Detecting Grouting Quality in Post-Tensioned Prestressed Ducts with

IE Method

Hai Liu

*a

and Lei Xu

CCCC First Highway Consultants Co., Ltd., Xi’an 710075, China

*

Keywords: Grouting Quality, Post-Tensioned Prestressed Ducts, Impact-Echo, Non-Destructive Evaluation.

Abstract: In post-tensioned prestressed bridges, the grouting quality of prestressed ducts is of paramount importance to

the durability and load-bearing capacity of the bridge. Voids within the ducts may allow water and other

corrosive substances to penetrate, leading to corrosion of the steel reinforcement and ultimately affecting the

structural safety of the bridge. Impact-echo (IE) testing, an effective non-destructive evaluation (NDE)

method, enables scientific and accurate assessment of the grouting quality of grouting ducts in pre-stressed

structures without damaging the structure. This paper examines the impact-echo method for assessing

grouting quality in post-tensioned prestressed ducts, confirming its adaptability and reliability for practical

engineering applications.

1 INTRODUCTION

Prestressed concrete structures are widely used in

civil engineering due to their superior mechanical

properties and economic benefits (Sun et al., 2022).

However, the grouting quality within prestressed

ducts directly affects the protection of prestressing

tendons and the long-term performance of the

structures. Traditional testing methods have several

limitations: they are often destructive, making the

sample unusable and increasing costs, and usually

assess only localized areas, missing overall

conditions and latent issues. Furthermore, these

methods depend on subjective human judgment,

leading to variability and lack of precise real-time

data, and are inadequate for detecting hidden internal

defects. NDE technologies provide accurate and real-

time inspection results without damaging materials or

structures, improving safety and cost-effectiveness in

industries like manufacturing and bridge

maintenance. The IE method is a robust non-

destructive evaluation technique, particularly

valuable for assessing concrete structures. It enables

comprehensive evaluations of internal elements

critical for maintenance, safety, and longevity. This

paper investigates the use of the IE method for

a

https://orcid.org/0009-0005-9231-8538

assessing grouting quality in pre-stressed concrete

pipelines (Hsieh and Lin, 2016).

2 THEORETICAL ANALYSIS

2.1 Theoretical Foundation:

Reflections of Three Different

Stress Waves

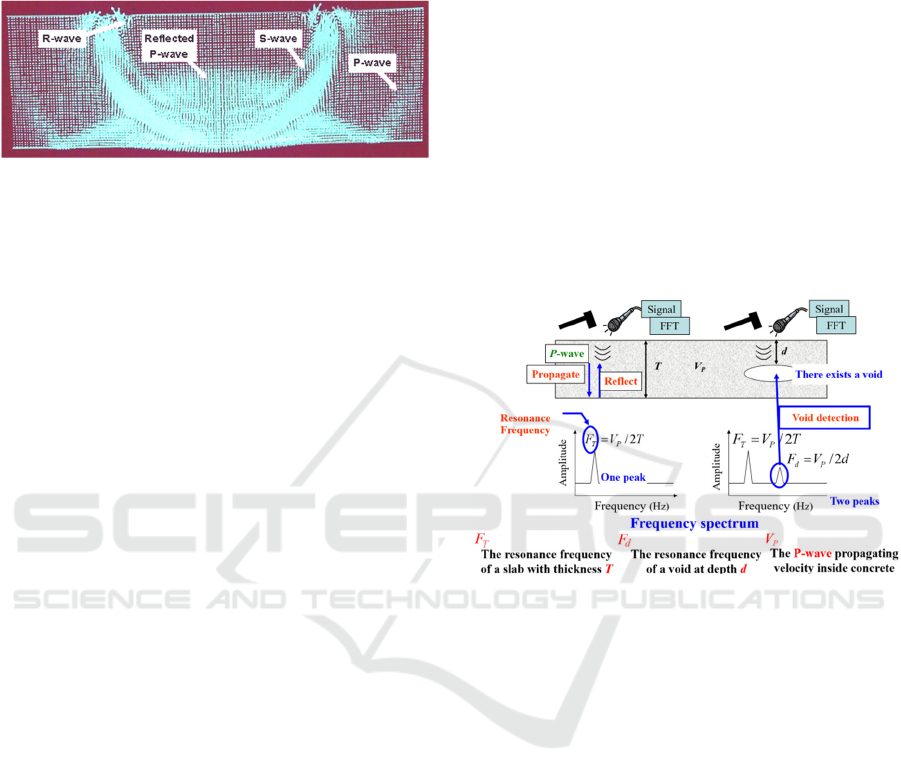

Impact-Echo (IE) is a non-destructive evaluation

method for concrete and masonry structures, based on

the generation and analysis of transient stress waves

induced by an elastic impact (Cheng et al., 2021). The

instantaneous disturbance (force or displacement)

applied to the surface of a solid propagates internally

in the form of three different stress waves: P-waves,

S-waves, and R-waves. The direction of propagation

of the P-wave is consistent with the direction of

particle vibration, generating compressive or tensile

stress. The S-wave propagates in a direction

perpendicular to the particle vibration, resulting in

shear stress. The R-wave propagates along the surface

of the solid and is a type of inhomogeneous plane

wave formed by the coupling of longitudinal and

transverse waves. Among the stress waves generated

by the impact, the P-wave and S-wave propagate into

Liu, H., Xu and L.

Detecting Grouting Quality in Post-Tensioned Prestressed Ducts with IE Method.

DOI: 10.5220/0013591200004671

In Proceedings of the 7th International Conference on Environmental Science and Civil Engineering (ICESCE 2024), pages 163-167

ISBN: 978-989-758-764-1; ISSN: 3051-701X

Copyright © 2025 by Paper published under CC license (CC BY-NC-ND 4.0)

163

the interior of the solid as spherical wavefronts, while

the R-wave radiates outward along the surface of the

solid. The propagation modes of the three types of

stress waves are shown in Figure 1.

Figure 1: Finite element simulation of impact on a plate

(Carino, 2001).

When a stress wave propagates through a material

and encounters an interface with a different material,

a portion of the incident wave is reflected. The

amplitude of this reflected wave is dependent on the

angle of incidence, achieving its maximum at 90°

(normal incidence). Different types of stress waves

can be clearly distinguished from one another,

providing valuable information about the material

properties. For instance, when the S-wave reaches the

boundary at the bottom of the concrete slab, the

reflected P-wave may have already arrived at the

midpoint of the slab, highlighting the differing

velocities of these wave types. As these waves

interact with interfaces that possess varying acoustic

impedances, they undergo complex phenomena such

as reflection, refraction, and diffraction. These

processes are critical for understanding the internal

structure of the material being tested. Once the waves

are captured by sensors, they undergo thorough

analysis using spectrum analysis techniques. This

involves transforming the time-domain signals into

the frequency domain, which allows for the

assessment of the relationship between the received

signals and the quality of the concrete, thereby

achieving the goal of NDE.

2.2 The Principle of IE Method

The principle of the IE method is that a brief

mechanical impact, such as the strike of a small steel

sphere on a concrete surface, generates low-

frequency stress waves that travel through the

structure and reflect off internal voids and external

boundaries. The transducer near the impact point

captures surface displacements from reflected waves.

The recorded time-domain signals are transformed

into the frequency domain to generate amplitude

versus frequency spectra. When stress waves interact

with the impact surface, voids, and external surfaces,

they cause multiple reflections that result in transient

resonances detectable in these spectra. These

resonances are used to assess the structural integrity

or locate voids within the structure. The principle of

the IE method is illustrated (see Figure 2).

The IE method is capable of detecting voids in

grouted prestressed ducts in various under a majority

of circumstances. However, its performance is

contingent upon several critical factors, including the

geometric configuration of the structure, the

dimensions and morphology of the voids, and the

positioning and arrangement of the prestressed ducts.

Furthermore, external environmental conditions, such

as temperature fluctuations and humidity levels, can

significantly influence the propagation characteristics

of the stress waves and the accuracy of detection

(Losanno et al., 2024; Dethof and Kessler, 2024;

Tang, 2021).

Figure 2: Principle diagram of IE method.

Similar to other defect types, voids within

prestressed ducts may be positioned too deep in a

structure to be detected. The IE signals recorded from

intact concrete, completely grouted ducts, and

partially grouted ducts will exhibit distinct patterns

(JGJ/T 411-2017) (see Figure 3).

2.2.1 Normal Concrete

The principle is similar to that employed in the

Impact-Echo method for detecting the thickness of

concrete slabs. The tests produce distinctive

waveforms and spectra, in which the prominent

characteristics—especially the quantity and

distribution of peaks—are clearly identifiable, as

illustrated in Figure 3 (a). The relationship among the

frequency peak (F

T

), the compression wave velocity

(V

P

) and the echo depth (T) is expressed in the

following equation:

/2

Tsp

FVT

α

=⋅

(1)

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

164

Where 𝛼

is a factor equal to 0.96 for a slab

shape.

2.2.2 Fully Grouted Duct

Besides the frequency peak corresponding to the

thickness, there is a higher frequency peak (F

steel

) due

to the existing of tendons as shown in Figure 3 (b).

The reflection of the P-wave will occur from the

tendons within the duct at a frequency of F

steel

, which

can be calculated:

/4

steel s P steel

FVd

α

=⋅

(2)

Where d

steel

is the distance from the impact point

to steel tendons and

P

V

being the P-wave speed in

concrete.

2.2.3 Not Fully Grouted Duct

The reflection from the backside is observed at a

lower frequency than that from the shallower

concrete/flaw interface (refer to Figure 3 (c)). In the

presence of a void in the duct, the frequency

measured will be:

/2

void s P void

FVd

α

=⋅

(3)

Where d

void

is the depth to the void.

When flaws exist in grouted prestressed ducts, the

waveforms and spectra patterns, especially the

spectra, are disrupted and modified. These alterations

provide both qualitative and quantitative information

regarding the presence and location of the flaws.

Figure 3: Impact response of different ducts.

In general, the IE method is favored for its

simplicity and effectiveness, providing a

straightforward approach to quickly and efficiently

detect internal defects in materials and structures. It’s

non-destructive nature and ease of application make

it an ideal choice for assessing the integrity of

grouting quality in post-tensioned pre-stressed ducts

without compromising their usability.

3 FIELD TEST AND

CALCULATION OF THE

EXPECTED FREQUENCY

The post-tensioned concrete bridge was a simply

supported box beam bridge under construction, and

IE method was employed to detect the grouting

quality of the prestressed ducts on-site (see Figure 4).

The lateral ducts, with a cross section of 60×19

mm, were made of corrugated steel tubes. Each duct

contained 3 steel tendons, each~15 mm in diameter.

After the tendons were tensioned, the ducts were

filled with expanded cement grout.

Figure 4: The IE method to detect the grout quality on site.

Testing parameters, including P-wave velocity

and sampling frequency, should be determined before

initiating a new test. The average P-wave velocity

obtained from three measurements was 4050 m/s,

Detecting Grouting Quality in Post-Tensioned Prestressed Ducts with IE Method

165

with a sampling frequency of 60 kHz selected,

yielding 1024 data points per record.

Reflection from the tendons:

For a depth of the steel tendons of 17 cm the

expected frequency is:

f = C

P

/ 4d

steel

= 4050m/s / (4×17cm) =5956 Hz

Reflection from a void in the cable duct:

For a void depth of 14 cm within the duct, the

expected frequency is:

f = C

P

/ 2d

void

= 4050m/s / (2×14cm) =14464 Hz

4 RESULTS ANALYSIS

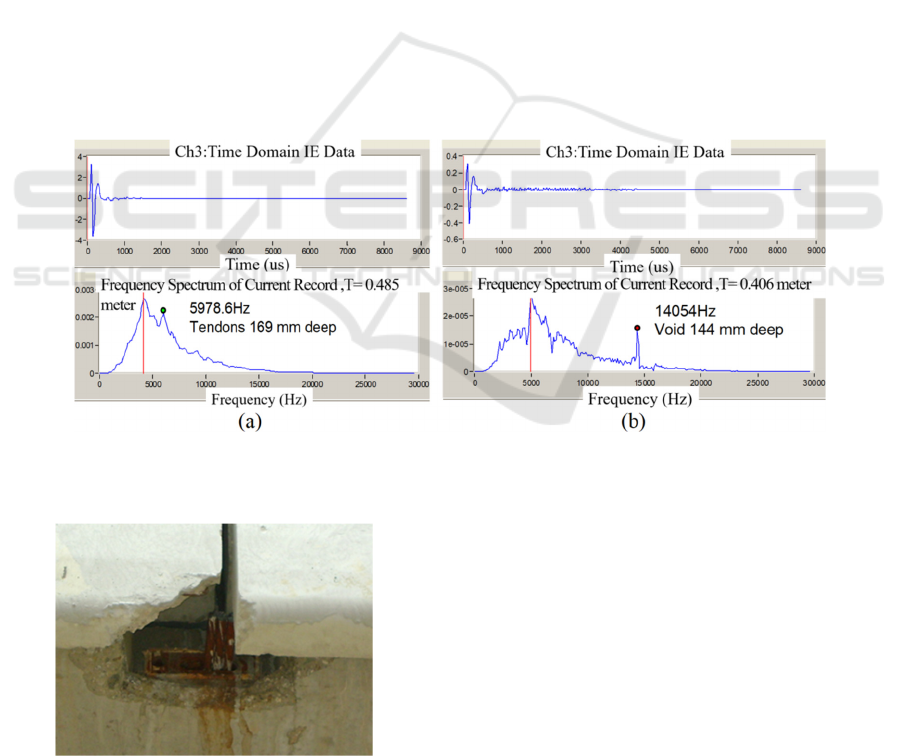

Two tendon ducts were selected for analysis: one that

underwent successful injection without any

discernible issues, and another suspected of

containing voids due to difficulties encountered

during the injection process.

The frequency spectrum of the fully grouted duct

is presented in Figure 5 (a). Upon examination of this

figure, a notable frequency peak at 5978.6 Hz is

observed, which corresponds to a depth of 16.9

centimeters. This peak, in conjunction with the plate

thickness frequency of 4576.1 Hz, representing the

frequency of reflections arriving from the external

surface, provides valuable insights. Importantly, the

depth of 16.9 centimeters aligns precisely with the

actual location of the tendons, which are situated

within a range of 16 to 18 millimeters.

In Figure 5 (b), two prominent frequency peaks

were observed. Notably, the plate thickness

frequency registered at 4988.1 Hz, indicating a depth

of 40.6cm. Yet, the intended thickness of the concrete

structures beneath the impact point was 39cm,

revealing the presence of voids in the tested area. This

discrepancy stems from the extended propagation of

P-waves, a clear indicator of cavities. Furthermore,

theoretical frequencies for voids in the ducts at depths

of 14cm and 18cm were predicted to be 14464 Hz and

11250 Hz respectively. Obviously, the detected

frequency peak of 14054 Hz falls squarely within this

range, confirming the presence of voids within the

grouted tendon ducts.

Figure 5: (a) Impact-echo frequency spectrum at the well-grouted section of cable duct. (b) The waveform and frequency

spectrum of voided duct.

Figure 6: Un-grouted tendon duct.

Indeed, from Figure 6 authenticates these by

showcasing the accurate representation of voids in

un-grouted ducts.

5 CONCLUSIONS

Practical experience demonstrates that the impact-

echo method is effective for detecting voids within

grouted prestressed ducts in post-tensioned

structures. A reliable assessment of internal grouting

quality can be achieved through precise analysis of

the IE signals.

ICESCE 2024 - The International Conference on Environmental Science and Civil Engineering

166

The accuracy of the IE method for detecting post-

tensioned prestressed ducts depends on factors such

as P-wave velocity, the diameter of the steel spheres,

and sampling frequency. Selecting appropriate testing

parameters and employing a suitable mechanical

impact to generate low-frequency stress waves are

crucial for obtaining accurate results. However, in

practical applications, the IE method may face

limitations related to signal attenuation and data

interpretation. To address these challenges, future

research should focus on enhancing signal processing

techniques, improving detection resolution,

developing propagation models for complex

structures, and advancing automated and multimodal

detection systems. These efforts will expand the

applicability and effectiveness of the impact-echo

method in engineering practice.

Assessing the quality of grout injection in tendon

ducts using non-destructive evaluation methods is an

emerging area of study. In China, there are currently

no ideal technologies or standards for this purpose.

Extensive experimental research is required to

calibrate the impact-echo testing method for

assessing the internal grouting condition of

prestressed ducts.

REFERENCES

Sun, B., Yang, Y., Li, X., Yan, M., Xie, M., Bao, Y. 2022.

Full-scale investigation of post-tensioned prestressed

concrete bridge girders subjected to frost heaving in

cold regions. Engineering Structures 250: 113413.

Hsieh, C. T., Lin, Y. 2016. Detecting debonding flaws at

the epoxy-concrete interfaces in near-surface mounted

CFRP strengthening beams using the impact-echo

method NDT & E International 83: 1-13.

Cheng, X., Hong, J., Ma, L., Li, G. 2021. Flexural

performance test of a prestressed concrete beam with

plastic bellows Structural Engineering and Mechanics.

79: 223-235.

Carino, N. 2001. Structures Congress & Exposition

(Washington, D.C. United States) (ASCE) pp. 1-18.

Losanno, D., Galan, S., Parisi, F., Pecce, M. R., Cosenza, E.

2024. Experimental investigation on nonlinear flexural

behavior of post-tensioned concrete bridge girders with

different grouting conditions and prestress

levels. Journal of Bridge Engineering 29: 04023121.

Dethof, F., Kessler, S. 2024. Explaining impact echo

geometry effects using modal analysis theory and

numerical simulations NDT & E International 143:

103035.

Tang, C., Zhang, G., Song, C., Li, X., Hou, Y. 2021.

Flexural behavior of unbonded prestressed concrete

bridge girders Advances in Civil Engineering 1:

6642513

JGJ/T 411-2017 Technical specification for testing of

concrete defects by impact echo method. Industry

Standards of the People's Republic of China. Beijing:

China Architecture & Building Press.

Detecting Grouting Quality in Post-Tensioned Prestressed Ducts with IE Method

167