Explore the Application of Waste Gypsum in Intelligent Construction

Yang Wen

1a

, Zixin Ai

2,* b

and Yaoyu Wang

1c

1

Key Laboratory for Prediction & Control on Complicated Structure System of the Education Department of Liaoning

Province, Dalian University, Dalian 116622, China

2

School of Transportation Engineering, Dalian Jiaotong University, Dalian 116622, China

*

Keywords: Phosphogypsum, 3D Printing, Mechanical Properties, Resource Utilization.

Abstract: This study explores the potential application of waste gypsum, particularly phosphogypsum (PG) in the field

of intelligent construction. Through calcination pretreatment and 3D printing technology,the physical and

chemical properties of phosphogypsum and their impact on 3D printing performance were investigated.

Initially,the chemical composition and microstructure of the raw phosphogypsum were analyzed using X-ray

fluorescence spectrometer (XRF), X-ray diffractometer (XRD), and scanning electron microscope (SEM).

Subsequently, the effect of different calcination temperatures on the dehydration reaction and phase

composition of phosphogypsum was studied through calcination treatment. Then, using 3D printing

technology, the influence of different water-to-cement ratios (w/c) on the printability and mechanical

properties of phosphogypsum paste was explored.The results indicated that the dehydration reaction of

phosphogypsum was most significant at a calcination temperature of 175℃, and the 3D printing effect of

phosphogypsum paste was optimal at w/c = 0.67,with the printed components being continuous, uniform,and

smooth without defects. Additionally, calcined phosphogypsum exhibited the highest mechanical

performance at w/c = 0.70. This study provides new ideas for the resource utilization of waste gypsum and is

of great significance for promoting the development of intelligent construction technology.

1 INTRODUCTION

Phosphogypsum is a solid waste generated by

phosphochemical enterprises in the production of

phosphoric acid fertilizers (Tayibi et al., 2009).

Statistics show that for every 1 ton of phosphoric acid

produced globally, 4.5 to 5.5 tons of phosphogypsum

is generated (Shakor et al., 2020). The composition of

phosphogypsum is similar to that of natural gypsum,

with CaSO

4

·2H

2

O accounting for more than 90%

(Sun et al., 2023). Its chemical composition is

influenced by the composition of phosphate ore and

production processes, often containing fluorides,

water-soluble phosphates,heavy metals, and other

harmful substances,and it has a strong acidity (Wu et

al., 2022). It may also contain radioactive elements

such as radium and thorium (Xiao et al., 2021). It is

a

https://orcid.org/0009-0003-9136-9208

b

https://orcid.org/0009-0009-6501-8950

c

https://orcid.org/0000-0002-9556-6765

hygroscopic and can react with water to form acidic

solutions (Yuvaraj et al., 2021). The long-term

stacking of phosphogypsum not only occupies a large

amount of land resources but also poses a serious

threat to regional ecological safety (Zhang et al.,

2021). These issues exert great pressure on the long-

term development of China's phosphochemical

industry (Zhang et al., 2019). Therefore, it is

necessary to promote the comprehensive utilization

of phosphogypsum and improve the level of resource

utilization technology (Zhang et al., 2020).

Provinces(cities) are actively promoting the resource

utilization of phosphogypsum (Zhao et al., 2020;

Zhou et al., 2023; Rashad, 2017), based on

which,various new types of building materials are

continuously innovated and transformed, striving to

achieve sustainable development.

Wen, Y., Ai, Z., Wang and Y.

Explore the Application of Waste Gypsum in Intelligent Construction.

DOI: 10.5220/0013627900004671

In Proceedings of the 7th International Conference on Environmental Science and Civil Engineering (ICESCE 2024), pages 213-219

ISBN: 978-989-758-764-1; ISSN: 3051-701X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

213

At the same time,with the rapid development of

urbanization and intelligent industries worldwide, 3D

printing technology has become a global research and

application hotspot. 3D printing concrete technology

has characteristics such as low construction costs,

free structural design, high molding precision, low

construction noise, and less dust pollution, playing an

irreplaceable role in the transformation and upgrading

of China's construction industry.

In this study, we systematically investigated the

impact of different calcination temperatures on the

dehydration reaction,phase transformation, and

mechanical properties of phosphogypsum, and

further explored the influence of w/c on the

morphology,structure, and strength of

phosphogypsum hydration products.In addition,this

paper also assessed the feasibility of 3D printing of

phosphogypsum, providing new ideas for the

application of phosphogypsum in the construction

field. Through this study,we aim to provide a

scientific basis for the high-value utilization of

phosphogypsum, promote the transformation of

phosphogypsum from waste to resources, and

contribute to environmental protection and

sustainable development.

2 METHOD

2.1 Raw Materials

Phosphogypsum, a byproduct generated during

phosphoric acid production, served as the primary

material in this investigation. Predominantly

comprised of CaSO

4

·2H

2

O, PG also contains

impurities like phosphorus oxide and silica. The

chemical composition of the initial PG sample was

assessed using a Rigaku ZSX Primus IV XRF

spectrometer, with the findings detailed in Table 1.

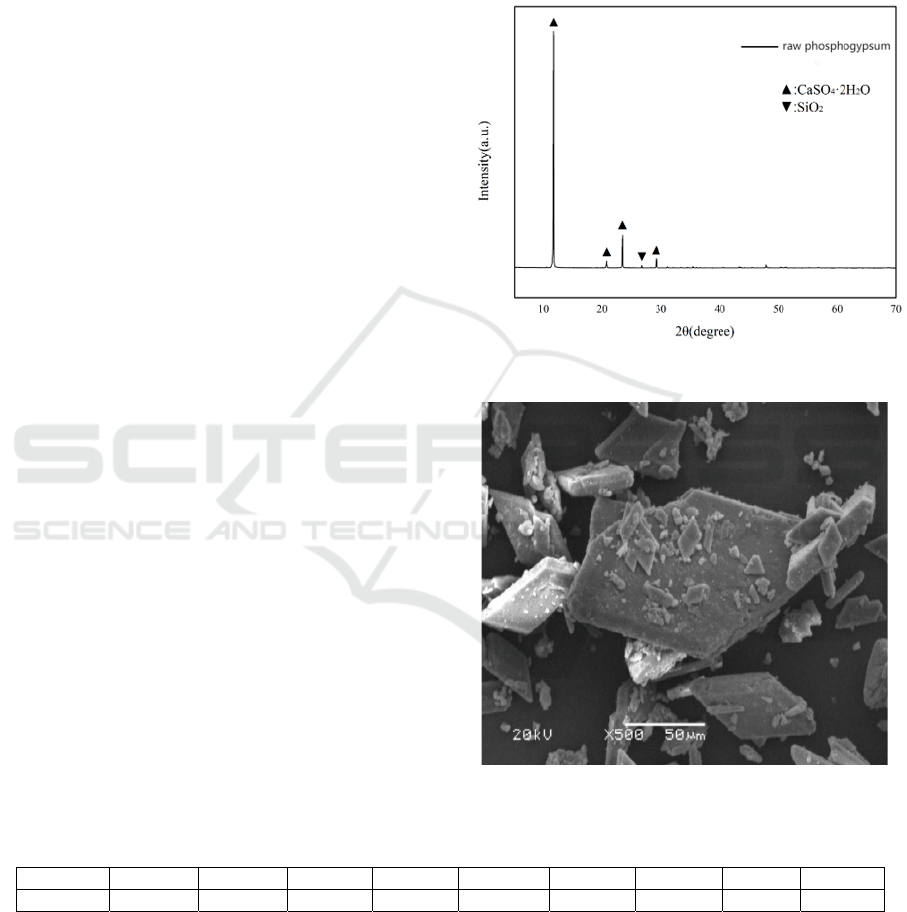

Qualitative analysis of the phase composition of the

original PG was conducted using XRD. Notably,

distinct peaks were observed in the X-ray diffraction

pattern within the 10°-30° 2θ range, as depicted in

Figure 1. The morphology of the initial

phosphogypsum was examined through SEM. The

crystal structure of phosphogypsum primarily

exhibited rhombus or parallelogram plate shapes,

with fine granular and flocculent impurities adhering

to the surface, as illustrated in Figure 2.

Figure 1: XRD of Phosphogypsum.

Figure 2: SEM of Phosphogypsum.

Table 1: Chemical composition of gypsum.

Sam

p

le SO

3

CaO SiO

2

P

2

O

5

Al

2

O

3

K

2

OM

g

O F Cl

PG/% 43.40 33.28 6.4 0.71 1.04 0.29 0.16 0.33 0.035

2.2 Method

This study investigates a low-energy pretreatment

approach to efficiently eliminate impurities and alter

the composition of phosphogypsum to increase its

utility. Calcination is chosen as the pretreatment

technique, employing an SX2-4-10A muffle furnace.

The calcination process involves controlling the

temperature to dehydrate the dihydrate gypsum in

phosphogypsum, converting it into hemihydrate

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

214

gypsum and anhydrous gypsum. Specifically,

calcination temperatures of 150°C, 175°C, 200°C,

225°C, and 250°C are utilized.

In this experiment, a small gantry integrated

concrete rapid-setting 3D printing equipment with

mixing and extruding functions as shown in the figure

was used. The pipeline of this equipment is not for

conveying mixed slurry,but separates the dry material

and liquid material conveying routes to achieve

dedicated pipe usage, and eliminates the pumping

device found in conventional 3D printing equipment.

Unlike conventional mixing methods, dry materials

and water can come into contact and mix rapidly in

the air within the printing system,allowing materials

such as phosphogypsum powder to undergo hydration

reactions quickly. The work of material

mixing,stirring, and extruding molding is all

completed within the printing system.This ensures

that the material can enter the wet extrusion from dry

powder,thereby breaking through the problem that

cement-based materials cannot be pumped and

extruded due to short setting times. In this

experiment, the water temperature was controlled

between 15°C and 20°C, and different w/c were

set,such as 1:1, 1.5:1, 2:1, 4:1, etc. The 3D printer was

used to strictly follow the standard ratios.

A TG test was conducted using a TGA/DSC 1

thermal analyzer from the STARe system by

METTER TOLEDO Group to measure the mass

change of samples with temperature under

programmed temperature control. The phase

composition of PG was determined using XRD.

Hydration kinetics of PG were investigated using a

TAM air C80 isothermal calorimeter at a constant

temperature of 25℃ and a water/cement ratio of 4.

Compressive and flexural strengths of PG were

assessed using a DYE-300S computerized constant

stress testing machine from Wuxi Huaxi Building

Materials Testing Instrument Co., Ltd., with sample

dimensions of 20mm × 20mm × 20mm and 40mm ×

40mm × 160mm, respectively. The microstructure of

the samples was analyzed using a Zeiss SUPRA 55

field emission SEM. Printability of PG was evaluated

with an architectural 3D printer, where the water-

cement ratio of printed components was adjusted by

controlling water output while maintaining a

consistent discharge speed.

3 RESULT

3.1 Thermal Analysis Characterization

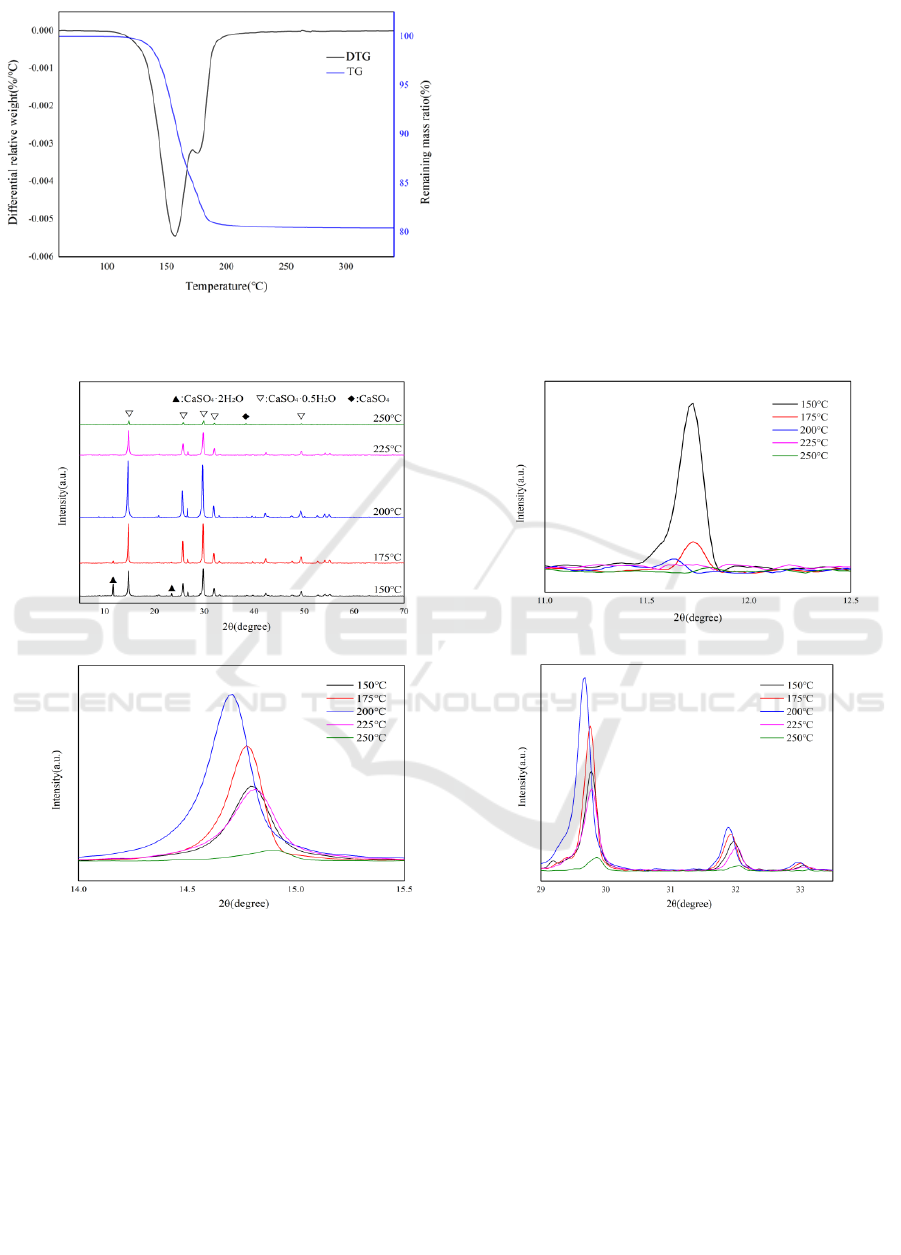

Figure 3 illustrates the thermogravimetric analysis of

PG. The dehydration process of PG initiates at

approximately 100°C, with a gradual release of water

until around 300°C, marking the completion of

dehydration, resulting in a weight loss of

approximately 19.5%. The derivative

thermogravimetric (DTG) curve displays two distinct

dehydration peaks. The first peak, occurring between

100°C and 166°C with a peak at 157°C, corresponds

to an initial mass loss of 14.7%. The second peak,

observed between 157°C and 300°C with a peak at

175°C, corresponds to an initial mass loss of 4.8%.

The transformation of CaSO

4

·2H

2

O to

CaSO

4

·1/2H

2

O involves the removal of 1.5H

2

O in the

first stage, followed by the conversion of CaSO

4

to

CaSO

4

·1/2H

2

O by eliminating the remaining 1/2H

2

O

in the second stage.

3.2 XRD

Figure 4(a) shows the XRD patterns of the PG sample

at different calcination temperatures ranging from

150°C to 250°C. When 2θ is 11.7°, 14.8° and 38.3°,

respectively, the diffraction peak falls on the peak

with the largest difference between CaSO

4

·2H

2

O and

CaSO

4

·1/2H

2

O and CaSO

4

. As can be seen from

Figure 4(b), (c) and (d), when 2θ is 11.7°C, the

diffraction peak decreases gradually with the increase

of calcination temperature, and the diffraction peak

disappears when the calcination temperature reaches

175°C. It can be concluded that CaSO

4

·2H

2

O is

gradually depleted after the calcination temperature

of the sample reaches 175°C, and the sample is

mainly composed of CaSO

4

·1/2H

2

O. In addition,

when 2θ is 14.8° and 29.7°, the diffraction peak of PG

increases first and then decreases with the increase of

calcination temperature, and reaches the maximum

value when the calcination temperature is 200°C,

which may be due to the fact that the CaSO

4

·1/2H

2

O

content of the sample first increases and then

decreases, and the CaSO

4

·1/2H

2

O content reaches the

maximum value at 200°C, and then the content

gradually decreases, and with the increase of

temperature, the content of CaSO

4

gradually

increases, when the calcination temperature is 250°C,

The diffraction peak appears at 2θ=38.3°, and the

sample is a mixture of CaSO

4

·1/2H

2

O and CaSO

4

.

Explore the Application of Waste Gypsum in Intelligent Construction

215

Figure 3: TG-DTG curves of the original PG.

(a) (b)

(c) (d)

Figure 4: XRD patterns of PG at different calcination temperatures.

3.3 Compressive Strength and Flexural

Strength

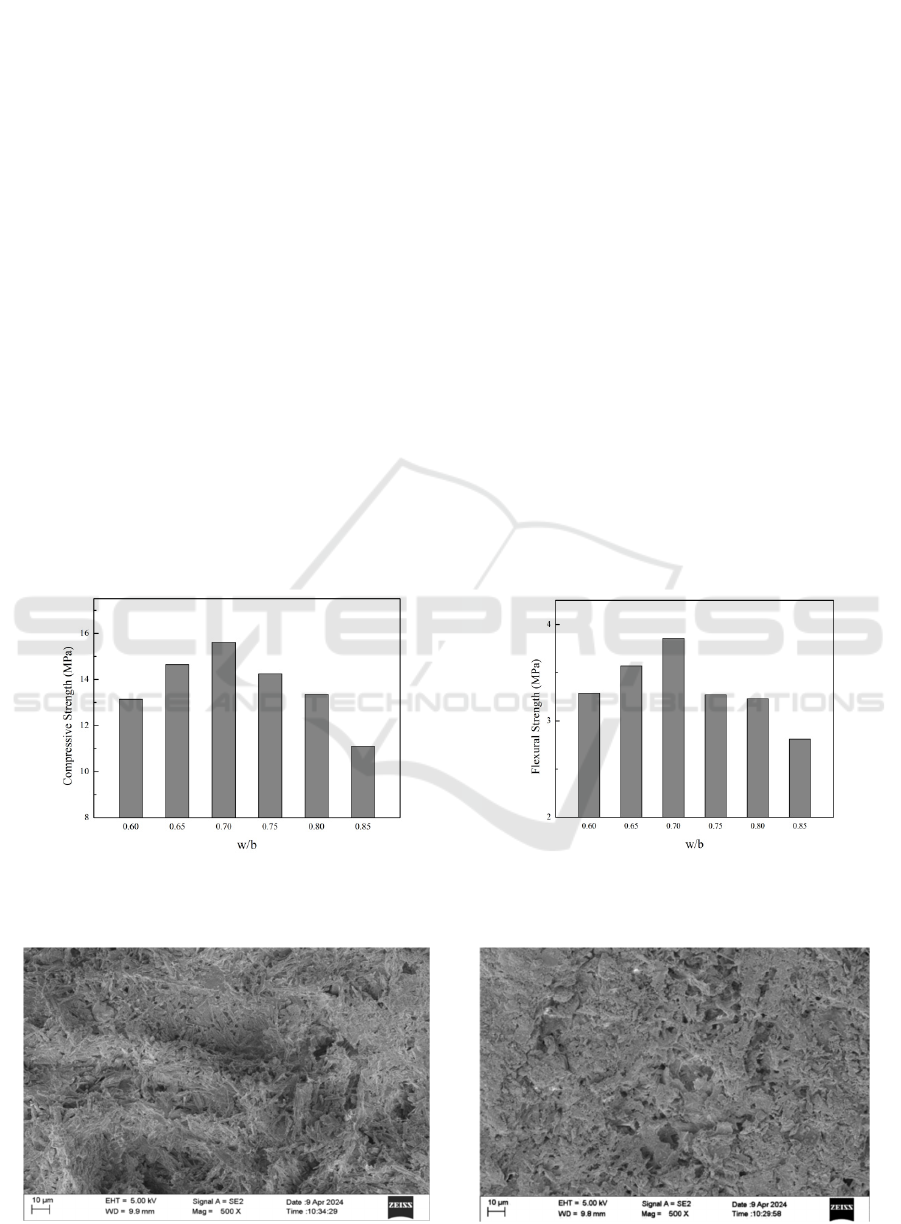

Figure 5 illustrates the 7-day compressive and

flexural strength of calcined PG under varying water-

to-ash ratios. The intensity of PG initially rises and

then declines as the water-to-ash ratio increases. For

ratios below 0.70, both compressive and flexural

strength of PG increase with the ratio. At a ratio of

0.70, peak values are reached at 15.62 MPa and 3.86

MPa for compressive and flexural strength,

respectively. Beyond a ratio of 0.70, both strengths

decrease. Specifically, at a ratio of 0.85, compressive

and flexural strengths are 28.87% and 27.20% lower

than those at a ratio of 0.70, measuring 11.11 MPa

and 2.81 MPa, respectively. The highest hydration

rate for calcined PG is observed at a water-to-ash ratio

of 0.70, indicating a direct correlation between

hydration level and strength. Excessive hydration

beyond this ratio leads to increased formation of

pores and microcracks within the material,

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

216

consequently diminishing its overall strength and

stability.

3.4 SEM

Figure 6 shows SEM photos of phosphogypsum after

natural curing for 7 days under different water-

cement ratio conditions. The strength of PG is

provided by the molecular forces connected to each

other through crystal contact. From the SEM cross-

sectional image with a magnification of two thousand

times, it can be seen that the microstructure of the

dihydrate PG crystal is relatively clear, the internal

morphology and lines are disordered, and the large

crystals The gaps between them are filled with small

crystals or small granular substances. When the

water-cement ratio is less than or equal to 0.70, PG

mainly takes the form of strips or needles after

hydration. The particles are cemented together and

interlaced to form a network structure. As the water-

cement ratio gradually increases, the structure

becomes loose and porous. There are obvious cracks

in the cross section. This should be the reason why

low water-cement ratio has higher strength compared

with high water-cement ratio.

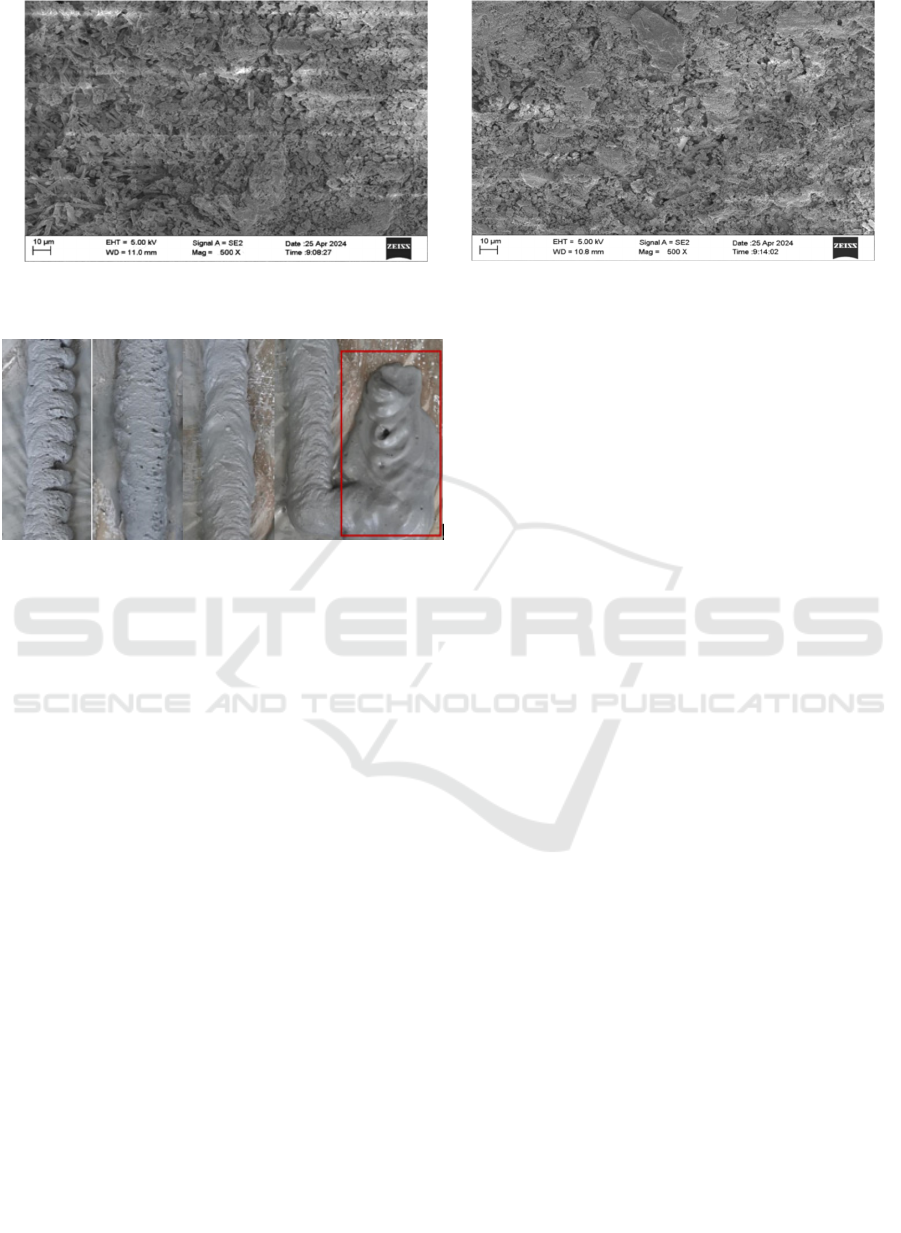

3.5 The Printability

Figure 7 illustrates the printing effects of calcined

phosphogypsum (PG) under varying water-cement

ratios of 0.60, 0.65, 0.67, and 0.70. In (a), at a water-

cement ratio of 0.60, the PG slurry exhibits severely

restricted fluidity, leading to discontinuous extrusion,

material breaks, and uneven surfaces with significant

cracking. Increasing the water-cement ratio to 0.65 (b)

reduces cracking but results in a rough surface with

noticeable flaws. At a ratio of 0.67 (c), the printing

quality improves markedly, with continuous and

uniform extrusion, and a smooth, flawless surface.

However, at 0.70 (d), the slurry becomes excessively

fluid, failing to maintain structural integrity and

preventing the formation of viable printed

components. These findings indicate that calcined PG

slurry is printable, with a water-cement ratio of 0.67

being optimal for achieving continuous, uniform, and

smooth printed structures.

(

a

)

(

b

)

Figure 5: 7d compressive and flexural strength of PG naturally cured: (a) compressive strength (b) flexural strength.

(a) w/c = 0.65 (b) w/c = 0.70

Explore the Application of Waste Gypsum in Intelligent Construction

217

(c) w/c = 0.75 (d) w/c = 0.80

Figure 6: SEM images of phosphogypsum under different w/c at 7 days.

(a) (b) (c) (d)

Figure 7: Printing effects of calcined PG under different

water-cement ratios: (a) w/c = 0.60 (b) w/c = 0.65 (c) w/c =

0.67 (d) w/c = 0.70.

4 CONCLUSION

(1) Effect of calcination temperature on XRD pattern

of PG sample. With the increase of calcination

temperature, part of CaSO

4

·2H

2

O in PG is dehydrated

to CaSO

4

·1/2H

2

O at 157℃, and CaSO

4

·1/2H

2

O may

be transformed into CaSO

4

when the temperature

reaches 175℃. Finally, the optimum heat treatment

temperature of phosphogypsum is determined to be

175℃.

(2) The mechanical properties of calcined

phosphogypsum increase and then decrease with the

increase of water ash ratio. And the mechanical

properties of phosphogypsum are the highest when

the water ash ratio is 0.70 (the compressive strength

and folding strength are 3.86MPa and 15.62MPa

respectively).

(3) The shape of hydration products gradually

changed from strip cross network to lamella gradually

to paste, the structure changed from dense to loose

and porous, and the fracture appeared obvious cracks.

(4) The calcined phosphogypsum slurry is

printable, and the 3D printing effect of the slurry is

best when the w/c is 0.67. The printed components are

continuous and uniform, and the surface is smooth

and flawless.

REFERENCES

Shakor, P., Nejadi, S., Paul, G., Sanjayan, J. 2020.

Dimensional accuracy, flowability, wettability, and

porosity in inkjet 3DP for gypsum and cement mortar

materials. Automation in Construction, 110: 102964.

Sun, T., Li, W., Xu, F., Yu, Z., Wang, Z., Ouyang, G., Xu,

D. 2023. A new eco-friendly concrete made of high

content phosphogypsum based aggregates and binder:

Mechanical properties and environmental benefits.

Journal of Cleaner Production, 400: 136555.

Tayibi, H., Choura, M., López, F.A., Alguacil, F.J., López-

Delgado, A. 2009. Environmental impact and

management of phosphogypsum. Journal of

Environmental Management, 90: 2377–2386.

Wu, F., Ren, Y., Qu, G., Liu, S., Chen, B., Liu, X., Zhao,

C., Li, J. 2022. Utilization path of bulk industrial solid

waste: A review on the multi-directional resource

utilization path of phosphogypsum. Journal of

Environmental Management, 313: 114957.

Xiao, J., Ji, G., Zhang, Y., Ma, G., Mechtcherine, V., Pan,

J., Wang, L., Ding, T., Duan, Z., Du, S. 2021. Large-

scale 3D printing concrete technology: Current status

and future opportunities. Cement and Concrete

Composites, 122: 104115.

Yuvaraj, K., Mohamed Ismail, A., Nagarajan, P.,

Vigneshwaran, S. 2021. Design and fabrication of

gypsum prototypes based on binder jetting technology.

Materials Today: Proceedings, 45: 3085–3090.

Zhang, C., Nerella, V.N., Krishna, A., Wang, S., Zhang, Y.,

Mechtcherine, V., Banthia, N. 2021. Mix design

concepts for 3D printable concrete: A review. Cement

and Concrete Composites, 122: 104155.

Zhang, J., Tan, H., He, X., Yang, W., Deng, X., Su, Y.,

Yang, J. 2019. Compressive strength and hydration

process of ground granulated blast furnace slag-waste

gypsum system managed by wet grinding. Construction

and Building Materials, 228: 116777.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

218

Zhang, Y., Yang, J., Cao, X. 2020. Effects of several

retarders on setting time and strength of building

gypsum. Construction and Building Materials, 240:

117927.

Zhao, Y., Gao, J., Liu, C., Chen, X., Xu, Z. 2020. The

particle-size effect of waste clay brick powder on its

pozzolanic activity and properties of blended cement.

Journal of Cleaner Production, 242: 118521.

Zhou, S., Lu, Y., Pan, Y., Li, J., Qu, F., Luo, Z., Li, W.

2023. Flowability prediction of recycled α-hemihydrate

gypsum for 3D powder printing under combined effects

of different glidants using response surface

methodology. Developments in the Built Environment,

16: 100265.

Rashad, A.M. 2017. Phosphogypsum as a construction

material. Journal of Cleaner Production, 166: 732–743.

Explore the Application of Waste Gypsum in Intelligent Construction

219