Applicability and Mechanical Response of Concrete Pavement Panel

Thickness of Road Network Highway

Xinghai Huang

1a

, Hui Huang

2,3,4,* b

and Jun Liang

5c

1

Department of Transport of Guangxi Zhuang Autonomous Region, Guangxi 530011, China

2

Guangxi Transportation Science and Technology Group Co., Ltd., Guangxi 530007, China

3

Guangxi Key Lab of Road Structure and Materials, Guangxi 530007, China

4

Research and Development Center on Technologies, Materials and Equipment of High Grade Highway Construction and

Maintenance Ministry of Transport, Guangxi 530007, China

5

Guangxi Zhuang Autonomous Region Transportation Comprehensive Administrative Law Enforcement Bureau, Guangxi,

Nanning 530022, China

Keywords: Concrete Pavement, Panel Thickness, Applicability, Mechanical Response.

Abstract: Concrete pavement has been widely used in highway builders of Guangxi road network because of its

outstanding characteristics such as high strength, low energy consumption, good economic and social benefits,

and long service life. It has nearly 8000 km of application mileage. However, with the continuous

development of heavy-duty traffic, the problems of impact resistance, fatigue resistance, comfort performance,

and inconvenient maintenance of cement pavement have gradually become prominent. The use of cement

pavement is restricted by broken plates, staggered platforms, large driving noise, and discomfort. In this paper,

aiming at the problems of uneven bearing capacity and different damage degree of cement pavement,

combined with the actual field investigation, the mechanical response calculation of different surface

thickness of cement pavement is carried out, and the influence of different surface thickness on the overall

use of cement pavement is obtained. This paper can provide scientific data and technical reference for the

selection and design of cement pavement structure.

1 INTRODUCTION

Concrete pavement is one of the important forms of

road pavement structure (JTG D40-2011, 2011).

Cement pavement has good applicability in road

network highways, especially in heavy-duty traffic

sections. Most of the cement pavements have a

service life of up to 10 years and good road conditions.

However, due to heavy-duty traffic loads, bearing

capacity of subgrade and base, more precipitation,

more voids at the edge of slab corners, material

composition and other unfavorable factors, with the

increase of its operating time, some road sections will

have different degrees of pavement damage such as

slab corner fracture, broken slab or broken slab, and

joint damage during use (JTJ 073.1-2001, 2001;

Wang et al., 2021; Wang et al., 2021).

a

https://orcid.org/0009-0008-1482-0284

b

https://orcid.org/0000-0002-0592-3328

c

https://orcid.org/0009-0006-8906-3543

In this paper, the cement pavement with different

surface thickness of G207 and G209 lines is taken as

the research object, and the investigation and analysis

of the use of cement pavement in road network

highway are carried out. Based on the field test results,

the mechanical calculation of cement pavement with

different surface thickness is carried out, and the

surface thickness suitable for cement pavement of

road network highway is analyzed and studied, which

provides strong data support for the selection and

design of cement pavement structure of road network

highway.

Huang, X., Huang, H., Liang and J.

Applicability and Mechanical Response of Concrete Pavement Panel Thickness of Road Network Highway.

DOI: 10.5220/0013627000004671

In Proceedings of the 7th International Conference on Environmental Science and Civil Engineering (ICESCE 2024), pages 183-188

ISBN: 978-989-758-764-1; ISSN: 3051-701X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

183

2 INVESTIGATION ON THE USE

OF CEMENT PAVEMENT WITH

DIFFERENT SURFACE

THICKNESS

With the increase of its operation time, concrete

pavement is affected by unfavorable factors such as

heavy traffic load, bearing capacity of subgrade and

base, more precipitation, more voids at the edge of

slab corner, and material composition. In the process

of use, some sections will have different degrees of

pavement damage, such as slab corner fracture,

broken slab or broken slab, joint damage and so on.

In order to understand the use of concrete pavement

structure with different panel thickness, this paper

investigates and studies the daily traffic volume,

heavy vehicle traffic ratio, service life and road

condition of concrete pavement with panel thickness

of 20, 24 and 26cm respectively. The FWD deflection

test vehicle is used to test the angular deflection value

of the plate and calculate the load transfer coefficient.

The comprehensive information above each road

section is shown in Table 1, and the on-site road

conditions and on-site drilling core samples are

shown in Figure 1.

Table 1: Three different panel thickness of concrete pavement structure road condition questionnaire.

serial

num

ber

Sectio

n

numb

er

pavement structure

types

Daily

traffic

volume

(vehicles)

Percentag

e of

heavy

traffic

in the

years

already

spent

Plate corner

deflection

value

(μm)

load

transfer

coefficie

nt

Road

conditions

1 G209

20cm cement

concrete

panel+20cm cement

stabilized gravel+

18cm graded crushed

stone

7276 70% 9 年 79.6 87.3%

Longitudina

l and

transverse

cracks

2 G209

24cm cement

concrete

panel+20cm cement

stabilized gravel+

18cm graded crushed

stone

7276 70% 9 年 88.7 93.8%

Longitudina

l and

transverse

cracks

3 G207

26cm cement

concrete

panel+20cm cement

stabilized gravel+

18cm graded crushed

stone

24882 23% 12 年 75.2 94.3% good

G209 20cm cement concrete panel

road map

G209 24cm cement concrete panel

road map

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

184

Figure 1: Three different thickness of concrete pavement structure field survey road map.

The concrete pavement structure of the three road

network highways shown in Table 1 represents the

typical structure of concrete pavement in Guangxi.

The concrete pavement ( panel thickness 20cm ) of a

section of G209 has been used for 9 years, and there

have been longitudinal and transverse cracks and

other diseases. The load transfer capacity between the

slabs is the worst; the concrete pavement ( panel

thickness 24cm) of a section of G209 has been used

for 9 years, and there have been longitudinal and

transverse cracks and other diseases, and the load

transfer capacity between the plates is in the middle.

The concrete pavement (panel thickness 26 cm) of a

section of G207 has been used for 12 years, and the

traffic volume has reached more than 20,000.

However, the road condition is good, there are no

cracks and other diseases, and the load transfer

capacity between slabs is the best.

3 STUDY ON MECHANICAL

RESPONSE OF CONCRETE

PAVEMENT STRUCTURE

WITH DIFFERENT PANEL

THICKNESS

3.1 Construction of Finite Element

Calculation Model of Concrete

Pavement Structure with Different

Panel Thickness

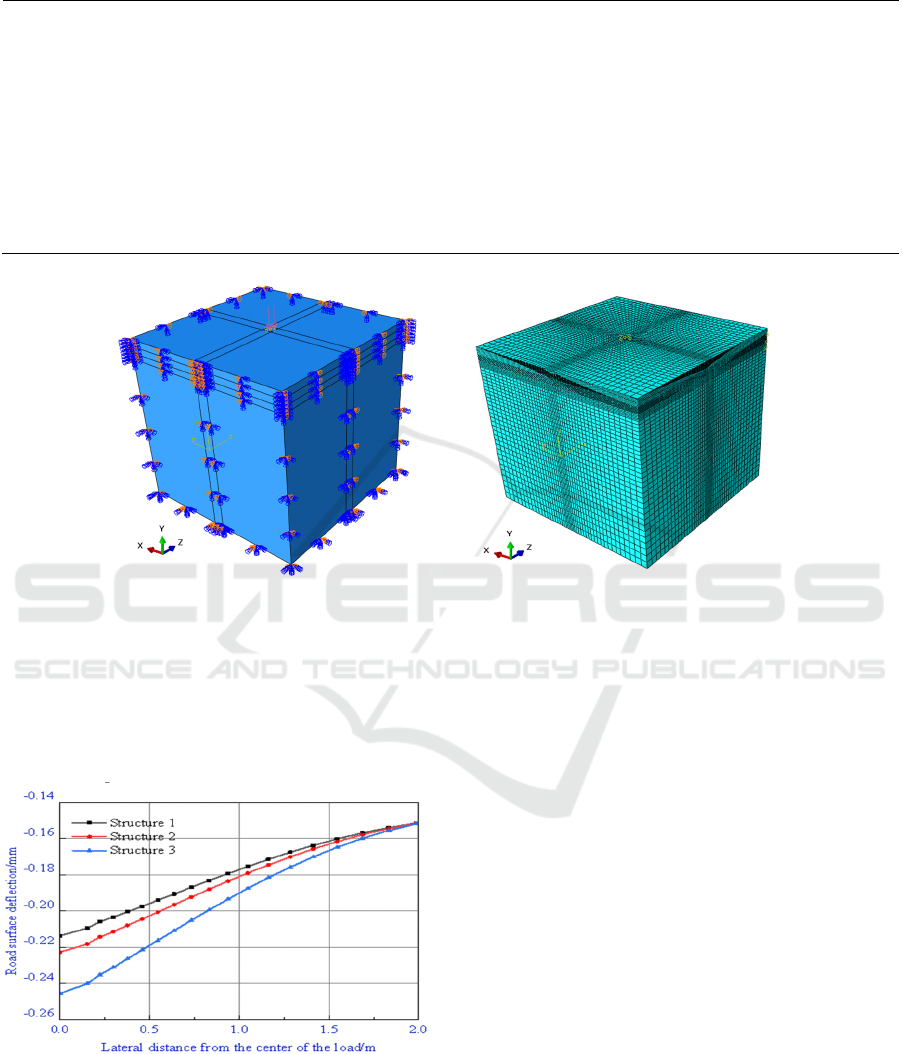

In order to grasp the mechanical properties of

concrete pavement structure with different panel

thickness, this paper constructs the finite element

model of concrete pavement structure with cement

panel thickness of 20,24 and 26cm based on

ABAQUS finite element software, as shown in Figure

2. In order to grasp the mechanical properties of

cement pavement structure with different panel

thickness, this paper constructs the finite element

model of cement pavement structure with cement

panel thickness of 20,24 and 26cm based on

ABAQUS finite element software, as shown in Figure

2. In order to analyze the mechanical properties of

three different cement pavement structures, this paper

builds a three-dimensional calculation model based

on ABAQUS software. The relevant calculation

parameters are shown in Table 2. The first structure

is G207 section (panel thickness 26cm), the second

structure is G209 section ( panel thickness 24cm), and

the third structure is G2094section ( panel thickness

20cm). As shown in Figure 2, the model size is

proposed to be 5m × 5m × 5m, and the mesh is

divided by C3D8R (three-dimensional hexahedron

eight-node linear reduced integral isoparametric

element) unit (AZAD et al., 2020; FEI et al., 2024;

Wang et al., 2022). The equivalent diameter D =

30.2cm, and the load uniform pressure P = 0.7MPa.

G207 26cm cement concrete panel

road map

Applicability and Mechanical Response of Concrete Pavement Panel Thickness of Road Network Highway

185

Table 2: Parameter model parameters of structural mechanics calculation of concrete pavement with different panel thickness.

structure one structure two structure three

layer thickness(

cm)

Elastic

modulus

(MPa)

poisson

ratio

cement concrete

slab

cement concrete

slab

cement concrete

slab

(20,24,26) 30000 0.2

cement stabilized

macada

m

cement stabilized

macada

m

cement stabilized

macada

m

20 2000 0.25

graded broken

stone

graded broken

stone

graded broken

stone

18 600 0.35

earth base earth base earth base / 35 0.35

Figure 2: Pavement structure finite element model diagram.

3.2 Finite Element Calculation and

Analysis of Concrete Pavement

Structure with Different Panel

Thickness

(1) concrete pavement surface deflection

Figure 3: The road surface deflection comparison diagram

of the three structures.

From Figure 3, it can be seen that the road surface

deflection of structure one is the smallest, and the

road surface deflection of structure two and three

gradually increases. With the decrease of the

thickness of the cement pavement surface layer, the

road surface deflection becomes larger and larger.

The thickness of the cement pavement surface layer

of structure two and structure three is reduced by

7.69 % and 23.08 % respectively, while the road

surface deflection of the load center is increased by

4.25 % and 14.92 % compared with the structure one.

This shows that the vertical deformation of the

cement pavement surface layer is closely related to its

thickness. As the thickness of the cement pavement

surface layer increases, its flexural strength increases,

while its surface deflection decreases relatively.

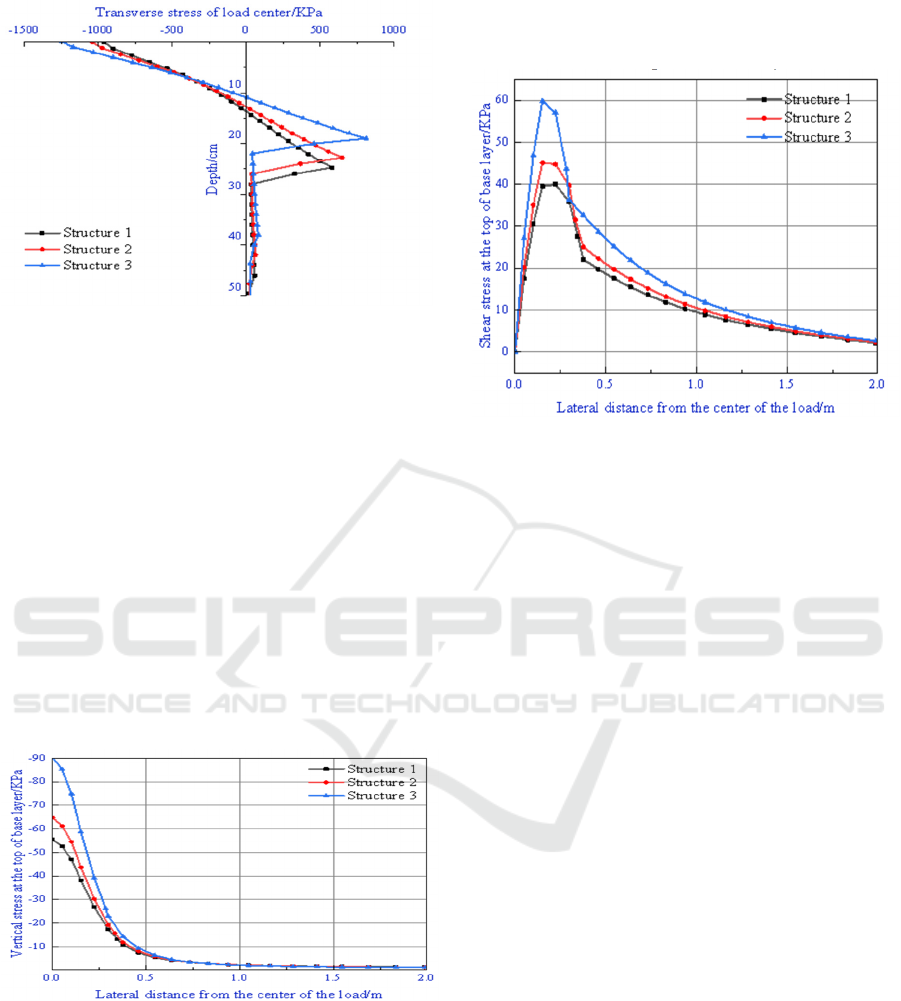

(2) The influence of concrete pavement panel

thickness on the internal stress of the structural layer

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

186

Figure 4: The transverse stress comparison diagram of the

load center of the three structures.

From Figure 4, it can be seen that the peak value

of transverse stress tension and compression of

structure one is the smallest, the peak value of

transverse stress tension and compression of structure

two and three increases in turn, and the peak value of

transverse stress tension and compression of structure

two and three increases by 11.75 % and 40.07 %

respectively. The peak transverse compressive stress

of the second and third structures increased by 8.08 %

and 28.96 %, respectively. This shows that as the

thickness of the cement pavement surface layer

increases, the peak value of the transverse stress

tension and compression inside the pavement

structure decreases accordingly, and the depth of the

position where tension and compression alternate will

increase.

Figure 5: Comparison of vertical stress at the top of the base

layer of three structures.

According to Figure 5, the peak vertical stress of

the top of the first, second and third base layers of the

structure is-55.533 MPa, -64.771 MPa and-90.499

MPa, respectively. The vertical stress of the load

center of the second and third structures is increased

by 16.64 % and 62.96 % respectively compared with

the first structure. This shows that the increase of the

thickness of the cement pavement surface layer will

lead to a significant increase in the peak value of the

vertical stress at the top of the base layer.

Figure 6: Comparison of shear stress at the top of the base

layer of three structures.

From Figure 6 that the shear stress at the top of the

cement pavement base layer increases first and then

decreases, reaching a peak at the edge of the single

wheel load. With the increase of the thickness of the

cement pavement surface layer, the shear stress of the

structure one, two and three decreases in turn, and the

peak values are 39.944 KPa, 44.784 KPa and 57.015

KPa, respectively, and the peak values of the shear

stress of the structure two and three are increased by

10.81 % and 29.94 % respectively compared with the

structure one.

In summary, the thickness of the cement pavement

surface layer of the second and third structures is

reduced by 7.69 % and 23.08 % compared with the

first structure, while the peak deflection of the road

surface is increased by 4.25 % and 14.92 % ; the peak

value of transverse tensile stress increased by 11.75 %

and 40.07 %. The peak value of transverse

compressive stress is increased by 8.08 % and

28.96 %. The peak value of vertical stress increased

by 16.64 % and 62.96 %. The peak shear stress

increased by 10.81 % and 29.94 %.

4 CONCLUSION AND

SUGGESTION

(1) In this paper, aiming at the problems of uneven

bearing capacity and different degrees of

damage of cement pavement, combined with the

actual investigation, it is found that the use of

cement pavement in road network highway is

Applicability and Mechanical Response of Concrete Pavement Panel Thickness of Road Network Highway

187

proportional to the thickness of its surface layer.

The thicker the surface layer, the better the use

condition, but the smaller the deflection value of

the plate angle, the larger the load transfer

coefficient between the plates, and the best

overall applicability.

(2) In this paper, the simulation results show that : 1

The vertical deformation of cement pavement

surface layer is closely related to its thickness.

The thicker the cement pavement surface layer

is, the higher the flexural strength will be, but the

deflection of the road surface will decrease. The

peak value of the transverse stress of the first

structure is the smallest, and the second and third

structures increase in turn. The increase of the

thickness of the cement pavement surface layer

will lead to the decrease of the internal

transverse stress. 3 The increase of the thickness

of the cement pavement surface layer will make

it produce smaller vertical stress at the top of the

base layer. In order to ensure the overall stability

and bearing capacity of the cement pavement

structure and improve its comprehensive service

life, it is recommended to increase the thickness

of the cement pavement surface layer when

construction and economic conditions permit.

DECLARATION OF COMPETING

INTEREST

The authors declare that they have no known

competing financial interests or personal

relationships that could have appeared to influence

the work reported in this paper.

ACKNOWLEDGEMENTS

The research of this paper is supported by the ' Field

Scientific Observation Station for Long-term

Performance of Subgrade and Pavement in Guangxi

Transportation Industry ' ( Guijiaokejiaohan [2023]

No. 513) and ' Field Scientific Observation and

Research on Long-term Performance of Large and

Medium Repair Structure of National and Provincial

Trunk Highways ' (Guijiaobianhan [2022] No. 174).

REFERENCES

JTG D40-2011, 2011. Specification for Design of Highway

concrete pavement [S]. People 's Transportation Press.

JTJ 073.1-2001, 2001. Technical Specification for

Maintenance of Highway concrete pavement [S].

People 's Transportation Publishing House.

Wang Lijuan, Hu Changbin, Sun Zenghua, 2021. Research

on warping behavior mechanism of concrete pavement

slab at early age [J]. Engineering Mechanics, 38(10):

215-228.

BEREBJI M, SARKAR A., 2022. Temperature curling and

gradient of roller-compacted concrete composite

pavements [J]. Construction and Building Materials,

353: 129008.

AZAD A M, TAGHREED K M A., 2020. Flexural

behavior of composite concrete-epoxy-reinforced

concrete beams[J]. Iranian Journal of Science and

Technology, Transactions of Civil Engineering, 44:

549-563.

FEI M, FU W, ZHENG X, et al., 2024. Enhancing cement

composite interface with waterglass modification on

bamboo fiber: a viable and effective approach[J].

Construction and Building Materials, 411: 134338.

Wang Shuai, Shen Xizhong, Cui Zhanwei, et al., 2022.

Mechanical properties and strength development law of

skeleton dense cement stabilized macadam [J]. Sci-tech

Information, 20(9): 47-49.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

188