti-Abrasion Performance of Ultra-

High Performance Conerete. YELLOW RIVER, 44(01):

129-133.

Huang, W. B., Hu, X., Xu, F. 2014. Research progress of

protection technologies for scour-abrasion resistance

of hydraulic concrete. Water Resources and

Hydropower Engineering, 45(02): 61-63+67.

Xiang, C. Q., Ni, K. L., Wang, K. 2010. Experimental

Study on Erosion and Abrasion Resistant

Polypropylene Fiber Concrete. Sichuan Water Power,

29(04): 91-93+172.

Orthogonal Test Study on Hybrid Fiber Concrete

247