Applicability of Recycled Overlay Structure of Old Cement Pavement

in Road Network

GuoShi Chen

1a

, Hui Huang

2,3,4,* b

and Guanhai Huang

1c

1

Guangxi Zhuang Autonomous Region Highway Development Center, Nanning 530028, China

2

Guangxi Transportation Science and Technology Group Co., Ltd., Nanning 530007, China

3

Guangxi Key Lab of Road Structure and Materials, Nanning 530007, China

4

Research and Development Center on Technologies, Materials and Equipment of High Grade Highway Construction and

Maintenance Ministry of Transport, Nanning 530007, China

*

Keywords: Old Cement Pavement; Regeneration Overlay; Green Economy Is Applicable; Applicability.

Abstract: The degree of damage of the old cement pavement is different, and the way of comprehensive utilization and

treatment of the old road will be very different. In this paper, aiming at the problems of insufficient bearing

capacity, uneven strength and reflection cracks after regeneration of old cement pavement, combined with the

actual engineering application investigation, two types of post-regeneration overlay structure of cement

pavement in road network are investigated and studied. The mechanical response of two different structural

types is calculated by finite element simulation, and the mechanical response characteristics of different

structures are compared. The rationality and applicability of the overlay structure of the old cement pavement

are verified, and the green and economical applicable structure of the old cement pavement is recommended.

It can provide a favorable technical reference for the selection of recycled overlay structure of old cement

pavement.

1 INTRODUCTION

Cement concrete pavement is one of the important

forms of highway pavement structure

(JTG D40-

2011, 2011). There will be different degrees of

damage in the use of cement pavement. It is urgent to

discuss and study the recycled overlay structure of

green and economical old cement pavement. The old

cement pavement recycling overlay technology is a

kind of green environmental protection and

economical recycling technology. However, the

irregular cracks in the rubblized structure layer of the

old cement pavement will directly affect the

durability and comprehensive performance of the

overlay structure. The overlay structure layer is one

of the key considerations to prevent crack reflection.

Therefore, how to choose a green and economical

recycling overlay structure to treat the damage of the

old cement pavement is particularly important (JTJ

a

https://orcid.org/0009-0005-2474-5204

b

https://orcid.org/

0000-0002-0592-3328

c

https://orcid.org/

0009-0000-0393-8342

2 INVESTIGATION AND

RESEARCH ON THE USE OF

RECYCLED OVERLAY

STRUCTURE OF CEMENT

PAVEMENT

In order to deeply understand the effect of various

treatment methods of recycled overlay after

rubblization of old cement pavement, this paper

selects two different overlay structure sections of a

representative road network highway for

comprehensive information and road condition

investigation. The comprehensive information of

different overlay structure sections is shown in Table

1, and the on-site road conditions are shown in Figure

1. Combined with the comprehensive information of

Chen, G., Huang, H., Huang and G.

Applicability of Recycled Overlay Structure of Old Cement Pavement in Road Network.

DOI: 10.5220/0013627200004671

In Proceedings of the 7th International Conference on Environmental Science and Civil Engineering (ICESCE 2024), pages 189-195

ISBN: 978-989-758-764-1; ISSN: 3051-701X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

189

the road section and the on-site road conditions, it can

be seen that the application effect of the asphalt

pavement structure of the old cement pavement

rubblization overlay ATB asphalt macadam base is

good, but the asphalt pavement structure of the old

cement concrete pavement rubblization overlay lime

aggregate base has appeared rutting, longitudinal

cracks, oil and other diseases.

Table 1: Two different overlay structure section comprehensive information questionnaire.

ser

ial

nu

mb

er

Sec

tion

nu

mb

er

pavement structure types

Daily

traffic

volume

(vehicle

s )

Percent

age of

heavy

traffic

(%)

in the

years

already

spent

(years)

Plate

corner

deflectio

n value

(μm)

load

transfe

r

coeffic

ient(%

)

Road

condition

s

1

G3

24

8cm asphalt concrete + 7cm asphalt concrete

ATB-25 + 1cm lower seal layer + rubblized layer

of old cement pavement + 17cm lime-fly ash

stabilized crushed stone + 17cm graded crushed

stone

14407

52 6 79.6 82.7 good

2

G3

24

7cm asphalt concrete + 20cm lime stabilized

aggregate + 1cm sealing oil layer + old cement

pavement rubblization layer + 20cm cement

stabilized gravel + 20cm graded gravel

6340 30 5 88.7 79.2

Rutting,

longitudi

nal joints

and

oiling

Figure 1: Two different overlay structure field survey road map.

3 COMPARATIVE

CALCULATION STUDY ON

RECYCLED OVERLAY

STRUCTURE OF CEMENT

PAVEMENT

3.1 The Finite Element Calculation

Method of Recycled Overlay

Structure of Cement Pavement

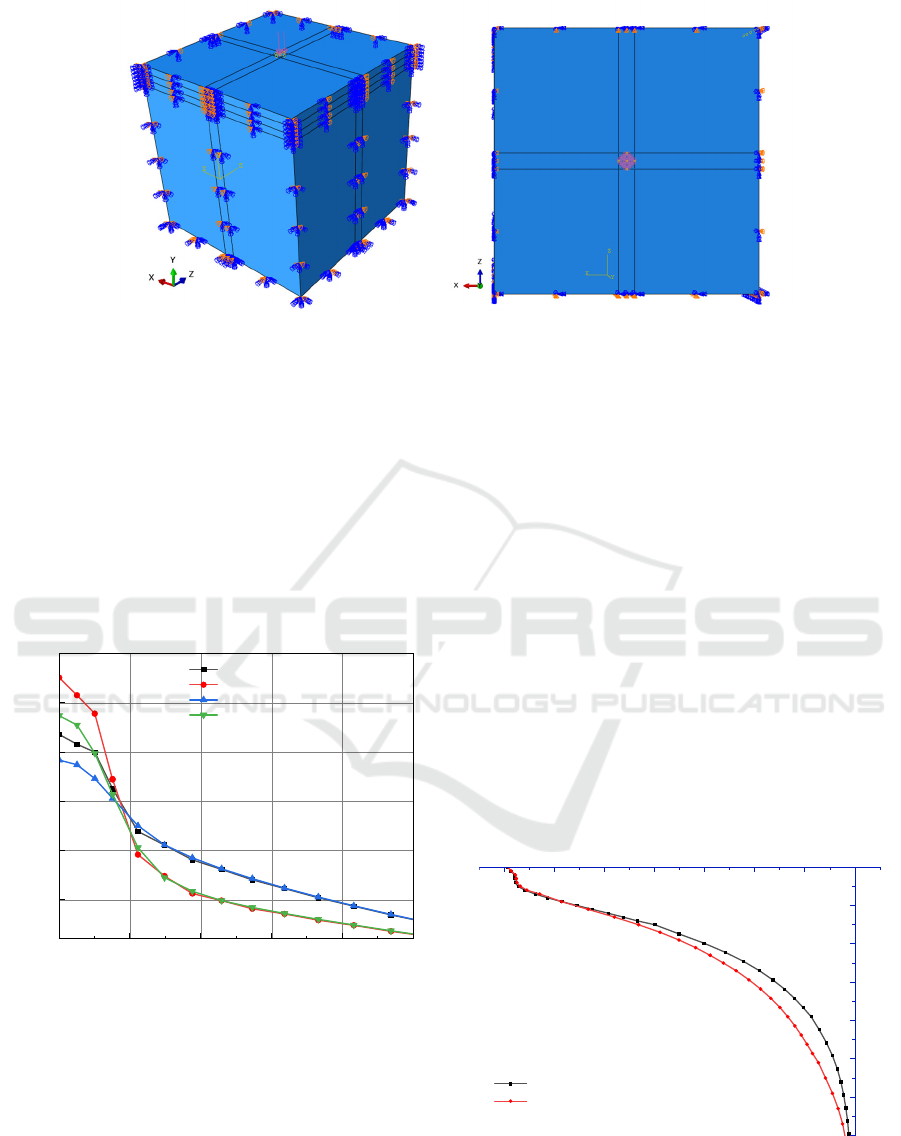

In order to grasp the mechanical properties of the

recycled overlay structure of cement pavement, this

paper establishes a three-dimensional pavement

structure model by ABAQUS finite element software

based on the structure of the above two on-site

investigation sections, as shown in Figure 2. The first

structure is paved with 8cm asphalt concrete +

7cmATB-25. Structure 2 is paved with 7 cm asphalt

concrete + 20cm lime stabilized aggregate. The

simulation parameters are shown in Table 2 and 3 (

Xu

et al., 2009; Cao et al, 2010; BEREBJI et al., 2022).

G324 8cm asphalt concrete+7cm

asphalt concrete ATB-25 + old cement

pavement rubblized layer pavement

G324 7cm asphalt concrete + 20cm

lime stabilized aggregate + old cement

pavement rubblized layer pavement

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

190

Table 2: Structure-pavement material and its calculation parameters.

name of the material

Thickne

ss

/cm

elastic

Modul

us

/MPa

poisson rat

io

New overlay structure layer

bituminous concrete facing membrane 8 1600 0.25

ATB-25 7 1500 0.25

Old cement pavement struc

ture

Rubblization layer of old cement paveme

n

t

24 1200 0.25

lime-fly ash stabilized-crushed-stone foun

dation

17 1000 0.25

gravel-sorted

subbase

17 500 0.35

earth base / 60 0.35

Table 3: Structural two-surface material and its calculation parameters.

name of the material

Thicknes

s

/cm

elastic

Modulu

s

/MPa

poisson rati

o

New overlay structure layer

b

ituminous concrete facin

g

membrane 7 1000 0.25

Lime stabilized

g

ranular la

y

e

r

20 600 0.25

Old cement pavement struct

ure

Rubblization layer of old cement pave

men

t

24 1200 0.25

cement stabilized macadam base 20 2400 0.25

gravel-sorted

subbase

20 500 0.35

earth base / 60 0.35

In order to simplify the calculation, the model size

is proposed to be 5m × 5m × 5m. The following

assumptions are made for each structural layer: (1)

each structural layer is a uniform, continuous and

isotropic linear elastic body; (2) The layers of each

structure are continuous; (3) The bottom of the

foundation adopts fixed constraint, the displacement

is zero, the side adopts horizontal constraint, the

horizontal displacement is zero; (4) The load is a

single wheel load, the wheel pressure is 0.7 MPa, and

the diameter of the load area is 30.2 cm;(5) The finite

element model mesh is divided by C3D8R (three-

dimensional hexahedron eight-node linear reduced

integral isoparametric element) element, and the seed

treatment is encrypted near the load area (

AZAD et al.,

2020; FEI et al., 2024

).

Applicability of Recycled Overlay Structure of Old Cement Pavement in Road Network

191

Figure 2: Pavement structure finite element model diagram.

3.2 Comparative Analysis of Finite

Element Calculation of Recycled

Overlay Structure of Cement

Pavement

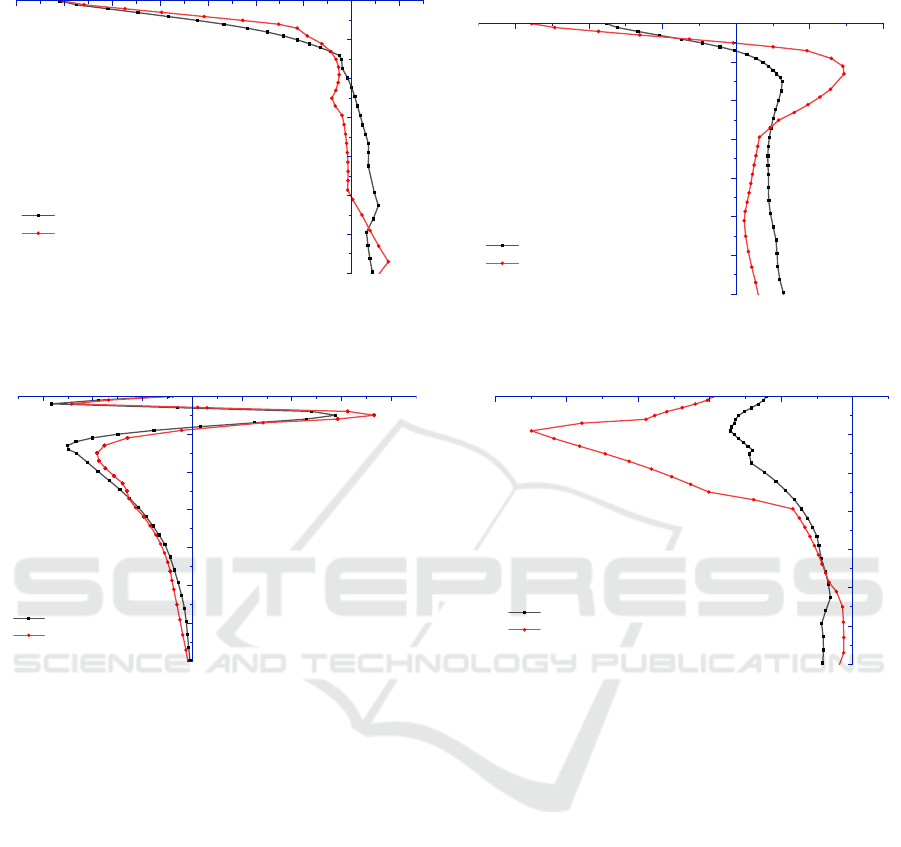

(1) Deflection

Deflection can reflect the overall bearing capacity of

the pavement. In this paper, the surface deflection of

two different asphalt overlay structures and the

bottom deflection of asphalt overlay are calculated

respectively. The results are shown in Figure 3.

0.0 0.2 0.4 0.6 0.8 1.0

-0.15

-0.20

-0.25

-0.30

-0.35

-0.40

Deflection/mm

Lateral distance from the center of the load/m

The road table of Structure 1

The road table of Structure 2

Asphalt overlay bottom of Structure 1

Asphalt overlay bottom of Structure 2

Figure 3: Deflection comparison diagram of the two

structures.

It can be seen from Figure 3 that at the center of

the load, the maximum deflection of the structure 2 is

much larger than the maximum deflection of the

structure 1, and the maximum deflection value is

shown in Table 4. Compared with structure 1, the

maximum deformation of surface deflection and

bottom deflection of asphalt overlay of structure 2

increased by 18.22 % and 15.49 % respectively. This

shows that the deflection is mainly determined by the

modulus of the new overlay structure. The structure 1

with 8cm asphalt concrete + 7cmATB-25 has better

pavement bearing capacity.

(2) Internal stress of structure

Figure 4: Load center transverse stress contrast diagram.

70

60

50

40

30

20

10

-700 -600 -500 -400 -300 -200 -100 0

Vertical stress of load center/KPa

Depth/cm

Structure 1

Structure 2

Figure 5: Vertical stress comparison diagram of load

center.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

192

70

60

50

40

30

20

10

-700 -600 -500 -400 -300 -200 -100 0 100

Longitudinal stress of load center/KPa

Depth/cm

Structure 1

Structure 2

Figure 6: Longitudinal stress comparison diagram of load

center.

70

60

50

40

30

20

10

-0.6 -0.4 -0.2 0.0 0.2 0.4 0.6 0.8

Shear stress of load center/KPa

Depth/cm

Structure 1

Structure 2

Figure 7: Load center shear stress comparison diagram.

It can be seen from Figure 4-6 that the first

structure completes the tension and compression

alternation in the rubblized layer of the old cement

pavement, while the second structure only occurs in

the cement stabilized gravel layer of the old pavement.

It can be seen from Figure 5 that the vertical stress of

structure 1 and structure 2 shows the same trend, and

it is always under compression, but the vertical stress

of structure 2 is greater than that of structure 1 at the

same depth. It can be seen from Figure 7 that the

maximum shear stress of the two structures appears at

a depth of 5cm, which is located in the new asphalt

overlay layer, and the maximum shear stress of the

first and second structures is 0.575KPa and 0.731KPa,

respectively. The analysis shows that the overall

thickness of the pavement of the second structure is

thicker, and the elastic modulus of the new overlay

structure layer is smaller, which causes the internal

vertical stress and shear stress of the second structure

to be larger, which will increase the risk of pavement

displacement, rutting and cracking.

(3) Internal strain of structure

70

60

50

40

30

20

10

-300 -200 -100 0 100 200

Transverse strain of load center/10^-6

Depth/cm

Structure 1

Structure 2

Figure 8: Load center transverse strain contrast diagram.

70

60

50

40

30

20

10

-1000 -800 -600 -400 -200 0

Vertical strain of load center/10^-6

Depth/cm

Structure 1

Structure 2

Figure 9: Vertical strain comparison diagram of load center.

It can be seen from Figure 8 to 9 that the transverse

and longitudinal strains of structures 1 and 2 express

to the peak of compressive strain in the road, and

decrease with the increase of depth. Tension and

compression alternate in the new pavement structure

layer and begin to increase until the peak of tensile

strain is reached at 15 cm, and then begin to decrease.

Therefore, on the whole, the effect of setting 8cm

asphalt concrete + 7cmATB-25 is better than that of

setting 7cm asphalt concrete + 20 cm lime stabilized

aggregate.

4 CONCLUSION AND

SUGGESTION

In this paper, the use of two different overlay

structures of ATB-25 layer and lime stabilized

granular layer after the recycling of old cement

pavement after rubblization is investigated and the

Applicability of Recycled Overlay Structure of Old Cement Pavement in Road Network

193

structural mechanical response is calculated. The

following conclusions are obtained :

(1) From the calculation and analysis of the failure

mode and damage mechanism of the pavement

structure, it is found that compared with the

structure one, the maximum deformation of the

surface deflection and the bottom deflection of

the asphalt overlay layer of the structure two

increased by 18.22 % and 15.49 % respectively.

The structure one with 8cm asphalt concrete +

7cmATB-25 has better pavement bearing

capacity. Due to the small elastic modulus of the

new overlay structure layer of the second

structure, the vertical stress and shear stress in

the second structure are larger, which will

increase the risk of pavement lapse, rutting and

cracking. The maximum stress of the second

structure in the transverse and longitudinal

directions is greater than that of the first

structure, which easily leads to a large stress

concentration at the bottom of the base layer in

the second structure, resulting in reflective

cracks in the pavement. The vertical strain of

structure one and structure two is always

compressive strain, and it begins to decrease

after reaching the peak of compressive strain at

10 cm. The peak strain of structure two is much

larger than that of structure one, and the

difference of transverse tensile strain peak is the

largest, and the percentage of difference reaches

134.27 %. Therefore, on the whole, the effect of

setting 8cm asphalt concrete + 7cmATB-25 is

better than that of setting 7cm asphalt concrete +

20cm lime stabilized aggregate.

(2) Based on the actual engineering investigation

and simulation analysis, it is found that

considering the overall thickness and bearing

capacity of the structure, the internal stress and

strain changes of the structural layer, it is

recommended to use the old cement pavement

regeneration overlay structure of the road

network, and adopt the ATB asphalt graded

gravel base asphalt overlay structure with better

flexibility and crack resistance. This paper can

provide good theoretical and application support

for the selection of overlay reconstruction

structure after the regeneration of old cement

pavement in road network.

DECLARATION OF COMPETING

INTEREST

The authors declare that they have no known

competing financial interests or personal

relationships that could have appeared to influence

the work reported in this paper.

ACKNOWLEDGEMENTS

The research of this paper is supported by the ' Field

Scientific Observation Station for Long-term

Performance of Subgrade and Pavement in Guangxi

Transportation Industry ' ( Guijiaokejiaohan [2023

No.513 ) and ' Field Scientific Observation and

Research on Long-term Performance of Large and

Medium Repair Structure of National and Provincial

Trunk Highways ' ( Guijiaobianhan [2022] No.174 ).

REFERENCES

JTG D40-2011, 2011. Specification for Design of Highway

Cement Concrete Pavement[S].People 's

Communications Press.

JTJ 073.1-2001, 2001. Technical Specification for

Maintenance of Highway Cement Concrete Pavement

[S]. People 's Transportation Publishing House.

Wang Songgen, Zhang Yuhong, Huang Xiaoming, et al.,

2007. Guide to the application of rubblization

technology in old cement concrete pavement [M].

People 's Transportation Publishing House.

Huang Hui, Feng Yongping, et al., 2016. Research on the

application of graded crushed stone base in the

rubblization overlay of old cement pavement in

Guangxi [J]. Highway and Motor Transport, (6): 147-

150.

Xu Xinquan, Wu Chuanhai, et al., 2009. Analysis of

Mechanical Properties of Asphalt Overlay on Old

Cement Concrete Pavement [J] Highway and Motor

Transport, (3): 55-58.

Cao Zhiyuan, Zhang Qisen, 2010. Mechanical Response

Analysis of Thin Asphalt Overlay on Old Cement

Concrete Pavement [J]. Highway Engineering, 35(4):

42-46.

BEREBJI M, SARKAR A, 2022. Temperature curling and

gradient of roller-compacted concrete composite

pavements [J]. Construction and Building Materials,

353: 129008.

AZAD A M, TAGHREED K M A, 2020. Flexural behavior

of composite concrete-epoxy-reinforced concrete

beams[J]. Iranian Journal of Science and Technology,

Transactions of Civil Engineering, 44: 549-563.

FEI M, FU W, ZHENG X, et al., 2024. Enhancing cement

composite interface with waterglass modification on

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

194

bamboo fiber: a viable and effective approach[J].

Construction and Building Materials, 411: 134338.

Applicability of Recycled Overlay Structure of Old Cement Pavement in Road Network

195